When it comes to selecting the right type of copper for your project, understanding the nuances between different grades is crucial. C110 and C101 copper, while seemingly similar, have distinct properties and applications that could make a significant difference in performance and cost-effectiveness. But what sets these two types of copper apart? Is one better suited for electrical applications than the other? In this comprehensive comparison, we will delve into the key differences between C110 and C101 copper, examining their properties, applications, and manufacturing considerations. By the end of this article, you’ll have a clearer picture of which copper type is best suited for your specific needs and why. Ready to uncover the intricacies of these two copper giants? Let’s dive in.

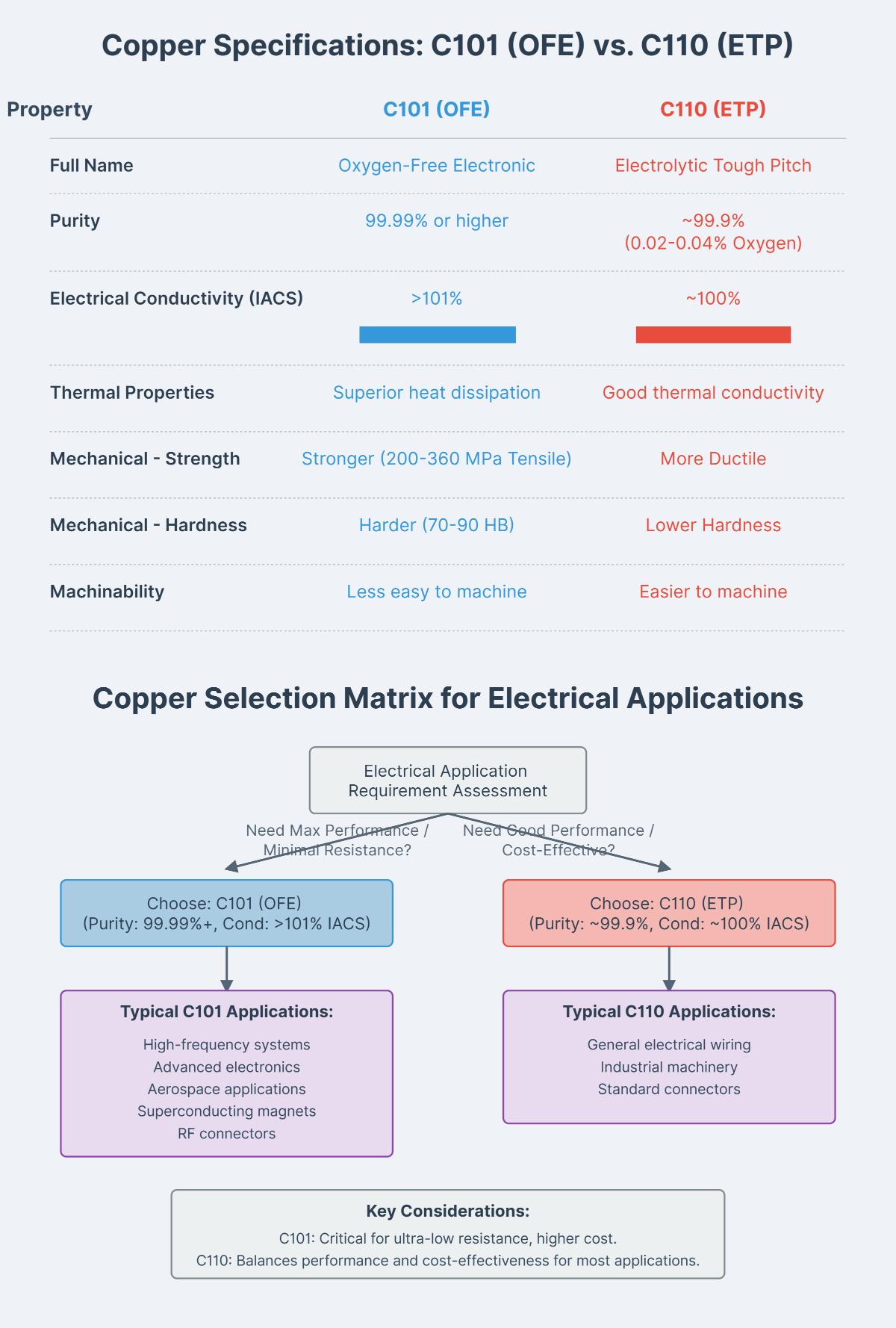

Purity and oxygen content help distinguish C110 from C101 copper.

