Imagine a material that can be stretched, bent, and twisted, yet always returns to its original shape without permanent deformation. This remarkable capability is precisely what makes spring steel an invaluable resource across numerous industries. In this comprehensive guide, we will delve into the intricate properties that grant spring steel its unique resilience, explore the various types available, and uncover the myriad of applications that rely on its exceptional performance. Whether you’re involved in manufacturing, metalworking, or any sector that demands durable and reliable components, understanding the nuances of spring steel is crucial. Ready to discover why this material is the backbone of so many critical applications? Let’s dive in.

Spring steel is a material known for its high yield strength, making it incredibly resilient and elastic. It is specifically engineered to undergo significant deformation and return to its original shape, which makes it ideal for applications subjected to repeated stress and strain. These properties are crucial for manufacturing components like springs, machinery parts, and various tools.

In the manufacturing industry, spring steel is indispensable due to its ability to withstand high stress and maintain its form. It is used extensively in producing precision components that require consistent performance under dynamic loads. Examples include tension, compression, and torsion springs, which are essential in many mechanical systems.

Spring steel’s robustness is particularly valuable in metalworking, where it can endure repeated loading and unloading without losing shape. This makes it suitable for tools and dies, which must maintain their shape and sharpness over prolonged use. The high carbon content enhances its hardness, making spring steel perfect for cutting and shaping metal parts.

Spring steel’s unique combination of high yield strength, elasticity, and durability makes it a vital material in various industries, from manufacturing and metalworking to automotive and medical equipment. Its ability to maintain performance under dynamic conditions ensures its widespread use in applications that demand reliability and longevity.

One of the most important properties of spring steel is its tensile strength. High tensile strength is crucial for ensuring that components can handle heavy forces without breaking or permanently deforming, which is vital in automotive suspension systems, heavy machinery parts, and various types of springs.

Elasticity means that spring steel can return to its original shape after bending or stretching. This property is fundamental for applications that require the material to undergo repeated flexing or bending. Elasticity ensures that components like springs and clips can maintain their functionality over long periods, even when subjected to continuous stress. The elastic nature of spring steel makes it ideal for dynamic applications where flexibility and resilience are paramount.

Hardness is a measure of a material’s resistance to deformation, particularly permanent indentation. For spring steel, hardness is a vital property because it affects the material’s wear resistance and durability. Hardened spring steel is highly resistant to stress and wear, making it ideal for demanding environments. The hardness of spring steel is often enhanced through heat treatment processes, which increase its strength and prolong its service life.

Corrosion resistance is the ability of spring steel to resist degradation caused by environmental factors such as moisture, chemicals, and oxidation. This property is particularly important for components exposed to harsh conditions, such as outdoor or marine environments. Certain grades of spring steel are alloyed with elements like chromium to enhance their corrosion resistance. Improved corrosion resistance extends the lifespan of the material, reducing maintenance costs and ensuring reliable performance.

Toughness is the ability of spring steel to absorb energy and plastically deform without fracturing. This property is crucial for applications where the material must withstand impact or shock loading. Toughness combines both strength and ductility, allowing spring steel to endure sudden forces without breaking. This makes it suitable for critical components in automotive, aerospace, and industrial machinery that require both high strength and the ability to absorb impact.

Fatigue resistance means spring steel can handle repeated stress without breaking. This property is essential for components that undergo repetitive stress, such as springs and fasteners. High fatigue resistance ensures that spring steel can perform reliably over many cycles of loading and unloading. This makes it ideal for applications in automotive suspensions, engine components, and other dynamic systems where long-term durability is crucial.

Spring steel’s combination of high tensile strength, elasticity, hardness, corrosion resistance, toughness, and fatigue resistance makes it an indispensable material in various high-stress applications. Its unique properties ensure that it can perform reliably under dynamic and challenging conditions, making it a preferred choice in many industrial and manufacturing processes.

