When it comes to selecting the ideal material for your project, the choice often boils down to Grade 5 Titanium and Stainless Steel. But what sets these two metals apart? Both are renowned for their exceptional properties, yet they cater to different needs and applications. Whether you’re concerned with strength, weight, corrosion resistance, or cost, understanding the nuances between Grade 5 Titanium and Stainless Steel can significantly impact your decision-making process. In this article, we’ll delve into the physical properties, corrosion resistance, durability, and cost-effectiveness of each material. Ready to discover which one is the perfect fit for your project? Let’s dive in and explore the key differences that could make all the difference.

Grade 5 Titanium, also known as Ti-6Al-4V, is an alloy that includes 6% aluminum and 4% vanadium, enhancing its strength and heat resistance. Stainless steel is an alloy of iron with at least 10.5% chromium, often containing elements like nickel, molybdenum, and manganese to improve its corrosion resistance, formability, and strength. Different grades of stainless steel have varying compositions to suit different applications.

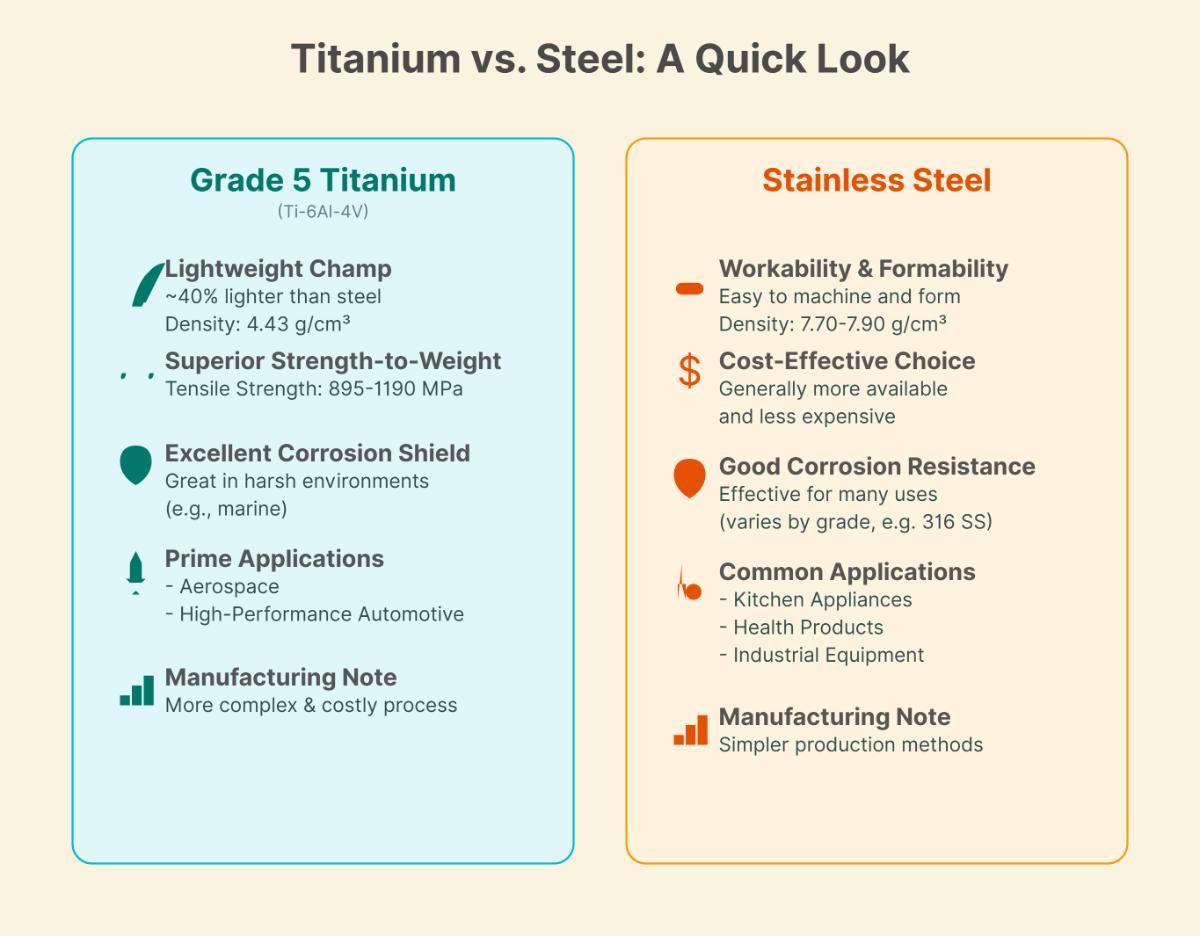

Grade 5 Titanium has a density of around 4.43 g/cm³, making it significantly lighter than stainless steel, which ranges from 7.75 to 8.1 g/cm³. This lower density is advantageous in applications where weight reduction is crucial.

Grade 5 Titanium boasts a tensile strength of 895 to 1190 MPa, offering an excellent strength-to-weight ratio. In comparison, stainless steel grades like AISI 304 have tensile strengths between 580 to 1180 MPa.

Grade 5 Titanium can withstand significant loads without permanent deformation due to its high yield strength. Stainless steel’s yield strength varies by grade, with austenitic types like 304 being generally lower but still strong enough for many applications.

Grade 5 Titanium has an elastic modulus of approximately 114 GPa, indicating its stiffness and how much it will deform under stress. Stainless steel, with an elastic modulus of around 190-210 GPa, is stiffer than Grade 5 Titanium. This makes stainless steel more suitable for applications requiring high stiffness.

Grade 5 Titanium’s low thermal conductivity of about 6.7 W/m·K can challenge machining but is useful for thermal insulation. In contrast, stainless steel’s higher conductivity of 15 to 25 W/m·K makes it better for heat-exchange applications.

