Imagine a material so versatile and reliable that it has become a cornerstone in industries ranging from construction to manufacturing. DIN EN 1.4301 stainless steel, also known as X5CrNi18-10 or AISI 304, is precisely that material. Known for its impressive balance of strength, durability, and corrosion resistance, this grade of stainless steel is a go-to choice for engineers and designers worldwide. But what exactly makes DIN EN 1.4301 so indispensable? In this article, we will delve into the specifications and properties that define this stainless steel, explore its common applications, and compare it with other popular grades. By the end, you’ll have a comprehensive understanding of why DIN EN 1.4301 is held in such high regard. Ready to uncover the secrets behind this engineering marvel? Let’s dive in.

Stainless steel is a durable, versatile iron-based alloy renowned for its excellent corrosion resistance. Its primary characteristic is the inclusion of chromium, which forms a passive layer of chromium oxide on the surface. This layer protects the metal from further corrosion and self-repairs if damaged, given that sufficient oxygen is present.

Stainless steel is categorized into several types based on its microstructure and alloying elements, which influence its properties and applications. The main types include:

Austenitic stainless steels are the most commonly used type, comprising approximately 70% of total stainless steel production. They contain high levels of chromium (16-26%) and nickel (6-22%), offering excellent corrosion resistance and easy formability. Examples include:

Ferritic stainless steels, with high chromium (10.5-27%) and low carbon content, offer good corrosion resistance and are magnetic, though less ductile than austenitic grades. Examples include:

Martensitic stainless steels are known for their high strength and hardness, achieved through heat treatment. They contain moderate to high chromium (12-18%) and higher carbon content. Examples include:

Duplex stainless steels have a mixed microstructure of austenite and ferrite, providing a balance of strength and corrosion resistance. They typically contain 22-25% chromium and 4-7% nickel. Examples include:

Precipitation-hardening stainless steels are designed to achieve high strength through heat treatment, where precipitates form in the microstructure. They contain chromium and nickel, along with elements like copper and aluminum. Examples include:

Stainless steel is favored in many applications due to its unique combination of properties:

Thanks to its diverse properties, stainless steel is used in many industries:

Stainless steel continues to be an essential material in modern engineering and manufacturing, offering reliability and performance across a wide range of applications.