High carbon spring steel contains a relatively high carbon percentage, typically around 0.6% – 1.0%. This higher carbon content significantly enhances the steel’s strength and durability. Due to its low cost and wide availability, it is commonly used for general-purpose springs. However, it has limitations and is not suitable for applications involving high or low temperatures, nor for shock-loading situations as it may become brittle.

Alloy spring steel incorporates elements like chromium and silicon. These additional elements enhance the steel’s strength and temperature resistance. Its excellent fatigue resistance makes it ideal for high-stress and shock-loading applications. Examples of alloy spring steel include Chromium Vanadium (ASTM A231) and Chromium Silicon (ASTM A401), which are used in various heavy-duty mechanical components.

Stainless spring steel contains chromium and nickel, providing excellent corrosion resistance. This type of spring steel is suitable for environments where corrosion is a concern and can also perform well at sub-zero temperatures. For example, 18-8 stainless steel is often used where corrosion resistance and low-temperature performance are crucial.

Copper base spring alloys offer good conductivity and corrosion resistance. They are often used in electrical components because of their conductivity properties. Moreover, they can also function well at sub-zero temperatures, making them a suitable choice for electrical applications in cold environments.

Nickel base spring alloys are known for their corrosion resistance and high-temperature stability. Alloys like Inconel, Monel, and Elgiloy (Phynox) fall into this category. These alloys are ideal for maintaining properties in harsh chemical environments and high temperatures, such as in aerospace and chemical processing industries.

Spring steel is the primary material for manufacturing various springs. Compression springs, for example, are used in automotive suspension systems to absorb shock and provide a smooth ride. They can withstand high compressive forces and return to their original shape after the load is removed. Torsion springs are employed in garage doors, where they store and release energy to facilitate the opening and closing process. These springs must have high fatigue resistance to endure repeated twisting motions. Extension springs are commonly found in trampolines and industrial equipment, providing a pulling force and maintaining their elasticity over long periods.

In the field of fasteners, spring steel plays a crucial role. Spring washers, made from spring steel, are used to prevent nuts and bolts from loosening due to shaking. Their elasticity allows them to exert a constant force on the fastener, ensuring a secure connection. Retaining rings, another type of fastener, are also often made from spring steel. They are used to hold components on a shaft or in a housing, and their ability to flex and snap into place makes them easy to install and remove.

Spring steel is widely used in machinery to enhance performance. In engines, valve springs made from spring steel open and close the engine’s valves at the right time, ensuring efficient combustion and enduring the high-speed, repeated movements in the engine. In conveyor systems, tension springs made from spring steel are used to maintain the proper tension of the conveyor belt, ensuring smooth and efficient operation.

Beyond suspension springs, spring steel is used in many other automotive parts. Clutch springs engage and disengage the clutch, enabling smooth gear changes, which is crucial for the proper functioning of the clutch system. Brake return springs are used to return the brake shoes or pads to their original position after braking, ensuring reliable braking performance.

In the medical field, spring steel is used in surgical tools. Forceps made from spring steel can easily grasp and hold tissues during surgery, providing precise control and minimizing damage to surrounding areas. Orthodontic appliances, such as braces, also utilize spring steel. The springs in braces apply gentle, continuous force to move teeth into the correct position over time.

Hand tools like pliers and wrenches benefit from the properties of spring steel. The strong, spring steel jaws of pliers provide a powerful grip, while the spring-loaded handles allow for easy opening and closing, making them indispensable in any toolbox. Wrenches made from spring steel can withstand high torque without deforming, ensuring accurate tightening and loosening of nuts and bolts.

In the aerospace industry, spring steel is used in critical components. Landing gear systems rely on springs made from spring steel to absorb the shock of landing and provide a smooth touchdown. Control mechanisms, such as those used in aircraft flaps and ailerons, use spring steel components to ensure precise movement and reliable operation. Structural reinforcements made from spring steel help to strengthen the aircraft’s frame and withstand the high stresses during flight.