Grade 5 Titanium (Ti-6Al-4V) is renowned for its exceptional oxidation resistance. This material forms a protective titanium oxide (TiO2) layer upon exposure to oxygen, which prevents further oxidation. This oxide layer is stable and self-healing, meaning it can regenerate if damaged, maintaining its protective properties. This characteristic is particularly beneficial in environments where the material is exposed to fluctuating temperatures and oxidative conditions.

The chemical resistance of Grade 5 Titanium is outstanding, especially in the presence of strong acids like hydrochloric and sulfuric acids. The self-healing oxide layer provides robust protection against a wide range of chemicals, making it ideal for applications in the chemical processing industry. This resistance extends to various organic compounds and chlorine-containing environments, where other materials might suffer from rapid degradation.

In marine environments, Grade 5 Titanium demonstrates superior corrosion resistance. It withstands the harsh conditions of seawater, showing minimal corrosion rates (less than 0.005 mm/year). This makes it excellent for marine applications such as offshore structures, ship components, and underwater pipelines. Additionally, Grade 5 Titanium performs exceptionally well in chloride-rich environments, where it resists pitting and crevice corrosion better than many other metals.

Stainless steel, particularly grades like 304 and 316, also has good oxidation resistance due to the formation of a chromium oxide (Cr2O3) layer on its surface. This layer provides protection against further oxidation, although it may not be as robust or self-healing as the titanium oxide layer on Grade 5 Titanium. Consequently, stainless steel may require more maintenance in highly oxidative environments to ensure long-term performance.

Stainless steel offers good chemical resistance, though it varies significantly with different grades. For instance, 316 stainless steel, which contains molybdenum, provides enhanced resistance to chlorides and acids compared to 304 stainless steel. However, it generally does not match the level of chemical resistance provided by Grade 5 Titanium in highly acidic or chloride-rich environments. This makes stainless steel suitable for applications where moderate chemical resistance is acceptable, such as in food processing equipment and general construction.

Stainless steel holds up well in many environments, including coastal and industrial areas with salt-laden air. While it performs adequately in seawater, it may experience pitting and crevice corrosion over time, especially in stagnant or low-oxygen conditions. Stainless steel is a good choice for applications where cost and availability are primary considerations, and where the environmental conditions are less aggressive than those requiring Grade 5 Titanium.

