In the world of industrial fasteners, choosing the right nut for the job is more than just a matter of preference—it’s a critical decision that impacts safety, performance, and durability. ASTM A194 2H and Grade 8 nuts, two commonly used options, each bring distinct advantages tailored to specific applications. From high-temperature environments to corrosive conditions, these nuts are engineered to excel under unique demands. But what sets them apart? Understanding their differences in material composition, mechanical properties, and ideal use cases is essential for selecting the right option for your project.

This article delves into the nuances of these two nut grades, providing a clear comparison to help you make informed decisions. Whether you’re dealing with high-pressure systems or environments prone to rust, this guide will clarify which nut fits your needs. Keep reading to explore how ASTM A194 2H and Grade 8 nuts stack up against each other in strength, durability, and application compatibility.

Choosing the right fastening hardware, such as nuts, is crucial for ensuring the safety, reliability, and performance of machinery and structures. Among the various options available, ASTM A194 2H and Grade 8 nuts stand out due to their specific mechanical and environmental properties. These nuts are designed to meet stringent requirements and are often used in demanding conditions, making it essential to understand their differences and appropriate uses.

Selecting the correct type of nut for a given application is not just a matter of preference but a necessity dictated by the operational environment. Choosing the wrong nut can cause mechanical failures, safety risks, and higher maintenance costs. Therefore, a thorough understanding of the characteristics and applications of ASTM A194 2H and Grade 8 nuts is vital for engineers and industry professionals.