Spring steel is used in the production of electrical connectors, switches, and relays. Electrical connectors made from spring steel can maintain a good electrical contact by exerting a constant pressure on the mating parts. This ensures reliable electrical conductivity. In switches and relays, spring steel components are used to provide the necessary mechanical action for opening and closing electrical circuits, and their durability ensures long-term operation.

In construction, spring steel is used for manufacturing clamps, saw blades, and industrial springs. Clamps made from spring steel can hold materials firmly in place during construction work. Saw blades made from spring steel are strong and flexible, allowing for efficient cutting of various materials. Industrial springs used in construction equipment, such as cranes and elevators, must be able to withstand high loads and repeated use.

Spring steel, integral to numerous industrial applications, is governed by a comprehensive set of global standards ensuring its quality, safety, and performance. These standards are established by organizations such as the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), Deutsches Institut für Normung (DIN), and the Japanese Industrial Standards (JIS). These standards cover aspects like material composition, mechanical properties, manufacturing processes, and testing methodologies.

The ISO 683 series is particularly relevant for spring steel. ISO 683-14, for example, specifies the requirements for heat-treatable steels, alloy steels, and free-cutting steels, ensuring the steel can endure necessary heat treatment processes to achieve desired mechanical properties.

ASTM standards are widely recognized in the industry for their rigorous specifications. ASTM A228, for example, covers the requirements for high-carbon steel wire used in the production of mechanical springs. Another important standard, ASTM A401, specifies the requirements for chromium-silicon alloy steel wire used for high-stress applications. These standards ensure that the materials used in spring manufacturing meet stringent criteria for strength, durability, and performance.

DIN standards, such as DIN 17223, and JIS standards like JIS G 3560, are crucial for manufacturers who need to comply with European and Japanese regulations. These standards provide detailed guidelines on the composition, mechanical properties, and testing methods for spring steel, ensuring that products meet local quality and safety requirements.

Choosing the right grade of spring steel is crucial for compliance. Each application has specific requirements that dictate the choice of material. For instance, high-carbon steel grades like AISI 1074 or AISI 1095 are preferred for their high strength and excellent elasticity, making them suitable for high-performance springs. However, these materials must meet the compositional and mechanical property requirements specified in the relevant standards.

The manufacturing processes for spring steel, such as quenching and tempering, are critical to achieving the desired mechanical properties. Compliance with standards like SAE J2329, which governs heat treatment processes for spring steel, ensures that the material attains the necessary hardness and strength. Adhering to these standards is particularly important in aerospace applications, where stringent process controls are mandatory.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) and the Restriction of Hazardous Substances (RoHS) directives are significant. These regulations address the environmental and health impacts of materials used in manufacturing. Companies exporting to the EU must comply with these directives, which mandate safer substances and the reduction of hazardous materials in products.

Implementing a robust quality management system, such as ISO 9001:2015, is vital for ensuring compliance with international standards. This system provides a framework for continuous improvement, monitoring, and documentation, which helps manufacturers maintain consistent quality and meet regulatory requirements. It involves regular audits, training, and process evaluations to ensure that all aspects of production adhere to the established standards.

The evolving landscape of global standards presents both challenges and opportunities for spring steel manufacturers. Adapting to new materials and technologies while meeting increasingly stringent environmental and sustainability standards will require innovation and agility. Manufacturers that lead in sustainability and compliance can differentiate themselves in the market, driving growth and establishing themselves as industry leaders.

Emerging trends include the development of new alloys with enhanced properties, such as higher strength and better corrosion resistance, and the integration of advanced manufacturing techniques like additive manufacturing. Staying abreast of these trends and proactively adapting to new standards will be crucial for maintaining competitive advantage.

