Picture this: a blade so sharp it slices through paper effortlessly, with a mesmerizing, wavy pattern etched into its surface. Now, imagine another blade, gleaming and pristine, renowned for its resistance to rust and corrosion. These two captivating materials are Damascus steel and stainless steel, each with its unique set of characteristics and applications. But what truly sets them apart?

In this article, we’ll delve into the fascinating worlds of Damascus steel and stainless steel, comparing their properties, manufacturing processes, and practical uses. From the legendary craftsmanship of ancient Damascus blades to the modern marvels of stainless steel, you’ll discover the strengths and limitations of each material. Whether you’re a knife enthusiast, a toolsmith, or simply curious about the differences between these two steels, join us as we uncover which one reigns supreme in durability, sharpness, and beyond. Ready to find out which steel best suits your needs? Let’s dive in.

Damascus steel is famous for its unique patterns, which look like flowing water. Historically, it was produced using the ancient wootz steel process, which originated in India and was later perfected in the Middle East. This process involved melting iron and steel with plant matter to produce high-carbon steel ingots, known as wootz, which were then forged into blades and other tools.

Damascus steel, known for its high carbon content of around 1.5%, gains its hardness and strength from a unique process. By repeatedly folding and hammering layers of different steel types, a distinctive layered structure is created. This not only enhances its mechanical properties but also produces the prized, intricate patterns.

Damascus steel is admired for its beautiful patterns, which also show its strong and tough microstructure. The folding process mixes hard and soft layers, making it both hard and durable.

The high carbon content and folding process make Damascus steel both strong and hard, often with a Rockwell hardness of 62 to 67. Despite its hardness, it remains flexible and less brittle than other high-carbon steels. Its sharp edge retention makes it perfect for cutting tools and blades.

Damascus steel has a fascinating history that dates back to ancient times. Originally, wootz steel ingots were made in India and traded across the Middle East, where they were crafted into weapons and tools. For many years, the techniques to create Damascus steel were lost, adding to its legend and mystery. Today, modern metallurgists have revived and improved these techniques, blending traditional methods with advanced technology to create high-quality Damascus steel.

Stainless steel is an alloy composed mainly of iron and chromium, with additional elements like nickel and molybdenum. The key characteristic that sets stainless steel apart from other steel types is its resistance to corrosion, achieved through the addition of chromium. Chromium content in stainless steel typically ranges from 10.5% to 11% or higher, which forms a passive layer of chromium oxide on the surface, protecting the steel from further oxidation.

There are several types of stainless steel, each with unique properties that make them suitable for different applications.

Stainless steel’s composition includes iron as the base element, with chromium being the primary alloying element that provides corrosion resistance. Additional elements such as nickel, molybdenum, titanium, and manganese may be added to enhance specific properties:

The microstructure of stainless steel varies based on its type. For example, austenitic stainless steel has a face-centered cubic (FCC) crystal structure, while ferritic stainless steel has a body-centered cubic (BCC) structure.

The most notable feature of stainless steel is its resistance to corrosion, achieved through the formation of a protective chromium oxide layer. This passive layer acts as a barrier to oxygen and moisture, preventing rust and degradation. This property is further enhanced by adding elements like nickel and molybdenum.

The steel manufacturing process transforms raw materials into a variety of steel products through several stages, each designed to refine and enhance the properties of the steel.

Creating Damascus steel requires high-carbon steel, flux, and specialized tools such as a forge, anvil, and hammer. Occasionally, ball bearings are used as an unconventional starting material.

Damascus steel is renowned for its unique layering technique. Multiple layers of steel are folded and welded, usually resulting in 300 – 500 layers, but some pieces can have over half a million. This layering creates the characteristic patterns and enhances the material’s mechanical properties.

The steel billets are heated to 1500 – 2000°F in a forge. The high heat minimizes oxidation, resulting in a clean weld. The heated steel is then hammered and folded multiple times to achieve the desired layer count and pattern.

After the forging process, the steel is tempered at 350 – 450°F. This tempering increases the steel’s durability and strength. The final step involves etching with ferric chloride to reveal the distinctive patterns that Damascus steel is famous for.

In contrast to Damascus steel, stainless steel production involves a mix of iron, chromium, nickel, and other alloys. The process requires extensive machinery, including furnaces, rolling mills, and finishing equipment.

