When it comes to choosing the right type of steel for your project, understanding the subtle differences between carbon steel and mild steel can save you time, money, and ensure optimal performance. At first glance, these two materials might seem quite similar, but their distinct properties and applications tell a different story. How does the varying carbon content influence their price and mechanical characteristics? Which one stands out in terms of strength, ductility, and cost-efficiency for industrial use? This comprehensive comparison will delve into these aspects, providing you with the insights needed to make an informed decision. Ready to uncover which steel type is best suited for your needs? Let’s dive in.

Carbon steel is a type of steel where carbon is the main alloying element, typically containing between 0.05% and 1.70% carbon by weight. This type of steel can be further classified into low, medium, high, and ultra-high carbon steels based on the carbon content. The carbon content significantly influences the steel’s hardness, strength, and ductility, making it suitable for various industrial applications. Carbon steel is known for its durability and is often used in construction, automotive manufacturing, and machinery components.

Mild steel, also known as low carbon steel, contains a relatively low amount of carbon, usually between 0.05% and 0.25%, making it more malleable and ductile compared to other types of carbon steel. This lower carbon content makes mild steel easier to weld, form, and machine, which makes it a popular choice for a wide range of applications, including construction, automotive parts, and general fabrication. Due to its versatility and cost-effectiveness, mild steel is one of the most commonly used types of steel.

| Steel Type | Carbon Content (%) | Properties | Common Uses |

|---|---|---|---|

| Low Carbon (Mild) Steel | 0.05 to 0.25 | Highly ductile, cost-effective, and versatile | Building construction, automotive manufacturing, piping |

| Medium Carbon Steel | 0.3 to 0.6 | Good mix of strength and ductility, can be heat-treated | Machine components, gears, axles |

| High Carbon Steel | 0.6 to 1.0 | Very hard, suitable for cutting tools and machinery components | Cutting tools, blades for industrial equipment |

| Ultra High Carbon Steel | 1.25 to 2.0 | Extremely hard and potentially brittle, used for specialized machining | High-quality knife sets, tooling for machining metals |

The amount of carbon in steel plays a crucial role in shaping its properties and performance.

Carbon steel encompasses a broad range of carbon contents, typically between 0.05% and 1.7% by weight. Within this range, the specific percentage of carbon dramatically influences the steel’s characteristics. Higher carbon content generally increases strength and hardness but reduces ductility, making the steel more brittle.

Mild steel, a subset of carbon steel, contains a lower percentage of carbon, usually between 0.05% and 0.25%. This reduced carbon content makes mild steel more malleable and ductile, allowing it to be easily formed and shaped. These properties make mild steel highly suitable for applications that require extensive forming and welding.

The carbon content in steel determines various mechanical properties. Here is an analysis of how different levels of carbon affect these properties:

Here is a side-by-side comparison of the key characteristics of carbon steel and mild steel:

| Characteristics | Carbon Steel | Mild Steel |

|---|---|---|

| Carbon Content | 0.05% to 1.7% | 0.05% to 0.25% |

| Strength | Higher strength, especially in high-carbon types | Lower strength but adequate for many applications |

| Ductility | Lower ductility as carbon content increases | High ductility, easy to form and shape |

| Hardness | Higher hardness in high-carbon steels | Lower hardness, easier to machine and weld |

| Common Applications | Construction beams, cutting tools, machinery | Automotive parts, building frames, general fabrication |

Understanding these differences is essential for selecting the appropriate steel type for specific applications, ensuring optimal performance and cost-efficiency.

Carbon content is a crucial factor in determining the properties of steel, influencing its mechanical characteristics significantly. The carbon content in steel can range widely, from as low as 0.05% to as high as 2.1%. This range allows for various classifications of steel, each with distinct properties.

