Imagine a world where the relentless force of the ocean meets the resilience of human engineering, creating structures that withstand the test of time and tide. This fascinating intersection hinges on one crucial element: marine-grade metals. Whether you’re a shipbuilder, an offshore engineer, or a curious enthusiast, understanding the properties, types, and uses of these specialized metals is essential for navigating the complexities of marine environments.

In this comprehensive guide, we will dive into the unique characteristics that make certain metals suitable for harsh marine conditions. You’ll discover the various types of marine-grade metals, from stainless steel and aluminum alloys to copper-nickel and marine brass, each offering distinct advantages in terms of cost, strength, and maintenance. By the end, you’ll have a thorough grasp of how to select the right metal for your specific project needs, ensuring durability and efficiency in the face of the sea’s challenges.

Ready to explore the metals that anchor our maritime ventures? Let’s set sail into the world of marine-grade metals and uncover the secrets behind their remarkable resilience.

Marine grade metals are specialized materials crafted to endure the harsh conditions of marine environments. These include exposure to saltwater, high humidity, and fluctuating temperatures. They are indispensable in shipbuilding, offshore structures, and marine equipment, where long – term durability and corrosion resistance are crucial for safety and performance.

One of the main features of marine grade metals is their corrosion resistance. Alloying elements like chromium, molybdenum, and nickel are added to the metal. These elements form a protective layer on the metal’s surface, like a shield that stops saltwater and other corrosive substances from getting in and causing damage.

Marine grade metals need to have high tensile strength and durability. They must withstand the mechanical stresses and impacts from waves, currents, and the operation of marine vessels and equipment, maintaining their structural integrity.

Some marine grade metals, such as copper alloys, have a remarkable quality. They can naturally prevent marine organisms from attaching and growing on their surfaces. This is extremely beneficial for ship hulls and underwater structures, as biofouling can increase drag, reduce efficiency, and raise maintenance costs.

Stainless steel is widely used in marine applications because of its excellent corrosion resistance and mechanical properties. Grade 304 is commonly used in less severe marine environments where the exposure to saltwater is not continuous. It offers good corrosion resistance at a relatively lower cost. Grade 316, on the other hand, has a higher molybdenum content. This makes it more resistant to the corrosive effects of saltwater, so it is preferred for applications in harsh, salt – laden marine settings.

Aluminum alloys are favored for their lightweight nature and corrosion resistance. They are commonly used in ship hulls, superstructures, and other components where a high strength – to – weight ratio is beneficial.

Copper – nickel alloys are known for their outstanding resistance to seawater corrosion and biofouling. They are often used in seawater piping systems, heat exchangers, and other marine applications where long – term reliability is essential.

Marine brass, an alloy of copper and zinc, is valued for its high corrosion resistance and thermal conductivity. It is frequently used in marine fittings, pumps, and valves due to its durability and ability to withstand harsh marine conditions.

Bronze alloys, including aluminum – bronze and silicon – bronze, are preferred for marine fasteners, propellers, and other components that require a combination of strength and resistance to biofouling. These alloys perform well in both saltwater and freshwater environments.

Marine grade metals are integral to shipbuilding (used in hulls, decks, and structural components), offshore structures (such as oil rigs and wind farms), and marine equipment (like anchors, propellers, pumps, and fittings).

Choosing the right marine grade metal for a specific application involves considering several factors:

Regular maintenance, including cleaning and inspection, is vital to ensure the longevity and optimal performance of marine grade metals. Proper care helps prevent corrosion, biofouling, and other issues that can compromise the integrity and functionality of marine structures and equipment.

In marine environments, corrosion resistance is crucial because saltwater accelerates oxidation. Elements like chromium, molybdenum, and nickel create a protective oxide layer on the metal’s surface, shielding it from moisture, salt, and corrosion. This layer significantly extends the lifespan of marine structures and components by preventing rust and corrosion.

High tensile strength is essential for marine grade metals to endure the mechanical stresses from waves, currents, and vessel operations without deforming or breaking. Metals such as stainless steel and certain aluminum alloys are known for their excellent strength-to-weight ratios, making them ideal for use in ship hulls, offshore platforms, and other critical marine structures.