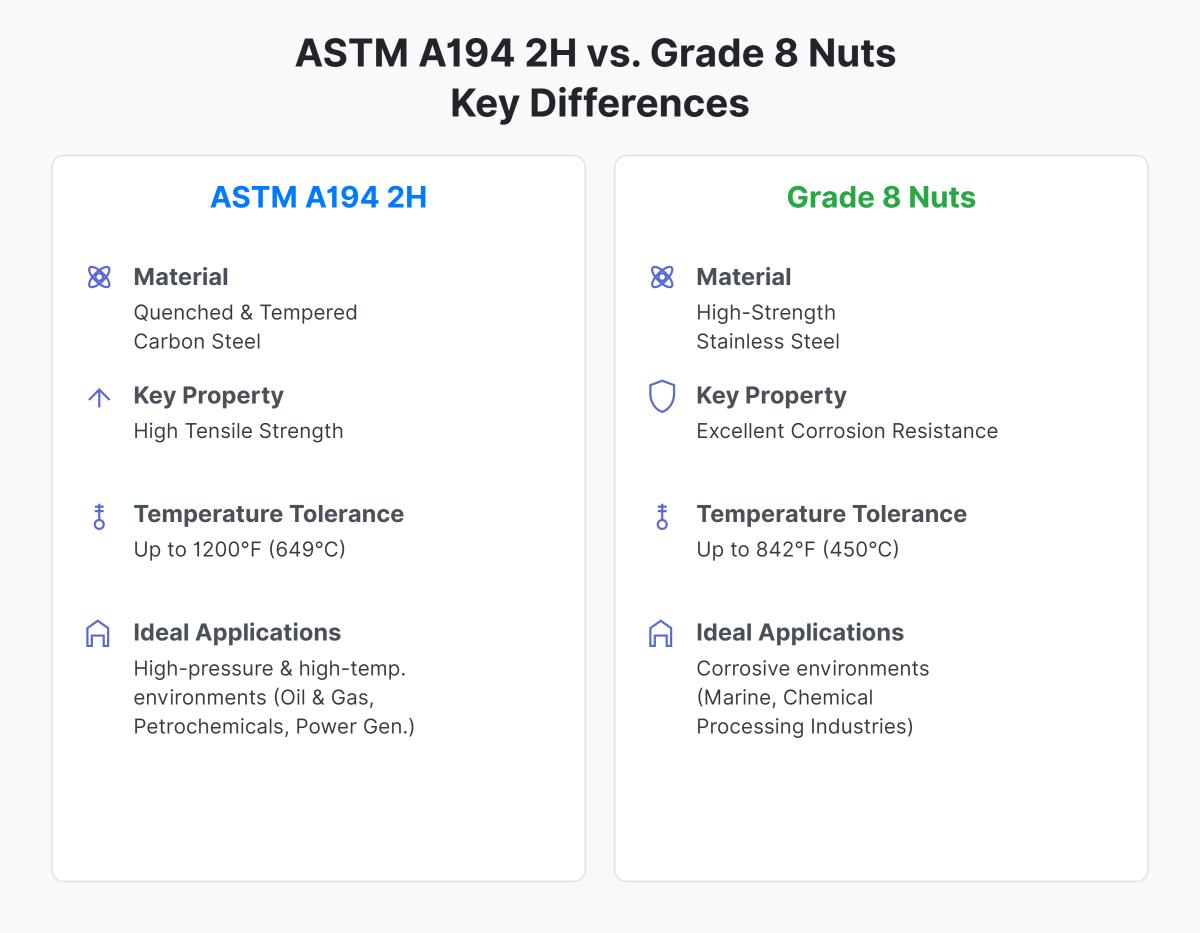

One of the primary considerations in selecting nuts is their mechanical strength, including tensile and yield strength. ASTM A194 2H nuts are known for their high tensile strength, making them suitable for high-pressure and high-temperature environments, while Grade 8 nuts provide a balanced combination of strength and corrosion resistance, ideal for critical applications.

The working environment greatly influences whether to use ASTM A194 2H or Grade 8 nuts. For instance, ASTM A194 2H nuts are preferred in high-temperature applications due to their superior heat resistance. Conversely, Grade 8 nuts excel in corrosive environments thanks to their excellent resistance to rust and chemical degradation.

The material composition of these nuts plays a crucial role in their performance. ASTM A194 2H nuts are made from quenched and tempered carbon steel, often alloyed with elements like chromium and molybdenum to enhance their strength and temperature resistance. In contrast, Grade 8 nuts are typically manufactured from high-strength stainless steel, such as AISI 304 or 316, providing them with superior corrosion resistance.

Knowing the strengths of each nut type helps in making the right selection. ASTM A194 2H nuts are commonly used in industries such as oil and gas, petrochemicals, and power generation, where high temperatures and pressures are prevalent. Grade 8 nuts, on the other hand, are more suitable for environments prone to corrosion, such as marine and chemical processing industries.

ASTM A194 2H nuts are high-strength fasteners made from quenched and tempered carbon steel. Chromium and molybdenum are added to the steel to enhance its strength and resistance to high temperatures. The quenching and tempering process further improves the mechanical properties, making these nuts suitable for demanding applications.

ASTM A194 2H nuts can be produced through hot forging, cold forging, or machining from heat-treated bar stock. They must meet specific proof load and hardness requirements, with rigorous testing to ensure reliability in critical applications.

Grade 8 nuts are high-strength fasteners made from stainless steel, commonly AISI 304 or AISI 316. These materials provide excellent mechanical strength and superior corrosion resistance, making them ideal for use in harsh environments.

Grade 8 nuts are marked with “8” for AISI 304 and “8M” for AISI 316, ensuring easy identification and appropriate use in corrosive environments.

| Property | ASTM A194 2H Nuts | Grade 8 Nuts |

|---|---|---|

| Material | Quenched and tempered carbon steel with chromium and molybdenum | High-strength stainless steel (AISI 304, 316) |

| Usage | High-temperature and high-pressure applications | Corrosive environments |

| Yield Strength | 100 ksi | 36 ksi |

| Temperature Range | Up to 1200°F (649°C) | Up to 842°F (450°C) |

Note: ASTM A194 2H nuts excel in strength and temperature resistance, while Grade 8 nuts offer superior corrosion resistance.

ASTM A194 2H nuts are made of carbon steel, which contains carbon and small amounts of other elements like manganese, phosphorus, sulfur, and silicon. No harmful elements such as Bi, Se, Te, and Pb are added. These nuts are produced through forging or machining from heat – treated bar stock and are quenched and tempered at a high temperature to improve their strength.

Grade 8 nuts are made of austenitic stainless steel, mainly 304 or 304L. This steel has a good amount of chromium and nickel, which gives it excellent corrosion – resistant properties. They are forged or machined and may undergo a special heat treatment to keep their performance stable.

ASTM A194 2H nuts, made of carbon steel, offer high tensile strength, making them a great choice for high – pressure and high – temperature applications. The carbon in the steel makes the nuts hard and able to handle significant stress. However, their limited corrosion resistance can be a problem in corrosive environments.

On the other hand, Grade 8 nuts made of stainless steel have outstanding corrosion resistance due to the chromium and nickel in their composition. These elements form a protective layer on the nuts’ surface, shielding them from rust and chemical attack. While their tensile strength is lower than that of ASTM A194 2H nuts, their corrosion – resistant feature makes them ideal for moist and chemically – exposed settings.