Carbon steel generally has a carbon content ranging from 0.05% to 2.1%. This range of carbon content significantly affects the hardness, strength, and ductility of the steel, leading to its classification into low, medium, and high carbon steel:

Mild steel is a subset of low carbon steel with a carbon content typically less than 0.3%. This low carbon content makes mild steel highly ductile and malleable, which is beneficial for applications requiring extensive forming and welding.

| Carbon Content | Steel Type | Properties | Applications |

|---|---|---|---|

| 0.6% | High Carbon Steel | Hard, strong, less ductile | Cutting tools, springs, high-strength wires |

Choosing the right steel type for a specific application largely depends on its carbon content and mechanical properties:

Understanding the impact of carbon content on steel properties is essential for selecting the appropriate steel type for specific industrial needs.

Carbon steel and mild steel are produced using similar foundational techniques, but variations in their carbon content necessitate specific differences in the production processes. Understanding these processes is crucial for selecting the appropriate steel type for various applications.

The production of carbon steel begins with preparing raw materials such as iron ore, limestone, and coke. These materials are processed in a blast furnace to produce pig iron, which forms the basis for steel production.

Two primary methods are used to convert pig iron into steel: the Basic Oxygen Furnace (BOF) and the Electric Arc Furnace (EAF). The BOF method involves blowing pure oxygen through molten pig iron to remove impurities and carbon, making it highly efficient and suitable for mass production. On the other hand, the EAF method uses electrical energy to melt scrap steel or direct reduced iron, offering flexibility in alloy additions and being more environmentally friendly due to lower energy consumption and emissions.

Secondary steelmaking refines the steel’s composition to achieve the desired properties, often through techniques like ladle metallurgy. This process involves adding alloying elements or removing excess impurities to fine-tune the chemical composition.

Once the desired composition is achieved, the molten steel is cast into slabs, ingots, or billets. These forms are then rolled into various shapes and sizes through primary and secondary forming processes. Techniques such as hot rolling, cold rolling, and heat treatment are utilized to achieve specific mechanical properties.

Mild steel, which has a lower carbon content (below 0.3%), follows similar production steps as carbon steel but with simpler alloying and refining processes to maintain low carbon levels. The focus is on ensuring ductility and weldability.

The production techniques for mild steel involve both the Basic Oxygen Furnace (BOF) and the Electric Arc Furnace (EAF). The BOF is used for large-scale production, similar to carbon steel, but with adjustments to maintain the lower carbon content. The EAF is ideal for recycling scrap steel, offering flexibility and environmental benefits.

Mild steel undergoes similar forming processes as carbon steel. However, due to its lower carbon content, it requires less intensive heat treatment, making it easier to shape and weld. Techniques like cold rolling and machining are commonly used to achieve the final product specifications.

BOFs are more efficient for large-scale production, while EAFs are more cost-effective for smaller batches and recycling due to lower energy consumption and flexibility in alloy additions. Both methods generate emissions, but EAFs produce fewer emissions due to their reliance on electricity rather than fossil fuels. BOFs require substantial amounts of coal for coke production, whereas EAFs primarily use scrap metal, reducing the environmental footprint.

Carbon steel is suitable for applications requiring high strength and hardness, such as construction beams and cutting tools. Mild steel is ideal for applications needing high ductility and weldability, including automotive parts and general fabrication.

Understanding the nuances of these production processes helps in making informed decisions about which type of steel to use for specific industrial applications.

The price of carbon steel is influenced by its carbon content, production complexity, and market demand.

The carbon content in carbon steel, which ranges from 0.30% to 2.0%, significantly affects its cost. Higher carbon content generally increases the steel’s strength and hardness but also raises its cost due to more complex manufacturing processes and additional heat treatments required to achieve desired properties.

Producing carbon steel involves intricate processes such as quenching, tempering, and specific alloying techniques. While these methods improve the steel’s mechanical properties, they also increase the production costs. The need for precise control over carbon levels and additional treatments makes carbon steel more expensive than mild steel.

The demand for carbon steel in specialized applications like tools and machinery components can drive up its price, as manufacturers must meet stringent performance requirements.

Mild steel, with its lower carbon content, has distinct factors that affect its price.

Containing only 0.05% to 0.25% carbon, mild steel is less expensive than higher-carbon steels. This lower carbon content reduces the complexity of production processes, making mild steel more affordable.

