When it comes to selecting the right stainless steel for your project, the choice between A1 and A2 grades can be pivotal. These two types of stainless steel, each with their unique properties and applications, often spark debates among engineers and material specialists. But what exactly sets them apart? Understanding the differences between A1 and A2 stainless steel can significantly impact the performance and longevity of your applications. In this guide, we’ll delve into the chemical compositions, mechanical properties, and corrosion resistance of both grades. By the end, you’ll have a clear grasp of which stainless steel is best suited for your specific needs, whether it’s for industrial machinery, consumer products, or architectural projects. Ready to uncover the nuances of A1 and A2 stainless steel? Let’s dive in.

Stainless steel is a material that has become indispensable in our daily lives and numerous industries, thanks to its unique blend of strength, durability, and corrosion resistance. But did you know that there are different grades of stainless steel, each with its own distinct properties and applications? Among these, A1 and A2 stainless steel grades stand out, offering a range of characteristics that make them suitable for various uses.

A1 stainless steel is recognized for its high sulfur content, which greatly enhances its machinability. Its composition includes:

Due to its high sulfur content, A1 stainless steel is less resistant to corrosion, especially in environments rich in chlorides. However, its ease of machining makes it a top choice for components that require extensive fabrication.

A2 stainless steel is another well – known grade, valued for its excellent balance between strength and corrosion resistance. Its chemical composition consists of:

A2 stainless steel is more corrosion – resistant than A1 because of its lower sulfur content, making it suitable for applications exposed to mild corrosive conditions.

Austenitic stainless steels, which include both A1 and A2 grades, have a crystal structure that’s like a well – organized grid. This structure gives these steels several important benefits:

Austenitic stainless steels are widely used in applications where corrosion resistance and strength are crucial, from kitchen appliances to chemical processing equipment.

When it comes to chemical composition, A1 has a higher sulfur content than A2. The high sulfur in A1 improves machinability but compromises corrosion resistance, while A2’s lower sulfur content ensures better corrosion resistance, making it suitable for a wider range of applications.

In terms of corrosion resistance, A1 is less resistant, especially in chloride environments, while A2 offers superior corrosion resistance, making it suitable for mild corrosive conditions.

Regarding strength and hardness, A1 is softer and less strong, making it ideal for applications requiring formability. In contrast, A2 has higher strength and hardness, which is suitable for durable and wear – resistant applications.

When comparing applications, A1 is best for food processing, kitchen utensils, and automotive components where machinability is crucial. On the other hand, A2 is ideal for chemical industries, outdoor applications, and tools where corrosion resistance and durability are needed.

A1 stainless steel is known for its unique chemical composition, which includes:

A2 stainless steel is also widely used, appreciated for its balanced chemical composition:

Both A1 and A2 stainless steels contain chromium, which is crucial for corrosion resistance. A2 has a slightly broader range (15-20%) compared to A1 (16-19%).

Nickel content in A2 (8-19%) is generally higher than in A1 (5-10%), contributing to better corrosion resistance and toughness in A2.

A1 has a slightly higher maximum carbon content (≤0.12%) compared to A2 (≤0.08%). Lower carbon content in A2 helps prevent intergranular corrosion, especially in welded applications.

A1 has a significantly higher sulfur content (0.15-0.35%) than A2 (≤0.03%). High sulfur in A1 enhances machinability but reduces corrosion resistance, while A2’s low sulfur content ensures better corrosion resistance.

Both grades contain similar levels of manganese (≤2%) and silicon (≤1%), which contribute to the overall strength and hardness of the steel.

Choosing between A1 and A2 depends on the application needs: A1 is better for machinability, while A2 excels in corrosion resistance.

Tensile strength is a crucial factor in determining the suitability of stainless steel for various applications. A1 stainless steel typically exhibits a tensile strength of around 500 N/mm² in softened conditions. This makes it ideal for jobs that need some strength but also require easy machining. In contrast, A2 stainless steel shows a tensile strength ranging from 500 to 750 N/mm², depending on the processing condition such as cold drawing. This higher tensile strength makes A2 stainless steel more suitable for applications requiring greater durability and load-bearing capacity.