C101, or Oxygen – Free Electronic (OFE) copper, has a purity of at least 99.99% with virtually zero oxygen content. This near – zero oxygen ensures exceptional electrical conductivity and superior oxidation resistance, making it ideal for applications where these properties are crucial.

C110, known as Electrolytic Tough Pitch (ETP) copper, contains about 99.90% copper and 0.02 – 0.04% oxygen. This small amount of oxygen slightly reduces electrical conductivity but enhances machinability. The oxygen also helps form a more stable oxide layer, beneficial for certain manufacturing processes.

Copper’s electrical conductivity is crucial for its use in electronics.

C101 copper has excellent electrical conductivity, often exceeding 101% IACS (International Annealed Copper Standard). This makes it the top choice for high – tech applications in high – frequency and high – voltage environments where low electrical resistance is essential.

C110 copper has good electrical conductivity at around 100% IACS, sufficient for most general electrical applications like power transmission and distribution systems.

Thermal conductivity is important for copper in thermal management applications.

Due to its high purity, C101 copper has slightly better thermal conductivity, making it suitable for heat dissipation in electronic devices, such as in heat sinks and thermal management systems.

C110 copper has excellent, though slightly lower, thermal conductivity than C101. It’s a strong option for thermal applications, especially when cost is a factor.

Mechanical properties like strength, ductility, and hardness are key for copper in structural applications.

C101 copper has higher strength and hardness, with a tensile strength of 250 – 350 MPa. It’s suitable for high – stress environments but is less ductile, which can pose machining challenges.

C110 copper has a tensile strength of 150 – 220 MPa, is more ductile, and easier to work with. The oxygen in it improves machinability, making it good for manufacturing complex shapes.

Machinability refers to how easily a material can be machined.

The high purity and hardness of C101 copper make machining difficult. Specialized tools and techniques are needed. These challenges are worth it for high – performance applications due to its superior properties.

C110 copper is more machinable because of its lower hardness and oxygen content. It allows for easier shaping, lower tool wear, and better chip formation, making it preferred for extensive machining processes.

Corrosion resistance is vital for materials in harsh environments.

C101 copper has good corrosion resistance, beneficial in oxidation – and corrosion – prone environments. Its high purity helps it maintain stability and properties over time.

C110 copper offers slightly better corrosion resistance due to the oxygen – formed protective oxide layer. It’s a cost – effective choice for industrial applications where moderate corrosion resistance is needed.

C101 copper, known as Oxygen – Free Electronic (OFE) copper, boasts an impressive purity level of 99.99% or higher, with minimal oxygen content. This high – purity characteristic results in outstanding electrical conductivity, often surpassing 101% on the International Annealed Copper Standard (IACS). In contrast, C110 copper has a purity of around 99.90% and contains trace amounts of oxygen (0.02 – 0.04%). Its IACS rating is approximately 100%, which is slightly lower than that of C101 but still remarkable for general electrical use.

C101 copper’s high purity also contributes to its superior thermal conductivity, making it ideal for high – efficiency heat transfer systems requiring precise thermal management. While C110 copper has good thermal conductivity, it is slightly less effective than C101 but remains widely used in general thermal management applications and heat exchangers.

Machining C101 copper requires careful handling due to its hardness, which can lead to significant tool wear. With a tensile strength of 250 – 350 MPa and a hardness of 70 – 90 HB, it is suitable for applications needing robust materials. C110 copper, due to its trace oxygen content, is easier to machine. The oxygen enhances ductility and reduces tool wear. It has a lower tensile strength of 150 – 220 MPa and a hardness of 45 – 60 HB.

C101 copper offers good corrosion resistance due to its high purity, but it may not form a protective patina as effectively as C110 copper. C110 copper, however, forms a protective patina when exposed to environmental elements, providing excellent corrosion resistance while being cautious around certain chemicals.

C101 copper is more expensive due to its higher purity and rigorous manufacturing process, whereas C110 copper is a cost – effective alternative for applications where high purity is not essential.

Aerospace and High-Tech Electronics: C101 copper, with its exceptional purity and high electrical conductivity, is highly sought after in aerospace and advanced electronics applications. Its near-zero oxygen content and extremely high purity ensure minimal interference and maximum efficiency in high-frequency and high-voltage environments. This makes C101 an excellent choice for components such as connectors, signal cables, and other critical electronic parts where even the slightest impurity could affect performance.