In comparing the two materials, Grade 5 Titanium generally offers superior corrosion resistance across a broader range of environments, particularly in highly aggressive conditions. Stainless steel, while versatile and cost-effective, may require more frequent maintenance and monitoring in such environments.

Grade 5 Titanium has a density ranging from approximately 4.43 to 4.51 g/cm³. In contrast, stainless steel typically ranges from 7.70 to 7.90 g/cm³. This means titanium is about 40% lighter than stainless steel. The significant weight advantage makes titanium highly valuable in industries like aerospace and high-performance automotive, where reducing weight leads to improved fuel efficiency, higher speeds, and better performance. The reduced weight of titanium components can also contribute to lower emissions and enhanced maneuverability.

Grade 5 Titanium can withstand up to 1190 MPa of stretch resistance, often higher than many stainless steel grades. Some high-grade stainless steels, like 17-PH, can match or exceed this, but most common grades do not. Titanium also maintains its shape better under stress, with bend resistance typically ranging from 800 to 1100 MPa, compared to stainless steel’s 240 to 800 MPa. This means titanium can handle greater loads before permanently deforming.

Both Grade 5 Titanium and stainless steel offer good resistance to corrosion. Titanium has a natural protective oxide layer that gives it superior performance in harsh environments. While stainless steel can improve its corrosion resistance with additional alloys, it may degrade over time under extreme conditions.

Titanium generally provides better wear resistance due to its moderate hardness and natural oxide layer, which acts as a protective barrier. However, some hardened stainless steels can be more resistant to wear, making them preferable in certain applications where extreme wear is expected.

Grade 5 Titanium is ideal for applications demanding high strength-to-weight ratios. For example, in the aerospace industry, using titanium in aircraft components helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and performance.

Stainless steel is more suitable for applications prioritizing formability, corrosion resistance, and cost-effectiveness over weight savings. It is commonly used in construction, food processing equipment, and general industrial use. In these industries, the lower cost and ease of fabrication make stainless steel a preferred choice.

Titanium is significantly more expensive than stainless steel due to its complex extraction and processing methods. However, in applications where its unique properties provide substantial benefits, the higher cost can be justified.

Stainless steel is generally easier to machine than Grade 5 Titanium. Its lower hardness and higher thermal conductivity make the machining process less challenging. Titanium’s properties can pose difficulties during machining, increasing the time and cost of production.

Grade 5 Titanium (Ti-6Al-4V) is highly valued but comes with a significant cost due to its complex and energy-intensive extraction and refinement processes. The material cost for Grade 5 Titanium can range from $35 to $50 per kilogram. This high price is influenced by the limited availability of titanium ore and the sophisticated techniques needed to produce the alloy.

Stainless steel usually costs between $1 and $1.50 per kilogram, thanks to more abundant raw materials and simpler production processes. This lower cost makes stainless steel a popular choice for a wide range of industrial applications.

Processing and manufacturing Grade 5 Titanium present several challenges that increase its overall costs. The material’s high strength and low weight make it desirable for many applications, but these same properties also make it difficult to machine and form. Specialized equipment and techniques are required to handle the material without causing damage or excessive wear on tools.

Stainless steel is easier to process and manufacture due to its higher thermal conductivity and lower hardness, allowing for machining with standard tools and techniques. This ease of fabrication reduces production costs and allows for more efficient manufacturing processes. As a result, stainless steel components can be produced more quickly and at a lower cost than those made from titanium.

While initially more expensive, Grade 5 Titanium can provide long-term savings in specific applications. Titanium’s superior strength-to-weight ratio and exceptional corrosion resistance can lead to significant savings over time. For example, in aerospace and marine applications, the use of titanium can result in reduced maintenance requirements and longer service life,

Stainless steel’s lower upfront cost makes it an attractive option for many applications. While it may not match titanium’s performance in highly demanding environments, stainless steel offers good corrosion resistance and durability for less aggressive conditions. This balance of performance and cost makes stainless steel a cost-effective choice for general industrial use, construction, and food processing equipment. However, in highly corrosive or weight-sensitive applications, the long-term maintenance and replacement costs may be higher compared to titanium.