Basic processes like cold rolling and heat treatments are enough to achieve the needed properties, which lowers manufacturing costs.

Mild steel is widely used in construction, automotive parts, and general fabrication due to its cost-effectiveness and ease of fabrication. Its broad application base ensures steady demand, which helps keep the prices relatively stable and affordable.

When comparing the prices of carbon steel and mild steel, several key differences emerge.

Mild steel typically costs between $600 and $800 per ton. Its affordability is attributed to the lower carbon content and simpler production processes. This makes mild steel a cost-effective choice for applications where extensive forming and welding are required.

Carbon steel is generally more expensive, with prices varying significantly depending on the specific grade and application. The higher carbon content and more complex manufacturing processes contribute to the increased cost. Specific grades of carbon steel used in high-stress applications can be substantially more expensive than mild steel.

Recent trends indicate fluctuations in steel prices due to various economic factors, including raw material costs, energy prices, and global supply and demand dynamics.

The price of mild steel remains relatively stable, supported by consistent demand in construction and automotive industries. However, occasional price adjustments occur due to changes in energy costs and raw material availability.

Carbon steel prices are more volatile due to specialized demand and economic factors like trade policies and energy costs, causing high-performance grades to experience significant price swings.

In construction, mild steel is favored for its affordability and ease of fabrication. Using mild steel for building frameworks and pipelines can result in substantial cost savings compared to higher-carbon steels.

For automotive parts, mild steel offers cost-effective solutions for components that require high ductility and ease of welding. Carbon steel may be used for parts requiring higher strength and wear resistance, but at a higher cost.

Mild steel typically contains between 0.05% and 0.25% carbon, contributing to its high ductility and ease of machining. The low carbon content not only makes mild steel easier to machine but also reduces the risk of cracking during welding and forming, which is beneficial in various fabrication processes.

Carbon steel has a broader range of carbon content, from 0.05% to 2.1%, encompassing low, medium, and high carbon steels. The higher the carbon content, the stronger and harder the steel becomes, but this also reduces its ductility. This range allows carbon steel to be tailored for specific applications that require varying degrees of strength and hardness.

Mild steel is generally more affordable, with prices ranging from $600 to $800 per ton. The simpler production processes and fewer alloying elements required for mild steel contribute to its lower cost.

Carbon steel can be more expensive, particularly high-carbon types, with costs ranging from $800 to $1,200 per ton due to the additional processing and alloying elements required to achieve desired strength and hardness.

Mild steel is easier to machine and weld due to its lower carbon content, which reduces brittleness. This makes it less prone to cracking during welding, allowing for more straightforward fabrication processes.

Carbon steel can be more challenging to machine and weld, particularly for higher carbon content types. Specialized equipment and techniques are often required to handle the increased brittleness and hardness associated with higher carbon steels.

Both mild and carbon steel are susceptible to corrosion and do not have significant inherent corrosion resistance. Protective coatings, such as galvanization, are often applied to enhance their corrosion resistance and extend their service life in corrosive environments.

Mild steel offers lower production costs and potentially reduced environmental impact due to simpler production processes and lower carbon emissions. Its widespread use and recyclability contribute positively to its environmental profile.

Advancements in recycling and production technologies, such as the use of electric arc furnaces relying on recycled steel, help reduce the environmental impact and energy consumption of carbon steel production.

Mild steel is preferred for applications where ease of fabrication, weldability, and cost-effectiveness are crucial, such as in construction, machinery, and cookware manufacturing. In contrast, carbon steel is chosen for applications that demand higher strength and hardness, like cutting tools and structural components. Understanding these differences is essential for selecting the appropriate material based on specific project requirements.

Carbon steel, particularly medium and high-carbon grades, is favored in construction projects requiring materials with high strength and durability. Carbon steel’s increased hardness and strength support heavy loads and resist wear, enhancing the longevity of structures.