Yield strength is the stress at which a material begins to deform plastically. For A1 stainless steel, the yield strength is approximately 210 N/mm² in the annealed state. This relatively low yield strength allows A1 stainless steel to be more easily shaped and formed, which is beneficial for machining processes. In contrast, A2 stainless steel starts with a yield strength of about 205 N/mm² and can increase up to 450 N/mm² with cold drawing. This variability in yield strength enhances A2’s versatility, making it suitable for applications that require both high strength and good formability.

Machinability refers to the ease with which a material can be cut into a desired shape. A1 stainless steel is specifically designed to offer superior machinability due to its higher sulfur content (0.15-0.35%). The sulfur acts as a lubricant and chip breaker, facilitating easier cutting and reducing tool wear. This makes A1 stainless steel an excellent choice for applications that involve extensive machining operations, such as manufacturing fasteners and intricate components.

In contrast, A2 stainless steel has a lower sulfur content (≤0.03%), which improves its corrosion resistance but makes it less machinable compared to A1. However, A2 stainless steel still maintains reasonable machinability, especially when cold-worked. This balance allows A2 to be used in applications where both machining and corrosion resistance are important, such as in the production of kitchen equipment and chemical containers.

Elongation measures the ability of a material to stretch or elongate before breaking. In its softened state, A1 stainless steel can stretch by at least 0.6d, which indicates good ductility and formability. This property is essential for applications requiring extensive deformation without cracking.

A2 stainless steel, on the other hand, provides an elongation of about 40% in a 50mm gauge length for the basic form. This elongation can decrease with cold working, but it still offers significant ductility. This makes A2 stainless steel suitable for applications requiring both strength and the ability to undergo moderate deformation, such as in architectural elements and pressure vessels.

Hardness is a measure of a material’s resistance to deformation and wear. A2 stainless steel usually has a Brinell hardness between 123 and 201 and a Rockwell hardness from 70 to 88. This higher hardness level compared to A1 stainless steel enhances A2’s wear resistance and durability, making it suitable for applications involving abrasive environments or high contact stresses.

The cost of stainless steel can vary significantly based on its properties and intended applications. A1 stainless steel is generally more cost-effective due to its enhanced machinability, which reduces manufacturing time and tool wear. However, its lower corrosion resistance limits its use in certain environments, particularly those with high chloride concentrations. A2 stainless steel, while potentially more expensive due to its higher nickel and chromium content, offers a better balance of strength, durability, and corrosion resistance. This makes it a more versatile and long-lasting option for a wide range of applications, despite the higher initial cost.

A1 stainless steel is highly machinable because it contains more sulfur. However, this characteristic also affects its corrosion resistance. The sulfur in A1 acts as an inclusion that can initiate localized corrosion, particularly in chloride-rich environments. Consequently, A1 stainless steel is less suitable for use in highly corrosive conditions, such as marine applications or environments with high humidity and salt exposure.

In general, A1 stainless steel offers adequate corrosion resistance in less aggressive environments and performs well in indoor applications with minimal exposure to corrosive elements. This makes A1 stainless steel a good choice for applications where ease of machining is prioritized over extreme corrosion resistance, such as in some automotive parts, kitchen appliances, and architectural structures.

A2 stainless steel, also known as AISI 304, is well-known for its better corrosion resistance compared to A1. The key to A2’s enhanced corrosion resistance lies in its chemical composition: it has higher chromium and nickel content and significantly lower sulfur content. Chromium forms a protective oxide layer on the steel surface, preventing further corrosion. Nickel enhances this protective layer, making it more stable and resilient.

A2 stainless steel excels in resisting corrosion in a variety of environments, including those with exposure to acids, alkalis, and moisture. It is particularly effective in environments where mild corrosive conditions are present. However, it is important to note that A2 stainless steel is not immune to corrosion in high-chloride environments, such as coastal areas or marine applications. In such cases, higher-grade stainless steels like A4 (316) are recommended due to their improved resistance to chloride-induced corrosion.

When comparing general corrosion resistance, A2 stainless steel outperforms A1 due to its higher chromium and nickel content and lower sulfur levels. These elements contribute to forming a more robust passive oxide layer, providing A2 with better protection against a wide range of corrosive agents.

A1 stainless steel is more susceptible to pitting and crevice corrosion in chloride-rich environments due to its higher sulfur content. In contrast, A2 stainless steel, with its lower sulfur content, offers better resistance to chloride-induced corrosion but still falls short in highly saline conditions. For marine and highly chlorinated environments, stainless steel grades with molybdenum, like A4 (316), are more appropriate choices.