For ASTM A194 2H nuts, new methods are being developed to improve their mechanical properties. Advanced quenching and tempering processes are used to make the carbon steel stronger and tougher. These new heat – treatment methods adjust the steel’s grain structure to make the nuts perform better under high stress.

In the case of Grade 8 nuts, research focuses on enhancing corrosion resistance and mechanical stability. New carbide – solution heat – treatment techniques are being explored. These simpler processes aim to refine the stainless steel’s microstructure, improving its resistance to pitting and crevice corrosion. Sometimes, small amounts of other elements are added to further boost the nuts’ performance in harsh conditions.

Understanding the mechanical properties of ASTM A194 2H and Grade 8 nuts is essential for selecting the appropriate fastener for specific industrial applications. These properties include tensile strength, hardness, and proof load, which determine the performance and suitability of these nuts under various conditions.

ASTM A194 2H nuts are renowned for their high tensile strength, typically ranging between 150 KSI and 175 KSI (1,034 to 1,207 MPa). To put this into perspective, these nuts can handle the kind of stress that would be equivalent to suspending a large truck from a single bolt.

Grade 8 nuts, manufactured from high-strength stainless steel such as AISI 304 or 316, also possess considerable tensile strength, although generally lower than that of ASTM A194 2H nuts. Their proof load stress ranges from 80 KSI to 126 KSI, making them suitable for many demanding applications where mechanical strength is crucial.

The hardness of ASTM A194 2H nuts is measured using the Brinell hardness scale, with values typically falling between 212 and 327 BHN. The Brinell hardness scale assesses how resistant a material is to indentation, which is crucial for ensuring the nuts can withstand wear and deformation under heavy loads.

Grade 8 nuts exhibit a Rockwell C hardness range of 24 to 38. The Rockwell C scale measures the resistance of a material to penetration, which indicates how well the nuts can resist surface wear and tear. Although their hardness is lower compared to ASTM A194 2H nuts, they still provide sufficient durability for various applications, particularly those requiring resistance to corrosion and moderate mechanical stress.

Proof load is a critical mechanical property indicating the maximum load a nut can support without permanent deformation. For ASTM A194 2H nuts, proof load values vary by size, with a 1-inch nominal size nut having a proof load of 106,000 lbf. This demonstrates the nuts’ ability to handle substantial forces. Grade 8 nuts, on the other hand, feature proof load stress ranging from 80 KSI to 126 KSI, ensuring reliability in structural applications. This side-by-side comparison highlights the robust capabilities of both nut types under heavy loads.

The heat treatment process for ASTM A194 2H nuts involves quenching and tempering at a temperature of at least 455°C (850°F). This process significantly enhances the mechanical properties of the nuts, such as tensile strength and hardness, making them suitable for high-temperature applications.

Grade 8 nuts, typically made from stainless steel, may also undergo heat treatment to stabilize their mechanical properties. This process ensures that the nuts maintain consistent performance, even under stress and in corrosive environments.

The key difference in material composition between ASTM A194 2H and Grade 8 nuts lies in the type of steel used. ASTM A194 2H nuts are made from quenched and tempered carbon steel, which provides high tensile strength and hardness. In contrast, Grade 8 nuts are made from stainless steel, offering excellent corrosion resistance but generally lower tensile strength.

When selecting between ASTM A194 2H and Grade 8 nuts, it’s important to consider the specific requirements of the application. ASTM A194 2H nuts are ideal for high-pressure and high-temperature environments, such as in the oil, gas, and petrochemical industries. Grade 8 nuts, with their superior corrosion resistance, are more suitable for marine and chemical processing industries where exposure to corrosive elements is a concern.

Understanding these mechanical properties ensures that engineers and industry professionals can make informed decisions when selecting the appropriate nut for their specific application needs.

Corrosion resistance is crucial when choosing the right fastener for industrial applications. This section compares the corrosion resistance properties of ASTM A194 2H nuts and Grade 8 nuts, emphasizing their suitability for different environments.

ASTM A194 Grade 2H nuts are made from quenched and tempered carbon steel, which provides excellent mechanical strength and high – temperature resistance but lacks inherent corrosion – resistant properties. Consequently, Grade 2H nuts are more prone to rust and degradation when exposed to corrosive environments.

Manufacturers often coat ASTM A194 2H nuts with protective layers like zinc galvanizing or PTFE (Teflon) to reduce corrosion. These coatings act as sacrificial layers, corroding before the base material, thereby extending the nut’s lifespan in corrosive settings.