Copper-nickel alloys naturally inhibit marine organisms like barnacles and algae, reducing maintenance needs and improving vessel efficiency by minimizing drag. This not only decreases the frequency of cleaning but also extends the operational life of underwater components.

Effective heat dissipation is essential for many marine applications, particularly in systems such as heat exchangers and cooling systems. Marine grade metals like copper and its alloys offer high thermal conductivity, enabling efficient heat transfer. This property is crucial for maintaining the operational efficiency of marine engines and other heat-sensitive equipment.

Marine grade metals often need to be formed into various shapes and structures, making ductility and malleability important properties. Ductility allows the metal to be drawn into wires or thin sheets without breaking, while malleability enables it to be hammered or rolled into different shapes. These properties are vital for manufacturing complex marine components and ensuring they can be fabricated to precise specifications.

Marine environments subject materials to cyclical loading and unloading due to waves and the movement of vessels. Fatigue resistance is the ability of a metal to withstand repeated stress cycles without fracturing. Metals such as stainless steel and certain aluminum alloys exhibit excellent fatigue resistance, making them suitable for dynamic marine applications where long-term reliability is essential.

High-hardness alloys and coatings help marine grade metals resist wear and abrasion from contact with other materials and marine organisms, ensuring durability in harsh conditions. This property ensures the longevity and durability of components such as propellers, shafts, and fittings that are subject to constant friction and impact.

Stainless steel stands out in marine applications due to its excellent resistance to corrosion and robust mechanical properties. This metal is often alloyed with chromium, molybdenum, and nickel, which form a protective oxide layer on the surface. This layer enhances its ability to withstand harsh marine environments.

Aluminum alloys are favored in marine applications for their lightweight nature and good corrosion resistance. When alloyed with elements like magnesium, silicon, and chromium, aluminum becomes more durable and resistant to seawater’s corrosive effects.

Copper-nickel alloys are highly valued for their exceptional resistance to seawater corrosion and biofouling. These alloys are often used in seawater piping systems, heat exchangers, and other marine components where long-term reliability is essential.

Marine brass, an alloy of copper and zinc, sometimes combined with tin or lead, is known for its high corrosion resistance and excellent thermal conductivity. It suits various marine applications, including valves and pumps.

Bronze alloys, particularly aluminum-bronze and silicon-bronze, are commonly used in marine environments for their strength and resistance to corrosion and biofouling. These properties make them ideal for applications such as propellers, fasteners, and piping.

Alloy steel is used in marine applications where high strength and enhanced corrosion resistance are required. Special grades, such as MD, ME, MF, and MG, are formulated to withstand the corrosive marine environment while providing the necessary mechanical properties for structural components.

When selecting marine-grade metals, key factors to consider include corrosion resistance, strength, durability, and resistance to biofouling. Understanding the specific requirements of the application and the environmental conditions will guide the choice of the most suitable metal.

Stainless steel is a highly versatile and widely used material in marine environments due to its excellent corrosion resistance, durability, and mechanical properties. It is an alloy primarily composed of iron, chromium, and often nickel, with other elements added to enhance specific characteristics.

Stainless steel owes its key characteristic – corrosion resistance – to its chromium content. It typically has a significant amount of chromium, which forms a passive oxide layer on the surface. Nickel is also commonly added to improve formability and toughness. Other elements like molybdenum, manganese, and nitrogen may be included to boost specific properties such as pitting resistance and strength.

There are several types of stainless steel, each well – suited to different marine applications:

To ensure the longevity and performance of stainless steel in marine environments, regular maintenance is essential:

Understanding how stainless steel behaves and following proper maintenance practices is key to getting the most out of this remarkable material in marine settings.

Marine grade aluminum alloys are designed to withstand the harsh marine environment. They offer outstanding corrosion resistance, lightweight characteristics, and a high strength-to-weight ratio. These features make them invaluable in shipbuilding, offshore drilling platforms, and various marine equipment, as they can withstand saltwater and constant moisture exposure.

