When it comes to cleaning and disinfecting, bleach is often hailed as a go-to solution. However, its powerful properties can have a detrimental effect on materials like stainless steel. Does bleach corrode stainless steel? The answer, unfortunately, is yes. The interaction between bleach and stainless steel can lead to various forms of corrosion, compromising the integrity and appearance of this otherwise resilient material.

In this article, we’ll delve into the chemical dynamics that cause bleach to corrode stainless steel, explore the specific types of corrosion it induces, and examine the factors that influence the severity of the damage. Moreover, we’ll compare bleach with alternative disinfectants and provide practical strategies to prevent corrosion and maintain the longevity of your stainless steel surfaces. Are there safer ways to keep your stainless steel clean without risking corrosion? Let’s find out.

Bleach is usually a liquid solution of sodium hypochlorite (NaOCl). As a powerful oxidizing agent and disinfectant, bleach is widely used in household cleaning, medical sanitation, pharmaceutical sterilization, and industrial processes. Bleach effectively kills many microorganisms, making it a popular choice for cleanliness and hygiene.

The chemical makeup of sodium hypochlorite in bleach helps it break down and oxidize organic matter. The solution typically contains chlorine, which is responsible for its strong disinfecting properties. The hypochlorite ion (OCl⁻) in bleach reacts with organic compounds and pathogens, disrupting their cellular structures and rendering them inactive. This powerful oxidizing property also plays a role in its interaction with metal surfaces, such as stainless steel.

Stainless steel is a versatile and widely used alloy composed mainly of iron, carbon, and chromium. The addition of chromium (at least 10.5%) is crucial as it forms a thin, stable layer of chromium oxide (Cr2O3) on the surface, which acts as a protective barrier against corrosion. This passive film prevents the metal underneath from reacting with oxygen and other environmental elements, thereby maintaining its integrity and appearance.

Stainless steel is favored in applications requiring high standards of hygiene and durability. It is commonly found in kitchen appliances, medical instruments, pharmaceutical equipment, and industrial machinery. The material’s resistance to rust and its ease of cleaning make it ideal for environments where cleanliness is paramount.