Mild steel, with its lower carbon content, offers high ductility and ease of fabrication, which is beneficial in construction applications that require extensive forming and welding. Mild steel’s malleability and lower carbon content facilitate versatile designs and easy adjustments during construction. It is commonly used in building frames, roofing, and pipelines due to its cost-effectiveness and favorable strength-to-weight ratio.

In automotive manufacturing, carbon steel is utilized for parts that demand high strength and wear resistance, such as gears, crankshafts, and axles. The increased hardness of medium to high-carbon steel provides the necessary durability for components subjected to high stress and friction. This ensures reliable performance and longevity of critical automotive parts.

Mild steel is widely used in the automotive industry for body panels, frames, and other components that require high ductility and ease of welding. Its lower carbon content makes it easier to shape and form, allowing manufacturers to produce complex designs and lightweight structures. Additionally, the cost-effectiveness of mild steel helps in maintaining competitive pricing for automotive products.

Tool manufacturing often requires materials with high hardness and strength to withstand rigorous use and abrasion. High-carbon steel’s sharpness and durability under heavy use make it ideal for durable, efficient tools. The ability to maintain sharp edges and resist deformation under heavy use makes high-carbon steel ideal for producing durable and efficient tools.

Choosing materials for tool manufacturing involves considering hardness, strength, and cost. High-carbon steel is preferred for applications requiring maximum durability, while mild steel may be chosen for tools that require more flexibility and ease of fabrication. The choice between carbon steel and mild steel depends on the specific performance requirements and cost considerations of the tool being manufactured.

Mild steel is extensively used in wiring and tubing applications due to its high ductility and cost-effectiveness. The ease of formation and welding makes mild steel an ideal choice for producing intricate wire products and durable tubes. Its lower carbon content ensures flexibility, which is crucial for applications that require bending and shaping without compromising structural integrity.

Carbon steel is suitable for applications requiring high strength, hardness, and wear resistance. It is ideal for structural components in construction, high-stress parts in automotive manufacturing, and durable tools. The varying carbon content allows for tailoring the steel properties to meet specific needs, making carbon steel a versatile material for demanding applications.

Mild steel is suitable for applications where ductility, ease of fabrication, and cost-effectiveness are essential. It is widely used in construction, automotive body parts, wiring, and tubing due to its favorable mechanical properties and affordability. Mild steel’s versatility makes it a popular choice for general fabrication and extensive forming processes.

Knowing when to use carbon steel or mild steel helps industries choose the best material for performance and cost.

The sustainability and environmental impact of carbon steel and mild steel are critical considerations in today’s manufacturing and construction industries, influenced by factors such as recyclability, energy consumption, and material lifespan.

| Aspect | Mild Steel | Carbon Steel |

|---|---|---|

| Recyclability | 100% recyclable, cost-effective | Generally recyclable, depends on carbon content |

| Energy Consumption | Lower energy requirements | Varies with carbon content, modern methods reduce carbon footprint |

| Durability | Prone to corrosion, needs protective treatments | Durability increases with carbon content, but ductility decreases |

| Sustainability | Smaller carbon footprint, highly recyclable | Offers balance of strength and sustainability, depending on carbon content |

In the context of sustainability, mild steel offers notable advantages in terms of recyclability and energy consumption due to its lower carbon content and simpler production process. However, its vulnerability to corrosion can be a drawback in certain applications. Carbon steel, with its varying carbon contents, provides a range of durability and strength options, necessitating a more nuanced approach to assess its environmental impact based on specific applications and production methods. Both materials can be sustainable choices when selected appropriately for their intended use.

Below are answers to some frequently asked questions:

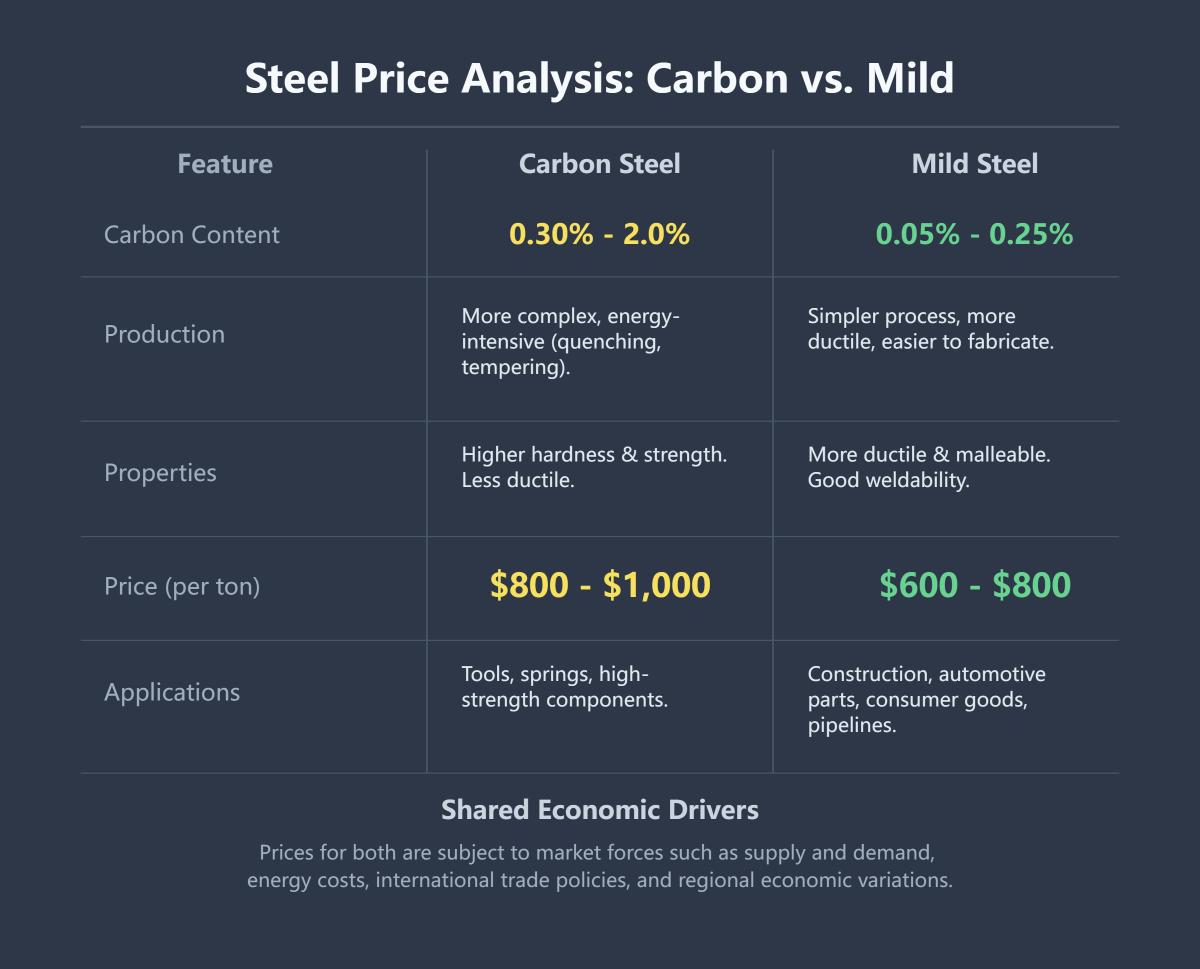

The primary differences in price between carbon steel and mild steel are influenced by their carbon content, production complexity, and specific application requirements. Carbon steel, with a higher carbon content (typically 0.30% to 2.0%), requires more complex and energy-intensive production processes such as quenching and tempering. This results in higher costs, with prices generally ranging from $800 to $1,000 per ton, depending on the grade and application.

In contrast, mild steel has a lower carbon content (typically 0.05% to 0.25%), making it more ductile and easier to fabricate. Its simpler production process leads to lower costs, generally between $600 and $800 per ton. Additionally, the demand for mild steel in construction, automotive parts, and consumer goods, where affordability and ease of fabrication are crucial, contributes to its lower price.

Economic factors, such as supply and demand dynamics, energy costs, and international trade policies, can also impact the prices of both carbon and mild steel, with regional variations influencing local costs.