Grade 8 nuts are typically manufactured from austenitic stainless steel, such as AISI 304 or 316. This composition offers superior corrosion resistance due to the presence of chromium and nickel. These elements form a passive oxide layer on the surface, protecting the nuts from rust and chemical attacks.

Grade 8 nuts are ideal for chemical processing plants, power generation facilities, and water supply systems due to their excellent corrosion resistance. Their ability to withstand harsh conditions ensures long – term durability and reliability in environments where corrosion is a significant concern.

| Feature | ASTM A194 Grade 2H Nuts | ASTM A194 Grade 8 Nuts |

|---|---|---|

| Material | Quenched and Tempered Carbon Steel | Austenitic Stainless Steel (304, 316) |

| Corrosion Resistance | Limited; requires coatings for protection | Excellent; inherent corrosion resistance |

| Best Use | High – temperature, high – pressure applications | Corrosive environments, chemical plants |

When deciding between ASTM A194 2H and Grade 8 nuts, consider the environmental conditions of your application. If high mechanical strength and temperature resistance are crucial, ASTM A194 2H nuts with appropriate coatings can be effective. However, for environments where corrosion resistance is paramount, Grade 8 nuts are the preferred choice due to their inherent ability to resist chemical attacks and maintain structural integrity over time.

Manufacturers make ASTM A194 2H nuts from quenched and tempered carbon steel. This process enhances the nuts’ mechanical properties, giving them high tensile strength to withstand high – temperature and high – pressure environments. Chromium is added to these nuts as it forms a thin, protective oxide layer on the surface. This layer acts as a shield, preventing further oxidation and corrosion even at high temperatures. Molybdenum improves the steel’s hardenability and strength, especially at elevated temperatures, ensuring the nuts maintain their integrity.

Manufacturers typically make Grade 8 nuts from high – strength stainless steel, such as AISI 304 or 316. These materials offer good corrosion resistance. The stainless steel in Grade 8 nuts can handle temperatures up to approximately 842°F (450°C), making them suitable for applications with moderate temperatures and corrosive conditions.

ASTM A194 2H nuts have robust mechanical properties, including high tensile strength and durability under high – stress conditions. They can handle temperatures up to 1200°F (649°C), making them ideal for high – temperature applications.

Grade 8 nuts also have significant mechanical strength. However, their performance in high – temperature environments is more limited. They are suitable for applications where the temperature does not exceed 842°F (450°C), offering a balance of strength and corrosion resistance.

ASTM A194 2H nuts are ideal for high – temperature and high – pressure applications in industries such as oil and gas, petrochemicals, and power generation. These industries often face extreme thermal conditions, and the nuts’ material composition and mechanical properties ensure reliable performance. They are commonly paired with ASTM A193 Grade B7 bolts for compatibility and reliability in high – pressure and high – temperature environments.

Grade 8 nuts are best for corrosive environments, such as in marine and chemical processing industries. Their ability to resist corrosion while maintaining moderate mechanical strength makes them a reliable choice. They are typically used with ASTM A193 Grade B8 and B8M bolts, which are also corrosion – resistant. Although they have a lower maximum operating temperature compared to ASTM A194 2H nuts, their corrosion resistance is their key advantage.

ASTM A194 2H nuts must meet specific hardness and proof – load standards for reliable performance in high – pressure applications. The quenching and tempering process involves heating the nuts to at least 850°F (455°C) and then rapidly cooling them. This process enhances their mechanical properties.

Grade 8 nuts comply with standards focused on high corrosion resistance. These standards ensure that the nuts maintain their properties in environments where stainless steel’s resistance to oxidation and chemical attack is crucial, providing consistent performance in applications requiring both mechanical strength and corrosion resistance.

ASTM A194 2H nuts are made from quenched and tempered carbon steel, offering high tensile strength and durability essential for demanding industrial applications. However, producing carbon steel requires significant energy and emits considerable carbon, impacting the environment. The high carbon content, beneficial for mechanical properties, poses sustainability challenges due to the emissions during steelmaking.

Grade 8 nuts are typically made from high-strength stainless steel, like AISI 304 or 316. Producing stainless steel is more energy-intensive than carbon steel due to the higher melting points and alloying elements like chromium and nickel. Despite this, stainless steel’s excellent durability and recyclability can offset the initial energy costs over time through its longevity and reduced need for replacements.