Telecommunications: In the telecommunications industry, the need for reliable and high-performance materials is paramount. C101 copper’s superior conductivity and strength make it suitable for high-frequency circuits and advanced communication systems. Its high electrical conductivity allows electrical signals to travel through the material with minimal resistance. This means that the signals can maintain their strength and integrity over long distances, thus minimizing signal loss and ensuring clear, uninterrupted communication.

Thermal Management Systems: C101 copper’s high thermal conductivity makes it ideal for use in thermal management systems. It is commonly used in heat sinks and other components where efficient heat dissipation is critical. This property is particularly beneficial in electronic devices and systems that generate substantial heat during operation, requiring efficient thermal management to maintain performance and longevity.

Electrical Systems and Components: C110 copper, also known as Electrolytic Tough Pitch (ETP) copper, is widely used in general electrical applications like busbars, connectors, and circuit breakers due to its good (albeit slightly lower than C101) electrical conductivity and cost – effectiveness.

Industrial Applications: The enhanced machinability of C110 copper, due to its trace oxygen content, makes it well – suited for various industrial applications. It is commonly used in plumbing fittings, wave guides, and other power transmission components. Its ability to form stable oxide layers also provides a degree of protection against corrosion, making it suitable for environments where moderate corrosion resistance is required.

General Machining: C110 copper is favored for general machining applications because of its excellent ductility and lower hardness. This makes it easier to shape and form, resulting in lower tool wear and better chip formation during machining processes. For example, it is used to manufacture intricate gears with fine teeth and complex internal structures where ease of machining is a significant factor.

C101 and C110 copper have distinct applications based on their unique properties. C101 copper is indispensable in high – tech and demanding applications requiring the highest purity and conductivity, such as aerospace and advanced electronics. On the other hand, C110 copper’s versatility and cost – effectiveness make it suitable for a broader range of general electrical, industrial, and machining applications. Choosing between these copper types depends largely on the specific needs of the project, including performance requirements, cost considerations, and the desired application outcomes.

C101 copper, also known as Oxygen-Free Electronic (OFE) copper, is extremely pure, containing 99.99% copper. This high level of purity is achieved through a specialized and costly vacuum melting process that eliminates oxygen, enhancing electrical conductivity. The complexity of this process not only improves the copper’s performance but also significantly raises its production costs.

C110 copper, or Electrolytic Tough Pitch (ETP) copper, has a slightly lower purity of 99.90% and contains small amounts of oxygen (0.02-0.04%). This copper is produced using a more conventional electrolytic refining process, which is less costly and simpler than the vacuum melting process used for C101. The presence of oxygen, while slightly reducing electrical conductivity, improves machinability and makes the manufacturing process more cost-effective.

The cost of C101 copper is significantly higher due to its superior purity and the complex vacuum melting process required for its production. This high purity level is essential for applications where minimal impurities are critical, such as in high-tech electronics and aerospace components. The additional expense is justified in these fields where the performance benefits outweigh the higher cost. On average, C101 copper can be 25-30% more expensive than C110 copper.

C110 copper is more affordable and widely used because its production is simpler and less costly, making it ideal for large-scale industrial applications. The lower production costs associated with its electrolytic refining process and the presence of trace oxygen make C110 copper a cost-effective alternative for many applications where ultra-high purity is not a necessity. This cost advantage allows it to be used extensively in power distribution systems, busbars, and other industrial components.

While C101 copper offers excellent electrical and thermal conductivity, its high purity and hardness can make it challenging to machine. The material’s hardness leads to increased tool wear and requires specialized machining techniques and equipment. Despite these challenges, the superior properties of C101 copper make it indispensable for applications where these qualities are paramount.

C110 copper, on the other hand, is easier to machine due to its lower hardness and the presence of oxygen. The trace oxygen content reduces tool wear and improves machinability, making it more suitable for extensive machining processes. This ease of machining translates into lower manufacturing costs and faster production times, further enhancing its cost-effectiveness.

C101 copper’s high purity and exceptional conductivity make it essential for high-performance applications. These include aerospace, advanced electronics, and high-frequency telecommunications systems. The higher cost of C101 copper is justified in these scenarios where performance and reliability are critical.

C110 copper’s good electrical conductivity and excellent machinability make it suitable for a wide range of industrial and electrical applications. It is commonly used in power distribution systems, electrical connectors, and industrial machinery. Its cost-effectiveness and ease of machining make it a preferred choice for many general-purpose applications, where the highest purity is not required.

In recent years, advancements in manufacturing processes have significantly impacted the production and quality of both C110 and C101 copper. Continuous casting and better refining techniques have made copper production more consistent and higher in quality. These innovations enhance the physical properties of the copper and reduce production costs, making high-purity copper more accessible for various applications.