Alloying aluminum with metals like magnesium significantly enhances its resistance against saltwater and marine atmospheres. This protective quality is crucial as it extends the lifespan of components in marine settings, reducing the need for frequent replacements.

Marine grade aluminum alloys are lightweight yet strong, improving fuel efficiency and supporting heavy loads in marine applications. This property is beneficial for reducing the overall weight of vessels, which in turn enhances their speed and maneuverability.

Marine grade aluminum alloys are compatible with various fabrication processes, such as welding, forming, and extrusion. This versatility allows for the creation of complex and customized components for different marine applications.

Commonly used for casting purposes, these alloys have high fluidity, allowing for the production of detailed and precise castings.

In shipbuilding, aluminum alloys are used for hulls and superstructures, ensuring durability and performance even in the toughest conditions. Their strength and lightweight properties enhance fuel efficiency and reduce the overall weight of the vessel, allowing for increased cargo capacity and improved speed.

These alloys are essential for structural components and equipment exposed to seawater. Their lightweight nature and corrosion resistance make them ideal for offshore applications, where reducing weight and ensuring longevity are critical.

Often used in ladders, railings, and other fittings, marine grade aluminum alloys provide the necessary corrosion resistance and light weight required for these applications.

Aluminum alloy honeycomb panels offer high strength, impact resistance, and thermal insulation, making them ideal for marine structures.

The corrosion resistance of marine grade aluminum reduces the need for protective coatings, resulting in lower maintenance costs over the long term.

Aluminum is 100% recyclable, which supports sustainable practices in the marine industry by reducing energy use and environmental impact.

Compared to other materials like steel, marine grade aluminum offers significant cost savings in terms of production and maintenance. Its lightweight nature also reduces transportation costs.

Non-toxic and fully recyclable, marine grade aluminum aligns with eco-friendly construction practices, helping to minimize the environmental impact of marine projects.

Copper-nickel alloys, also known as cupronickel, are prized in marine applications for their unique properties. Adding nickel to copper significantly enhances corrosion resistance, particularly in seawater. This improvement is due to the formation of a protective surface film that reacts with seawater. Nickel also increases the strength of copper while keeping it ductile. Depending on the application, other elements such as iron, manganese, chromium, and aluminum can be added to enhance specific properties. For example, these additional elements can improve the alloy’s resistance to wear and galling.

Another notable property of copper-nickel alloys is their inherent resistance to macrofouling. This reduces the need for biocide dosing and regular cleaning in marine systems, leading to lower maintenance costs and increased operational efficiency.

Copper-nickel alloys are widely used in naval and commercial shipping, offshore oil and gas production, desalination, and power generation because of their excellent seawater corrosion resistance. Their resistance to seawater corrosion makes them a reliable choice for components in these seawater systems.

The 70-30 alloy, in particular, is used in multistage flash desalination units. Its ability to handle high flow rates makes it well-suited for this application, ensuring the efficient operation of desalination processes.

These alloys protect offshore platforms and boat hulls against corrosion and biofouling. By reducing drag forces and maintenance needs, they contribute to the longevity and performance of these structures.

Marine brass is a specialized alloy mainly made up of copper, zinc, and tin. The copper content usually ranges from 59% to 62%, with most of the remainder being zinc, and tin accounting for 0.5% to 1%. This specific composition is key to its excellent performance in marine environments.

Adding tin to marine brass greatly enhances its resistance to seawater corrosion. Tin effectively prevents dezincification, a process where zinc is leached from the alloy, which could otherwise weaken the structure. This property makes marine brass an ideal choice for components exposed to saltwater.

Marine brass has high tensile strength, making it ideal for applications that need durability and rigidity. Components made from this alloy can withstand significant mechanical stresses without deforming or breaking, ensuring long-term reliability in marine settings.

It offers moderate machinability, facilitating the manufacturing of a wide range of marine hardware and components. In some compositions, the presence of lead further enhances this machinability, allowing for more precise and efficient production processes.