Producing ASTM A194 2H nuts involves high energy consumption due to the quenching and tempering processes. However, the resulting high-strength properties mean these nuts can be used in applications requiring longevity and minimal maintenance, conserving resources by reducing the need for frequent replacements. The high-strength carbon steel used in these nuts can also reduce Recycling carbon steel, while energy-intensive, helps reduce waste. The process involves melting the steel at high temperatures, which consumes significant energy but contributes to sustainability by reducing the need for new raw materials.

The stainless steel used in Grade 8 nuts requires substantial energy to produce, but these nuts excel in corrosive environments, significantly extending their service life. This durability means fewer replacements over time, conserving both materials and energy. The longer lifespan of Grade 8 nuts in challenging conditions makes them a more sustainable option for specific applications.

Stainless steel is highly recyclable, and its recycling process, although energy-intensive, benefits from the material’s longevity and resistance to degradation. This contributes to a more sustainable lifecycle by minimizing waste and reducing the need for new raw materials.

ASTM A194 2H nuts are ideal for high-temperature and high-pressure environments, such as those in the oil, gas, and petrochemical industries. Their reliability in these demanding settings ensures safety and efficiency, which are crucial for sustainable industrial operations.

Grade 8 nuts are best suited for corrosive environments, including marine and chemical processing industries. Their exceptional durability in these settings reduces the need for frequent replacements.

ASTM A194 2H nuts are crucial in the oil and gas industry due to their durability in extreme conditions. They are commonly used in high – pressure pipelines, wellhead equipment, and on deep – sea oil drilling platforms, where the pressure can reach extremely high levels and the temperature can vary significantly. These nuts provide the necessary strength and stability in such challenging environments. They are typically paired with ASTM A193 Grade B7 bolts to ensure a secure connection in high – stress applications.

Grade 8 nuts are ideal for offshore platforms exposed to saltwater and onshore facilities dealing with corrosive chemicals due to their corrosion resistance. They are often used with ASTM A193 Grade B8 and B8M bolts in equipment like storage tanks and chemical processing units.

The petrochemical industry involves processes with high temperatures and pressures. ASTM A194 2H nuts are used in reactors, distillation columns, and heat exchangers. These components often operate at temperatures up to 1200°F, and the high tensile strength and temperature resistance of ASTM A194 2H nuts ensure the integrity of the equipment.

Certain areas in petrochemical plants have a high presence of corrosive chemicals. Grade 8 nuts are used in piping systems that carry corrosive substances, such as acid or alkaline solutions. Their ability to resist corrosion helps prevent leaks and equipment failures, ensuring the safety and efficiency of the plant.

ASTM A194 2H nuts are used in boilers, turbines, and steam pipes in thermal power plants. These components operate at high temperatures and pressures, and the high – strength properties of ASTM A194 2H nuts are essential for maintaining the structural integrity of the equipment.

In hydroelectric and nuclear power plants, where there is a risk of corrosion from water or radioactive materials, Grade 8 nuts are preferred. They are used in cooling systems, control rod mechanisms, and other components that require corrosion resistance. Their durability in these environments helps extend the service life of the equipment.

One of the key benefits of ASTM A194 2H nuts is their high-performance characteristics. These nuts offer exceptional tensile strength, capable of withstanding significant forces, making them ideal for high-pressure and high-stress environments. They can handle temperatures up to 1200°F (649°C), which is particularly significant in power generation and petrochemical industries where extreme heat is common.

Additionally, the durability of ASTM A194 2H nuts is noteworthy. Made from quenched and tempered carbon steel, they maintain their integrity even under demanding conditions. They are often paired with ASTM A193 Grade B7 bolts, a combination that ensures a reliable fastening system capable of performing well in high-stress and high-temperature applications.

However, there are some limitations to consider. The carbon steel composition of ASTM A194 2H nuts offers limited corrosion resistance. In corrosive environments, these nuts may require protective coatings to prevent rust and degradation. Additionally, they are generally heavier than stainless steel alternatives, which can be a consideration in weight-sensitive applications. The production process, involving quenching and tempering, can also make these nuts more expensive compared to other common fasteners on the market.

Grade 8 nuts are recognized for their excellent corrosion resistance. Made from high-strength stainless steel such as AISI 304 or AISI 316, they are well-suited for use in marine environments and chemical processing industries where exposure to moisture and chemicals is prevalent. This resistance to oxidation ensures long-term reliability and minimal maintenance.