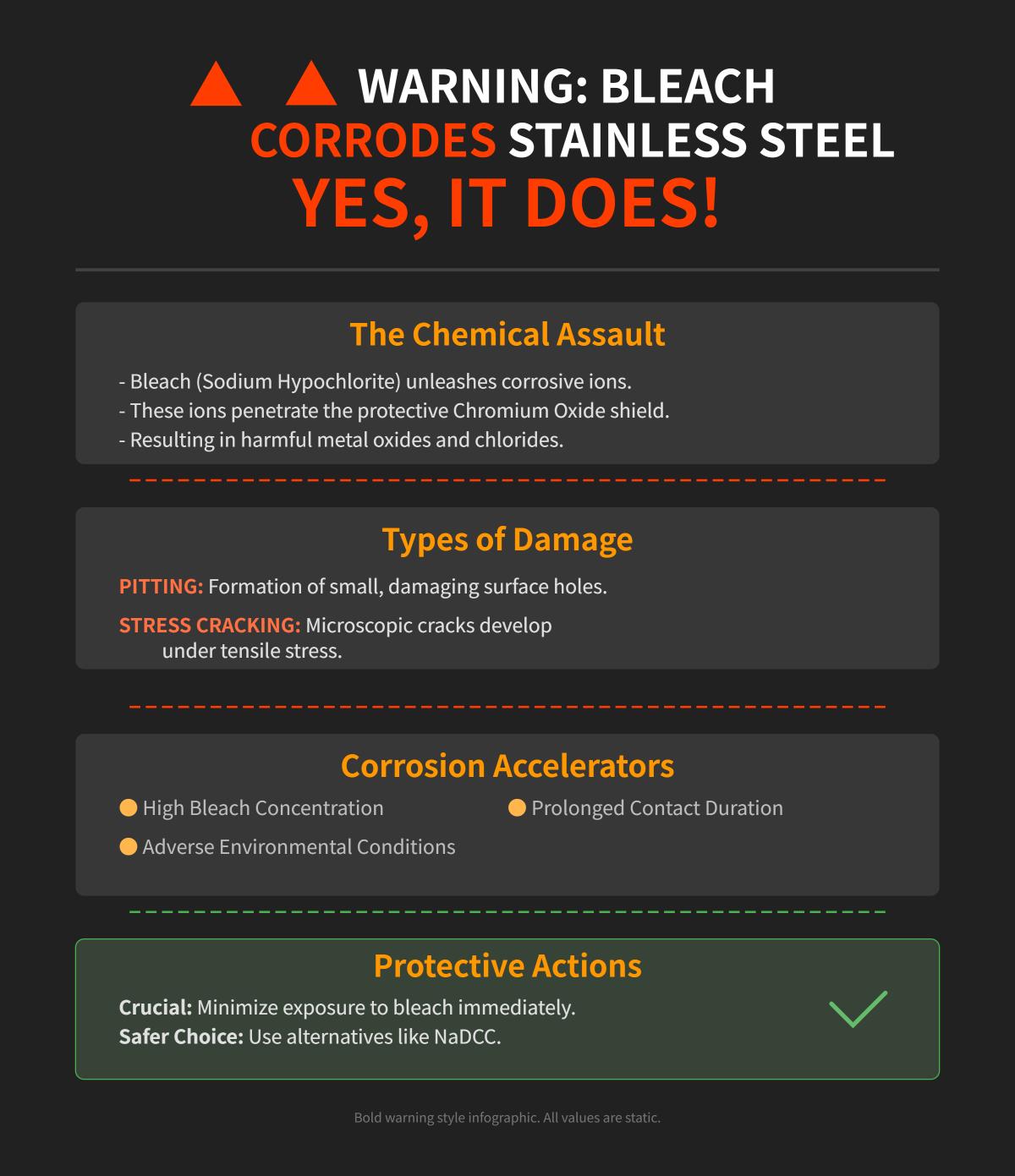

Bleach can interact with stainless steel in ways that may cause corrosion under certain conditions. When bleach comes into contact with stainless steel, the chloride ions (Cl⁻) present in sodium hypochlorite can penetrate the protective chromium oxide layer. This penetration disrupts the passive film and initiates corrosion processes.

Several factors influence the severity of corrosion when bleach interacts with stainless steel:

Understanding these factors is crucial for preventing damage and ensuring the longevity of stainless steel components in environments where bleach is used frequently for disinfection.

Corrosion is a natural process where metals deteriorate due to chemical or electrochemical reactions with their surroundings. For stainless steel, corrosion can compromise structural integrity, leading to potential failures in applications where hygiene and durability are critical. Understanding the mechanisms behind corrosion, especially when caused by bleach, is essential for preventing damage and ensuring long-term performance.

When bleach, which contains sodium hypochlorite (NaOCl), contacts stainless steel, it starts chemical reactions that damage the metal’s protective layer. The chloride ions (Cl⁻) in bleach aggressively penetrate the chromium oxide (Cr2O3) layer that protects stainless steel from corrosion. This penetration disrupts the passive film, leading to localized breakdown and corrosion.

Chloride ions are highly reactive and can cause significant damage to stainless steel. When bleach is applied to stainless steel surfaces, chloride ions infiltrate the protective chromium oxide layer. This infiltration accelerates corrosion processes by creating localized weaknesses in the metal. The breakdown of this passive layer exposes the underlying metal to further chemical attacks, exacerbating the corrosion.

Chloride ions from bleach cause pitting corrosion by penetrating the chromium oxide layer, creating small, localized areas where the protective film breaks down. Once a pit forms, it can trap aggressive agents like chloride ions, further accelerating the corrosion process within the pit.