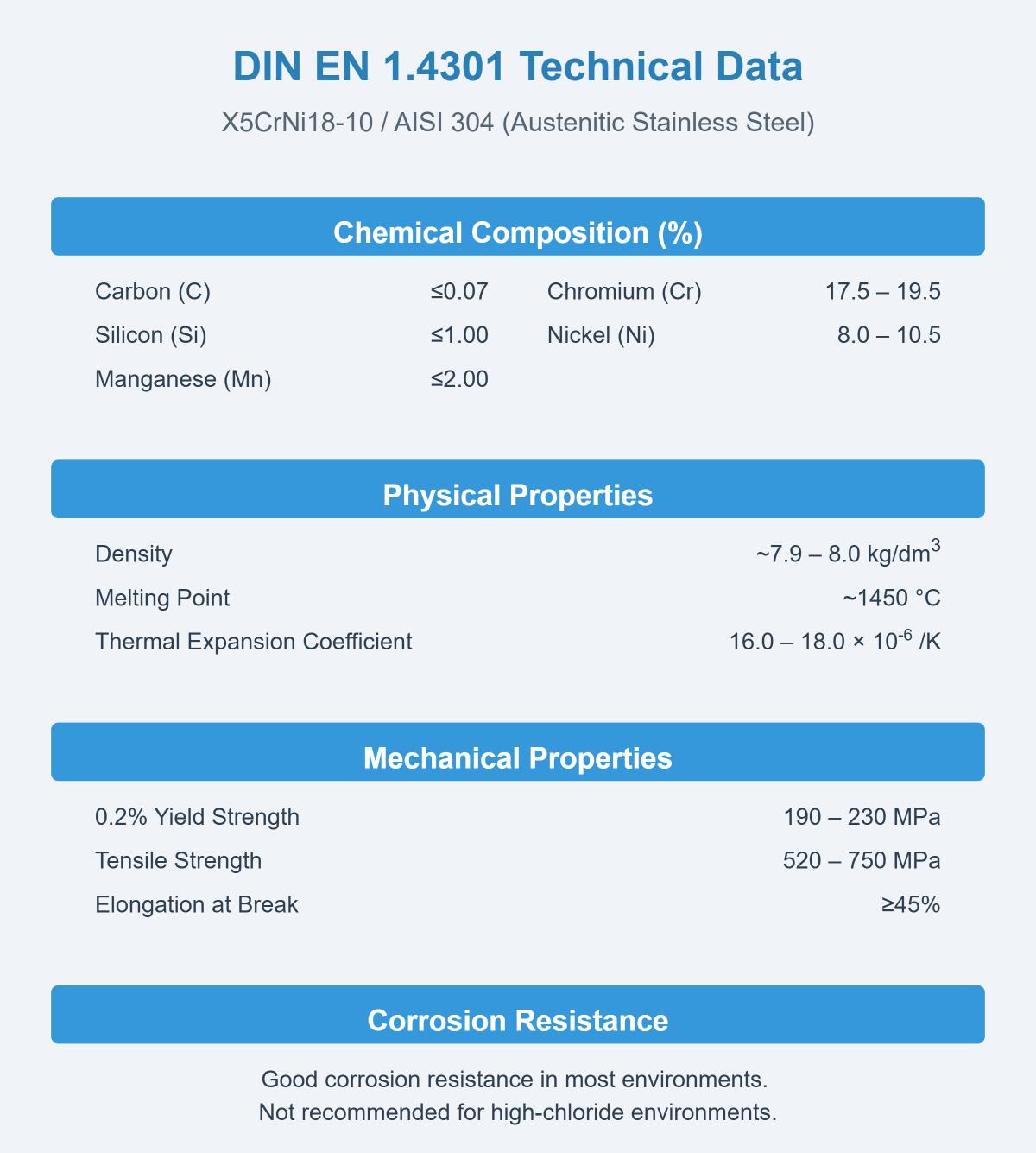

The chemical composition of DIN EN 1.4301 is standardized to ensure consistent performance:

DIN EN 1.4301’s physical properties enhance its suitability for various applications:

Understanding the mechanical properties is crucial for assessing performance under stress:

In the kitchen, DIN EN 1.4301 is a top choice for utensils and cookware due to its high resistance to corrosion and appealing aesthetics. In the chemical industry, it excels with its resistance to a wide range of chemicals. For medical devices, its hygiene and ease of sterilization make it indispensable. Architectural elements benefit from its durability and attractive finish, while automotive parts rely on its strength and resistance to environmental factors.

During fabrication, dedicated stainless steel tools should be used to avoid contamination. Cold working may require intermediate annealing. Transitioning to welding, conventional methods are suitable, but post-weld annealing might be necessary to restore corrosion resistance.

DIN EN 1.4307 (304L) offers improved weldability and resistance to intergranular corrosion due to its lower carbon content, making it ideal for welding-heavy applications. On the other hand, DIN EN 1.4948 (304H) is designed for high-temperature applications where increased strength is required, thanks to its higher carbon content.

X5CrNi18-10, like DIN EN 1.4301, is an austenitic stainless steel with a similar chemical composition, containing approximately 18% chromium and 8-10% nickel. The primary difference lies in the specific standards and tolerances defined by the DIN EN 10088 standard for X5CrNi18-10.

Both grades exhibit comparable mechanical properties, including tensile strength, yield strength, and elongation. Generally, the tensile strength ranges from 500 to 720 MPa, and the yield strength is around 190 MPa, with a minimum elongation of 45%. These slight variations may result from different production processes and quality control standards.

X5CrNi18-10 is commonly used in construction, food processing, and medical equipment due to its high formability and weldability, making it suitable for manufacturing complex shapes and components.

