Nickel plating on brass can offer a sleek, shiny finish, but when it starts to chip or wear, it can detract from the underlying beauty of the brass. If you’re grappling with the challenge of restoring your brass items to their original glory, you’ve come to the right place. Whether you’re aiming for precision in a DIY project or seeking professional-grade results, understanding the most effective methods for removing nickel plating is crucial. This article will guide you through a comprehensive step-by-step process, exploring both chemical and mechanical techniques. We’ll delve into safety measures to prevent damage to the brass and ensure your workspace remains hazard-free. Are you ready to uncover the secrets to flawless brass restoration? Let’s dive in and explore the tools, techniques, and tips that will make nickel plating removal a breeze.

Nickel plating is widely used in metalworking to enhance metal objects’ durability and appearance. This electroplating process involves applying a thin nickel layer to a metal substrate, such as brass, to provide benefits like improved corrosion resistance, increased hardness, and a shiny, smooth finish.

While nickel plating offers several advantages, there are times when it needs to be removed due to wear, discoloration, or damage. Removal may also be necessary for:

The process of removing nickel plating requires careful handling to avoid damaging the underlying metal, particularly with delicate substrates like brass. Several methods can be employed, each with unique benefits and limitations.

Key factors to consider include:

Understanding these factors helps in effectively planning and executing the removal of nickel plating, allowing for the restoration of the metal’s original appearance or preparation for future treatments.

To remove nickel plating from brass, you can use chemical methods that involve acids or alkaline solutions.

Definition and Properties: Muriatic acid, a diluted form of hydrochloric acid, is a strong and highly corrosive acid commonly used in metal cleaning and etching.

Procedure:

Precautions:

Explanation: Alkaline solutions, such as sodium hydroxide (lye), can effectively strip nickel plating without the extreme corrosiveness of strong acids.

Procedure:

Precautions:

Types and Application:

Precautions:

Mechanical methods can also be used to remove nickel plating from brass, combining techniques such as buffing, polishing, and sandblasting.

Buffing and Polishing:

Sandblasting Techniques:

Preservation Tips for Brass:

Muriatic acid, a form of hydrochloric acid, is commonly used to effectively remove nickel plating from brass due to its strong dissolving properties.

Alkaline solutions like sodium hydroxide offer a gentler alternative to acids for removing nickel plating, minimizing the risk of damage to brass.

Nickel strippers are specially formulated chemicals designed to remove nickel plating without harming the brass substrate. They often contain inhibitors that protect brass during the stripping process.

Chemical methods for nickel removal are diverse, offering solutions tailored to different needs and substrates. Each method requires careful consideration of safety protocols and disposal practices to ensure effective and responsible use.

Buffing and polishing are effective ways to mechanically remove nickel plating from brass without chemicals. These techniques utilize abrasive tools to strip away the nickel layer, revealing the brass underneath.

Sandblasting uses high-pressure abrasive particles to strip the nickel plating from brass items. This method is efficient and precise, safeguarding the brass surface.

Grinding and sanding are suitable for removing nickel plating from brass, particularly for thicker coatings. These techniques use abrasive tools to effectively strip the nickel layer.

Safety considerations are crucial when using mechanical methods to remove nickel plating. Always wear protective gear and handle tools with precision to preserve the integrity of the brass substrate.

Effectiveness and efficiency are crucial when comparing chemical and mechanical methods for removing nickel plating from brass. Each approach has distinct advantages and challenges, making the choice dependent on the specific needs of the task.

Chemical methods are highly effective in dissolving nickel plating and can penetrate thick or uneven layers. These methods are advantageous for intricate parts, ensuring uniform removal even on complex geometries. However, they require careful control of concentration, time, and temperature to avoid damaging the brass substrate. Handling hazardous chemicals necessitates strict safety measures, including the use of personal protective equipment, adequate ventilation, and proper disposal of chemical waste.

Mechanical methods, such as buffing, polishing, and sandblasting, use physical abrasion to strip away nickel plating. These methods are safer in terms of chemical exposure and provide immediate visual feedback, allowing for more controlled removal. However, they are time-consuming and labor-intensive, potentially resulting in surface scratches or deformation, especially on delicate brass items. Mechanical methods mainly require spending on equipment and abrasives. Though the initial investment in tools can be high, ongoing costs are typically lower than chemical methods.

Chemical methods use hazardous substances that need strict safety measures, including protective gear and proper ventilation. Mechanical methods, while posing fewer chemical hazards, still require precautions against physical injury and dust inhalation. Both methods have their environmental impacts, with chemical methods producing hazardous waste and mechanical methods generating dust and debris.

Choosing the right method depends on the brass item’s specifics and the application. Chemical methods are ideal for precision parts with intricate details, where uniform removal is critical. Mechanical methods are more suitable for robust items with thick nickel plating, where surface finish is less of a concern and environmental considerations are a priority.