Emerging trends in copper technology focus on improving electrical and thermal properties. Research aims to achieve higher purity levels for C101 copper, enhancing its conductivity, and refining the thermal conductivity of both C101 and C110 copper, making them more efficient for heat dissipation and thermal management.

The integration of copper with advanced technologies such as 3D printing and nanotechnology is another significant trend. The use of 3D printing allows for creating complex copper components that were previously hard to produce with traditional methods. This technology is particularly beneficial for producing intricate parts for high-tech applications in aerospace and electronics.

Nanotechnology also plays a crucial role in enhancing the properties of copper. By manipulating copper at the atomic and molecular levels, researchers can create materials with superior electrical, thermal, and mechanical properties. These advancements are expected to lead to the development of copper-based materials with unprecedented performance characteristics.

Sustainability and environmental impact are increasingly important factors in copper production. Efforts are increasing to develop eco-friendly refining processes that reduce environmental impact. There is a growing emphasis on reducing the carbon footprint of copper manufacturing by implementing energy-efficient technologies and using renewable energy sources.

Advanced recycling techniques are being developed to recover copper from electronic waste and other sources, reducing the need for new copper mining and conserving natural resources.

The demand for high-purity copper, particularly C101, is expected to grow in sectors such as renewable energy, electric vehicles, and telecommunications. C101 copper’s superior electrical and thermal properties make it ideal for high-efficiency solar panels and electric vehicle batteries. It’s also increasingly used in 5G network infrastructure.

For C110 copper, its cost-effectiveness and machinability continue to make it a popular choice in traditional industrial applications. There is also a growing interest in utilizing C110 copper in new areas such as smart grids and advanced manufacturing systems, where its balance of performance and affordability is highly valued.

Looking ahead, the copper industry is poised for significant advancements driven by technological innovation and sustainability efforts. The ongoing research and development in refining processes, the integration of advanced manufacturing techniques, and the emphasis on environmental responsibility are likely to shape the future of copper technology. As these trends continue to evolve, both C110 and C101 copper are expected to find new applications and markets, further solidifying their roles as essential materials in modern technology.

C101 copper, known for its high purity (99.99% copper), is produced through a specialized refining process. This method involves refining in a vacuum or an environment devoid of oxygen to ensure its oxygen-free status.

However, this high-purity production process is energy-intensive, which leads to a higher carbon footprint compared to standard copper production methods. The advanced refining techniques required can result in increased greenhouse gas emissions, contributing to its environmental impact.

C110 copper is produced through an electrolytic refining process, which is generally less energy-consuming than the vacuum refining required for C101. This process involves the presence of trace oxygen, which aids in its machinability and durability.

While the production of C110 copper is more energy-efficient, the presence of oxygen and other impurities may affect its conductivity and corrosion resistance. These impurities can lead to a slight reduction in electrical conductivity compared to higher-purity coppers like C101.

The high purity of C101 copper makes it highly recyclable without significant loss of its desirable properties. This characteristic contributes positively to resource efficiency, as recycled copper can be reused in high-performance applications.

Recycling C101 copper reduces the need for raw material extraction and processing. This minimizes environmental damage associated with mining activities, leading to less waste and lower energy consumption in the long run.

Unlike C101, C110 copper is recyclable, though the presence of trace impurities may necessitate additional processing steps during recycling. This may potentially increase the energy needed to recycle C110 copper compared to ultra-pure grades like C101.

Despite the potential need for additional processing, recycling C110 copper remains beneficial by reducing the demand for virgin materials. This practice lowers the environmental impact associated with mining and extracting new copper. Recycling helps conserve natural resources, reduces greenhouse gas emissions, and minimizes the ecological footprint of copper production.

Using C101 copper in high-tech fields such as aerospace, advanced electronics, and thermal management systems leads to a reduced environmental footprint due to improvements in efficiency. Its superior conductivity and purity make it ideal for applications requiring minimal interference and high efficiency. For example, its application in telecommunications equipment and aerospace components results in lower energy consumption and longer service life.

C110 copper finds extensive use in general electrical components, vacuum capacitors, circuit breakers, and construction materials. Its good conductivity and cost-effectiveness make it suitable for a wide range of industrial applications. The broad use of C110 copper in construction and electrical systems can contribute to a larger environmental footprint due to the volume of material used. However, its role in improving the efficiency of electrical systems can also lead to energy savings over time.

