Have you ever wondered how metal parts are joined together in the construction of cars, bridges, or even household appliances? Welding is the key, and it’s crucial in many industries. There are two main types: fusion and non – fusion welding. Fusion welding melts the base metals to join them, like in MIG and TIG methods, while non – fusion welding uses filler materials without melting the base metals, such as brazing and soldering. But which is stronger? And where are they best applied? Dive in to find out more about these welding techniques.

Welding is crucial in multiple industries such as construction, manufacturing, and automotive. It involves joining two or more parts together using heat, pressure, or a combination of both. The ability to create strong, durable joints makes welding essential for building structures, fabricating machinery, and assembling vehicles.

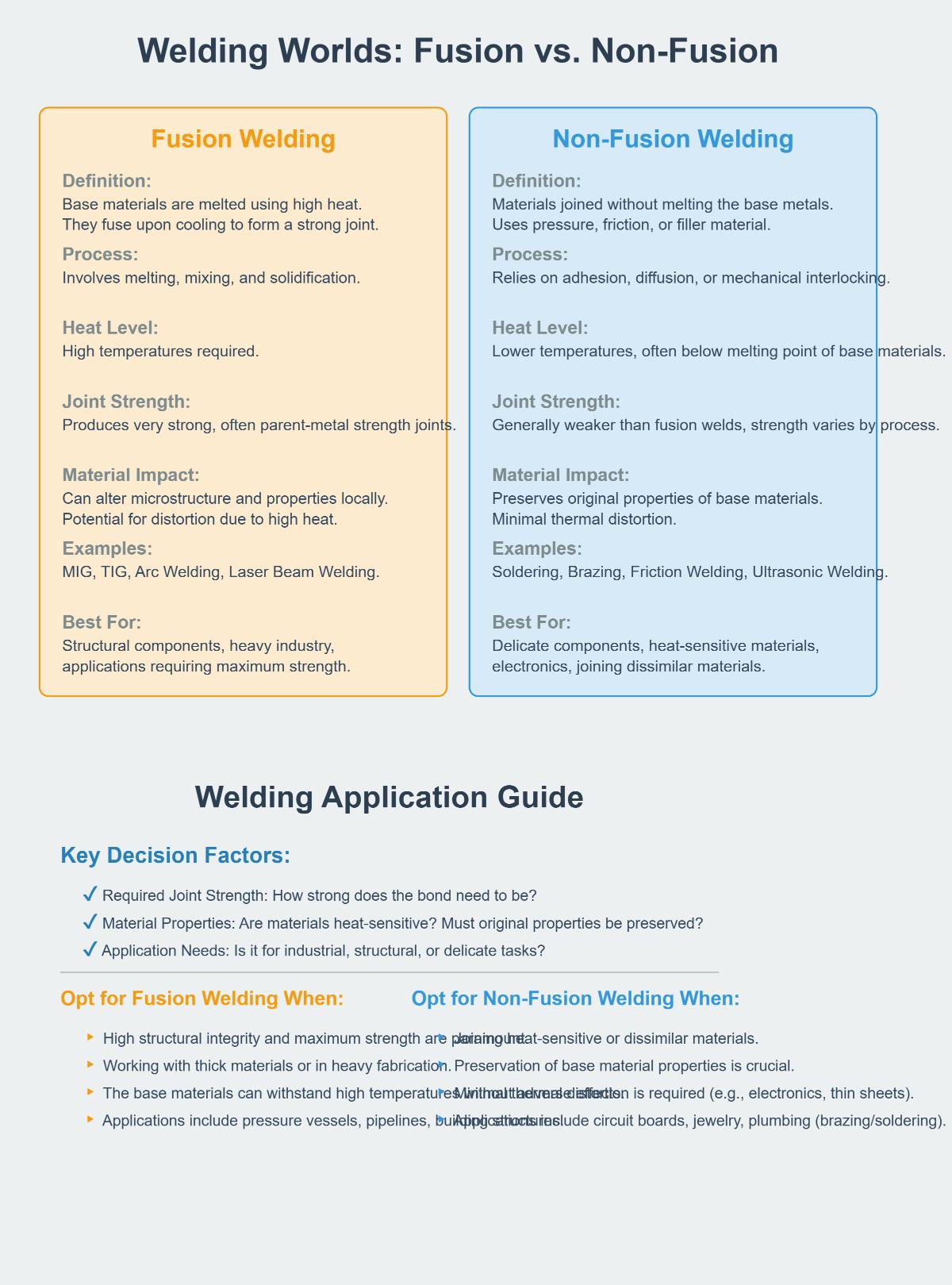

Welding techniques can be broadly categorized into two main types: fusion welding and non-fusion welding. Understanding these methods is crucial for selecting the appropriate technique based on the material and application requirements.