Handling chemicals safely is crucial when removing nickel plating from brass. Always work in a well-ventilated area to avoid inhaling harmful fumes, using a fume hood or working outdoors when possible. Store chemicals in clearly labeled, secure containers away from heat sources and out of reach of children and pets.

To ensure safety during the removal process, equip yourself with appropriate personal protective gear:

Ensure your workspace is well-ventilated to disperse any harmful fumes. Enhance airflow by using fans or opening windows, and organize your work area with all necessary tools and materials within reach to minimize movement and reduce the risk of accidental spills.

Be prepared for accidents by having a first-aid kit readily available. Familiarize yourself with these emergency procedures for chemical exposure:

When using mechanical methods like buffing, polishing, or sandblasting to remove nickel plating, follow safety protocols to prevent injury.

Inspect all equipment beforehand to confirm it’s in good working condition. Check for loose parts, worn-out components, and ensure all safety guards are in place.

Dispose of chemicals and waste responsibly by following local regulations to minimize environmental impact. Use designated disposal sites for hazardous waste and avoid pouring chemicals down the drain. Always adhere to local and national regulations regarding chemical use and disposal to ensure an environmentally responsible process.

Below are answers to some frequently asked questions:

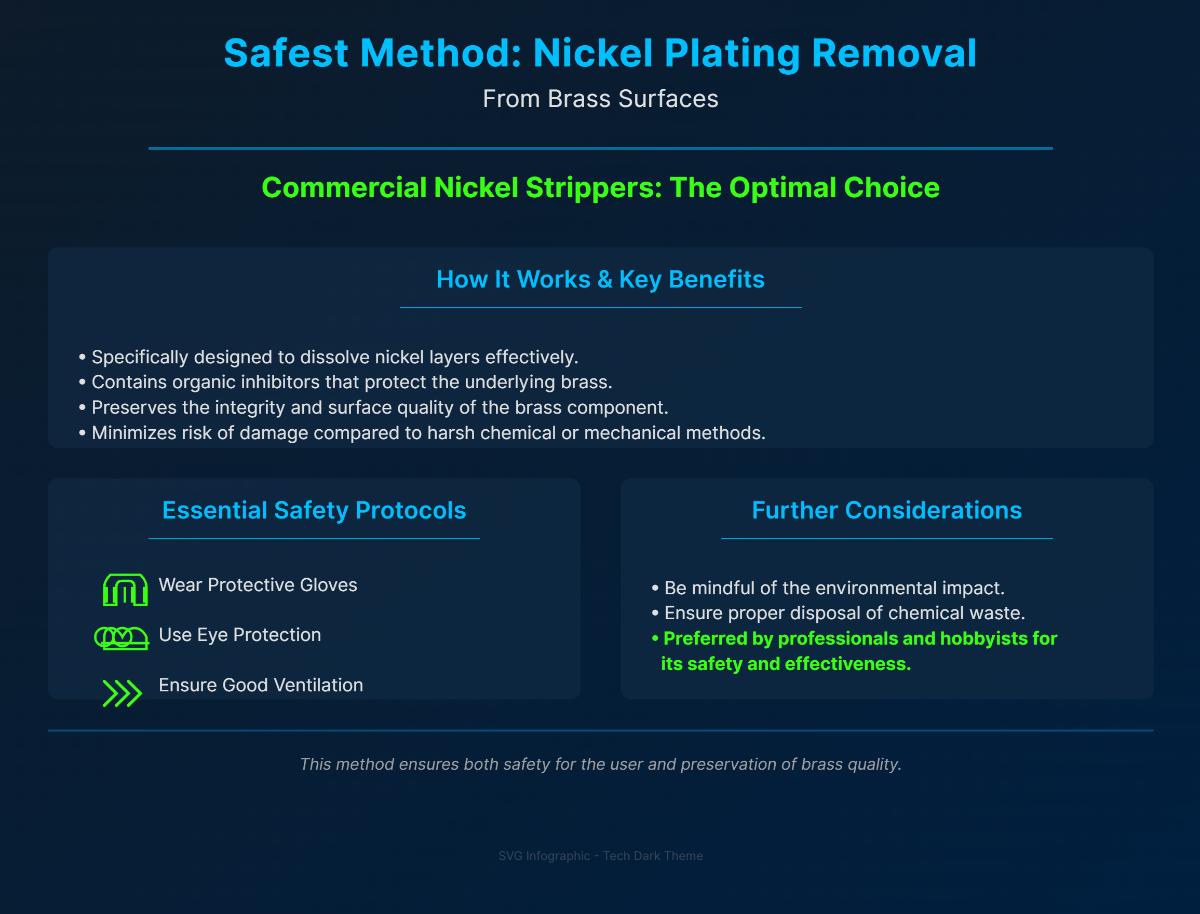

The safest method to remove nickel plating from brass is using commercial nickel strippers. These products are specifically designed to dissolve nickel without harming the underlying brass. They often contain organic inhibitors that protect the brass during the removal process, ensuring the integrity of the brass is maintained. This method is particularly effective as it minimizes the risk of damage compared to harsher chemical or mechanical methods.