AISI 304 is the American equivalent to DIN EN 1.4301, sharing a similar composition of 18% chromium and 8% nickel, which balances strength and corrosion resistance. The minor differences in composition standards between ASTM and DIN/EN specifications are negligible in most practical applications.

The mechanical properties of AISI 304 align closely with those of DIN EN 1.4301, offering a tensile strength of 500 to 700 MPa and a yield strength of around 215 MPa. The elongation at break is typically around 45%, ensuring good ductility.

AISI 304 is extensively used in kitchen equipment, chemical containers, and architectural cladding. Its excellent corrosion resistance and ease of fabrication are key factors in its widespread use.

DIN EN 1.4307, or AISI 304L, has a lower carbon content (maximum 0.03%) compared to DIN EN 1.4301 (maximum 0.07%). This reduction minimizes the risk of carbide precipitation during welding, enhancing intergranular corrosion resistance.

The lower carbon content slightly reduces the tensile strength of DIN EN 1.4307, which typically ranges from 480 to 680 MPa, with a yield strength of around 170 MPa. Despite this, the elongation remains high, ensuring good formability.

DIN EN 1.4307 is preferred for applications involving extensive welding, such as chemical processing equipment and piping systems, due to its improved weldability and reduced risk of intergranular corrosion.

DIN EN 1.4401, also known as AISI 316, includes molybdenum (2-3%) in its composition, which significantly enhances its resistance to pitting and crevice corrosion, especially in chloride environments.

DIN EN 1.4401 offers similar mechanical properties to DIN EN 1.4301, with tensile strength ranging from 515 to 690 MPa and yield strength of around 205 MPa. The presence of molybdenum may slightly increase the material’s toughness and high-temperature strength.

DIN EN 1.4401 is favored in marine environments, chemical processing, and medical implants due to its superior corrosion resistance, making it more suitable for harsh conditions where exposure to chlorides and acids is common.

301 and 302 grades are also austenitic stainless steels, offering good corrosion resistance and mechanical properties. They are often used in automotive components and other applications where cost-effectiveness and formability are essential. However, their corrosion resistance and mechanical properties are generally lower than those of DIN EN 1.4301.

431 stainless steel is a martensitic grade known for its high strength and hardness, containing higher levels of chromium (around 16%) and carbon. It is suitable for applications requiring mechanical robustness, such as aerospace and mechanical engineering. However, it does not offer the same level of corrosion resistance as austenitic grades like DIN EN 1.4301.

When selecting a stainless steel grade, it is crucial to consider the specific requirements of the application, including mechanical strength, corrosion resistance, cost, and workability. The choice between different grades depends on these factors and the environment in which the material will be used.

DIN EN 1.4301, also known as X5CrNi18-10 or AISI 304, is characterized by a specific chemical composition that ensures its properties and performance. The main elements include:

DIN EN 1.4301 has physical properties that make it suitable for a wide range of applications:

These properties contribute to its excellent formability, making it a preferred material for products that require precise dimensions and consistent performance under varying conditions.

DIN EN 1.4301’s mechanical properties are crucial for its application in demanding environments:

These mechanical characteristics provide a balance of strength and ductility, allowing the material to withstand significant stress and deformation without failure.

DIN EN 1.4301 is widely used in various industries due to its versatility:

The material’s weldability is generally excellent, but it is prone to intergranular corrosion if not properly post-weld heat-treated. For applications requiring extensive welding, DIN EN 1.4307 (304L) with lower carbon content is preferred to mitigate this issue.

When working with DIN EN 1.4301, several fabrication techniques should be considered:

First, when cold working, remember the material work-hardens quickly. Intermediate annealing may be necessary to avoid tearing and maintain formability.

Then, for hot working, forging should be done between 1180 °C and 950 °C. Follow this by rapid cooling to preserve corrosion resistance.

These considerations ensure that the material retains its desirable properties throughout the manufacturing process, making it reliable for high-precision and high-performance applications.