This alloy demonstrates excellent wear resistance, making it well-suited for parts that experience constant friction and mechanical wear in marine environments. It can maintain its integrity and functionality over time, reducing the need for frequent replacements.

There are different types of marine brass, such as alpha and alpha-beta brass. Alpha brass is mainly used for wrought metalwork, offering good formability for creating various shapes. Alpha-beta brass, on the other hand, is more suitable for hot working processes. These variations allow marine brass to be used in a diverse array of applications, including marine hardware like bushings and fasteners, heat exchangers, and the manufacturing of propellers, pumps, and valves.

Bronze alloys are essential in many industries because of their unique properties. In marine environments, their resistance to corrosion, strength, and durability make them invaluable. Bronze is primarily composed of copper, combined with other elements such as tin, aluminum, silicon, and nickel, which enhance its properties for diverse applications.

Composition: Aluminum bronze typically contains 9 – 14% aluminum, often with iron and nickel.

Properties: It exhibits high corrosion resistance, particularly in seawater, and excellent mechanical strength due to the formation of a protective oxide layer, making it suitable for challenging marine environments.

Applications: Commonly used in propellers, valves, fasteners, and structural components, aluminum bronze is favored for its resistance to corrosion and cavitation.

Composition: This alloy includes both nickel and aluminum.

Properties: It offers exceptional corrosion resistance, even in acidic solutions, and high strength. Additionally, it has excellent weldability, making it versatile for various applications.

Applications: Widely used in marine and aerospace applications where superior corrosion resistance is crucial, such as in propellers and valves.

Composition: Contains up to 12% tin.

Properties: Tin bronze is known for its good castability and high resistance to corrosion. The tin content enhances its resistance to polluted seawater, making it suitable for specific marine environments.

Applications: Used in gears, bearings, and intricate castings, tin bronze is valued for its durability and reliability.

Composition: Typically includes 85 – 95% copper, 5 – 10% tin, and a small amount of phosphorus.

Properties: This alloy is highly resistant to wear and corrosion, making it ideal for parts that face significant friction and mechanical stress.

Applications: Commonly used in springs, bearings, and electrical connectors due to its low friction and high durability.

Composition: Mainly copper with 2.8 – 4.0% silicon.

Properties: Silicon bronze offers superior corrosion resistance in marine environments, good malleability, and an appealing aesthetic. Its resilience makes it ideal for underwater applications.

Applications: Silicon bronze is often used in marine hardware and architectural features because it is durable and easy to work with.

Composition: High manganese content.

Properties: Known for its high strength, moderate corrosion resistance, and excellent wear resistance, manganese bronze is suitable for heavy – duty applications.

Applications: Used in heavy – duty mechanical products, marine fittings, and machinery parts, manganese bronze excels in applications that require robust performance.

Corrosion resistance in marine-grade metals is vital due to the aggressive nature of the marine environment. Seawater is rich in chlorides, which speed up corrosion. Therefore, metals used in marine environments must have strong corrosion resistance.

Advanced metallurgical techniques are employed to control the microstructure of marine-grade metals. Refining the grain structure and ensuring proper phase distribution reduces the risk of localized corrosion. A stable microstructure also contributes to the mechanical strength and fatigue resistance of the alloy, which is crucial in dynamic marine environments.

Steel is a fundamental material in the construction of ship hulls and offshore platforms because of its high strength and durability. Specific grades of steel, such as AH36, DH36, and EH36, are preferred in these applications due to their enhanced manganese and chromium content, which improve their strength and corrosion resistance. These properties ensure that the structures can withstand the harsh marine environment, including high mechanical stresses from waves and currents.

Aluminum is light, which reduces vessel weight, improves fuel efficiency, and increases payload capacity. Marine grade aluminum alloys are extensively used in the construction of boat hulls, superstructures, and decks. Alloys like 5083 and 6061 – T6 offer excellent corrosion resistance and strength, making them ideal for structural components that are exposed to seawater and other marine conditions.