While using commercial nickel strippers, it’s crucial to follow safety precautions: wear protective gloves, eye protection, and ensure good ventilation in the workspace. Additionally, consider the environmental impact and ensure proper disposal of any chemical waste. This approach is not only safe but also effective, making it the preferred choice for both professionals and hobbyists looking to preserve the quality of brass components.

To safely remove nickel plating from brass without damaging the underlying material, it is essential to choose a method that balances effectiveness with gentleness. One of the safest chemical methods is using proprietary nickel strippers, which are specifically formulated to dissolve nickel plating without harming the brass. These products are reliable and user-friendly, making them a preferred choice for many.

Alternatively, an alkaline solution can be used for a gentler approach. This method involves submerging the brass item in a solution that gradually removes the nickel plating. Both methods require careful handling and appropriate safety measures, including wearing gloves, eye protection, and ensuring proper ventilation.

Mechanical methods like polishing and buffing can also be effective. These techniques involve using abrasive compounds to wear away the nickel layer gradually. While time-consuming, they offer precise control and minimize the risk of damaging the brass.

Regardless of the method chosen, always prioritize safety by using appropriate protective gear and ensuring a well-ventilated workspace. This approach will help ensure the nickel plating is removed effectively without compromising the integrity of the brass.

To effectively remove nickel plating from brass, a variety of tools and products can be employed depending on the specific requirements of the task and the condition of the brass substrate. Chemical methods are often preferred for their ability to handle complex shapes without mechanical damage. Recommended chemical products include the Caswell MetalX Nickel Stripper Kit, which offers a comprehensive solution with specialized nickel stripper powder for efficient removal. Ready-to-use liquid nickel stripping solutions are also advantageous due to their convenience and rapid action. For those seeking a more controlled approach, electrolytic stripping methods, which require a DC power source and cathodes, provide precision and environmental benefits. Mechanical methods such as sanding or sandblasting can be used for thicker or heavily damaged plating but require caution to avoid damaging the brass. Regardless of the method chosen, ensure proper safety measures are in place, including the use of personal protective equipment and adequate ventilation.

When comparing chemical methods to mechanical ones in terms of cost for removing nickel plating from brass, several key factors should be considered.

Chemical methods generally involve using acids or alkaline solutions to dissolve the nickel plating. These methods can be precise and efficient but often require specialized chemicals, safety equipment, and proper handling procedures, which can increase overall costs. The need for personal protective equipment (PPE), adequate ventilation, and waste disposal adds to the expense.

On the other hand, mechanical methods such as buffing, polishing, or sandblasting involve physically removing the plating. These methods typically use existing tools and equipment, making them more cost-effective upfront. However, they can be labor-intensive and time-consuming, potentially increasing labor costs. Mechanical methods also carry a risk of damaging the underlying brass if not done carefully, which could incur additional costs for repairs.

Chemical removal methods for nickel plating from brass have several environmental impacts that require careful consideration. These methods typically involve the use of acids, alkaline solutions, or specialized strippers, which generate hazardous waste containing nickel ions and other toxic compounds. Improper disposal can lead to significant environmental issues such as water pollution, where heavy metals contaminate aquatic ecosystems, and soil contamination, affecting land quality and biodiversity. Additionally, the release of volatile organic compounds (VOCs) during these processes can contribute to air pollution.

To mitigate these impacts, adopting eco-friendly chemicals and implementing advanced waste treatment techniques are crucial. Techniques such as chemical precipitation and ion exchange can effectively detoxify waste, allowing for metal recovery and reducing hazardous discharges. Safe disposal practices and process optimization further minimize environmental risks, ensuring sustainable metal finishing operations.

To ensure the safety of your workspace while removing nickel plating from brass, prioritize personal protective equipment (PPE) and proper ventilation. Use chemical-resistant gloves, safety goggles, face masks, and protective clothing to shield against chemical exposure. Establish a well-ventilated area equipped with fume hoods or extraction systems to manage airborne contaminants. Handle chemicals with care by following safety data sheets, using labeled, leak-proof containers, and adhering to local disposal regulations for hazardous waste. Opt for proprietary chemical strippers that are effective yet gentle on brass, as discussed earlier. Implement environmental safeguards such as waste containment and treatment. Ensure all personnel are trained in safety protocols and have access to emergency kits for potential spills or exposure incidents. By following these guidelines, you can maintain a safe and efficient workspace during nickel plating removal.