DIN EN 1.4301 stainless steel, also known as AISI 304 or X5CrNi18-10, is well-known for its excellent corrosion resistance in various environments. This performance is primarily attributed to its chromium content, which forms a thin, stable, and adherent oxide layer on the surface. This passive layer acts as a barrier, protecting the underlying metal from further corrosion, and extends the material’s resistance to many organic and inorganic chemicals.

DIN EN 1.4301 exhibits remarkable resistance to atmospheric corrosion, making it suitable for outdoor applications. The passive layer formed by chromium ensures that the steel remains protected in most environmental conditions, including urban and rural atmospheres.

The material performs well in environments with exposure to acids, alkalis, and other chemical agents. However, in chloride-rich environments like seawater, it can suffer from pitting and crevice corrosion. This limitation should be considered when selecting materials for applications in these environments.

DIN EN 1.4301 can withstand temperatures up to 300°C while maintaining its corrosion resistance. This makes it ideal for moderate heat applications, though higher temperatures may require different grades.

Sustainability is a significant advantage of using DIN EN 1.4301 stainless steel. The environmental benefits stem from its recyclability, durability, and hygiene properties.

Stainless steel is fully recyclable, meaning it can be reused without losing any of its original properties. The recycling process of stainless steel is efficient and widely practiced, making it one of the most sustainable materials available. The long lifespan of DIN EN 1.4301 reduces the need for frequent replacements, which in turn lowers the environmental impact associated with production and disposal.

The long lifespan of DIN EN 1.4301 reduces the need for frequent replacements, which in turn lowers the environmental impact associated with production and disposal. Its durability ensures that products made from this material can withstand harsh conditions and prolonged use.

The ease of cleaning and maintaining stainless steel is another factor contributing to its sustainability. Its smooth surface and corrosion resistance make it ideal for sanitary applications, such as food processing and medical equipment. This property helps maintain high hygiene standards, reducing the need for harsh cleaning chemicals and contributing to better health outcomes.

DIN EN 1.4301 stainless steel combines excellent corrosion resistance with sustainability benefits, making it a versatile and environmentally friendly choice for various industrial and consumer applications.

DIN EN 1.4301 stainless steel is highly valued in manufacturing for its excellent corrosion resistance, mechanical properties, and ease of fabrication. Its versatility makes it a preferred material for a variety of components and equipment.

In the food and beverage industry, DIN EN 1.4301 is used for processing equipment, storage tanks, and kitchen appliances due to its non-toxic nature and high corrosion resistance, ensuring that food products remain uncontaminated. Additionally, the material’s smooth surface and ease of cleaning help maintain hygiene standards, which is crucial in this sector.

DIN EN 1.4301 stainless steel is crucial in the pharmaceutical and medical sectors. It is used in pharmaceutical processing equipment, surgical instruments, and medical devices. The material’s biocompatibility, ease of sterilization, and resistance to corrosion make it ideal for maintaining the stringent hygiene requirements of these industries.

In the chemical industry, DIN EN 1.4301 is utilized for tanks, pipes, and reactors. Its resistance to a wide range of chemicals ensures durability and reliability in processing environments. The material’s ability to withstand exposure to various organic and inorganic substances makes it a suitable choice for chemical storage and transportation.

DIN EN 1.4301 stainless steel is also extensively used in the construction industry, where its aesthetic appeal and structural integrity are highly valued.

Architectural elements such as façade cladding, railings, and decorative panels often use DIN EN 1.4301 for its excellent formability, corrosion resistance, and attractive finish. The material provides a modern, appealing finish that enhances the visual appeal of buildings while ensuring long-term durability.

For structural components, DIN EN 1.4301 offers the necessary strength and resistance to environmental factors. It is used in load-bearing applications, including support beams and framework, where its mechanical properties provide reliability and safety.