Stainless steel is commonly used for functional and decorative elements in marine settings. Its excellent corrosion resistance and aesthetic appeal make it suitable for ornamental tubing, handrails, and other decorative components. Stainless steel grades such as 304 and 316 are particularly favored, with 316 being preferred in highly corrosive environments due to its higher molybdenum content, which provides superior resistance to saltwater corrosion.

Copper – nickel alloys, such as C70600 and C71500, are commonly used in marine fittings, valves, and pumps due to their excellent corrosion resistance and biofouling resistance. These properties are crucial for maintaining the integrity and functionality of marine equipment that is constantly exposed to seawater. Marine brass, which is often alloyed with tin and zinc, is also used in fasteners and piping, providing high temperature resistance and improved corrosion properties.

Bronze alloys, including aluminum – bronze and silicon – bronze, are essential materials for propulsion components such as propellers and propeller shafts. These alloys provide low friction and high corrosion resistance, essential for the smooth operation and durability of propulsion systems. The durability and resistance to marine corrosion make bronze alloys an ideal choice for hardware that operates underwater and is subject to constant friction and impact.

In offshore structures, such as oil rigs and wind farms, materials need to withstand extreme conditions, including high winds, waves, and saltwater exposure. Stainless steel and aluminum alloys are often used for structural frameworks due to their high strength, corrosion resistance, and durability. Duplex stainless steels, with their combined properties of austenitic and ferritic steels, are particularly suited for these applications, offering high strength and excellent resistance to pitting and stress corrosion cracking.

Copper – nickel alloys are widely used in offshore platform piping systems. Their resistance to seawater corrosion and biofouling makes them ideal for seawater cooling systems, firewater systems, and desalination plants. These alloys ensure the reliability and longevity of piping systems that are critical for the operation of offshore structures.

Stainless steel and copper – nickel alloys are vital in desalination plants and water treatment systems. Stainless steel is used in pumps, valves, and piping systems due to its ability to handle high temperatures and pressures while resisting corrosion. Copper – nickel alloys are employed for their durability and biofouling resistance, which are essential for the efficient operation of desalination equipment.

Selecting the right marine – grade metal for a project involves understanding the specific requirements and environmental challenges unique to marine applications. Various factors must be evaluated to ensure optimal performance, longevity, and cost – effectiveness.

The metal’s corrosion resistance is one of the most crucial factors. Marine environments are highly corrosive due to the presence of saltwater, humidity, and varying temperatures. Metals such as stainless steel (especially Grade 316), copper – nickel alloys, and aluminum alloys like 5083 and 6061 are known for their superior corrosion resistance. The presence of alloying elements like chromium, nickel, and molybdenum enhances the metal’s ability to form a protective oxide layer, preventing corrosion.

Alongside corrosion resistance, the strength – to – weight ratio is vital for applications where reducing weight without compromising strength is crucial. Aluminum alloys are particularly advantageous in this regard, offering high strength and lightweight properties, making them ideal for ship hulls and superstructures. Stainless steel and certain bronze alloys also provide excellent strength while maintaining manageable weight, suitable for structural components and fasteners.

Biofouling, or the buildup of marine organisms on surfaces, can greatly affect the efficiency and maintenance costs of marine structures. Metals like copper – nickel alloys and marine brass possess natural anti – fouling properties, reducing the buildup of marine organisms. This property is especially beneficial for underwater components such as piping systems, heat exchangers, and hulls, where biofouling can lead to increased drag and decreased performance.

The cost of the metal and its ease of fabrication are practical considerations affecting the project’s budget and timeline. While stainless steel and aluminum alloys may have higher initial costs, their durability and low maintenance requirements can result in long – term savings. Additionally, metals that are easy to fabricate, such as aluminum and certain stainless steel grades, allow for more efficient manufacturing processes, reducing labor costs and production time.

It’s important to consider environmental conditions like temperature changes, humidity, and seawater exposure at the project site. Different metals react differently to these conditions. For instance, aluminum alloys perform well in a range of temperatures and resist corrosion in both saltwater and freshwater environments. In contrast, stainless steel, particularly Grade 316, is suited for environments with continuous saltwater exposure.

