When it comes to selecting the right aluminum alloy for your project, the choice between duralumin and 6061 aluminum can be pivotal. Both of these materials offer unique properties that make them suitable for various applications, but understanding their differences is crucial for making an informed decision. In this comprehensive comparison, we will delve into the chemical compositions, mechanical properties, and corrosion resistance of duralumin and 6061 aluminum. We’ll also explore their suitability for high-stress applications and their performance in different environmental conditions. By the end of this article, you’ll have a clear understanding of which alloy is the best fit for your needs. So, which will it be—duralumin or 6061 aluminum? Let’s find out.

Aluminum alloys are widely used in many industries because they are lightweight, strong, and resistant to corrosion. These alloys are created by combining aluminum with one or more other elements to enhance their mechanical and chemical characteristics. The resulting materials offer a balance of properties that make them suitable for a wide range of applications.

Aluminum alloys are crucial in aerospace, automotive, construction, and consumer electronics. Their lightweight nature improves fuel efficiency in transportation, and their strength and durability make them perfect for building structures and machinery. The corrosion resistance of aluminum alloys also ensures long-term performance in environments where other materials might degrade quickly.

Two notable aluminum alloys that stand out for their specific properties and uses are duralumin and 6061 aluminum. Both have distinct compositions and characteristics that make them suitable for different applications.

Duralumin, an early aluminum alloy mainly used in aerospace, typically contains aluminum with significant copper and small amounts of magnesium and manganese. This alloy is known for its high strength-to-weight ratio, which is crucial in applications where reducing weight without compromising strength is essential.

6061 aluminum is popular for its versatility. It includes aluminum, magnesium, and silicon, offering a great mix of strength, corrosion resistance, and ease of working. This alloy is often chosen for its excellent weldability and ability to be easily machined and formed, making it suitable for a variety of general-purpose applications.

Knowing the differences and similarities between duralumin and 6061 aluminum helps in choosing the right material for specific uses, as their compositions affect their strength, corrosion resistance, and performance.

Duralumin is an aluminum alloy celebrated for its high strength and impressive mechanical properties. The primary constituents of duralumin include aluminum (91-95%), copper (3.8-4.9%), magnesium (1.2-1.8%), and manganese (0.3-0.9%). Duralumin may also contain small amounts of iron, silicon, zinc, titanium, and chromium, which further enhance its properties.

6061 aluminum is renowned for its versatility and excellent corrosion resistance. Its main components are aluminum (95.85-98.56%), magnesium (0.80-1.20%), and silicon (0.40-0.80%). Smaller amounts of copper (0.15-0.40%), along with trace quantities of iron, chromium, zinc, and manganese, contribute to its balanced combination of strength, machinability, and resistance to wear.

The chemical composition of duralumin and 6061 aluminum reveals significant differences that influence their properties and applications. Duralumin has a higher copper content than 6061 aluminum, giving it greater tensile strength and hardness but reducing its corrosion resistance. On the other hand, 6061 aluminum has a balanced composition of magnesium and silicon, enhancing its corrosion resistance and making it more suitable for environments where durability against weather and moisture is crucial. This composition also contributes to its excellent machinability and weldability.

The trace elements like manganese in duralumin improve ductility, while chromium in 6061 aluminum enhances corrosion resistance. Understanding these differences helps in selecting the appropriate alloy based on the specific requirements of strength, corrosion resistance, and application-specific properties.

Tensile strength is vital as it shows the maximum stress an alloy can endure before breaking when stretched or pulled.

6061 aluminum, especially in its T6 temper, has a tensile strength of around 310 MPa (45,000 psi), achieved through heat treatment that significantly enhances its mechanical properties.

Due to its higher copper content, duralumin generally offers greater tensile strength compared to 6061 aluminum.

Yield strength measures the stress at which a material begins to deform plastically. After surpassing the yield point, the material will deform permanently.

6061 aluminum has a yield strength of about 276 MPa (40,000 psi) in the T6 temper, making it a strong candidate for applications requiring a good balance between strength and flexibility.