Fusion welding involves melting the base materials to create a bond. This method requires high temperatures and often includes a filler material to strengthen the joint. Common fusion welding techniques include:

Fusion welding is advantageous for creating strong joints and joining dissimilar metals. However, it can cause significant thermal distortion and alter the material’s properties due to the heat-affected zone (HAZ).

Non-fusion welding, also known as solid-state welding, joins materials without melting them, relying on pressure, friction, or other mechanisms to bond the surfaces. Common non-fusion welding techniques include:

Non-fusion welding is preferred for applications requiring minimal heat-induced changes, such as welding thin materials or high-strength alloys. It helps preserve the original properties of the materials and reduces thermal distortion.

Understanding the differences between fusion and non-fusion welding is essential for selecting the appropriate method:

| Characteristic | Fusion Welding | Non-Fusion Welding |

|---|---|---|

| Heat Requirement | High temperatures to melt materials | Lower heat or no heat, relies on pressure/friction |

| Filler Material | Usually uses filler materials | Rarely uses filler materials |

| Heat-Affected Zone (HAZ) | Significant HAZ, altering material properties | Minimal or negligible HAZ, preserves material properties |

| Applications | Suitable for strong joints and dissimilar metals | Ideal for preserving material properties and low distortion |

By understanding these fundamental welding techniques, industry professionals can make informed decisions that ensure the integrity and performance of their welded structures and components.

Fusion welding is a method that joins materials by melting their edges together. This process creates a seamless bond as the molten materials cool and solidify, producing strong and durable joints.

Fusion welding is employed in various sectors, including:

Common materials used in fusion welding are:

Non-fusion welding, also called solid-state welding, joins materials without melting them. Instead of using high heat to melt the base materials like fusion welding, it uses pressure, friction, or other methods to bond the materials. This leads to a very small or almost non-existent heat-affected zone, keeping the original properties of the materials intact.

Friction welding creates heat through rotational friction. Two parts are pressed together while one rotates, and the friction heats the materials enough to form a bond. In the aerospace industry, it’s used to join the shafts of jet engines to turbine blades. This allows for the connection of different materials that have different properties, which is crucial for the high-performance requirements of jet engines.

Diffusion welding applies pressure and heat to materials, causing atoms to spread across the interface and create a bond. In the semiconductor manufacturing industry, it’s used to join silicon wafers. This method can achieve high joint strength and is suitable for materials with high melting points, which is essential for the precision and durability needed in semiconductor components.

Explosion welding uses the energy from an explosion to force two materials together at high speed, creating a metallurgical bond. In the production of large heat exchangers, it’s used to join different metal plates. This method can quickly and effectively bond large sheets or plates of different metals, ensuring efficient heat transfer in the heat exchanger.

In industries where precision and material integrity are paramount, non-fusion welding shines. It’s well-suited for delicate tasks, joining thin metal sheets, and working with dissimilar or high-strength alloys. Commonly used in electronics, medical device manufacturing, and the production of high-precision components, it ensures that the base material’s properties remain largely unchanged.

Common materials used in non-fusion welding include aluminum, copper, and high-strength alloys. These materials can be joined without significant alterations to their mechanical or physical properties, making non-fusion welding a top choice for many applications.

Solid state welding is a method that joins materials without melting them. Instead of relying on high temperatures to melt the base materials, this technique uses pressure, friction, or other mechanisms to create a bond. This minimizes or eliminates the heat-affected zone (HAZ), preserving the materials’ original properties.

Diffusion welding involves applying heat and pressure to materials, causing atoms to diffuse across the interface and form a bond, making it particularly useful for high melting point materials in the aerospace and semiconductor industries.

Friction welding generates heat through mechanical friction between two surfaces. The materials are pressed together and rotated to generate heat, which bonds them. This method is effective for joining dissimilar materials and is commonly used in automotive and aerospace applications.