For shipbuilding, selecting metals that balance corrosion resistance, strength, and weight is essential. Aluminum alloys like 5083 and 6061 are often used for hulls and superstructures due to their lightweight and durable nature. Stainless steel (Grade 316) is preferred for fittings, fasteners, and submerged components where high corrosion resistance is critical.

Offshore platforms and wind farms require metals that can withstand harsh marine conditions and mechanical stresses. Duplex stainless steels and copper – nickel alloys are commonly used for structural frameworks and piping systems due to their excellent strength, corrosion resistance, and biofouling resistance.

In desalination plants, the choice of metal must consider high corrosion resistance and the ability to handle high pressures and temperatures. Stainless steel and copper – nickel alloys are frequently used in pumps, valves, and piping systems, ensuring reliable operation and longevity in a corrosive environment.

Stainless steel, particularly grade 316, is highly resistant to corrosion thanks to its alloying elements like chromium, nickel, and molybdenum. This makes it suitable for long-term use in harsh marine environments, such as offshore platforms and desalination plants. Aluminum alloys also offer good corrosion resistance due to a protective oxide layer formed by alloying with elements like magnesium and silicon. However, in extremely corrosive conditions, they may require periodic coatings. Copper-nickel alloys excel in seawater corrosion and biofouling resistance, with antimicrobial properties that reduce marine organism buildup, making them ideal for seawater piping and heat exchangers. Marine brass, blended with tin, zinc, or lead, offers enhanced corrosion resistance and can withstand extreme temperatures, while bronze alloys, like aluminum-bronze and silicon-bronze, are designed for high corrosion and biofouling resistance, making them ideal for underwater components such as propellers.

Stainless steel is strong and heavy, providing necessary structural integrity for large marine structures, and can withstand significant mechanical stresses. Aluminum alloys are strong but lightweight, offering a high strength-to-weight ratio. This is particularly beneficial for applications where reducing weight is crucial, such as ship hulls and superstructures, as it can improve fuel efficiency. Copper-nickel alloys are strong, and those with higher nickel content, such as C71500, are even more durable. Marine brass has high tensile strength, making it suitable for components that require durability and rigidity. Bronze alloys, especially aluminum-bronze and nickel-aluminum bronze, have good mechanical strength comparable to some steels, which is important for load-bearing applications.

Stainless steel generally has a higher initial cost, but its low maintenance requirements can result in long-term savings. It requires minimal maintenance, primarily regular cleaning to remove contaminants. Aluminum alloys may have a relatively lower cost, and their corrosion resistance reduces the need for protective coatings, leading to lower maintenance costs, although periodic inspections might be necessary. Copper-nickel alloys can be more expensive due to their excellent properties, but their resistance to biofouling reduces long-term maintenance needs, such as the requirement for biocide dosing. Marine brass offers a balance between cost and performance, with its moderate machinability potentially reducing manufacturing costs. Although the cost of bronze alloys varies, their durability and wear resistance can lead to fewer replacements and long-term savings.

Stainless steel is used in a wide range of marine applications, including marine structures, fasteners, fittings, and desalination plants. Aluminum alloys are popular in shipbuilding, docks, boat hulls, and structural components. Copper-nickel alloys are primarily used in seawater systems, heat exchangers, and desalination equipment. Marine brass is suitable for marine fasteners, pumps, fittings, and piping. Bronze alloys are essential for propellers, propeller shafts, fasteners, and pipes.

Below are answers to some frequently asked questions:

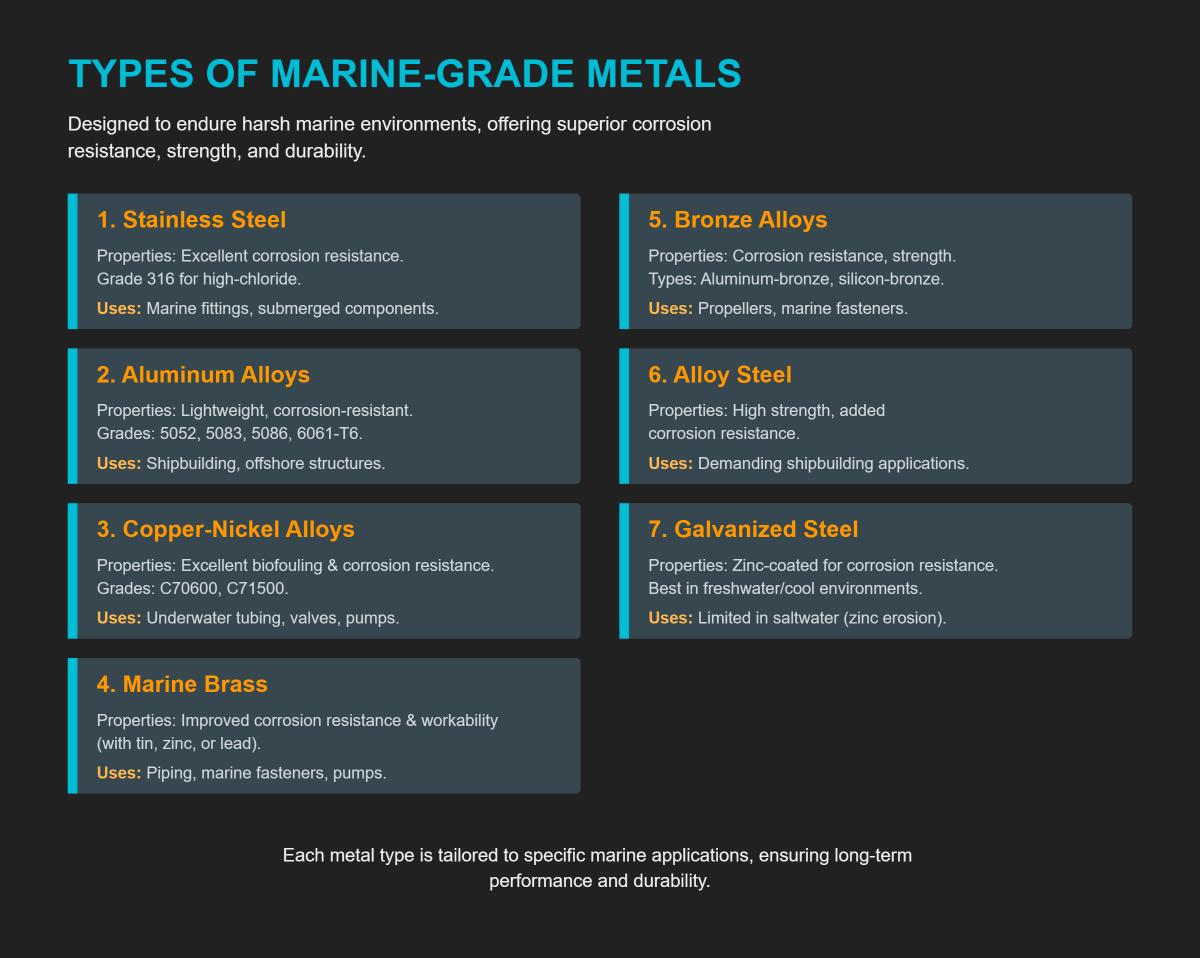

Marine-grade metals are designed to endure the harsh conditions of marine environments, offering superior corrosion resistance, strength, and durability. The primary types include:

Each metal type is tailored to specific marine applications, ensuring long-term performance and durability in challenging conditions.

Metals suitable for marine environments must exhibit several key properties to withstand the harsh conditions of saltwater and high humidity. Firstly, corrosion resistance is crucial; metals must contain alloying elements like chromium, molybdenum, and nickel that form protective oxide layers, preventing rust and degradation. Secondly, high tensile strength is essential for enduring physical stresses such as wave impact and currents, ensuring the structural integrity of marine vessels and structures. Durability and toughness are also important, allowing the metal to resist wear and fatigue over time. Anti-fouling properties, found in metals like copper-nickel alloys and bronze, help minimize biofouling and reduce maintenance needs. Lastly, recyclability and sustainability are significant, with metals like aluminum and stainless steel being highly recyclable, promoting eco-friendly practices in maritime applications.