Similar to its tensile strength, duralumin’s yield strength is generally higher than that of 6061 aluminum, again due to its copper content. This makes duralumin particularly suitable for high-stress applications where maximum strength is paramount.

Density is a key factor in applications where weight reduction is critical, such as in aerospace and automotive industries.

6061 aluminum has a density of approximately 2.70 g/cm³, making it one of the lighter aluminum alloys. This property is highly advantageous for applications needing lightweight yet strong materials.

Duralumin, while still lightweight compared to steel, is slightly heavier than 6061 aluminum due to its higher copper content. This marginal increase in weight can be a trade-off for its higher strength.

Corrosion resistance is essential for materials used in environments prone to moisture and other corrosive elements.

6061 aluminum exhibits excellent natural corrosion resistance, largely due to its lower copper content and the formation of a protective oxide layer. This makes it ideal for marine and outdoor applications where exposure to the elements is common.

Duralumin, on the other hand, has poorer corrosion resistance owing to its high copper content. This necessitates the use of protective coatings or treatments to enhance its durability in corrosive environments.

Ductility is a material’s ability to stretch under stress, while machinability is how easily it can be cut or shaped.

6061 aluminum is highly ductile, allowing it to be shaped without cracking. Its excellent machinability makes it versatile for manufacturing processes like welding and machining.

Duralumin is less ductile than 6061 aluminum due to its higher copper content, making it harder and more brittle. However, it still possesses satisfactory machinability for producing precise components.

The applications of these alloys are influenced by their mechanical properties.

6061 aluminum is widely used in bike frames, automotive parts, and sporting equipment due to its balance of strength, weldability, and corrosion resistance.

Duralumin is primarily used in high-performance applications that require high strength-to-weight ratios, such as in the aerospace and aviation industries.

Fatigue limit is the maximum stress a material can endure for a specified number of cycles without failing.

6061-T6 aluminum has a fatigue limit of about 97 MPa (14 ksi) for 500 million completely reversed cycles, making it suitable for applications where repeated stress is a concern.

While specific fatigue data for duralumin is less commonly referenced, its higher strength implies better resistance to fatigue under certain conditions.

These properties define the elasticity of the material.

6061 aluminum has a Young’s modulus of approximately 69 GPa (10,000 ksi) and a Poisson’s ratio of 0.33.

While specific values for Young’s modulus and Poisson’s ratio are not frequently cited for duralumin, aluminum alloys generally exhibit similar elastic properties to 6061, with variations based on composition.

Thermal conductivity is crucial in applications requiring efficient heat dissipation.

6061 aluminum has a thermal conductivity ranging from 151 to 202 W/(m·K), providing good heat dissipation in various applications.

Duralumin typically has lower thermal conductivity compared to 6061 aluminum due to its higher copper content, affecting its heat transfer properties.

Corrosion resistance is a key factor when selecting aluminum alloys for various applications, including duralumin and 6061 aluminum. Both alloys exhibit distinct corrosion properties influenced by their chemical compositions.

Duralumin is known for its high strength, containing significant amounts of copper, magnesium, and manganese. The copper content, while beneficial for strength, negatively impacts its corrosion resistance, making it prone to pitting in corrosive environments. To reduce corrosion, duralumin is often made with a pure aluminum outer layer called ‘alclad.’

6061 aluminum, on the other hand, comprises primarily magnesium and silicon, with a lower copper content (typically between 0.15% and 0.40%). The inclusion of silicon helps form a stable, protective oxide layer on the surface, providing better natural corrosion resistance compared to duralumin. This makes 6061 aluminum less susceptible to corrosion, particularly in marine and outdoor environments, although it is not as corrosion-resistant as some other alloys like 7075.

Despite its lower corrosion resistance, duralumin remains extensively used in the aviation and aerospace industries due to its high strength-to-weight ratio and fatigue resistance. For applications where corrosion is a concern, protective coatings or treatments are often applied to duralumin to extend its lifespan and maintain performance.