Ultrasonic welding uses high-frequency vibrations to create a bond between materials. This technique is popular in the electronics and medical device industries due to its precision and ability to join small parts without excessive heat.

| Characteristics | Fusion Welding | Non-Fusion Welding | Solid State Welding |

|---|---|---|---|

| Melting Process | Melts base materials | No melting, uses filler metal | No melting, uses pressure or friction |

| Heat Application | High heat required | Moderate heat, uses filler | Low or no heat, uses pressure |

| HAZ | Significant | Moderate | Minimal |

| Filler Material | Often used | Required | Rarely used |

| Distortion | High distortion | Moderate distortion | Minimal distortion |

| Applications | Suitable for similar and dissimilar metals | Suitable for joining similar materials with filler | Ideal for heat-sensitive materials and precision applications |

Fusion welding typically produces strong joints because the materials are melted and fused together, forming a homogeneous bond. Non-fusion welding, which includes techniques like brazing and soldering, generally results in joints that may not be as strong as those created by fusion welding, especially in high-stress applications. Solid state welding, despite not involving melting, can produce strong joints because of the high pressures and friction applied, making it suitable for many industrial applications.

Fusion welding processes, such as MIG and TIG welding, can be highly efficient but often require significant energy input due to the high temperatures involved. Non-fusion welding methods, like brazing and soldering, are generally more energy-efficient but may not be as suitable for large-scale industrial applications. Solid state welding processes are often more sustainable as they require less energy and produce minimal waste. They also preserve the material properties, reducing the need for additional processing.

When choosing a welding method, consider the following factors:

By understanding these factors, you can make an informed decision on the most appropriate welding method for your specific application.

Fusion welding is extensively used in various industries because it creates strong, durable joints. Below are some of its main applications:

In construction, fusion welding is vital for buildings, bridges, and infrastructure. Techniques like GMAW and SMAW weld structural steel components, ensuring stability and strength.

In the automotive sector, fusion welding is used for car bodies, exhaust systems, and chassis. GTAW is favored for its precision, crucial for welding thin sections and ensuring high-quality welds.

In aerospace, high-strength, reliable joints are essential, making fusion welding ideal for aircraft structures and components. Techniques like GTAW are used to weld lightweight materials like aluminum and titanium.

Shipbuilding requires welding large sections of metal to form the hull and other structural parts of ships. Fusion welding techniques such as SMAW and GMAW ensure the joints are strong enough to withstand the harsh marine environment.

In electronics manufacturing, precision is vital. Non-fusion welding techniques like ultrasonic welding join delicate components without applying excessive heat, which could damage sensitive electronic parts.

Medical devices often require joining small, intricate parts made of heat-sensitive materials. Non-fusion welding methods such as cold welding create strong joints without altering the material properties, ensuring the functionality and reliability of the devices.

Non-fusion welding is also used in aerospace for joining dissimilar materials and components that cannot tolerate high temperatures. Friction welding is particularly useful for joining materials with different properties, such as turbine blades to shafts in jet engines.

Choosing the right welding method depends on factors like the materials being joined, the required joint strength, and the application. Consider the following:

The choice of materials for welding plays a crucial role in the overall success and integrity of the welded structure. Factors such as the material’s thermal conductivity, melting point, and compatibility with the welding process must be carefully evaluated.

Below are answers to some frequently asked questions:

Fusion welding and non-fusion welding are two primary categories of welding, each with distinct processes and applications. Fusion welding involves the application of high heat to melt the base materials being joined. As the melted materials cool and solidify, they form a strong joint. Common techniques include MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and Arc welding. Fusion welding is known for producing strong joints suitable for various materials, but it requires specialized skills and equipment.

In contrast, non-fusion welding joins materials without melting them. Instead, it uses methods such as pressure, friction, or adhesive properties to bond materials. Techniques include soldering and brazing, which involve lower temperatures and are ideal for delicate tasks and heat-sensitive materials. Non-fusion welding generally results in weaker joints compared to fusion welding but preserves the original properties of the base materials and causes minimal distortion.

The choice between fusion and non-fusion welding depends on factors such as the strength required, the materials used, and the specific application needs. Fusion welding is preferred for high-strength and industrial applications, while non-fusion welding is suitable for tasks requiring the preservation of material properties.