Choosing between Grade 5 Titanium and Stainless Steel requires a careful evaluation of your project’s specific needs. Think about the operating environment, mechanical loads, and weight limitations. If your project requires high strength and low weight, like in aerospace components, Grade 5 Titanium is ideal for its excellent strength-to-weight ratio. However, if cost and ease of fabrication are more important, stainless steel might be a better option.

Budget is a crucial factor in material selection. Grade 5 Titanium, while offering superior properties in some areas, is significantly more expensive than stainless steel. Titanium’s higher cost is due to its complex extraction and processing methods. If the budget is tight and the application does not demand the unique properties of titanium, stainless steel can be a cost-effective alternative. It is widely available, easier to process, and generally less expensive, making it suitable for many general-purpose applications.

Long-term performance should also be a key consideration. Grade 5 Titanium offers exceptional corrosion resistance, making it ideal for harsh environments like marine or chemical processing applications. Its durability can lead to lower maintenance costs and a longer lifespan, potentially offsetting its higher initial cost. Stainless steel, while also corrosion-resistant, may need more frequent maintenance in very aggressive environments. However, it is often adequate for less demanding conditions and provides a good balance of performance and cost.

Referencing industry standards can provide additional guidance in material selection. Standards such as ASTM and ISO offer detailed specifications for various materials, including mechanical properties, chemical compositions, and testing methods. These standards ensure that the selected material meets the necessary quality and performance criteria for your application. For example, ASTM standards for Grade 5 Titanium (such as ASTM B348) and stainless steel (such as ASTM A240) can help you compare the materials based on standardized criteria.

By thoroughly evaluating these factors, you can make an informed decision that balances performance, cost, and long-term benefits for your specific project requirements.

Grade 5 Titanium (Ti-6Al-4V) is a preferred material in the aerospace industry due to its high strength-to-weight ratio and excellent corrosion resistance. It is used in airframe components, engine parts, and landing gear, all of which benefit from titanium’s ability to handle high stresses while reducing aircraft weight, leading to improved fuel efficiency and performance.

Stainless steel is used in aerospace for structural components, fasteners, and fuel tanks due to its durability and resistance to varying temperatures. Although it is heavier than titanium, it is a cost – effective and formable option.

In marine environments, Grade 5 Titanium is highly valued for its exceptional resistance to seawater corrosion, making it ideal for offshore platforms, ship hulls, and underwater piping. Titanium’s ability to withstand harsh marine conditions with minimal maintenance makes it suitable for long – term applications in this sector.

Stainless steel is widely used in marine applications, especially in less aggressive conditions. It is found in shipbuilding for structural components, railings, and fittings. Grades like 316 stainless steel, which contains molybdenum, offer enhanced resistance to chloride – induced corrosion.

In the construction industry, Grade 5 Titanium is utilized in high – performance architectural elements and structural components. It is often used in skyscrapers, bridges, and other large structures where lightweight and high strength are required. Its corrosion resistance also reduces the need for protective coatings and maintenance.

Stainless steel is prevalent in construction due to its versatility, cost – effectiveness, and aesthetic appeal. It is commonly used for building facades, roofing, and interior elements like railings and countertops, being suitable for both functional and decorative purposes.

A notable example is the use of Grade 5 Titanium in the Boeing 787 Dreamliner, where titanium components contribute to the aircraft’s reduced weight and increased fuel efficiency. The high strength-to-weight ratio of Grade 5 Titanium allows for lighter structural components without compromising safety or performance.

Grade 5 Titanium is employed in the construction of the Seawolf – class submarines, where its resistance to seawater corrosion ensures long – term durability and minimal maintenance. In contrast, stainless steel is used in commercial shipping for constructing durable and corrosion – resistant cargo holds and deck equipment.