6061 aluminum’s excellent corrosion resistance makes it ideal for marine and outdoor applications where exposure to moisture is frequent. This alloy is also widely used in automotive parts, bike frames, and sporting equipment, where both strength and corrosion resistance are required.

Both duralumin and 6061 aluminum can benefit from various methods to enhance corrosion resistance. Applying protective coatings or using treatments like anodizing can significantly improve the durability of these alloys in corrosive environments.

Duralumin’s corrosion resistance can be notably improved by utilizing the alclad form, which involves adding a pure aluminum outer layer. This protective layer helps prevent corrosive damage, making duralumin more suitable for applications where high corrosion resistance is necessary.

6061 aluminum naturally resists corrosion better due to its lower copper content and stable oxide layer, whereas duralumin needs extra protection to prevent corrosion. The choice between these two alloys depends on specific application requirements, balancing factors such as strength, weight, and environmental conditions.

Duralumin, a high-strength aluminum alloy, is primarily utilized in industries where both strength and lightweight characteristics are crucial.

Duralumin has played a crucial role in the aviation industry due to its high strength-to-weight ratio. Its superior properties make it ideal for aircraft structural components, including fuselage frames, wing ribs, and other critical parts where reducing weight is essential without compromising strength.

In the automotive sector, duralumin is used to manufacture engine components and gearboxes, providing high strength while remaining lightweight. This combination enhances vehicle performance and efficiency by handling substantial mechanical stress without adding unnecessary weight.

Duralumin’s strength and lightweight properties make it ideal for high-performance sports equipment, such as bicycle frames. These attributes contribute to better performance and durability in competitive sports.

6061 aluminum is renowned for its versatility, excellent corrosion resistance, and balanced mechanical properties, making it suitable for a wide range of applications.

6061 aluminum is widely used in structural applications within the construction industry, including building frameworks, bridges, and other infrastructure projects. Its corrosion resistance and durability ensure long-lasting performance in various environmental conditions.

6061 aluminum is perfect for marine applications because it resists corrosion in saltwater environments. This corrosion resistance extends the lifespan of marine structures and reduces maintenance costs, making it ideal for boat and ship fittings, including hulls, decks, and other structural components.

6061 aluminum is also used in the automotive industry for parts that benefit from both strength and corrosion resistance, such as frames, wheels, and other components. This alloy’s properties help enhance vehicle longevity and reduce the need for frequent replacements.

6061 aluminum’s machinability and corrosion resistance make it a preferred material for consumer electronics like mobile phones and laptops, allowing for durable and high-quality products. Its ability to be easily shaped and finished ensures the production of reliable electronic devices.

| Industry/Application | Duralumin | 6061 Aluminum |

|---|---|---|

| Aviation | High strength-to-weight ratio ideal for aircraft fittings | Not typically used due to corrosion concerns |

| Automotive | Used for strength, but less corrosion-resistant | Preferred for corrosion resistance |

| Sporting Equipment | Lightweight and strong, used in high-performance equipment | Offers a balance of strength and corrosion resistance |

| Marine | Not ideal due to poor corrosion resistance | Excellent choice for marine environments due to its corrosion resistance |

| Consumer Electronics | Not commonly used | Used due to its corrosion resistance and ease of fabrication |

Understanding the specific requirements of an application—whether it is strength, corrosion resistance, or cost—will guide the selection of the appropriate aluminum alloy. Both duralumin and 6061 aluminum have their unique advantages and are chosen based on the demands of the industry and the specific conditions they will face.

Duralumin is an alloy primarily made of aluminum, copper, magnesium, and manganese, and it requires a more complex manufacturing process due to its diverse composition. The presence of copper necessitates advanced heat treatment techniques to achieve the desired mechanical properties. The manufacturing steps typically include casting, rolling, and aging processes. These steps are critical for enhancing the alloy’s strength and hardness, making it suitable for high-stress applications. However, these processes are energy-intensive and costly, impacting the overall production cost and environmental footprint.