In sanitary engineering, the material is used for sinks, faucets, and other fittings. The durability of DIN EN 1.4301 ensures that sinks, faucets, and fittings remain functional and visually appealing over time. Its corrosion resistance and ease of cleaning make it ideal for maintaining hygiene in bathrooms and kitchens.

The renewable energy sector also benefits from the use of DIN EN 1.4301 stainless steel. It is employed in the construction of solar panels and wind turbines, where its resistance to corrosion and environmental factors ensures the longevity and efficiency of these installations.

In automotive manufacturing, DIN EN 1.4301 is used for various components, including vehicle body parts and exhaust systems. The material’s high strength, corrosion resistance, and ability to withstand high temperatures make it suitable for these demanding applications.

DIN EN 1.4301 stainless steel is widely used in industrial equipment for its corrosion resistance, strength, and ease of fabrication. This case study explores its application in chemical processing equipment.

In a chemical plant, DIN EN 1.4301 was chosen for fabricating storage tanks and piping systems. The plant processes various organic and inorganic chemicals, requiring materials that can withstand harsh chemical environments.

The stainless steel’s high chromium and nickel content ensured outstanding resistance to acids and alkalis, maintaining the integrity of the tanks and pipes. This prevented common issues like pitting and crevice corrosion, which are prevalent in chemical processing.

The ease of welding and shaping DIN EN 1.4301 facilitated the construction of complex shapes and large vessels. Regular maintenance and inspections showed that the material degraded very little over time, confirming its durability and reliability in demanding conditions.

DIN EN 1.4301 stainless steel is also popular in architectural applications due to its aesthetic appeal and structural integrity. This case study focuses on its use in a prominent architectural project.

A major skyscraper in an urban center utilized DIN EN 1.4301 for both its external cladding and internal structural components. The material’s resistance to atmospheric corrosion and its ability to maintain a polished finish made it ideal for this high-visibility application.

The stainless steel cladding has remained rust-free and polished for over ten years, despite constant exposure to rain and pollution. Internally, the structural components have provided reliable support without any significant wear or degradation.

The material’s ease of shaping allowed for creating intricate design elements that enhanced the building’s aesthetic appeal. Maintenance has been straightforward, with periodic cleaning required to maintain the material’s shine and appearance.

Renewable energy projects often demand materials that can endure harsh environmental conditions. This case study examines the application of DIN EN 1.4301 in the construction of solar panel frames.

Solar farms in coastal areas were equipped with solar panels mounted on frames made from DIN EN 1.4301. The coastal environment posed challenges due to high humidity and salt exposure.

The stainless steel frames demonstrated excellent resistance to corrosion, ensuring the structural stability of the solar panels. The material’s durability minimized maintenance costs and extended the lifespan of the installations.

The frames were fabricated with precision, taking advantage of the material’s excellent shaping ability. Routine inspections showed that the frames remained in good condition, with no significant signs of corrosion or mechanical failure.

In the food and beverage industry, hygiene and corrosion resistance are paramount. This case study explores the use of DIN EN 1.4301 in a dairy processing facility.

DIN EN 1.4301 was used for manufacturing milk storage tanks and processing equipment. The non-toxic nature and corrosion resistance of the material ensured that the dairy products remained uncontaminated.

The stainless steel tanks and equipment have proven highly effective in maintaining the purity of the milk. The material’s smooth surface and resistance to corrosion helped in maintaining high hygiene standards within the facility.

The equipment was easily fabricated to meet the specific requirements of the dairy processing operations. Regular cleaning and sterilization were efficient, with the material showing no adverse effects from the cleaning agents used.

Below are answers to some frequently asked questions:

DIN EN 1.4301 is an austenitic stainless steel, also known as X5CrNi18 – 10 or AISI 304. Its chemical composition includes ≤0.07% carbon, ≤1.00% silicon, ≤2.00% manganese, among others, with 17.5 – 19.5% chromium and 8.0 – 10.5% nickel. Physically, it has a density of about 7.9 – 8.0 kg/dm³, a melting point around 1450 °C, and a thermal expansion coefficient of 16.0 – 18.0 × 10-6 /K. Mechanically, its 0.2% yield strength is 190 – 230 MPa, tensile strength 520 – 750 MPa, and elongation at break is at least 45%. It offers good corrosion resistance in most environments, except high – chloride ones.