Fusion welding is generally stronger than non-fusion welding. This is because fusion welding involves melting the base materials to form a strong joint, often enhanced with filler materials. The resulting joints can be as strong as or even stronger than the parent materials, making fusion welding suitable for high-strength applications like shipbuilding and aerospace.

In contrast, non-fusion welding methods, such as brazing and soldering, bond materials without melting them. While these techniques are useful for maintaining the original properties of the base materials and are ideal for delicate tasks, they typically do not achieve the same level of strength as fusion welding. Therefore, for applications requiring the strongest possible joints, fusion welding is the preferred method.

Fusion welding is widely used in industrial manufacturing due to its ability to create strong, durable joints. Common applications include the construction of buildings and bridges, automotive manufacturing for body and frame assembly, aerospace for structural components, and shipbuilding. Fusion welding is also employed in the production of pipelines, pressure vessels, and other complex machinery, where high-strength joints are critical. Additionally, it finds use in artistic and decorative metalwork, where techniques like TIG welding offer precision and aesthetic quality.

Non-fusion welding, on the other hand, is often used for joining delicate or heat-sensitive materials where the integrity of the material properties must be preserved. This includes applications in the aerospace industry for maintaining the properties of high-strength alloys, electronics for the precise assembly of components, and medical devices where minimal material alteration is crucial. Techniques such as brazing and soldering are commonly used for these purposes due to their lower thermal input and ease of use. Non-fusion welding is also employed in the assembly of small mechanical parts and various types of metalwork that require a more controlled heat application.

Solid-state welding, fusion welding, and non-fusion welding each have unique characteristics and applications.

Fusion welding involves melting the base materials and sometimes adding filler material to create a strong joint. This method requires high temperatures above the materials’ melting points, which can lead to thermal distortion and changes in material properties due to the heat-affected zone. It’s commonly used in construction and manufacturing for high-strength joints.

In contrast, solid-state welding joins materials without melting them, using pressure and moderate heat below the melting point. This method preserves the original properties of the materials, minimizes thermal distortion, and is suitable for heat-sensitive and precise applications. It is less energy-intensive and often easier to learn and requires simpler equipment.

Non-fusion welding, often synonymous with solid-state welding, shares these characteristics, making it ideal for joining dissimilar metals, thin metal sheets, and high-strength alloys without compromising their integrity.

Understanding these differences is crucial for selecting the right welding technique based on the specific requirements of your project.

When choosing a welding method, several key factors should be considered to ensure the best results for your project.

First, consider the material type. Fusion welding is versatile and can handle metals, plastics, and ceramics, while non-fusion welding is ideal for heat-sensitive materials. Next, assess the material thickness. Thicker materials often require fusion welding methods, whereas thinner materials might benefit from non-fusion techniques to avoid thermal distortion.

Project requirements are also crucial, such as joint design, welding position, desired speed, and quality. For example, Gas Metal Arc Welding (GMAW) suits high-speed production, while Gas Tungsten Arc Welding (GTAW) offers precise control for high-quality welds.

Additionally, consider the skill level and experience required. Fusion welding typically needs more skill and specialized tools compared to non-fusion welding, which can be easier to learn and execute.

Lastly, take into account safety and environmental conditions, ensuring the chosen method complies with safety regulations and adapts to conditions like moisture or confined spaces.

By evaluating these factors, you can select the most suitable welding method for your project, balancing strength, efficiency, and safety.

When choosing materials for welding, the suitability largely depends on whether you are using fusion or non-fusion welding methods.

For fusion welding, materials like steel and stainless steel are ideal due to their strength and corrosion resistance. Techniques such as MIG and TIG welding are commonly used for these metals. Aluminum is also suitable for fusion welding, particularly with TIG and MIG methods, despite its high thermal conductivity, which makes it challenging. Copper and nickel alloys, known for excellent thermal and electrical conductivity, can also be effectively welded using fusion techniques, though they require careful handling to prevent oxidation.

Non-fusion welding is suitable for materials that are heat-sensitive or require minimal thermal distortion. Magnesium and aluminum alloys can be effectively joined using non-fusion methods like friction stir welding, which preserves the material’s properties. High-strength alloys are also suitable for non-fusion techniques, especially when joining dissimilar metals or materials that cannot withstand high temperatures.

Overall, the choice of material is influenced by the specific welding technique, the desired properties of the final product, and the application’s thermal, mechanical, and corrosion resistance requirements.