6061 aluminum, composed mainly of aluminum, magnesium, and silicon, benefits from a simpler and more cost-effective manufacturing process. The alloying elements in 6061 aluminum allow for easier fabrication, including processes such as extrusion, rolling, and welding. The heat treatment process for 6061 aluminum, while necessary to achieve optimal mechanical properties, is less complex compared to duralumin. This simplicity in manufacturing translates to lower production costs and higher efficiency, making 6061 aluminum a popular choice in various industries.

The environmental impact of manufacturing aluminum alloys is a significant consideration. Duralumin, with its higher copper content, requires more energy-intensive production processes, contributing to a larger carbon footprint. Extracting and processing copper leads to higher emissions and increased resource use.

In contrast, 6061 aluminum is more environmentally friendly due to its simpler composition and less energy-intensive manufacturing processes. The lower copper content in 6061 aluminum reduces the environmental burden associated with its production. Additionally, the primary alloying elements, magnesium and silicon, have less environmental impact compared to copper.

Both duralumin and 6061 aluminum are recyclable, but the recycling process for duralumin is more complicated due to its higher copper content. Separating the copper from the aluminum during recycling can be challenging and less efficient.

6061 aluminum, on the other hand, is easier to recycle due to its simpler composition. The lower copper content simplifies the recycling process, making it more efficient and cost-effective. This ease of recyclability enhances the sustainability of 6061 aluminum, as it can be reused in various applications with minimal environmental impact.

The complexity of duralumin’s manufacturing process results in higher production costs. The advanced heat treatments and energy-intensive steps needed to attain its high strength and mechanical properties increase its production costs. These costs are often justified in applications where the superior strength of duralumin is critical, such as in aerospace and high-performance automotive parts.

6061 aluminum is more cost-effective due to its straightforward manufacturing process. The simpler heat treatment and fabrication steps reduce production costs, making 6061 aluminum a more economical option for a wide range of applications. This cost-effectiveness, combined with its good mechanical properties and corrosion resistance, makes 6061 aluminum a versatile and widely used material.

Both duralumin and 6061 aluminum must meet specific industry standards to ensure quality and performance.

Duralumin and 6061 aluminum are required to comply with ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards. These standards specify the chemical composition, mechanical properties, and manufacturing processes for aluminum alloys to ensure they meet industry requirements.

Duralumin typically adheres to standards such as ASTM B209 for aluminum and aluminum-alloy sheet and plate, while 6061 aluminum must comply with standards like ASTM B221 for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes. Meeting these standards ensures both alloys perform reliably, giving confidence in their use across various industries.

When comparing the initial costs of Duralumin and 6061 aluminum, consider the complexity of production and the cost of alloying elements.

Duralumin is generally more expensive due to its higher copper content and the intricate manufacturing processes required to achieve its high strength properties, with prices ranging from $3.60 to $4.50 per kilogram for sheet plates.

The simpler production process and lower cost of alloying elements like magnesium and silicon make 6061 aluminum more affordable, with sheet plates costing about $2.80 to $3.20 per kilogram.

When evaluating the long-term benefits and drawbacks, consider factors such as durability, maintenance, and lifecycle costs.

The availability and economic factors of these aluminum alloys influence their practicality for various industries.

Duralumin often requires larger minimum order quantities due to its specialized production and application in high-performance sectors. This can lead to longer lead times and higher costs, making it less accessible for smaller projects or industries with immediate material needs.

6061 aluminum is widely available in various forms and sizes, making it more accessible for immediate delivery and smaller projects. Its broad availability and lower cost contribute to its widespread use across multiple industries, including construction, marine, and consumer goods.

Duralumin and 6061 aluminum are prominent aluminum alloys with distinct characteristics tailored for specific industrial applications. This summary provides a detailed analysis of their composition, mechanical properties, corrosion resistance, and typical uses, helping professionals choose the right material.