Below are answers to some frequently asked questions:

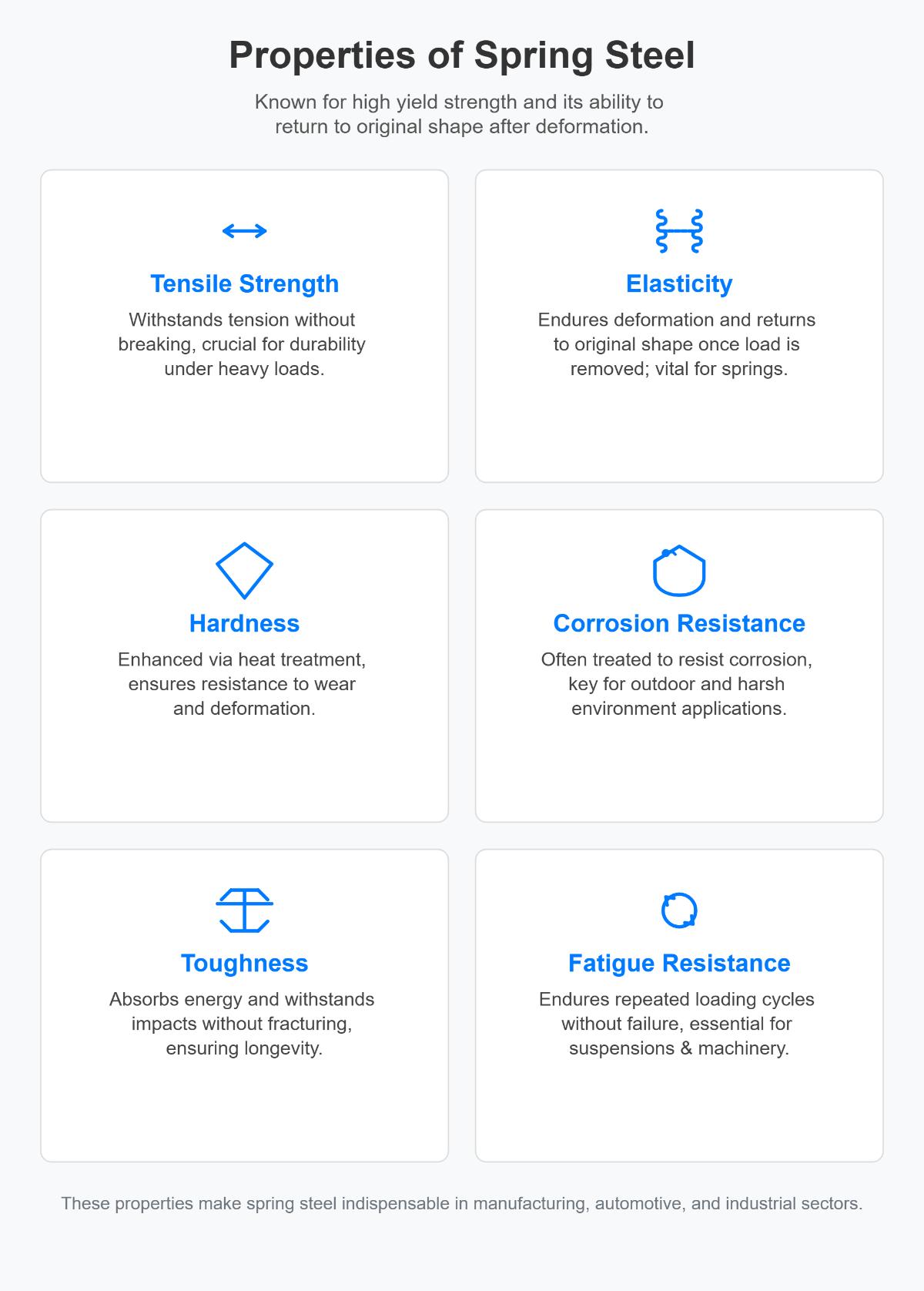

Spring steel is a type of steel known for its high yield strength, which enables it to return to its original shape despite significant bending or twisting. Key properties of spring steel include:

These properties collectively make spring steel indispensable in manufacturing, automotive, and industrial sectors.