These nuts are versatile and can be used in various applications, particularly where environmental conditions pose a risk to less resistant materials. They are marked with “8” for AISI 304 and “8M” for AISI 316, ensuring easy identification and appropriate use. Grade 8 nuts are compatible with ASTM A193 Grade B8 and B8M bolts, which also resist corrosion, providing a dependable fastening system in harsh environments.

On the downside, Grade 8 nuts have a lower tensile strength compared to ASTM A194 2H nuts. They can withstand forces but are not as strong, making them less suitable for high-pressure applications. Additionally, their temperature tolerance is up to approximately 842°F (450°C), which is lower than that of ASTM A194 2H nuts, limiting their use in high-temperature scenarios.

The cost of Grade 8 nuts is another factor to consider. The materials used, such as chromium and nickel, make them more expensive than carbon steel nuts. While this cost can be justified by their superior corrosion resistance, it might be a concern for budget-sensitive projects.

Below are answers to some frequently asked questions:

ASTM A194 2H nuts and Grade 8 nuts differ primarily in their material composition, mechanical properties, and suitability for various applications. ASTM A194 2H nuts are made from quenched and tempered carbon steel, offering high tensile strength and the ability to withstand temperatures up to 1200°F. This makes them ideal for high-pressure and high-temperature environments like oil and gas, petrochemicals, and power generation.

In contrast, Grade 8 nuts are typically manufactured from high-strength stainless steel, providing excellent corrosion resistance. They are best suited for corrosive environments, such as marine and chemical processing industries, but have a lower temperature tolerance, generally up to 842°F.

For high-temperature applications, ASTM A194 2H nuts are the best choice. These nuts are made from quenched and tempered carbon steel, which provides them with high tensile strength and durability. They can withstand temperatures up to 1200 degrees Fahrenheit, making them suitable for demanding environments such as oil, gas, and petrochemical industries where both high temperature and pressure are prevalent.

In contrast, Grade 8 nuts, typically made from high-strength stainless steel, offer excellent corrosion resistance but are only suitable for temperatures up to 842 degrees Fahrenheit. While they are ideal for corrosive environments, they do not provide the same level of mechanical strength and high-temperature resistance as ASTM A194 2H nuts. Therefore, for applications involving extreme temperatures, ASTM A194 2H nuts are the superior option.

Grade 8 nuts offer several advantages over ASTM A194 2H nuts. Made from high-strength stainless steel, they have superior corrosion resistance, which is crucial in environments with corrosive substances. They are more versatile in applications involving corrosive chemicals or moisture, and can provide a longer lifespan in harsh conditions. Additionally, while ASTM A194 2H nuts are better for extreme high – temperature applications, Grade 8 nuts can operate effectively in environments needing both corrosion resistance and moderate temperature resistance.

To choose between ASTM A194 2H and Grade 8 nuts for your project, consider three main factors. First, assess the environmental conditions: ASTM A194 2H nuts are better for high – temperature or high – pressure settings, while Grade 8 nuts, made from high – strength stainless steel, are superior in corrosive environments. Second, evaluate mechanical requirements. If high tensile strength is crucial, opt for ASTM A194 2H; for corrosion resistance, Grade 8 is more suitable.

Yes, there are industry standards that govern the use of ASTM A194 2H and Grade 8 nuts. ASTM A194 is the primary standard for nuts used in high-pressure and high-temperature environments, including Grade 2H. This standard specifies the material composition, mechanical properties, and testing requirements for these nuts to ensure their performance and safety in critical applications such as oil and gas, petrochemicals, and power generation. Similarly, Grade 8 nuts, typically defined by the SAE J429 standard, outline the specifications for high-strength carbon steel nuts used in various demanding applications. These standards ensure that both ASTM A194 2H and Grade 8 nuts meet stringent criteria for durability, tensile strength, and suitability for their intended industrial uses. Adhering to these standards is crucial for maintaining the integrity and reliability of fastened assemblies in various industrial scenarios.

No, ASTM A194 2H nuts and Grade 8 nuts cannot be used interchangeably in all applications. Each type of nut is designed for specific conditions and has unique properties that make them suitable for different environments. ASTM A194 2H nuts are made from quenched and tempered carbon steel, providing high tensile strength and durability, making them ideal for high-pressure and high-temperature environments such as oil and gas, petrochemicals, and power generation industries. In contrast, Grade 8 nuts are typically made from high-strength stainless steel, offering excellent corrosion resistance but generally lower mechanical strength compared to 2H nuts. They are better suited for corrosive environments like marine and chemical processing industries. Therefore, selecting the appropriate nut type based on the specific requirements of your application is crucial to ensure safety and performance.