The Guggenheim Museum Bilbao is an iconic example, featuring a titanium – clad exterior that combines durability with striking visual appeal. On the other hand, the Chrysler Building in New York City showcases the use of stainless steel in its construction, with its stainless steel spire standing as a testament to the material’s longevity and formability.

The extraction and production of titanium are more energy-intensive and complex compared to stainless steel. Titanium is typically extracted from ilmenite or rutile ores, followed by a multi-step process involving the Kroll process to obtain pure titanium. This high energy requirement leads to a greater environmental impact during the initial production phase. However, the high strength-to-weight ratio of Grade 5 Titanium means that less material may be required for the same application, potentially mitigating some of the environmental costs over the product’s lifecycle.

Grade 5 Titanium offers exceptional corrosion resistance due to its self-healing oxide layer, which provides robust protection in harsh environments such as seawater and chloride-rich conditions. This resilience reduces the frequency of replacements and minimizes waste over time, contributing to its sustainability by ensuring a long service life.

Stainless steel also boasts good corrosion resistance, though its performance can vary significantly among different grades. For instance, 316 stainless steel offers enhanced resistance in coastal environments, but may not match titanium’s performance in more aggressive conditions. This can lead to shorter lifespans and the need for more frequent replacements, potentially increasing environmental impact over time.

Titanium is highly biocompatible, making it ideal for medical implants. Its ability to integrate well with human tissue reduces the risk of adverse reactions and ensures long-term stability within the body. This property not only enhances patient safety but also reduces the environmental footprint associated with medical device replacements and waste.

While stainless steel is used in some medical devices, it may not be as biocompatible as titanium. Its ease of fabrication and lower cost make it a viable option for certain medical applications where biocompatibility is less critical. However, in applications where tissue integration is essential, the use of titanium is often preferred.

Recycling titanium is less common and more complex than recycling stainless steel due to its high reactivity and the costs involved. However, as the demand for titanium increases, efforts to improve recycling methods are ongoing. Enhanced recycling processes can help reduce waste and the need for new raw materials, aligning with sustainability goals.

Stainless steel is highly recyclable and widely recycled. The closed-loop recycling process of stainless steel helps reduce waste and the demand for virgin materials, contributing to a more sustainable supply chain. This ease of recycling makes stainless steel a more environmentally friendly option in terms of end-of-life management.

The production of titanium requires significant energy input due to the complex extraction and processing stages. This results in a higher carbon footprint per unit compared to stainless steel. However, the material efficiency of titanium, due to its high strength-to-weight ratio, can lead to reduced overall energy consumption in applications where weight savings are critical, such as in aerospace and automotive industries. This can offset some of the initial carbon footprint associated with its production.

Stainless steel production generally involves lower energy requirements and results in a smaller carbon footprint compared to titanium. This makes stainless steel a more environmentally friendly option from a production standpoint, especially when considering the material’s entire lifecycle.

The high strength-to-weight ratio of titanium means that less material is often needed to achieve the same structural integrity as stainless steel. This efficiency can lead to reduced material usage and lower transportation emissions, contributing to a smaller carbon footprint.

While stainless steel is heavier than titanium, its lower cost and easier fabrication often offset the additional weight in terms of overall project expenses. Stainless steel’s durability and resistance to corrosion make it a popular choice for a wide range of applications, from kitchen appliances to industrial machinery.

Grade 5 Titanium is significantly lighter, with a density of about 4.43 – 4.51 g/cm³. Its tensile strength ranges from 895 – 1190 MPa, offering high strength, while yield strength is between 800 – 1100 MPa, providing excellent deformation resistance. The Rockwell Hardness (HRC) usually falls between 32 – 36. Titanium’s superior corrosion resistance makes it ideal for use in aggressive environments like seawater. Although highly reactive with oxygen, it forms a protective oxide layer that enhances its durability.

In terms of thermal properties, it has lower thermal conductivity, around 21.9 W/m·K, and its electrical conductivity is relatively low, at about 3.1% of IACS. These characteristics contribute to its high performance in specialized applications. Titanium is highly biocompatible, making it suitable for medical implants.

