In the world of metallurgy, selecting the right type of steel for a project can significantly impact its success. When it comes to 1117 steel and 1018 steel, understanding their differences is crucial for making an informed decision. These two types of steel, while seemingly similar, offer distinct advantages in terms of composition, machinability, mechanical properties, and suitability for various applications. Are you curious about which steel is more machinable or how they perform after heat treatment? In this article, we’ll delve into a detailed comparison of 1117 and 1018 steel, exploring their unique characteristics and helping you determine which one is best suited for your specific needs. Let’s uncover the specifics and see how they stack up against each other.

Both 1117 and 1018 steels are classified as low-carbon steels, but they exhibit slight variations in their carbon content. 1018 steel contains between 0.15% and 0.20% carbon, while 1117 steel has a slightly broader range from 0.14% to 0.20%. This minimal difference in carbon content means both materials offer similar levels of hardness and strength, which is typical of low-carbon steels. However, 1018 steel can reach a slightly higher carbon content at its upper limit, potentially offering marginally higher strength in some applications.

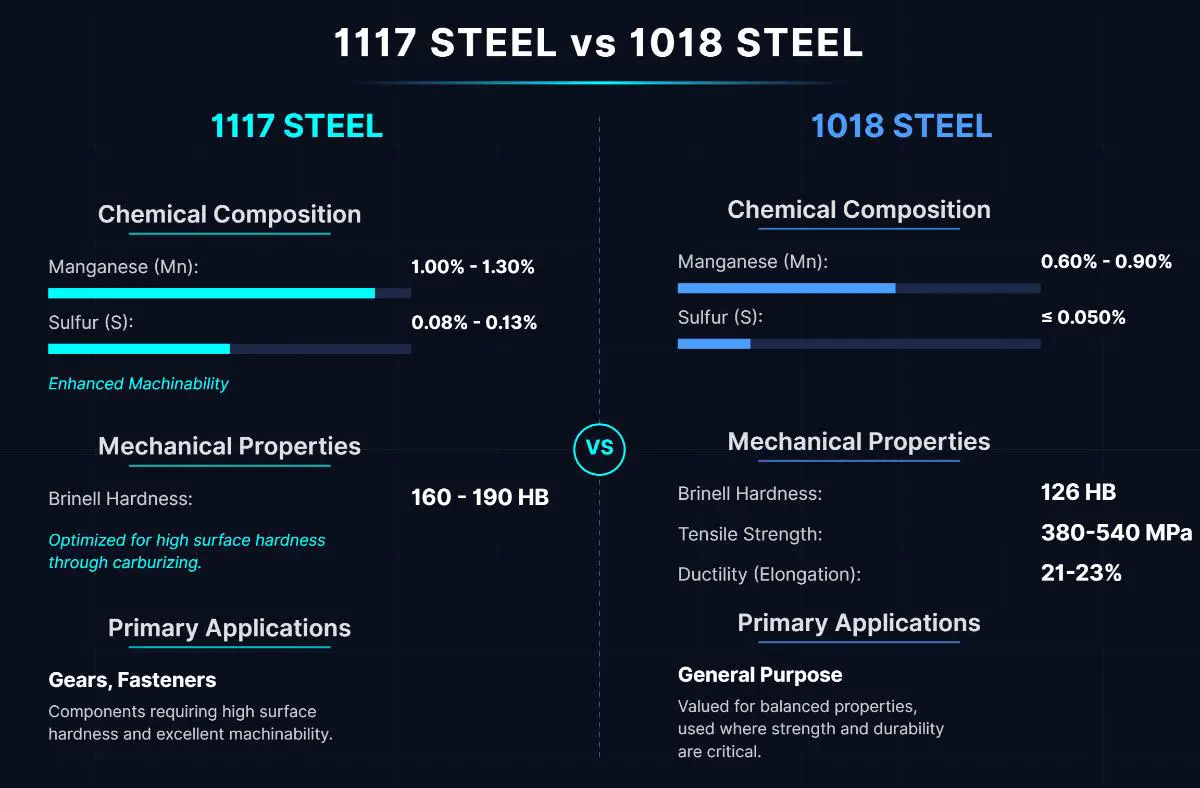

A key difference between 1117 and 1018 steels is their manganese content. 1018 steel contains 0.60% to 0.90% manganese, whereas 1117 steel has a higher manganese content, ranging from 1.00% to 1.30%. Manganese is a crucial alloying element that enhances the steel’s hardenability and tensile strength. The increased manganese in 1117 steel contributes to its superior machinability and strength compared to 1018 steel.