Pitting corrosion typically appears as small, dark spots on the stainless steel surface. These spots can be difficult to detect initially but may grow over time, leading to significant structural damage if not addressed. The pits often vary in size and depth, depending on the concentration of bleach and the duration of exposure.

Stress corrosion cracking (SCC) happens when stainless steel is under tensile stress and exposed to chloride ions from bleach. This combination of mechanical stress and chemical attack leads to the formation of microscopic cracks on the metal surface. These cracks can propagate rapidly, potentially causing catastrophic failure of the material, especially in high-stress environments.

Stress corrosion cracking manifests as fine cracks that may be difficult to see with the naked eye. These cracks often appear in areas subjected to the highest levels of stress, such as weld zones or regions under mechanical load. Over time, these cracks can grow and coalesce, leading to significant structural weakening and potential failure.

The concentration of bleach is crucial in determining how much it corrodes stainless steel. Higher concentrations of sodium hypochlorite increase the presence of chloride ions, which are the primary agents of corrosion. As concentration rises, the aggressive nature of these ions becomes more pronounced, leading to faster and more severe degradation of the protective chromium oxide layer on the stainless steel surface. This heightened activity accelerates both pitting corrosion and stress corrosion cracking, making it crucial to manage bleach concentrations carefully to mitigate corrosive effects.

The length of time that stainless steel is exposed to bleach significantly influences the severity of corrosion. Longer exposure allows more chloride ions to damage the protective chromium oxide layer, leading to extensive damage. Continuous or repeated contact with bleach can exacerbate the deterioration, as the protective layer has less time to regenerate between exposures. Therefore, minimizing the duration of bleach contact with stainless steel surfaces can help reduce the overall corrosive impact.

Environmental factors such as temperature and humidity play a critical role in the corrosion process of stainless steel when exposed to bleach. Elevated temperatures can accelerate the chemical reactions between bleach and the stainless steel, enhancing the corrosive activity of chloride ions. High humidity maintains a moist environment that, along with elevated temperatures, accelerates the penetration of chloride ions and enhances corrosion. Controlling these environmental conditions is essential in environments where bleach is used regularly to disinfect stainless steel surfaces.

The specific alloy composition of stainless steel can influence its resistance to bleach-induced corrosion. Stainless steels with higher molybdenum content, such as grades 316 and 317, exhibit better resistance to chloride-induced corrosion compared to lower-grade alloys like 304. The presence of molybdenum enhances the stability of the protective chromium oxide layer, making it more resistant to breakdown by chloride ions. Choosing the right stainless steel grade based on its intended use and exposure can significantly reduce corrosion risks.

The condition of the stainless steel surface affects its corrosion resistance. Smooth, polished surfaces tend to be more resistant to corrosion compared to rough or scratched surfaces. Surface imperfections can trap bleach and chloride ions, creating localized sites where corrosion can initiate and propagate. Regular maintenance to ensure a smooth, clean surface can help reduce the risk of corrosion by eliminating potential sites for chloride ion accumulation.

Mechanical stress, whether from external loads or residual stresses from manufacturing processes, can exacerbate corrosion, particularly stress corrosion cracking (SCC). Tensile stresses can create microcracks in the stainless steel, providing pathways for chloride ions to penetrate and initiate corrosion. Reducing mechanical stresses through proper design, manufacturing, and maintenance practices can help prevent SCC and prolong the life of stainless steel components exposed to bleach.

When disinfecting stainless steel, both bleach (sodium hypochlorite) and sodium dichloroisocyanurate (NaDCC) are popular choices. However, they have distinct attributes that influence their suitability for different applications.

Bleach, which contains sodium hypochlorite, is a widely-used disinfectant known for its strong antimicrobial properties. Despite its effectiveness in disinfection, bleach is notorious for causing corrosion on stainless steel surfaces due to the aggressive action of chloride ions. Here are some key characteristics:

NaDCC is a chlorine-based disinfectant that is often considered a safer alternative to bleach for use on stainless steel.