Choosing between A1 and A2 stainless steel depends on the environment and the need for machinability versus corrosion resistance. A1 stainless steel is suitable for applications where high machinability is essential, and the exposure to corrosive elements is minimal. On the other hand, A2 stainless steel is ideal for applications that demand higher corrosion resistance, especially in environments with exposure to mild acids, alkalis, and moisture.

Chemical Composition: A1 has a relatively high sulfur content, between 0.15% and 0.35%. This helps with machining but reduces corrosion resistance. A2, on the other hand, contains minimal sulfur, at most 0.03%, which enhances its corrosion resistance. Both grades contain chromium and nickel, but A2 typically has higher nickel content, contributing to its improved corrosion resistance and toughness.

Strength and Hardness: A2 stainless steel generally exhibits higher tensile strength, ranging from 500 to 750 N/mm². This means A2 can handle greater loads and is more durable in demanding applications compared to A1, which has a tensile strength around 500 N/mm². A2 also has higher hardness, enhancing its wear resistance, making it ideal for abrasive environments.

Machinability: The high sulfur content in A1 stainless steel significantly improves its machinability, making it an excellent choice for components requiring extensive machining. A2 stainless steel, with its lower sulfur content, is less machinable but offers a better balance of machinability and corrosion resistance, suitable for applications where both are important.

A1 Stainless Steel Applications

A1 stainless steel is best suited for applications where machinability is a priority. Typical uses include:

A2 Stainless Steel Applications

A2 stainless steel is ideal for applications requiring a balance of corrosion resistance and strength. Common applications include:

A1 Stainless Steel

Advantages:

Disadvantages:

A2 Stainless Steel

Advantages:

Disadvantages:

In the automotive sector, A1 stainless steel is used for parts requiring extensive machining but not exposed to highly corrosive environments. Typical components include:

A1 stainless steel is widely used in food processing equipment due to its ease of fabrication. Items like knives, forks, and spoons, as well as components in food machinery, benefit from A1’s machinability, allowing for mass production with consistent quality.

In the medical field, A1 stainless steel is used for instruments where precision machining is essential. Examples include:

A1 stainless steel is also used in architectural applications where ease of machining and aesthetic finish are important. These include:

A2 stainless steel is widely used in construction, particularly for fasteners and structural components exposed to varying environmental conditions. Examples include:

In chemical processing, A2 stainless steel is ideal due to its resistance to mild acids and alkalis. Applications include:

A2 stainless steel is also used in the automotive industry for components that require both strength and corrosion resistance. Examples include:

A2 stainless steel is used in marine applications like boat fittings and dock hardware, where moderate resistance to corrosion is required.

ISO 3506 is an important international standard that defines the mechanical properties of fasteners made from austenitic stainless steels, including A1 and A2 grades. This standard ensures that fasteners meet specific strength and durability requirements, providing a consistent benchmark for manufacturers and users.

A1 stainless steel fasteners conform to ISO 3506 specifications, particularly in terms of their mechanical properties like tensile strength and yield strength. A1’s high sulfur content makes it easier to machine, ideal for producing complex fasteners where machinability is essential. However, A1 fasteners are less suitable for highly corrosive environments due to their lower corrosion resistance.

A2 stainless steel fasteners are also compliant with ISO 3506, offering a balanced combination of strength, durability, and corrosion resistance. The lower sulfur content in A2 results in better corrosion resistance, making these fasteners suitable for a wide range of applications, including those exposed to mild corrosive environments. A2 fasteners are often preferred in the chemical and food industries due to their reliability and long – term performance.

ASTM (American Society for Testing and Materials) sets additional standards for both A1 and A2 stainless steels, ensuring quality and consistency across various applications.

ASTM A276 specifies the requirements for stainless steel bars and shapes, which include both A1 and A2 grades. This standard covers several aspects such as chemical composition, mechanical properties, and heat treatment. Compliance with ASTM A276 ensures that the stainless steel used in bars and shapes meets stringent quality requirements, providing confidence in its performance for various structural and mechanical applications.

ASTM A240 applies to stainless steel plates, sheets, and strips, including A1 and A2 grades. This standard outlines the requirements for chemical composition, mechanical properties, and surface finish, ensuring that the materials are suitable for high – quality manufacturing processes. Compliance with ASTM A240 is essential for applications needing precise and reliable stainless steel components, such as in construction and automotive industries.