Different marine-grade metals vary significantly in terms of cost, strength, and maintenance, making the selection process crucial depending on the specific requirements of a project.

Stainless steel, particularly grade 316, is generally the most expensive option but offers exceptional strength and corrosion resistance, which translates to lower long-term maintenance costs. Aluminum alloys, while less costly than stainless steel, provide a strong yet lightweight alternative, though they may require protective coatings and regular inspections to prevent corrosion. Copper-nickel alloys fall in the middle in terms of cost and are highly valued for their excellent corrosion and biofouling resistance, leading to low maintenance needs.

Marine brass is a cost-effective choice, especially for fittings and fasteners, offering moderate strength and good corrosion resistance with regular cleaning required to prevent marine organism buildup. Bronze alloys, more expensive than brass but cheaper than copper-nickel, provide high strength and wear resistance, suitable for propellers and marine fittings, with moderate maintenance.

Selecting the appropriate marine-grade metal for a project involves evaluating several critical factors to ensure optimal performance and longevity in harsh marine environments. Key considerations include corrosion resistance, strength, weight, cost, maintenance needs, and specific application requirements.

Corrosion resistance is paramount due to the constant exposure to saltwater and high humidity. Stainless steel, particularly grades 304 and 316, and copper-nickel alloys are well-regarded for their excellent resistance to corrosion. Strength and durability are also essential to withstand mechanical stresses and adverse weather conditions. While aluminum alloys are favored for their lightweight and cost-effectiveness, stainless steel offers superior durability, albeit at a higher cost.

Maintenance requirements vary, with stainless steel generally requiring less frequent upkeep compared to metals like aluminum and marine brass, which may need periodic inspections and protective coatings. Application-specific needs also dictate metal selection; for instance, bronze is ideal for propellers due to its low friction, whereas copper-nickel alloys are preferred for seawater systems because of their biofouling resistance.

Using marine-grade metals in shipbuilding and offshore structures offers several significant benefits. Firstly, these metals possess high corrosion resistance, which is crucial for longevity in harsh marine environments. Metals such as stainless steel and aluminum alloys can withstand the corrosive effects of seawater, reducing the need for frequent maintenance and replacements. Secondly, marine-grade metals have high tensile strength, ensuring structural integrity under the stress of strong waves and varying temperatures. This is essential for the safety and durability of ships and offshore platforms.

Additionally, some marine-grade metals, like copper-nickel alloys, exhibit natural anti-fouling properties, reducing biofouling and thereby minimizing maintenance costs and improving operational efficiency. These metals also contribute to sustainability, as they are often recyclable, reducing environmental impact. Their versatility allows them to be used in a wide range of maritime applications, adapting well to different marine conditions.

Maintenance requirements for marine-grade metals vary based on their type and application, but generally include regular cleaning, inspection, and protective measures.

For stainless steel, such as 316L, maintenance involves regular cleaning with mild soap solutions and soft cloths, rinsing with freshwater to remove salt deposits, thorough drying to prevent water spots, periodic inspections for signs of wear, and applying protective coatings to enhance corrosion resistance.

Aluminum alloys require cleaning with mild detergents, regular inspection for corrosion, maintaining or reapplying protective anodizing or painting, and preventing galvanic corrosion by avoiding direct contact with incompatible metals like stainless steel or copper.

Copper alloys, such as bronze, need cleaning with mild soap and water, regular inspection for green patina or corrosion, applying wax or specialized marine coatings, and insulating when in contact with other metals to prevent galvanic corrosion.

Titanium alloys, known for their high corrosion resistance and strength, should be cleaned with mild soap solutions and soft cloths, regularly inspected for wear or damage, stored in dry, clean environments, and handled carefully to avoid harsh chemicals or abrasives.

Common practices across all marine-grade metals include regular inspections for rust or damage, cleaning and rinsing to remove salt and debris, applying protective coatings, storing in dry environments, and avoiding harsh chemicals. Following these practices ensures the longevity and performance of marine-grade metals in harsh maritime environments.