Various factors affect how bleach corrodes stainless steel compared to NaDCC:

Apart from NaDCC, there are other disinfectants that can be considered to mitigate corrosion risks when cleaning stainless steel surfaces:

Given the comparative advantages of NaDCC over bleach, it is advisable to adopt NaDCC as a routine disinfectant in environments with frequent stainless steel usage, such as healthcare and pharmaceuticals. For current setups, thorough rinsing after using bleach can significantly reduce corrosion.

Choosing the right disinfectant involves balancing efficacy, safety, and material compatibility. NaDCC’s consistency, non-corrosiveness, and comparable disinfection efficacy make it a superior alternative to bleach for preserving stainless steel integrity.

Reducing the exposure of stainless steel to bleach is a fundamental strategy in mitigating corrosion. Implementing these best practices can help protect stainless steel surfaces:

Diluting bleach is crucial to reduce its corrosive effects on stainless steel. Additionally, minimizing the duration of bleach contact with stainless steel surfaces is essential, as shorter exposure times lessen the likelihood of significant corrosion. A recommended dilution ratio is 1 part bleach to 10 parts water. This reduces the concentration of chloride ions, lessening their ability to penetrate and damage the protective chromium oxide layer on stainless steel. Rinse the surface thoroughly with water immediately after cleaning to remove any residual bleach.

Regular maintenance is key to preserving the integrity of stainless steel in environments where bleach is used. Adopting comprehensive care protocols can significantly reduce corrosion risks:

Conduct regular inspections to identify early signs of corrosion, such as discoloration or small pits. Early detection allows for prompt action to prevent further damage.

Regularly clean stainless steel surfaces with non-chlorine-based cleaners to keep them looking good and prevent damage. Passivation involves treating stainless steel with an acid bath to restore its protective layer and enhance its resistance to corrosion.

Adding protective coatings and barriers can help shield stainless steel from bleach damage:

Coatings such as polymer-based films or epoxy resins can shield stainless steel surfaces from direct contact with bleach. These coatings act as a physical barrier, preventing chloride ions from reaching the metal surface.

In environments where bleach use is frequent, consider using barriers or linings made from materials resistant to chlorine-based corrosion. These can include plastic or rubber liners that provide an effective barrier between the bleach and the stainless steel.

Exploring alternative disinfectants can help reduce the risk of corrosion while maintaining hygiene standards:

NaDCC is a chlorine-based disinfectant that is less corrosive to stainless steel compared to bleach. It provides effective disinfection without the aggressive action of chloride ions on the protective chromium oxide layer.

Consider using non-chlorine-based cleaners such as vinegar, baking soda paste, or lemon oil. These alternatives are effective in cleaning and disinfecting stainless steel without causing corrosion.

Implementing a consistent maintenance routine is crucial for the longevity of stainless steel surfaces:

Establish a regular cleaning schedule using appropriate cleaning agents to prevent the buildup of contaminants that could cause corrosion. Additionally, controlling environmental factors like temperature and humidity can help protect stainless steel surfaces by preventing accelerated corrosion processes.

Below are answers to some frequently asked questions:

Yes, bleach does cause corrosion on stainless steel. Bleach, primarily composed of sodium hypochlorite, contains hypochlorite and chloride ions which can react with the surface of stainless steel. These ions disrupt the protective chromium oxide layer, leading to the formation of metal oxides and metal chlorides. This process results in two common types of corrosion: pitting corrosion, where small holes or pits form on the surface, and stress corrosion cracking, where microscopic cracks develop under tensile stress. Factors such as the concentration of bleach, duration of exposure, and environmental conditions can influence the severity of corrosion. To mitigate these effects, it is advisable to minimize bleach exposure and consider alternative disinfectants like sodium dichloroisocyanurate (NaDCC).