On the other hand, stainless steel typically has a density of 7.70 – 7.90 g/cm³, making it about 40% heavier than titanium. Its tensile strength varies by grade, generally ranging from 480 – 1180 MPa, with yield strength from 240 – 800 MPa. The hardness of stainless steel can vary greatly by grade; for example, 440C can reach up to 58 HRC. While it offers good corrosion resistance, it is less effective than titanium in extreme conditions, though it can be enhanced with additives.

Stainless steel is less reactive and stable in various chemical environments. Its thermal conductivity ranges from 15 – 25 W/m·K, making it better for heat-exchange applications. The electrical conductivity of stainless steel is typically around 2.5% IACS, even lower than that of titanium. Although used in medical devices, stainless steel may cause more immune response compared to titanium.

Titanium is more expensive due to complex extraction and processing, whereas stainless steel is generally more affordable and easier to fabricate. The machinability of titanium is more challenging due to its low thermal conductivity and galling tendency, while stainless steel, especially austenitic grades like 304, is easier to work with.

Grade 5 Titanium is ideal for aerospace, high-performance automotive, and medical implants. Stainless steel finds common applications in kitchenware, construction, and industrial equipment.

Interactive tools significantly aid in the decision-making process when choosing between Grade 5 Titanium and stainless steel. These tools offer dynamic and customized insights based on specific project requirements, helping engineers and material scientists make informed choices.

Material selection calculators help compare the physical and mechanical properties of Grade 5 Titanium and stainless steel. These calculators can input project-specific parameters such as load requirements, environmental conditions, and weight constraints, allowing users to see how each material performs under different scenarios and choose the most suitable one.

Cost comparison tools allow users to evaluate the financial implications of using Grade 5 Titanium versus stainless steel. These tools factor in material, processing, machining, and long-term maintenance costs. Offering a comprehensive cost analysis, these tools help users understand the total ownership cost of each material and aid in budget planning and cost-effective decisions.

Environmental impact assessors help users evaluate the sustainability of their material choices. These tools analyze the environmental footprint of both Grade 5 Titanium and stainless steel, considering factors such as energy consumption, carbon emissions, and recyclability. By comparing the environmental impact of each material, users can make decisions that align with their sustainability goals and regulatory requirements.

Interactive comparison charts allow users to visually compare the properties of Grade 5 Titanium and stainless steel. These charts dynamically display data on density, tensile strength, yield strength, corrosion resistance, and thermal conductivity. Users can hover over data points to see detailed information and adjust the charts to focus on specific properties relevant to their project.

Case study simulations provide practical examples of how Grade 5 Titanium and stainless steel have been used in real-world applications. Users can explore detailed case studies from various industries, such as aerospace, marine, and construction, to understand the performance and benefits of each material in different contexts. These simulations help users draw parallels to their own projects and make more informed material selections.

Decision-making frameworks offer structured approaches to selecting materials based on project-specific criteria. These frameworks guide users through a step-by-step process that includes assessing mechanical requirements, environmental conditions, budget constraints, and long-term performance. By systematically evaluating these factors, users can make well-rounded decisions supported by comprehensive analysis.

Leveraging these interactive elements enhances the material selection process, ensuring that choices are informed, cost-effective, and aligned with project goals.

Below are answers to some frequently asked questions:

Grade 5 Titanium (Ti-6Al-4V) and stainless steel are two distinct materials with unique properties. Grade 5 Titanium is known for its exceptional strength-to-weight ratio, being about 40% lighter than stainless steel, with a density of 4.43 g/cm³ compared to stainless steel’s 7.70 to 7.90 g/cm³. This makes it ideal for applications where weight reduction is crucial, such as in aerospace and high-performance automotive components. It also boasts superior tensile strength (895 to 1190 MPa) and excellent corrosion resistance due to its protective oxide layer, especially in marine environments.