The raw materials are melted in an electric arc furnace (EAF) or an induction furnace. Once melted, the steel is cast into slabs using continuous casting machines, forming the base material.

The cast slabs undergo rolling and forming to achieve the desired shapes such as sheets, plates, or rods. This process involves multiple stages of heating and rolling to ensure the steel attains the required thickness and dimensions.

While some stainless steels require heat treatment to enhance their properties, many types are used in their annealed state. Heat treatment can include processes like annealing, quenching, and tempering to improve hardness, ductility, and resistance to wear.

| Feature | Damascus Steel | Stainless Steel |

|---|---|---|

| Materials | High-carbon steel, flux | Iron, chromium, nickel, and other alloys |

| Technique | Layering and folding | Melting, casting, rolling, and forming |

| Tools | Forge, anvil, hammer | Furnaces, rolling mills, finishing equipment |

| Temperatures | ||

| – Forging | 1500 – 2000°F | |

| – Tempering | 350 – 450°F | |

| – Melting | Varies | |

| – Casting | Varies | |

| – Rolling | Varies | |

| Patterns/Finishes | Distinctive patterns through etching | Uniform finish, can be polished or brushed |

Damascus steel is highly regarded for its aesthetic patterns and strength, making it ideal for high-quality blades and decorative items. In contrast, stainless steel is prized for its corrosion resistance and versatility, making it suitable for a wide range of applications, from cookware to industrial machinery.

Both Damascus and stainless steels undergo various heat treatments to enhance their properties. Heat treatment processes include annealing, quenching, and tempering, each affecting the steel’s hardness, ductility, and strength.

Surface treatments are applied to enhance both the appearance and properties of the steel.

Damascus steel is renowned for its unique microstructure, characterized by layered patterns achieved through repeated folding and forging of high and low-carbon steels. This process, known as pattern welding, results in a composite material with visible carbide banding when etched.

The hallmark of Damascus steel is its layered composition. The repeated folding and welding create hundreds of alternating layers, which contribute to its strength and toughness. These layers are not merely decorative; they play a critical role in the material’s mechanical properties.

Ancient Wootz Damascus steel exhibits distinctive macroscopic patterns due to aligned cementite (Fe₃C) carbides within a pearlite or martensite matrix. Modern Damascus steel replicates these patterns through controlled thermomechanical processing and cooling. The carbide banding enhances wear resistance and edge retention, making Damascus steel particularly valued in cutting tools and blades.

Before forging, Damascus steel typically consists of a pearlite matrix with ledeburite (a eutectic carbide network) and minimal free cementite. After forging, the ledeburite transforms into stable eutectic carbides, and martensite forms during quenching, enhancing the steel’s hardness and strength.

Damascus steel often contains higher impurity levels compared to modern steels, resulting in non-metallic inclusions visible as black features in polished micrographs. These inclusions can affect the steel’s mechanical properties, such as its strength, toughness, and hardness.

Stainless steel’s microstructure is predominantly homogeneous, with iron and a minimum of 10.5% chromium forming a passive oxide layer that provides corrosion resistance. The specific microstructure depends on the type of stainless steel, with various alloying elements enhancing different properties.

Stainless steel consists mainly of iron and chromium, with additional elements like nickel and molybdenum to improve strength and corrosion resistance. The homogeneous distribution of these elements ensures consistent performance across the material.

Stainless steel can be classified into several types based on its microstructure:

Modern high-end stainless steels, like Damasteel, use powder metallurgy (PM) techniques to minimize porosity and achieve fine carbide distributions. This method improves the material’s strength, toughness, and overall performance, making it ideal for demanding applications such as aerospace, medical instruments, and high-quality knives.

| Feature | Damascus Steel | Stainless Steel |

|---|---|---|

| Microstructural Origin | Layered carbides from folding/forging | Homogeneous Cr-rich matrix |

| Carbide Type | Cementite (Fe₃C) bands | Chromium carbides (e.g., Cr₂₃C₆) in some grades |

| Hardness | 60-62 HRC (Wootz) | 55-60 HRC (martensitic grades) |

| Toughness | Moderate (carbide banding improves crack resistance) | Higher in austenitic grades |

| Corrosion Resistance | Low (carbon content promotes rust) | High (passive Cr₂O₃ layer) |

| Edge Retention | Superior due to carbide banding | Lower unless alloyed with hard carbides |

| Fracture Behavior | Mixed transcrystalline/intercrystalline | Predominantly transcrystalline |

Note: HRC stands for Rockwell Hardness Scale C, a measure of hardness.