European standards, particularly EN 10088, are also relevant for A1 and A2 stainless steels, providing comprehensive guidelines for their chemical composition and mechanical properties.

EN 10088 specifies the technical delivery conditions for stainless steels, including A1 and A2 grades. This standard is essential for ensuring that stainless steel products meet the necessary quality and performance criteria for various industrial applications. Compliance with EN 10088 guarantees that A1 and A2 stainless steels are produced to high standards, making them suitable for demanding environments.

Practical Implications

Compliance with these international standards ensures that A1 and A2 stainless steels meet specific quality and performance benchmarks, providing reliability and consistency across different applications. For manufacturers, adherence to these standards simplifies the selection process, ensuring that the materials chosen will perform as expected in their intended applications. For users, it provides assurance that the stainless steel components will meet the necessary requirements for strength, durability, and corrosion resistance.

Comparison tables clearly differentiate A1 and A2 stainless steel grades. They help readers quickly understand the key differences and similarities, making it easier to decide which material is best suited for their specific needs.

| Property | A1 Stainless Steel | A2 Stainless Steel |

|---|---|---|

| Chromium Content | 17 – 19% | 17 – 20% |

| Nickel Content | 8 – 10% | 8 – 10.5% |

| Carbon Content | ≤ 0.12% | ≤ 0.08% |

| Sulfur Content | 0.15 – 0.35% | ≤ 0.03% |

| Corrosion Resistance | Lower due to higher sulfur content | Higher due to lower sulfur content |

| Machinability | High | Moderate |

| Tensile Strength | ~500 N/mm² | 500 – 750 N/mm² |

| Yield Strength | ~210 N/mm² | 205 – 450 N/mm² |

| Applications | Food processing, medical instruments | Kitchen equipment, automotive parts |