Spring steel comes in several types, each with distinct characteristics and applications. High carbon spring steel is low – cost, easy to work with, and widely available, used for general – purpose springs. Alloy spring steel is suitable for high – stress, shock, or impact loadings and a wider temperature range, often used in automotive and machinery parts. Stainless spring steel is corrosion – resistant, used in medical instruments and food processing equipment. Copper base spring alloys have high conductivity and corrosion resistance, ideal for electrical components. Nickel base spring alloys are non – magnetic with good corrosion resistance, used in high – temperature and marine environments.

Spring steel, known for its high yield strength, elasticity, and durability, finds widespread applications across various industries. In the automotive sector, it’s used in suspension systems, clutch and valve springs, and seat springs. The aerospace industry employs it in landing gear springs, control cables, and spring washers. Industrial equipment uses spring steel in machinery springs, cutting tools, and conveyor belts. In medical devices, it’s found in surgical instruments, orthopedic implants, and dental tools. Consumer products like furniture, hand tools, and toys also utilize spring steel. Other applications include construction reinforcement, electrical connectors, musical instruments, and lockpicks.

Choosing the right type of spring steel for your application involves evaluating several key factors to ensure optimal performance and longevity. First, consider the environmental conditions where the steel will be used. For high-temperature applications, nickel alloys are suitable, while stainless steel grades like 301 and 302 are ideal for high humidity environments due to their corrosion resistance.

Next, assess the load and stress requirements. High yield strength is crucial for maintaining shape under stress, making materials like AISI 1095 suitable for demanding applications. Additionally, elasticity and fatigue resistance are important for applications involving repeated flexing, with materials such as 50CrV4 offering high fatigue resistance.

Design and performance requirements also play a significant role. Formability is essential for shaping the material, with annealed spring steels like AISI 1050 being more formable. Cost and availability should be evaluated to ensure the material is cost-effective and readily available for your project.

High carbon spring steels (e.g., AISI 1074/1075, AISI 1095) offer high hardness and elasticity, while alloy spring steels (e.g., 5160 grade, 50CrV4) provide enhanced strength and fatigue resistance. Stainless spring steels (e.g., AISI 301, AISI 302) are chosen for their high corrosion resistance, suitable for moisture or chemical exposure environments. Specialized alloys like music wire (ASTM A228) are used for general-purpose springs due to their high strength and cost-effectiveness.

By considering these factors and consulting with experts, you can select the most appropriate spring steel for your specific application needs.

Emerging trends in spring steel materials highlight advancements in processing techniques, sustainability, smart manufacturing, enhanced performance, expanding applications, customization, and regulatory compliance. Recent innovations like microalloying improve the strength-to-weight ratio, crucial for industries like automotive and aerospace. Sustainability initiatives focus on reducing carbon emissions and incorporating recycled materials. Smart manufacturing technologies such as AI and automation enhance efficiency and quality control in production. New spring steel grades with higher tensile and fatigue strengths are being developed for demanding applications. The versatility of spring steel is expanding its use in medical instruments, consumer electronics, and renewable energy. Customization efforts are tailoring spring steel to specific industry needs, while adherence to stringent quality and environmental standards ensures product reliability. These trends collectively drive the evolution of spring steel, making it a vital material across diverse sectors.

Industry standards and compliance are crucial for spring steel because they ensure the material meets stringent quality, safety, and performance benchmarks essential for its diverse applications. Standards such as ISO and ASTM provide guidelines on material properties, manufacturing processes, and testing methods. These guidelines ensure that spring steel maintains high yield strength, elasticity, fatigue resistance, and corrosion resistance, which are vital for reliable performance in critical components like automotive and aerospace parts.

Adhering to these standards also guarantees the safety and durability of spring steel products. Compliance with regulatory requirements minimizes legal risks and enhances the manufacturer’s reputation. Regular testing and certification, as mandated by industry standards, extend the lifespan of spring steel components, reducing maintenance costs and preventing premature failures. Thus, industry standards and compliance are indispensable for ensuring the consistent quality and reliability of spring steel in various demanding applications.