Carbon content significantly affects both the price and properties of steel. Higher carbon content in steel leads to increased strength and hardness, as it forms iron carbides within the steel structure. This makes high-carbon steel more suitable for applications requiring wear resistance, such as cutting tools and machinery parts. However, it also makes the steel less ductile and more prone to brittleness, limiting its use in applications needing flexibility and deformation without fracture.

Conversely, mild steel, with a lower carbon content (0.05% to 0.25%), exhibits lower strength but higher ductility and weldability. This makes it ideal for applications where formability and ease of fabrication are crucial, such as automotive panels and construction. Due to its lower strength and simpler production processes, mild steel is generally less expensive compared to carbon steel. Therefore, the carbon content directly influences the mechanical properties and cost-efficiency of steel, guiding its suitability for various industrial applications.

When choosing between carbon steel and mild steel for industrial applications, it is essential to consider the specific requirements of the application.

Carbon steel, with a higher carbon content (0.05% to 1.70%), is known for its increased strength and hardness, making it suitable for applications requiring these properties, such as cutting tools, machinery parts, and structural components. However, higher carbon content can reduce ductility and weldability, making carbon steel less ideal for applications where these characteristics are critical.

Mild steel, a low-carbon steel (0.05% to 0.25%), is more malleable and ductile, making it easier to work with and weld. This makes mild steel a preferred choice for construction projects, automotive manufacturing, and general engineering applications where formability and cost-effectiveness are important. Additionally, mild steel is generally more cost-effective due to its simpler production process.

The main production cost differences between carbon steel and mild steel stem from their varying carbon content and the complexity of their manufacturing processes. Carbon steel, with a higher carbon content (0.30% to 2.0%), requires more complex and energy-intensive production techniques, including specialized heat treatments and the addition of alloying elements like manganese or chromium. These factors result in higher production costs for carbon steel. Conversely, mild steel, which contains a lower carbon content (0.05% to 0.25%), can be produced using simpler and less energy-intensive methods, making it more cost-effective. Additionally, the cost of raw materials and energy usage also plays a significant role, with carbon steel necessitating more expensive resources. Therefore, mild steel is typically cheaper, costing between $600 and $800 per ton, while carbon steel ranges from $800 to $1,000 per ton. This cost difference makes mild steel a more economical choice for applications prioritizing affordability and ease of fabrication.

Environmental concerns impact the choice between carbon steel and mild steel through factors such as production energy consumption, recyclability, and Recyclability is another critical factor; both carbon steel and mild steel are highly recyclable, which helps mitigate their environmental impact by reducing the need for new raw materials and the associated energy consumption. Mild steel’s lower carbon content makes it easier to recycle without significant quality loss.

In terms of carbon footprint, the production method greatly influences the environmental impact. The Electric Arc Furnace (EAF) method, which often uses recycled steel, has a lower carbon footprint compared to the Blast Furnace-Basic Oxygen Furnace (BF-BOF) route. While specific data on the carbon footprint differences between carbon steel and mild steel are limited, mild steel’s generally lower production energy requirements might give it an edge in sustainability.

Carbon steel and mild steel differ significantly in their mechanical properties, primarily due to variations in their carbon content. Carbon steel contains a higher carbon content, typically up to 2.0%, which results in increased hardness and strength. However, this higher carbon content also makes carbon steel more brittle and reduces its ductility and weldability. On the other hand, mild steel, which is also known as low-carbon steel, has a carbon content ranging from approximately 0.05% to 0.25%. This lower carbon content gives mild steel higher ductility and toughness, making it easier to form and weld.

In terms of strength and hardness, carbon steel is superior but less pliable compared to mild steel. Mild steel, while having lower strength and hardness, is more manageable and better suited for applications requiring bending and forming. Additionally, both types of steel are prone to corrosion, although mild steel may offer slightly better corrosion resistance when properly coated due to its lower carbon content.

Ultimately, the choice between carbon steel and mild steel depends on the specific needs of the application, including considerations of strength, ductility, weldability, and cost.