| Cost | Generally higher | More affordable |

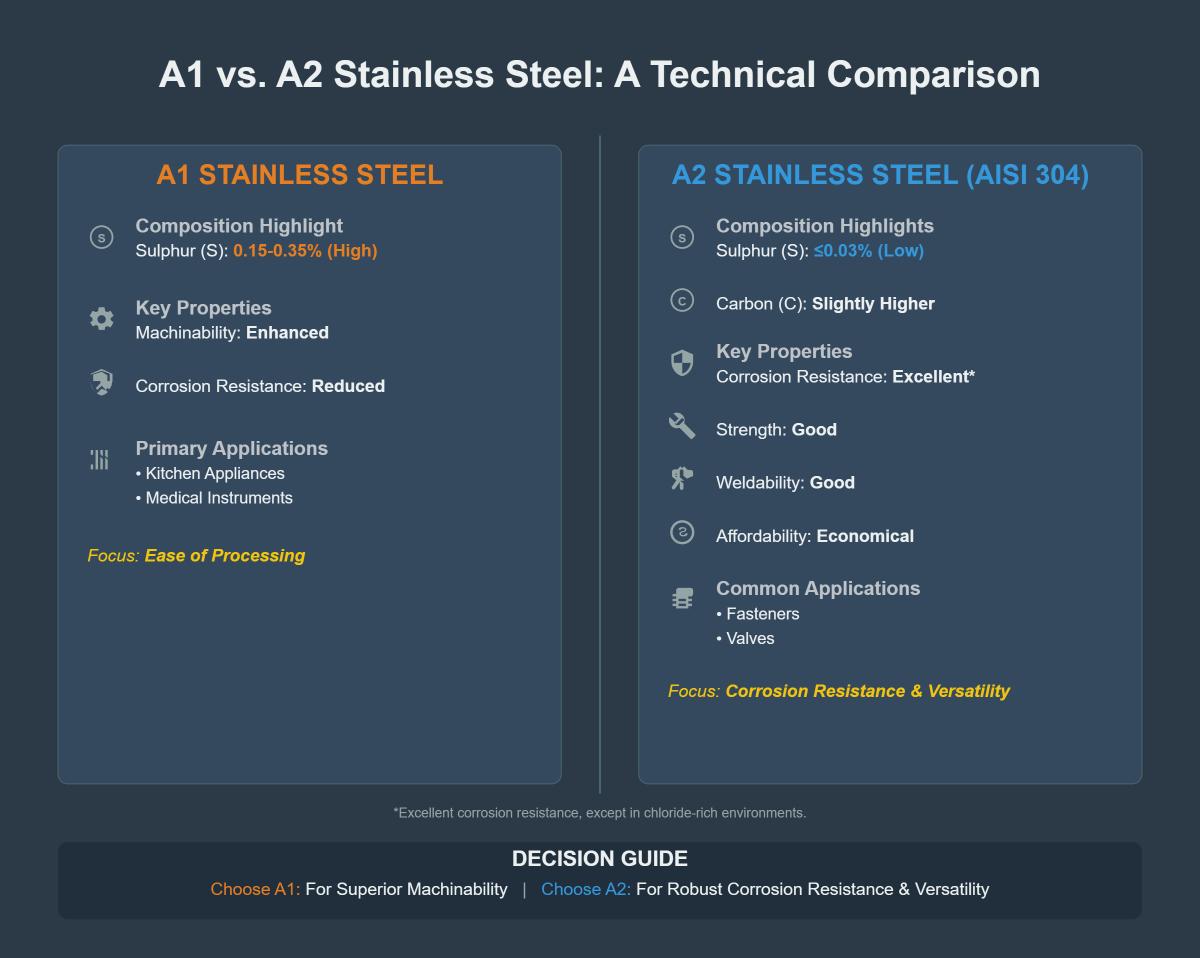

Infographics visually summarize complex information about A1 and A2 stainless steels, highlighting their compositions, properties, and applications. These visual aids are particularly useful for intermediate – level audiences who benefit from a quick overview.

An infographic depicting the chemical composition of A1 and A2 stainless steels can include pie charts or bar graphs to illustrate the percentage of key elements like chromium, nickel, carbon, and sulfur. This visual representation helps to immediately convey the differences in composition and their implications for properties like corrosion resistance and machinability.

A mechanical properties infographic can use bar graphs or side – by – side comparisons to showcase tensile strength, yield strength, and hardness. Such visual aids make it easier to understand the performance capabilities of each steel grade in various applications.

Diagrams showing corrosion resistance of A1 and A2 stainless steels in various environments are very informative. For instance, a series of side – by – side illustrations showing how each grade performs in marine, acidic, and chloride – rich environments can help users understand the limitations and advantages of each type.

Application – specific diagrams can provide insights into where A1 and A2 stainless steels are typically used. For example, a diagram showing A1 stainless steel in food processing equipment and A2 stainless steel in chemical containers can help readers visualize the practical uses of each material.

Tables summarizing case studies of industrial applications can be very effective. These tables can list the application type, environment, stainless steel grade, and performance outcome. Such practical examples can help readers relate the technical details to real – world scenarios.

| Application | Environment | Grade Used | Performance Outcome |

|---|---|---|---|

| Food Processing Equipment | Indoor, mild exposure | A1 Stainless Steel | High machinability, adequate corrosion resistance |

| Chemical Storage Tanks | Mild acids, alkalis | A2 Stainless Steel | Excellent corrosion resistance, high durability |

These visual aids enhance understanding by providing clear, easily digestible information. They help bridge the gap between technical specifications and practical applications, making the comparison of A1 and A2 stainless steels more accessible and actionable for users.

In the automotive sector, A1 stainless steel is often chosen for its excellent machinability, essential for manufacturing intricate components. One notable application is in the production of engine brackets. These components require precise machining to ensure they fit perfectly within the engine assembly. A1 stainless steel’s high sulfur content facilitates this process, allowing for detailed and accurate fabrication. Additionally, its adequate strength and formability make it suitable for various non-critical structural parts within vehicles.

A1 stainless steel is widely used in the food processing industry due to its ease of fabrication. For example, it is commonly employed in the production of kitchen utensils such as knives, forks, and spoons. A1 stainless steel’s high machinability allows for large-scale production of consistent quality items, while its mild corrosion resistance makes it ideal for food contact applications.

The medical field benefits from A1 stainless steel’s machinability, particularly in the production of surgical instruments. Tools like scalpels and forceps need precise machining to meet strict medical standards. A1 stainless steel’s composition allows for the creation of sharp, intricate edges and detailed components, essential for effective surgical tools. However, its lower corrosion resistance compared to A2 stainless steel means it is primarily used in instruments that are not exposed to highly corrosive environments.