Stainless steel, on the other hand, is favored for its formability, ease of machining, and cost-effectiveness. It is widely used in kitchen appliances, health products, and industrial equipment. While it also offers good corrosion resistance, certain grades like 316 SS can be more susceptible under specific conditions. Stainless steel is generally more available and less expensive to produce than Grade 5 Titanium, which involves a more complex manufacturing process.

When deciding whether Grade 5 Titanium or stainless steel is better suited for your project, consider the specific requirements such as strength, weight, corrosion resistance, cost, and ease of machining.

Grade 5 Titanium, known for its excellent strength-to-weight ratio, has a density of about 4.43 g/cm³ and can achieve tensile strengths up to 1190 MPa. It excels in applications where weight reduction and high strength are critical, such as in aerospace and high-performance automotive components. Additionally, its superior corrosion resistance, especially in seawater and acidic environments, makes it ideal for harsh conditions.

Stainless steel, with a higher density of approximately 7.8 g/cm³, offers a wide range of tensile strengths depending on the grade. While it may not match titanium’s strength-to-weight advantage, it provides good corrosion resistance, especially in grades like 316, and is easier to machine. Stainless steel is more cost-effective, typically ranging from $2 to $5 per pound, and is widely used in construction, kitchen appliances, and industrial equipment.

Grade 5 Titanium, or Ti-6Al-4V, has a high tensile strength ranging from 900 to 1,200 MPa, with a superior strength-to-weight ratio compared to most stainless steels. Stainless steel’s tensile strength varies between 480 and 1,100 MPa, and while some grades can approach titanium’s strength, many fall short. In terms of corrosion resistance, Grade 5 Titanium is excellent due to a naturally forming oxide layer, protecting it from acids, salts, and harsh environments. Stainless steel also offers good corrosion resistance but is generally less effective under extreme conditions, often needing higher chromium and molybdenum content in specialized grades to enhance resistance.

The typical costs associated with Grade 5 Titanium (Ti-6Al-4V) and Stainless Steel vary significantly due to their material properties and manufacturing processes. Grade 5 Titanium costs range from $35 to $50 per kilogram (approximately $10 to $15 per pound). This high cost is primarily due to its complex extraction and processing methods, which are energy-intensive and require specialized equipment. Despite this, its high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility make it essential for aerospace, medical, and high-performance automotive applications.

In contrast, Stainless Steel, particularly common grades like 304 and 316, is much more affordable, typically costing between $1 to $1.50 per kilogram. Its lower cost is due to more straightforward production processes and abundant availability. Stainless Steel is widely used in construction, kitchenware, and industrial equipment due to its cost-effectiveness and good corrosion resistance.

Yes, there are specific industry standards and certifications for using Grade 5 Titanium and stainless steel. Grade 5 Titanium (Ti-6Al-4V) is commonly regulated by standards such as ASTM B348 or AMS 4928 for round products and ASTM B265 or AMS 4911 for flat products. These standards ensure the material’s quality, safety, and performance, especially in critical applications like aerospace and medical fields. Manufacturers often hold certifications like AS9100D and ISO 9001:2015, which guarantee high-quality materials with strict traceability.

Stainless steel, including popular grades like 304 and 316, adheres to standards that define its chemical composition, mechanical properties, and testing methods, ensuring it meets required performance and durability criteria. Standards such as ASTM A240 and ASTM A276 are common.

When considering the environmental impact of Grade 5 Titanium and Stainless Steel, multiple factors come into play. Titanium extraction is energy – intensive and often occurs in ecologically sensitive areas, leading to a higher upfront carbon footprint. In contrast, stainless steel extraction is less energy – consuming and involves fewer environmental risks due to the abundance of iron.

In terms of recyclability, both are recyclable, but stainless steel has a higher recycling rate because of established infrastructure and lower processing costs. Titanium’s recycling is more complex.

Titanium offers excellent durability and corrosion resistance, extending its lifespan and potentially reducing long – term environmental impact by minimizing the need for replacements. However, its complex recycling process offsets some of these benefits. Overall, Grade 5 Titanium has a higher upfront environmental impact but long – term benefits, while stainless steel has a lower upfront impact but may need more frequent replacements.