Duralumin is primarily composed of aluminum, copper, magnesium, and manganese. The copper content, typically around 4%, significantly enhances its mechanical strength but adversely affects its corrosion resistance. The magnesium and manganese components contribute to the alloy’s hardness, durability, and ability to undergo precipitation hardening, which further boosts its overall strength.

6061 aluminum is made of aluminum, magnesium, and silicon, with about 1% magnesium and 0.6% silicon. This mix provides a balance of strength, corrosion resistance, and weldability, making it versatile for many applications.

Tensile strength, which indicates the stress at which a material begins to deform plastically, is also higher in duralumin, making it ideal for applications requiring maximum strength and minimal deformation. In contrast, 6061 aluminum provides a good balance of tensile strength and ease of processing.

Yield strength, which indicates the stress at which a material begins to deform plastically, is also higher in duralumin. This makes duralumin ideal for applications requiring maximum strength and minimal deformation.

The density of duralumin ranges from 2.8 to 2.9 g/cm³, slightly higher than 6061 aluminum’s 2.7 g/cm³. This slight density difference is a trade-off for duralumin’s greater strength.

Duralumin’s higher copper content makes it more prone to corrosion, often requiring protective coatings or treatments to improve its durability in corrosive environments.

6061 aluminum offers excellent corrosion resistance, largely due to its lower copper content and the formation of a protective oxide layer. This makes it ideal for applications in marine and outdoor environments.

Duralumin is historically significant in aerospace applications due to its high strength-to-weight ratio, making it suitable for aircraft structural components. 6061 aluminum, while versatile, is less commonly used in aerospace due to its lower strength compared to duralumin.

Both alloys are used in automotive applications, but 6061 aluminum is preferred for components requiring good corrosion resistance, such as frames and wheels. Duralumin is utilized for high-performance parts where strength is critical.

6061 aluminum is favored in consumer electronics for its machinability and corrosion resistance, used in products like mobile phones and laptops. Duralumin’s use in this industry is limited due to its poorer corrosion resistance.

The production of duralumin is generally more expensive due to its complex manufacturing process involving copper and other alloying elements. The higher cost is justified in applications where superior strength is essential.

6061 aluminum is more cost-effective, offering a reasonable price range and easier production processes. Its affordability and versatility make it a popular choice across various industries.

Below are answers to some frequently asked questions:

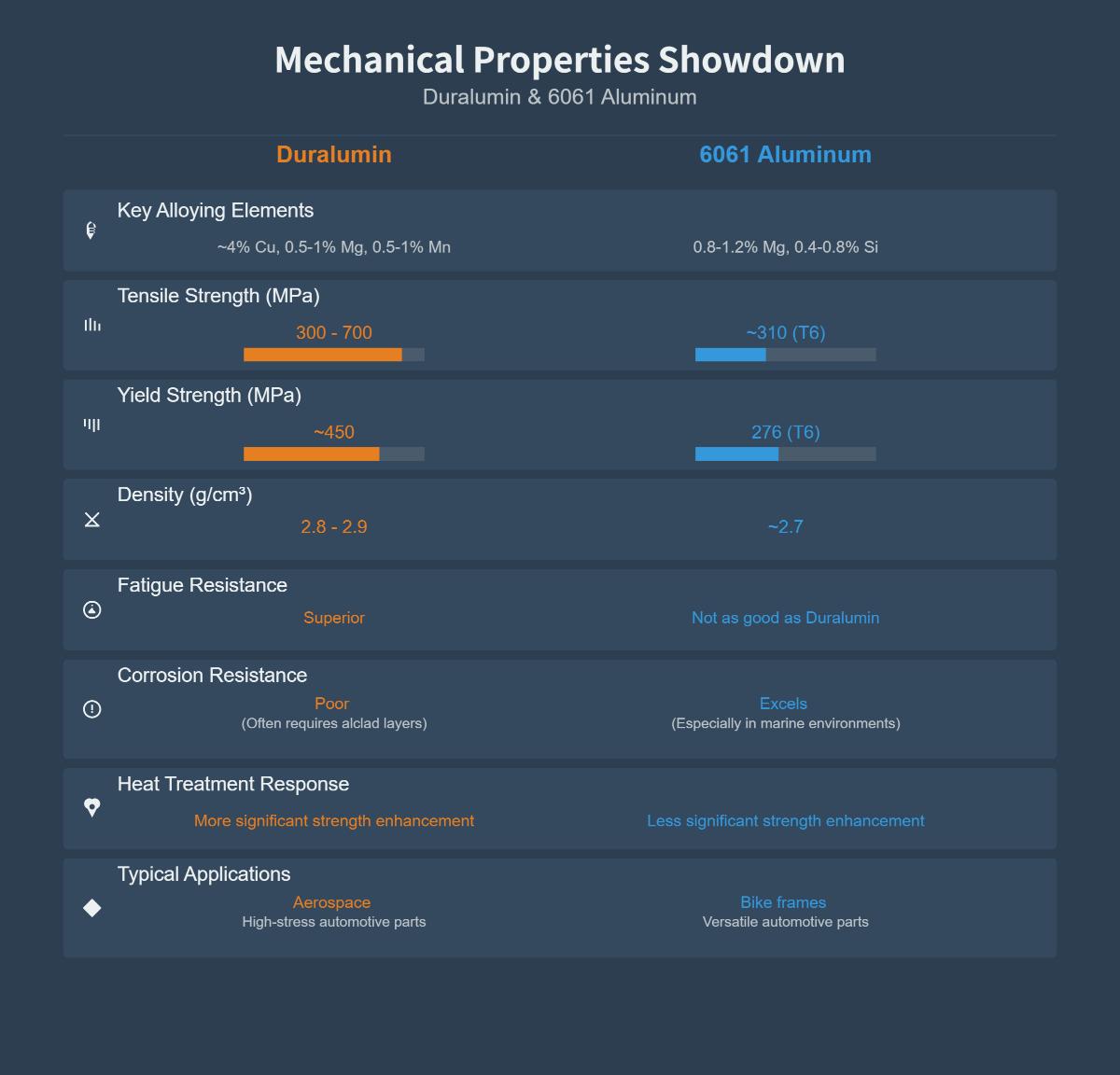

Duralumin and 6061 aluminum are both aluminum alloys with distinct mechanical properties suited to different applications. Duralumin, comprising approximately 4% copper, 0.5-1% magnesium, and 0.5-1% manganese, boasts a tensile strength ranging from 300 to 700 MPa and a yield strength around 450 MPa, making it stronger than pure aluminum and comparable to some mild steels. Its density is slightly higher, at 2.8 to 2.9 g/cm³, due to the added elements. Duralumin also has superior fatigue resistance, making it ideal for high-stress applications such as aerospace and automotive industries. However, its corrosion resistance is poor due to its copper content, often requiring protective “alclad” layers.

In contrast, 6061 aluminum, containing 0.80-1.20% magnesium and 0.40-0.80% silicon, has an ultimate tensile strength of about 310 MPa and a yield strength of 276 MPa in the T6 temper. Its density is lower at approximately 2.7 g/cm³, contributing to a better strength-to-weight ratio. While not as fatigue-resistant as duralumin, 6061 aluminum excels in corrosion resistance, particularly in marine environments, and is versatile in applications such as bike frames and automotive parts. Both alloys can be heat treated, but duralumin shows more significant strength enhancement.

When determining the suitability of materials for high-stress applications, duralumin and 6061 aluminum each offer distinct advantages. Duralumin is typically favored for its higher tensile strength, which can range from 300 to 700 MPa depending on its specific composition and heat treatment processes. This makes it particularly suitable for applications that demand high strength, such as aerospace components and high-performance sporting equipment.

In contrast, 6061 aluminum, while generally not as strong as duralumin, provides a tensile strength of approximately 310 MPa in the T6 temper. It offers better natural corrosion resistance due to its lower copper content, which is advantageous in environments where exposure to corrosive elements is a concern. Additionally, 6061 aluminum is more ductile and easier to machine, making it a versatile choice for many structural applications.