Below are answers to some frequently asked questions:

C110 and C101 copper differ primarily in terms of purity, electrical conductivity, thermal properties, mechanical properties, and machinability. C101 copper, known as Oxygen-Free Electronic (OFE) copper, has a purity of 99.99% or higher, resulting in superior electrical conductivity, typically exceeding 101% on the International Annealed Copper Standard (IACS). This makes C101 ideal for applications requiring low electrical resistance, such as high-frequency circuits.

C110 copper, known as Electrolytic Tough Pitch (ETP) copper, has a slightly lower purity of about 99.9% and contains trace amounts of oxygen (0.02-0.04%), giving it an IACS rating of around 100%. Although its electrical conductivity is marginally lower, C110 is still highly effective for most electrical applications.

In terms of thermal properties, C101 offers slightly better thermal conductivity, making it suitable for high heat dissipation needs. Mechanically, C101 is stronger and harder, with a tensile strength of 200-360 MPa and hardness of 70-90 HB, while C110 is more ductile and easier to machine due to its lower hardness and oxygen content.

C101 is typically used in high-end applications like superconducting magnets and RF connectors, while C110 is widely used in electrical wiring and industrial machinery, balancing performance and cost-effectiveness.

When determining which copper is better for electrical applications, it depends on the specific requirements of the application. C101 copper, also known as oxygen-free electronic (OFE) copper, has a purity of 99.99% or higher and offers the highest electrical conductivity, often exceeding 101% IACS (International Annealed Copper Standard). This makes it ideal for high-frequency systems, advanced electronics, and aerospace applications where minimal electrical resistance is critical.

On the other hand, C110 copper, with a purity of around 99.90%, provides excellent conductivity at approximately 100% IACS. While it does not match the ultra-high purity of C101, it is cost-effective and sufficient for general electrical applications such as wiring and connectors.

C110 copper is generally more cost-effective than C101 copper. C101 copper, with an ultra-high purity of 99.99%, requires complex and labor-intensive manufacturing processes, leading to a cost that is typically 25-30% higher than C110. This high purity makes C101 suitable for specialized applications such as aerospace and advanced electronics, where performance and reliability are critical.

On the other hand, C110 copper has a purity of about 99.90% and is produced using a standard electrolytic refining process, which is less expensive and straightforward. This makes C110 copper an attractive option for general industrial applications where large quantities are needed without significant performance compromise.

In terms of manufacturing, C101 copper is produced under stringent conditions to maintain its oxygen-free status, ensuring exceptional purity and electrical conductivity. C110 copper is produced through the electrolytic tough pitch (ETP) process, containing a small amount of oxygen that enhances its machinability.

The environmental impact of C110 and C101 copper varies significantly. C101, or Oxygen-Free Electronic (OFE) copper, has a purity of 99.99% or higher. Its high – purity production is energy – intensive. Recycling it demands precise processes and is also energy – consuming. In contrast, C110, Electrolytic Tough Pitch (ETP) copper, contains 99.9% copper with trace oxygen. It has a lower environmental impact as its production is less energy – intensive and recycling requires far less energy, reducing greenhouse gas emissions.

There are limited documented case studies specifically comparing C110 and C101 copper; however, their distinct applications in various industries provide practical insights. In aerospace and high-tech electronics, C101 copper is favored due to its exceptional purity (99.99%) and superior electrical and thermal conductivity, making it ideal for high-frequency circuits and advanced thermal systems. Conversely, C110 copper, with slightly lower purity (99.9%) and trace oxygen content, is more cost-effective and easier to machine, thus widely used in industrial and electrical applications such as power distribution systems, busbars, and circuit breakers. These real-world uses highlight the suitability of each copper type based on performance requirements and cost considerations.

Recent technological advancements in copper processing focus on enhancing sustainability and efficiency. Innovations include heap leaching and chemical extraction, where startups like Ceibo and Jetti Resources are improving traditional methods by altering pH levels and employing proprietary catalysts, respectively. These advancements enable more effective processing of primary sulfide ores, such as chalcopyrite, and promote greener practices. Another notable development is electrochemical reductive leaching, exemplified by Still Bright’s use of liquid vanadium, allowing copper extraction at ambient temperature and pressure, thereby reducing pollution and carbon emissions. Additionally, sulfide leaching technologies being developed by companies like Freeport-McMoRan aim to recover copper from waste piles, offering more cost-effective solutions. These methods not only reduce environmental impact but also improve efficiency and scalability, making them vital for applications in renewable energy and advanced electronics. As discussed earlier, the choice between C110 and C101 copper should consider these processing advancements alongside application-specific requirements.