DIN EN 1.4301 stainless steel, known for its corrosion resistance, formability, and weldability, has diverse applications. In households, it’s used for cookware, utensils, sinks, and splashbacks. The food and beverage industry employs it in processing and storage equipment, like milk and beer tanks. In automotive and mechanical engineering, it makes vehicle parts and machine components. Construction uses it for facades, railings, and interior design. It’s also found in chemical processing tanks, surgical instruments, and renewable energy infrastructure such as solar panels and wind turbines.

DIN EN 1.4301 and X5CrNi18-10 are essentially the same material. X5CrNi18-10 is the short name under the DIN EN standard for 1.4301. Both designations refer to an austenitic stainless steel known for its excellent corrosion resistance, versatility, and wide range of applications. They share identical chemical composition, including 17.5-19.5% chromium and 8.0-10.5% nickel, and exhibit similar mechanical properties, such as tensile strength between 500-720 MPa and yield strength of ≥190 MPa. These materials are extensively used in industries such as food and beverage, automotive, construction, and chemical processing.

DIN EN 1.4301 and AISI 304 are equivalent designations for the same type of austenitic stainless steel, also known as X5CrNi18-10. Both standards describe a steel with similar chemical compositions, containing 17.5-19.5% chromium and 8.0-10.5% nickel, with carbon content typically under 0.08%. These materials are known for their excellent corrosion resistance, formability, and weldability.

The primary difference lies in their standardization: DIN EN 1.4301 follows European norms (EN 10088), while AISI 304 adheres to American standards (ASTM A240). Despite this, both materials are interchangeable in most applications, including food processing, chemical equipment, and architectural projects. Differences in carbon content are minimal and generally do not affect performance. Both grades may require annealing after cold working to mitigate work hardening and exhibit good weldability, though AISI 304 may need post-weld annealing to prevent carbide precipitation.

DIN EN 1.4301 stainless steel, also known as AISI 304 or X5CrNi18-10, exhibits excellent corrosion resistance in various environments. It is particularly effective against atmospheric corrosion, making it suitable for outdoor applications up to 300 °C. The alloy also offers good resistance to many organic and inorganic chemicals, although the specific resistance can vary depending on the chemical’s nature and concentration.

However, DIN EN 1.4301 is not ideal for chloride-rich environments, such as marine or coastal areas, due to its susceptibility to pitting and crevice corrosion. Additionally, while it generally shows good intergranular corrosion resistance, welding can compromise this unless proper post-weld treatments like solution annealing are performed. For applications involving welding, the low-carbon variant DIN EN 1.4307 (AISI 304L) is preferred.

Stress corrosion cracking can occur in environments above 60°C, which should be considered for high-temperature applications. Despite these limitations, DIN EN 1.4301 remains a versatile and widely used material in industries like chemical processing, food and beverage, medical equipment, and automotive, thanks to its combination of corrosion resistance, ease of fabrication, and overall cost-effectiveness.

DIN EN 1.4301 stainless steel, also known as AISI 304 or X5CrNi18-10, is considered sustainable due to its key properties. It is fully recyclable, which reduces waste and conserves resources by minimizing the environmental impact of raw material extraction and processing. Its durability and high corrosion resistance contribute to its long lifespan, reducing the need for frequent replacements and thus lowering the overall environmental footprint. Additionally, its thermal properties enhance energy efficiency in various applications. The material is non-toxic and hygienic, making it suitable for food processing, medical devices, and pharmaceutical equipment, which mitigates environmental and health hazards. Furthermore, its use in renewable energy systems supports sustainable energy production. Overall, DIN EN 1.4301 stainless steel’s recyclability, longevity, energy efficiency, and non-toxic nature make it a sustainable choice for numerous applications.