A2 stainless steel is highly valued in the chemical processing industry for its superior corrosion resistance. This makes it ideal for applications such as storage tanks and pipelines that handle mild acids and alkalis. For instance, A2 stainless steel tanks are used to store chemicals safely, ensuring safety and long-term durability. The material’s ability to withstand corrosive substances without degrading makes it a reliable choice for maintaining the integrity of chemical processing systems.

In construction, A2 stainless steel is used extensively for fasteners and structural components. Its high strength and corrosion resistance are critical for ensuring the longevity and safety of buildings and infrastructure. A common application is in the production of bolts and screws that must withstand environmental exposure without corroding. These fasteners are essential for maintaining the structural integrity of constructions, particularly in outdoor and coastal environments where exposure to moisture and salt is prevalent.

A2 stainless steel is also prominent in the automotive industry, particularly for parts that require both strength and corrosion resistance. A prime example is the use of A2 stainless steel in exhaust systems. These components are exposed to high temperatures and corrosive exhaust gases, necessitating a material that can endure such harsh conditions without degrading. The high tensile strength and corrosion resistance of A2 stainless steel make it an excellent choice for ensuring the longevity and performance of automotive exhaust systems.

When comparing the applications of A1 and A2 stainless steels, the key differentiator is the trade-off between machinability and corrosion resistance. A1 stainless steel offers superior machinability, while A2 excels in corrosion resistance. A1 stainless steel, with its higher sulfur content, is ideal for applications requiring detailed fabrication and extensive machining. This is evident in its use in automotive components and medical instruments, where precision and ease of manufacturing are paramount.

On the other hand, A2 stainless steel excels in environments where corrosion resistance is crucial. Its lower sulfur content and higher chromium and nickel levels enhance its ability to withstand corrosive agents, making it suitable for chemical processing equipment, construction fasteners, and automotive exhaust systems. The balance of strength and durability in A2 stainless steel allows it to perform reliably in demanding applications where both mechanical properties and resistance to environmental factors are essential.

A manufacturer of automotive engine brackets needed a material that could be easily machined into complex shapes while maintaining adequate strength. They opted for A1 stainless steel due to its high machinability. The result was a series of engine brackets that fit precisely within the engine assembly, ensuring reliable performance and ease of production.

A chemical processing plant required storage tanks capable of withstanding exposure to mild acids and alkalis. A2 stainless steel was chosen for its superior corrosion resistance and strength. The tanks successfully resisted chemical corrosion over extended periods, maintaining the purity of the stored substances and ensuring operational safety.

A medical instrument manufacturer needed to produce scalpels with sharp, precise edges. They selected A1 stainless steel for its machinability, enabling the creation of intricate and effective surgical tools. These instruments met the required medical standards, providing reliable performance in surgical procedures.

When choosing between A1 and A2 stainless steel, it’s important to understand their unique properties and applications. A1 stainless steel, with its higher sulfur content, offers superior machinability, making it ideal for applications that require extensive machining and shaping. This makes it popular in industries where ease of fabrication is a priority, such as automotive components, kitchen utensils, and certain medical instruments. However, its reduced corrosion resistance limits its effectiveness in highly corrosive environments.

A2 stainless steel stands out for its excellent balance of strength, durability, and corrosion resistance. It has a lower sulfur content and higher chromium and nickel levels, making it better for corrosive environments. This makes A2 a preferred choice for applications in the chemical industry, construction, and automotive exhaust systems. The increased strength and hardness of A2 also make it more durable, enhancing its performance in demanding applications.

Picking the right stainless steel grade, say for a kitchen or a chemical plant, depends on the specific needs of the project. For projects where machinability and ease of fabrication are paramount, A1 stainless steel offers significant advantages. On the other hand, for applications requiring higher corrosion resistance and strength, A2 stainless steel is the more suitable option. Industries such as chemical processing, construction, and automotive manufacturing benefit greatly from the properties of A2 stainless steel.

While A1 stainless steel is more affordable due to better machinability, A2’s superior corrosion resistance and strength may justify a higher initial cost because of its longer lifespan in tough environments.

Deciding between A1 and A2 stainless steel should be based on the project’s specific needs, taking into account factors such as machinability, corrosion resistance, strength, and cost. By understanding the distinct properties and advantages of each grade, manufacturers and engineers can make informed choices that best meet their application requirements.