When comparing duralumin and 6061 aluminum in terms of corrosion resistance, 6061 aluminum is generally superior. This is primarily due to the different alloying elements present in each material. Duralumin contains a higher percentage of copper, which enhances its strength but makes it more susceptible to galvanic corrosion, especially in moist environments. On the other hand, 6061 aluminum, which primarily includes magnesium and silicon, forms a stable oxide layer that serves as a protective barrier against corrosion. This makes 6061 aluminum more suitable for applications exposed to corrosive elements, such as marine and outdoor environments. While both alloys can have their corrosion resistance improved through treatments like anodizing for 6061 aluminum and protective coatings for duralumin, 6061 aluminum inherently offers better natural corrosion resistance.

Duralumin and 6061 aluminum are utilized across various industries due to their distinct properties. Duralumin, known for its high strength-to-weight ratio, is primarily used in the aerospace industry for aircraft frames and components, and in the automotive industry for car bodies and engine parts. It is also applied in marine environments with protective coatings, and in sporting goods like bicycles and climbing equipment. Additionally, it finds use in electronics and construction for its structural strength.

6061 aluminum, with its excellent corrosion resistance and weldability, is widely employed in the aerospace industry for airplane wings and fuselage sections, and in the automotive industry for wheels and engine blocks. Its corrosion-resistant properties make it ideal for marine applications such as boat hulls and decks. The construction industry uses 6061 aluminum for building frameworks and bridges, while it is also favored in sporting goods like bike frames.

The manufacturing processes of duralumin and 6061 aluminum differ primarily in their composition, heat treatment, and machinability. Duralumin, which includes higher amounts of copper, magnesium, and manganese, undergoes a more complex heat treatment involving solution annealing, quenching, and aging to achieve its desired mechanical properties. This process enhances its strength but requires protective coatings due to poor corrosion resistance. Machining duralumin is challenging because of its hardness and brittleness.

In contrast, 6061 aluminum consists mainly of aluminum, magnesium, and silicon, making it easier to produce and machine. Its heat treatment process, achieving the T6 temper, involves solution heat treatment followed by artificial aging, enhancing its strength while maintaining good ductility and corrosion resistance. 6061 aluminum’s simpler composition and better machinability make it suitable for a wide range of applications, from aerospace to consumer electronics.

When comparing the sustainability aspects of duralumin and 6061 aluminum, several factors should be considered, including environmental impact, recyclability, energy efficiency, and lifecycle considerations.

Duralumin, known for its high strength and lightweight properties, contains a higher copper content, which can increase its environmental impact due to more intensive extraction processes and potential corrosion issues. Despite this, it remains a popular choice in high-performance applications. On the other hand, 6061 aluminum, with its excellent corrosion resistance and lower copper content, is generally more environmentally friendly. It naturally forms a protective oxide layer, enhancing durability without the need for additional coatings.

In terms of recyclability, both alloys are recyclable, but 6061 aluminum has a slight edge due to its simpler composition, which facilitates more efficient recycling processes. This alloy also requires significantly less energy to recycle compared to producing new aluminum, making it a more sustainable option.

Energy efficiency during use is comparable for both materials, though 6061 aluminum’s good thermal conductivity, particularly in the T6 temper, makes it suitable for applications requiring efficient heat dissipation, contributing to energy efficiency in electronic devices and automotive applications.

Considering lifecycle impact, 6061 aluminum’s versatility, weldability, and corrosion resistance lead to longer product lifetimes and reduced need for replacements, enhancing its sustainability. Duralumin’s higher strength and durability also offer extended product lifetimes, but its higher production cost and complex process can offset some sustainability benefits.

Overall, 6061 aluminum generally offers better sustainability due to its excellent recyclability, lower environmental impact, and wide applicability, making it a preferred choice for many manufacturers. However, the specific application requirements, including strength and cost considerations, ultimately determine the best material selection.