One of the most notable differences between these two steels is their sulfur content. 1018 steel has a sulfur content of less than 0.050%, while 1117 steel contains significantly more sulfur, between 0.08% and 0.13%. The higher sulfur in 1117 steel creates manganese sulfide inclusions, which enhance machinability. However, this increased sulfur content can negatively impact the steel’s weldability and toughness.

Both steels have similar phosphorus levels, capped at 0.040%. Phosphorus is typically kept low in steel compositions to avoid embrittlement and to maintain good ductility and toughness. The comparable phosphorus levels in both steels ensure that neither material suffers from significant brittleness or reduced ductility.

Both 1117 and 1018 steels have high iron content. 1018 steel contains between 98.8% and 99.25% iron, whereas 1117 steel has a slightly lower iron content, ranging from 98.3% to 98.8%. The reduced iron content in 1117 steel is due to its higher levels of manganese and sulfur, which are added to enhance specific properties like machinability.

The differences in composition between 1117 and 1018 steels directly affect their performance and suitability for different applications. The higher manganese and sulfur content in 1117 steel makes it exceptionally machinable, making it ideal for parts that require extensive machining. In contrast, 1018 steel’s balanced composition provides good machinability and excellent weldability, making it versatile for a wide range of applications, including structural components and general-purpose uses.

Machinability describes how easily a material can be machined to achieve specific requirements. It encompasses factors such as cutting speed, tool wear, surface finish, and the force required during machining. The machinability of a steel alloy significantly affects its processing efficiency and the quality of the final product.

1117 steel is renowned for its exceptional machinability, primarily due to its higher sulfur and manganese content.

1018 steel, while still considered good for machining, does not match the exceptional machinability of 1117 steel.

When selecting between 1117 and 1018 steel, it is essential to consider the specific requirements of the application:

The Brinell hardness test measures a material’s resistance to indentation, indicating its hardness. For 1018 steel, the Brinell hardness ranges between 126 and 140, while 1117 steel typically falls between 140 and 150, suggesting that 1117 steel is slightly harder than 1018 steel, which can influence its wear resistance and surface hardness.

Tensile strength is a critical mechanical property that defines the maximum stress a material can withstand while being stretched or pulled before breaking. 1018 steel exhibits a tensile strength ranging from 380 to 540 MPa. The tensile strength of 1117 steel is not explicitly specified, but it is known to be higher than 1018 steel after carburizing due to the enhanced surface hardness provided by the heat treatment process.

Yield strength is the stress at which a material starts to deform permanently. For 1018 steel, it ranges between 310 and 420 MPa. Yield strength values for 1117 steel are not specifically documented, but the steel’s performance characteristics after carburizing generally indicate a good balance of yield strength and ductility.

Elongation at break measures how much a material can stretch before it breaks, expressed as a percentage of its original length. 1018 steel ranges from 17% to 27%, showing good ductility, while 1117 steel ranges from 17% to 26%, indicating slightly lower ductility due to increased hardness.

Resilience describes the ability of a material to absorb energy when deformed elastically and to release that energy upon unloading. The ultimate resilience for 1018 steel ranges from 75 to 100 MJ/m³, while for 1117 steel, it ranges from 86 to 110 MJ/m³. The modulus resilience for 1018 steel is between 150 and 430 kJ/m³, compared to 180 to 550 kJ/m³ for 1117 steel. These figures indicate that 1117 steel can absorb and release more energy, making it suitable for applications requiring high impact resistance.

Thermal diffusivity and thermal shock resistance are important for applications involving temperature changes. Both 1018 and 1117 steels have similar thermal diffusivity at 14 mm²/s. However, the thermal shock resistance of 1117 steel ranges from 15 to 17 points, slightly higher than the 14 to 15 points for 1018 steel, suggesting better performance in environments with rapid temperature fluctuations.