Damascus steel typically outperforms traditional carbon steels like 52100 in edge retention tests due to its carbide banding. Modern powder metallurgy stainless steels, which include vanadium carbides, can surpass both in terms of wear resistance.

Damascus steel requires precise austenitization (1475–2000°F) and quenching to prevent the formation of pearlite, ensuring optimal hardness and strength. Stainless steels, on the other hand, undergo solution annealing and aging to stabilize their properties.

Hybrid blades combine the aesthetic appeal of pattern-welded Damascus steel with the corrosion resistance of stainless steel. These hybrids offer not just the striking visual patterns but also superior performance, making them a popular choice for both collectors and professionals.

Damascus steel is made by layering high-carbon steel with softer steel. Historically, it was linked to Wootz steel from ancient India and the trade routes through Damascus.

Stainless steel is primarily composed of iron, carbon, and at least 10.5% chromium, which provides corrosion resistance. It may also include nickel, manganese, and other elements to enhance specific properties.

Damascus steel is created through a process of folding, forging, and hammering different types of steel together. This repetitive process not only produces the distinctive patterns on the blade surface but also enhances the mechanical properties of the steel.

Stainless steel is produced by melting and alloying metals under controlled conditions. Unlike Damascus steel, stainless steel manufacturing does not involve layering or patterning processes. The steel is cast, rolled, and formed into the desired shapes.

Damascus steel typically ranges from 52 to 60 on the hardness scale. Modern laminated Damascus blades may have a core hardness of 58-64 HRC. Its layered structure and hard core provide superior edge retention, maintaining sharpness longer under proper care.

Stainless steel offers good hardness, with high-carbon stainless steels approaching or exceeding similar hardness levels to Damascus steel. However, its edge retention is generally less than that of Damascus steel, though harder stainless steels can provide better retention.

Damascus steel has moderate corrosion resistance due to its lower chromium content and high carbon. It is susceptible to rust if not properly maintained. The layered construction makes it tough and resilient but less resistant to chipping, requiring careful maintenance to avoid damage.

Stainless steel boasts high corrosion and rust resistance due to the protective layer. It is highly durable, resistant to chipping or breaking even under heavy use, and requires low maintenance.

Damascus steel is primarily used for high-end knives, specialty tools, and decorative items. It is highly valued for its aesthetics and sharp edges.

Stainless steel is widely used across various industries, including kitchen knives, medical instruments, and construction. Its versatility and durability make it suitable for a broad range of applications.

Damascus steel is highly prized for its artistic and unique patterned appearance, often considered collectible or luxury items. It is favored by enthusiasts and professionals who value craftsmanship, sharper edges, and distinctive design.

Stainless steel has a functional and professional look, with less focus on visual flair. It is preferred by users seeking practical, versatile, and easy-to-maintain tools for everyday use.

Damascus steel:

Stainless steel:

Damascus steel:

Stainless steel:

Damascus steel is generally more expensive due to its complex manufacturing process and unique design. The labor-intensive methods and the aesthetic value contribute to its higher cost.

Stainless steel is usually more affordable with broad availability. Its cost-effectiveness and practicality make it a popular choice for a wide range of applications.

Choosing between Damascus steel and stainless steel requires considering several factors to ensure you select the best option for your specific needs and preferences.

Damascus steel is often chosen for high – end knives, specialty tools, and decorative items because of its aesthetic appeal and superior edge retention, while stainless steel is commonly used for kitchen knives, medical instruments, and construction materials due to its versatility and excellent corrosion resistance.

Maintenance is crucial. Damascus steel needs regular care, including cleaning, drying, and oiling, to prevent rust and keep its appearance. Stainless steel, with its high chromium content, offers superior corrosion resistance and is much easier to maintain, making it ideal for everyday use.

Budget constraints also play a significant role in the decision – making process. Damascus steel tends to be more expensive due to its complex manufacturing process and unique design. Stainless steel is generally more affordable and readily available, making it a practical choice for those on a budget.