Bleach, primarily composed of sodium hypochlorite (NaOCl), causes several types of corrosion on stainless steel. The most common forms are pitting corrosion and stress corrosion cracking (SCC). Pitting corrosion results in localized holes or pits on the stainless steel surface, as chloride ions from bleach attack the protective chromium oxide layer, accelerating the corrosion process in specific areas. SCC occurs when tensile stress and chloride ions combine, leading to microscopic cracks that can result in structural failure, especially under conditions of elevated temperature and humidity. Additionally, bleach can cause general corrosion and discoloration, even in diluted solutions, affecting the appearance and integrity of stainless steel surfaces. Understanding these corrosion mechanisms is crucial for preventing damage and maintaining the longevity of stainless steel in various applications.

Yes, there are safer alternatives to bleach for disinfecting stainless steel surfaces. One effective option is 70% isopropyl alcohol, which is widely recommended for its disinfecting properties. It effectively kills a broad spectrum of pathogens and evaporates quickly, leaving no residue that could damage the stainless steel. Another option is using mild detergents with soap and water, which can sanitize the surfaces without causing chemical damage, although they may not be as effective against all pathogens as alcohol or bleach. Additionally, specialized stainless steel cleaners can be used to maintain and protect the surface, though they are not typically disinfectants. Choosing the appropriate disinfectant depends on the specific needs and the condition of the stainless steel.

Factors like concentration and exposure time significantly affect bleach corrosion on stainless steel. Higher concentrations of bleach, such as a 1:10 dilution, can cause rapid degradation, including pitting and discoloration within days. Lower concentrations, like a 1:50 dilution, still induce corrosion but at a slower rate. Sodium hypochlorite concentrations above 5% can trigger pitting and crevice corrosion even in corrosion-resistant grades at ambient temperatures.

Exposure duration also plays a crucial role. Short-term exposure (4-11 days) can lead to visible staining and localized pitting. Prolonged exposure over weeks can cause structural weakening, rust deposition, and accelerated stress corrosion cracking due to chlorine ion penetration. Repeated use of bleach erodes the chromium oxide layer, which is vital for corrosion resistance, thereby permanently compromising the material’s integrity. Therefore, both the concentration of bleach and the duration of exposure are critical factors in determining the extent of corrosion on stainless steel.

Chloride ions (Cl⁻) in bleach play a critical role in the corrosion of stainless steel by destabilizing its protective chromium oxide (Cr₂O₃) layer through electrochemical reactions. These ions form soluble chromium chloride (CrCl₃), depleting chromium from the passive layer and exposing the underlying iron to corrosion. This process can occur even with dilute bleach solutions, such as 5% sodium hypochlorite, at ambient temperatures.

Chloride ions also contribute to localized pitting corrosion by penetrating microscopic defects in the oxide layer. These pits trap bleach and moisture, creating acidic microenvironments that accelerate corrosion. Stainless steel grades like 304 are particularly susceptible, while 316 offers better resistance but can still be affected at high chloride concentrations.

Additionally, chloride ions promote stress corrosion cracking (SCC) under tensile stress, especially in welded joints, leading to structural failures. Factors such as chloride concentration, temperature, and exposure duration significantly influence corrosion rates, making it essential to manage these variables to protect stainless steel from bleach-induced damage.

To protect stainless steel from bleach corrosion, several preventive measures can be implemented. Firstly, selecting corrosion-resistant grades of stainless steel, such as 316 or higher, which contain elevated molybdenum content, enhances resistance to chloride-induced corrosion. Secondly, when using bleach, it should be appropriately diluted, maintaining a 1:10 bleach-to-water ratio or weaker to minimize corrosion risk. Limiting the exposure time and thoroughly rinsing the surfaces with distilled water after cleaning is also crucial to remove any residual chlorine.

Additionally, using non-chlorine disinfectants like sodium dichloroisocyanurate (NaDCC) or pH-neutral detergents can significantly reduce the risk of corrosion. Regular passivation treatments with nitric or citric acid can help restore the protective chromium oxide layer on stainless steel. Routine inspections for any signs of discoloration, pitting, or rust spots, especially in high-moisture environments, are also essential.