The strength to weight ratios indicate the efficiency of the material in terms of strength per unit weight. For axial loading, 1018 steel scores between 15 and 17 points, while 1117 steel scores between 17 and 19 points. For bending loads, 1018 steel scores between 16 and 17 points, whereas 1117 steel scores between 18 and 19 points. This indicates that 1117 steel is more efficient in terms of strength per unit weight, making it advantageous for applications where saving weight is important.

The mechanical properties of 1018 and 1117 steels highlight their suitability for different applications. 1018 steel offers a balanced combination of strength, ductility, and weldability, making it versatile for structural and general engineering purposes. In contrast, 1117 steel excels in machinability and surface hardness, particularly after heat treatment, making it ideal for precision machined parts and components requiring high wear resistance.

Heat treatment and carburizing are critical processes in enhancing the mechanical properties of steel. Both 1117 and 1018 steels undergo these treatments to improve their performance in various applications. Understanding how these processes affect each type of steel is essential for selecting the right material for specific engineering needs.

Carburizing is a heat treatment technique where carbon is added to the surface of low-carbon steel. This process enhances the surface hardness while maintaining a tougher, more ductile core. Carburizing is particularly beneficial for components that require a hard, wear-resistant surface combined with a tough interior.

1117 steel, with its higher levels of sulfur and manganese, is highly suitable for carburizing, allowing it to achieve a high surface hardness while maintaining a ductile core.

1018 steel can be carburized too, but it typically doesn’t reach the same surface hardness as 1117 steel. The lower sulfur content in 1018 steel results in fewer manganese sulfide inclusions, which can impact the depth and uniformity of the carburized layer.

Heat treatment processes, such as annealing, quenching, and tempering, are used to modify the microstructure of steel, enhancing its mechanical properties.

1117 steel, with its higher manganese content improving hardenability, responds well to heat treatment; annealing it refines the grain structure, enhancing machinability and reducing internal stresses.

1018 steel also benefits from heat treatment, though its response differs slightly from 1117 steel due to its lower manganese and sulfur content.

By understanding these differences, engineers and manufacturers can make informed decisions when selecting the appropriate steel for their specific applications, ensuring optimal performance and durability.

The unique chemical compositions of 1117 and 1018 steels play a crucial role in determining their specific applications.

The mechanical properties of these steels further influence their applications.

| Aspect | 1117 Steel | 1018 Steel |

|---|---|---|

| Machinability | Superior due to higher sulfur and manganese; ideal for extensive machining | Good, but less than 1117; suitable for moderate machining |

| Heat Treatment Capability | Excellent for carburizing and case hardening; deeper case due to Mn | Can be carburized but less effective; shallower case depth |

| Surface Hardness | Higher post-carburizing hardness | Moderate hardness; better as-rolled or normalized |

| Core Toughness | Maintains ductile core after heat treatment | Good ductility and toughness in as-rolled condition |

| Weldability | Lower due to higher sulfur; less suitable for welding-intensive applications | Excellent weldability; preferred for welded structures |

| Typical Applications | Precision gears, shafts, carburized parts, components requiring high surface hardness and machinability | Structural parts, automotive components, welded assemblies, shafts with moderate strength |

The choice between 1117 and 1018 steel ultimately depends on the key performance requirements: for machining and heat-treated surface hardness, 1117 is preferred; for weldability and balanced mechanical properties, 1018 is the better match.

The SAE-AISI standards are a crucial framework for classifying and specifying steels, particularly in terms of their chemical composition and mechanical properties. These standards, created by the Society of Automotive Engineers (SAE) and the American Iron and Steel Institute (AISI), systematically classify steel grades, ensuring industry-wide consistency.

The SAE-AISI classification system uses a four-digit numbering scheme to categorize steels based on their primary alloying elements and carbon content. The first digit indicates the primary alloying element(s), while the second digit represents the subgroup within the primary alloying element group. The last two digits specify the carbon content in hundredths of a percent.