When making your decision, consider the following practical aspects:

Below are answers to some frequently asked questions:

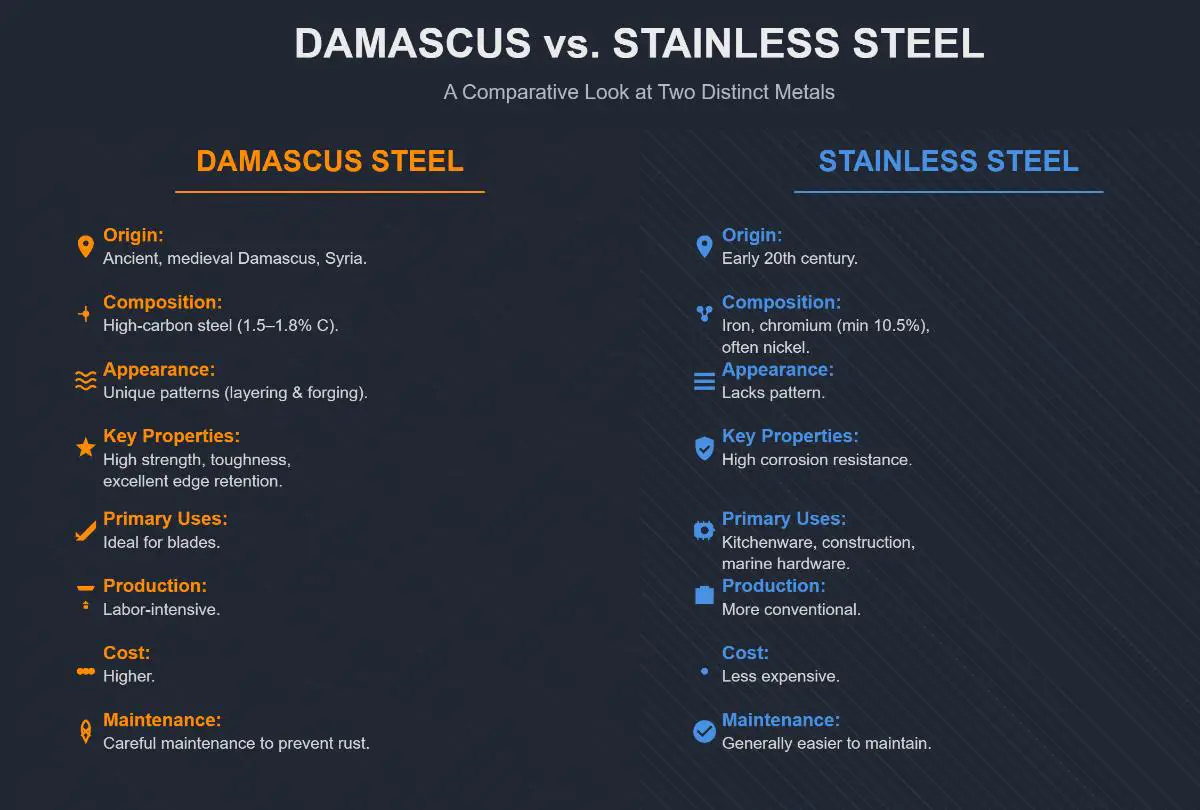

Damascus steel and stainless steel differ in several ways. Damascus steel has ancient origins from the medieval city of Damascus, Syria, and is composed of high – carbon steel (around 1.5 – 1.8% carbon). It’s known for its unique patterns from layering and forging, high strength, toughness, and excellent edge retention, ideal for blades. The production is labor – intensive, leading to a higher cost, and it requires careful maintenance to prevent rust.

In contrast, stainless steel was developed in the early 20th century. It consists mainly of iron, chromium (minimum 10.5%), and often nickel, providing high corrosion resistance. It lacks the pattern of Damascus steel, and is widely used in kitchenware, construction, and marine hardware. Its production is more conventional and less expensive, and it’s generally easier to maintain.

When comparing Damascus steel and stainless steel in terms of durability and sharpness, both materials have their distinct advantages and trade-offs.

Durability: Stainless steel is typically more durable due to its high resistance to corrosion and physical damage. The presence of chromium creates a self-healing oxide layer that protects the blade from rust and wear, making it ideal for everyday use with minimal maintenance. Damascus steel, while tough due to its layered structure, is more susceptible to rust and requires more meticulous care to maintain its durability. However, its layered construction also means it can absorb impacts better, reducing the risk of chipping.

Sharpness: Damascus steel generally excels in sharpness and edge retention. The high-carbon core can be heat-treated to achieve a hardness that maintains a sharp edge longer than many stainless steel blades. The layered design also contributes to its ability to stay sharp under prolonged use. Stainless steel, while easier to sharpen and maintain, tends to dull faster, especially under heavy or precise use.