Below are answers to some frequently asked questions:

A1 and A2 stainless steels are both austenitic grades but differ significantly in composition and properties. A1 stainless steel has a high sulphur content (0.15-0.35%), enhancing machinability but reducing corrosion resistance. It’s suited for applications where ease of processing is critical, such as in kitchen appliances and medical instruments. Conversely, A2 stainless steel, also known as AISI 304, contains lower sulphur (≤0.03%) and slightly higher carbon, offering excellent corrosion resistance except in chloride-rich environments. A2 is commonly used in fasteners and valves due to its good strength, weldability, and affordability. Choosing between them depends on specific needs: A1 for machinability, A2 for general corrosion resistance and versatility.

A1 stainless steel is best suited for applications requiring high machinability, such as precision components, fasteners, or parts that involve extensive chip removal during manufacturing. However, its lower corrosion resistance limits its use in environments exposed to moisture, acids, or chlorides.

A2 stainless steel, on the other hand, is highly versatile and widely used across industries due to its excellent corrosion resistance and durability. Common applications include kitchen equipment, food processing machinery, architectural elements like railings, automotive exhaust systems, medical devices, and chemical processing tanks. Its hygienic properties make it ideal for the food and beverage industry, while its resistance to oxidation and wear suits construction and automotive uses. However, A2 is less suitable for marine environments or chloride-rich conditions, where higher-grade stainless steels like A4 (316) are preferred.

When comparing A1 and A2 stainless steel in terms of corrosion resistance, it’s important to note that “A1” is not a standard classification within stainless steel grades. For the purpose of this comparison, we will focus on A2 stainless steel, specifically AISI 304.

A2 stainless steel (AISI 304) is known for its excellent corrosion resistance in normal atmospheric conditions. This is due to its composition of approximately 18% chromium and 8% nickel, which enhances its ability to resist oxidation and corrosion. A2 stainless steel is widely used in applications such as food processing, dairy equipment, and chemical industries due to its reliable performance in environments that are not overly aggressive.

In contrast, if we consider a hypothetical “A1” grade as a lower-grade stainless steel, it would likely have lower chromium and nickel content. This composition would result in reduced corrosion resistance, making it less suitable for environments that require high resistance to corrosion and oxidation.

Industries that prefer A1 stainless steel include automotive, medical, architectural, and kitchen appliances sectors. A1 stainless steel is favored for its high formability and weldability, making it ideal for automotive components, medical instruments, and decorative architectural elements in indoor environments. Its enhanced machinability also makes it a cost-effective choice for kitchen appliances.

On the other hand, A2 stainless steel is preferred in industries such as chemical processing, food processing, construction, and automotive. Its superior corrosion resistance makes it suitable for moderate chemical exposure and food handling environments. In construction and architectural applications, A2’s durability against weather conditions is highly valued. Additionally, A2 is used in automotive and machinery parts where both strength and corrosion resistance are crucial, such as engine components and fasteners.

The relevant standards for A1 and A2 stainless steel are primarily covered by the BS EN ISO 3506 standard, which specifically addresses stainless steel fasteners. Additionally, the UNI EN ISO 3506-1 standard provides specifications for the chemical composition of these materials. These standards outline the necessary chemical compositions, mechanical properties, and appropriate applications for various stainless steel grades.

A1 stainless steel, often associated with the 303 grade (DIN 1.4305), is known for its high sulfur content, enhancing machinability. A2 stainless steel, typically corresponding to AISI 304 (1.4301), is valued for its balance of corrosion resistance and mechanical strength, making it suitable for broader industrial applications, particularly in environments exposed to chemicals.

A1 and A2 stainless steels have distinct machining properties. A1 stainless steel (AISI 303) offers high machinability due to its sulfur content (0.15 – 0.35%), which acts as a lubricant. This results in reduced tool wear, improved surface finish, and allows for higher cutting speeds. It’s ideal for precision components requiring extensive machining. In contrast, A2 stainless steel (AISI 304) has moderate machinability. With a lower sulfur content (≤ 0.03%), it causes more tool wear than A1, though proper tools and techniques can manage this. It can achieve a decent surface finish at standard cutting speeds, and is suitable for applications prioritizing corrosion resistance, such as kitchenware and outdoor elements.