For example:

The primary alloying elements in SAE-AISI standards determine the classification of the steel. These include:

The chemical composition directly affects the mechanical properties and suitability for different applications. For instance:

The mechanical properties of steels under the SAE-AISI standards are essential for determining their performance in various applications. Key properties include:

SAE-AISI standards help choose the right steel grade for specific uses, considering their mechanical properties and how they can be processed:

| Feature | SAE-AISI 1018 Steel | SAE-AISI 1117 Steel |

|---|---|---|

| Carbon Content | Moderate (0.15-0.20%) | Similar (0.14-0.20%) |

| Manganese Content | Lower (0.60-0.90%) | Higher (1.00-1.30%) |

| Sulfur Content | Low (≤ 0.050%) | Elevated (0.08-0.13%) for machinability |

| Machinability | Good but less than 1117 | Optimized for high machinability |

| Weldability | Excellent due to lower sulfur and manganese | Lower due to higher sulfur |

| Mechanical Strength | Good balance of strength and flexibility | Becomes very hard after heat treatment |

| Typical Uses | General structural and mechanical parts | Precision machined parts, carburized components |

Below are answers to some frequently asked questions:

1117 steel and 1018 steel differ primarily in their chemical composition, mechanical properties, and suitability for various applications.

Chemically, 1117 steel contains higher levels of manganese (1.00%-1.30%) and sulfur (0.08%-0.13%) compared to 1018 steel, which has manganese content between 0.60% and 0.90%, and sulfur content of 0.050% or less. These differences enhance 1117 steel’s machinability, making it more suitable for applications that require extensive machining.

Mechanically, 1018 steel has a Brinell hardness of 126 and offers tensile strength between 380 MPa and 540 MPa with good ductility (elongation at break of about 21-23%). 1117 steel, while generally softer with a Brinell hardness of 160-190, is optimized for achieving high surface hardness through carburizing and heat treatment.

In terms of application, 1117 steel is preferred for components requiring high surface hardness and machinability, such as gears and fasteners. Conversely, 1018 steel is valued for its balanced mechanical properties, making it suitable for a broader range of applications where strength and durability are critical.

AISI 1117 steel is more machinable than AISI 1018 steel primarily due to its higher sulfur and manganese content. The increased sulfur (0.08-0.13%) in 1117 steel reduces friction between the cutting tool and the workpiece, facilitating easier chip formation and removal. Additionally, its higher manganese content (1.00-1.30%) enhances quenchability, further improving machinability. This results in a machinability rating of approximately 91% for 1117 steel, compared to 78% for 1018 steel, which contains lower levels of sulfur (≤ 0.050%) and manganese (0.60-0.90%). Therefore, 1117 steel is better suited for applications requiring high precision and ease of machining, while 1018 steel is preferable for applications where balanced mechanical properties are more critical.

After heat treatment, 1117 steel and 1018 steel exhibit notable differences in mechanical properties. 1117 steel, with its higher sulfur content, is optimized for high machinability. Post heat treatment, especially carburizing, 1117 steel achieves a significantly higher surface hardness, making it suitable for wear-resistant applications like gears. However, it has lower ductility compared to 1018 steel, which means it tends to be less flexible.

In contrast, 1018 steel is known for its balanced mechanical properties. After heat treatment, it maintains moderate tensile strength (380-540 MPa) and yield strength (310-420 MPa), with good ductility (elongation at break around 21-23%). This combination of properties makes 1018 steel versatile for various engineering and construction applications where strength and weldability are crucial.

In terms of application preferences, 1018 steel is widely used in various sectors due to its balanced combination of strength, ductility, and excellent machinability. It is commonly found in automotive components, industrial equipment, consumer products, and general-purpose manufacturing. Specific applications include shaft components, pins, bushings, machine parts, structural components, and support brackets, where its moderate strength and ease of machining are advantageous.

On the other hand, 1117 steel, while similar in its classification as a low-carbon steel, is less documented and therefore less commonly specified in detailed applications. It may be used in similar contexts as 1018 but generally in situations where precise material specifications are less critical. For applications requiring surface hardening through carburizing, both steels can be utilized, though 1018 is more frequently chosen due to its well-known properties and availability.