In summary:

Your choice depends on whether you prioritize maintenance convenience and durability or edge retention and craftsmanship.

Damascus steel is traditionally known for its distinctive wavy patterns and excellent mechanical properties. Historically, it was made using the wootz crucible steel process in the Near East, but the original technique was lost in the 19th century. Today, modern Damascus steel is produced through pattern welding, a method that involves layering and forge-welding different types of steel, typically high-carbon steels like 1095 and 15N20.

The process begins with selecting and preparing the steel materials, which are cut into billets and cleaned to ensure strong welding. These billets are stacked in alternating layers and heated in a forge to high temperatures (around 1500-2400°F). The heated billet is then hammered to weld the layers together. This process is repeated, often involving folding or cutting and restacking the billet to increase the number of layers, creating intricate patterns.

After the desired layering is achieved, the billet is forged into shape, followed by heat treatment to balance hardness and toughness. The final step involves polishing and etching the blade in an acid solution, which reveals the characteristic patterns of Damascus steel by reacting differently with the various layers.

While modern Damascus steel replicates the appearance and some properties of the original, it does not exactly match the microstructure of historical Damascus steel made from wootz. However, it remains highly valued for its aesthetic appeal and functional qualities.

Stainless steel resists corrosion through the formation of a chromium-rich passive oxide layer on its surface. This layer forms spontaneously when the steel is exposed to oxygen and consists of chromium oxide, which is highly stable and prevents further oxidation and electrochemical reactions with corrosive agents such as water, acids, and chlorides. The chromium content in stainless steel is typically at least 10.5%, which is sufficient to maintain this protective layer. Moreover, if the layer is damaged, it can self-repair as long as there is enough oxygen available.

The corrosion resistance of stainless steel can be further enhanced by the addition of alloying elements like nickel, which improves resistance to acids, and molybdenum, which boosts chloride resistance. This makes stainless steel highly suitable for applications in medical, marine, and chemical industries where durability and chemical stability are crucial. In contrast, Damascus steel, primarily composed of high-carbon steel, lacks this inherent corrosion resistance and is more prone to rust, making stainless steel the preferred choice for environments where corrosion resistance is essential.

Damascus steel holds a legendary place in the history of knife making, renowned for its unique combination of beauty, strength, and sharpness. Originating around the 3rd century BC in India, the steel, known as wootz, was produced using a crucible process that created a high-carbon content and distinct impurities, such as vanadium. These wootz steel ingots were traded to the Near East, where artisans in Damascus, Syria, forged them into blades.

The blades were celebrated for their exceptional sharpness, edge retention, and toughness. They featured a characteristic flowing, watery pattern, resulting from the microstructure of cementite and ferrite layers. This pattern, along with the steel’s superior mechanical properties, made Damascus steel swords highly sought after during the medieval period.

Production of true Damascus steel ceased in the 18th to 19th centuries due to changes in raw material sources and geopolitical upheavals. Modern “Damascus steel” often refers to pattern-welded steel, which mimics the original’s appearance but differs metallurgically. Despite this, the historical significance and aesthetic appeal of Damascus steel continue to inspire contemporary knife makers.

Yes, there are modern alternatives to traditional Damascus steel. Traditional Damascus steel, also known as Wootz steel, is renowned for its unique water-like patterns and exceptional sharpness and toughness, but its ancient forging techniques are largely lost. Modern alternatives include pattern-welded Damascus steel, San-Mai steel, and powder metallurgy Damascus.

Pattern-welded Damascus steel is created by forge-welding layers of different steels, such as 1084 and 15N20, to mimic the distinctive patterned appearance of traditional Damascus. This method combines the aesthetic appeal with modern steel properties, offering a balance of hardness, toughness, and edge retention.

San-Mai steel involves sandwiching a hard carbon steel core between softer, tougher outer layers. This technique enhances edge retention and toughness, though it lacks the intricate surface patterns of Damascus.

Powder metallurgy Damascus steels, such as combinations of S90V/20CV or RWL34/PMC27, provide excellent wear resistance, corrosion resistance, and sharpness, merging modern steel technology with the classic Damascus look.

These modern alternatives surpass traditional Damascus in many aspects due to advanced metallurgy, providing superior performance while maintaining the iconic Damascus aesthetic.