In the world of high – performance steels, finding a material that combines strength, durability, and resistance to wear can be a significant challenge. Hardox 500 emerges as a remarkable solution. Composed of a precise blend of alloy elements like carbon, chromium, and molybdenum, it boasts outstanding mechanical properties, including high hardness, excellent abrasion and impact resistance. These qualities make it a go – to choice in industries such as mining, construction, and transportation. But what makes its chemical makeup so unique, and how do its properties translate into real – world applications? Let’s delve deeper.

Hardox 500 is a high-strength, abrasion-resistant steel plate known for its exceptional performance in demanding industrial applications. This performance is achieved through a well-engineered chemical composition that balances various alloying elements to optimize hardness, toughness, corrosion resistance, and weldability.

Grain refinement is done to the steel to improve its mechanical properties. This process ensures uniform performance throughout the material thickness, making Hardox 500 a reliable choice for a wide range of industrial applications.

Hardness and yield strength are crucial mechanical properties that define the performance of Hardox 500 in industrial applications.

Abrasion resistance refers to the ability of Hardox 500 to withstand wear caused by friction and contact with other materials. This property is vital for industries where components are exposed to harsh environments and require long-lasting durability.

Compared to other steels, such as AR400 and AR450, Hardox 500 offers superior abrasion resistance due to its high hardness and toughness. This makes it a preferred choice for applications like mining machinery, construction equipment, and industrial hoppers, where wear and tear are significant concerns.

Impact resistance is the ability of Hardox 500 to absorb energy during sudden impacts without fracturing. This property is crucial for materials used in heavy-duty applications where mechanical shocks are common.

Impact resistance is typically measured using the Charpy V-notch test. For Hardox 500, the Charpy V-notch impact energy values are around 37 J at -40°C for longitudinal tests on 10×10 mm specimens. This means that Hardox 500 can absorb a significant amount of energy during impacts, making it suitable for use in environments where low temperatures and mechanical shocks are prevalent.

Toughness is the ability of Hardox 500 to absorb energy and deform plastically before fracturing. This property, combined with high hardness, contributes to the material’s exceptional wear resistance and durability, making it suitable for demanding applications such as in mining, construction, and heavy machinery.

Several case studies demonstrate the superior performance of Hardox 500 in demanding applications. For instance, in mining operations, equipment made from Hardox 500 has shown significantly longer service life and reduced maintenance compared to standard steel grades.

Hardox 500’s combination of high hardness, yield strength, impact resistance, and toughness makes it suitable for various industrial applications. Key uses include:

These properties make Hardox 500 a reliable choice for industries requiring durable, abrasion-resistant materials.

Hardox 500 is well-known for its great wear resistance and toughness, making it a top choice in various demanding industries. Here are some key applications:

In the mining industry, Hardox 500 is used in equipment that faces severe wear and tear.

Hardox 500’s robustness and impact resistance make it ideal for construction and transportation machinery.

Hardox 500 is also used in industrial hoppers and dump truck bodies, where abrasion resistance is critical. The material’s high hardness and toughness enable these components to handle heavy and abrasive materials efficiently, reducing the frequency of replacements and repairs.

Hardox 500 offers several advantages in harsh environments, including:

Using Hardox 500 in equipment and machinery reduces downtime caused by wear and tear. This saves costs and boosts productivity.

Hardox 500 is renowned for its excellent weldability, making it suitable for various industrial applications. Common welding methods include Manual Metal Arc (MMA), Submerged Arc Welding (SAW), Metal Inert Gas/Metal Active Gas (MIG/MAG), and Flux-Cored Arc Welding (FCAW).

To achieve optimal results, follow these best practices:

Bending and forming Hardox 500 require careful handling due to its high hardness and strength. Here are some guidelines:

Cutting and machining Hardox 500 can be challenging due to its hardness. Suitable methods include:

Proper cutting and machining techniques are crucial to preserving the mechanical properties of Hardox 500. Thermal cutting should be performed with controlled heat input to avoid affecting the steel’s microstructure. Mechanical cutting and machining must be done with sharp, durable tools to maintain the surface integrity and minimize the formation of heat-affected zones. It is also important to use appropriate cutting speeds, feeds, and cooling methods to prevent excessive wear or damage to the tools and the material.

When comparing Hardox 500 to other abrasion-resistant steels, several key performance metrics come into play: hardness, yield strength, wear resistance, and impact toughness. Hardox 500 stands out due to its balanced combination of these properties, making it a preferred choice in demanding applications.

Hardox 500 has a nominal hardness of about 500 HBW, which is higher than that of many other abrasion-resistant steels like AR400 and AR450. This high hardness translates to superior wear resistance, reducing the frequency of maintenance and replacements in industrial settings.

Yield strength is another critical parameter where Hardox 500 excels. With a typical yield strength around 1400 MPa, Hardox 500 can endure heavy loads and mechanical stresses without losing its shape. This makes it ideal for applications requiring robust structural integrity, such as mining machinery and construction equipment.

Wear resistance is the ability of a material to resist abrasion and surface damage caused by friction and contact with other materials. Hardox 500’s high hardness and optimized chemical composition, including elements like chromium and molybdenum, significantly enhance its wear resistance. This property is crucial for industries where equipment is exposed to abrasive environments, such as mining and earth-moving machinery.

Hardox 500 outperforms steels like NM500 and AR450 in wear resistance, crucial for prolonging the life of industrial components. For example, in mining operations, equipment made from Hardox 500 typically lasts longer and requires less frequent maintenance, leading to higher productivity and lower operational costs.

Impact toughness measures a material’s ability to absorb energy during sudden impacts without fracturing. Hardox 500 has an impressive impact toughness, with Charpy V-notch values around 37 J at -40°C. This high impact toughness ensures that Hardox 500 can handle mechanical shocks and impacts, making it suitable for applications in harsh environments.

Impact toughness is measured by tests like the Charpy V-notch test. Hardox 500 excels in these tests, showcasing its ability to withstand sudden mechanical stresses—a major advantage over other steels that might crack or fail.

Hardox 500 is highly regarded for its weldability and machinability, supporting conventional welding methods such as MMA, MIG/MAG, and FCAW without the need for preheating or postheating. This is due to its low carbon equivalent and high-temperature strength, which facilitate easy processing and fabrication. In comparison, other abrasion-resistant steels may require more stringent welding procedures and preheat treatments, complicating the fabrication process.

Industry case studies show Hardox 500’s success across various sectors. For example, in mining, crusher liners made from Hardox 500 last much longer than those made from AR450, reducing downtime and maintenance costs. Similarly, construction equipment such as excavator buckets and bulldozer blades benefit from Hardox 500’s superior wear resistance and toughness, enhancing operational efficiency and durability.

Conversely, some case studies reveal the limitations of other abrasion-resistant steels in comparison to Hardox 500. For example, components made from NM500 may exhibit premature wear and cracking under high-stress conditions, leading to increased maintenance and operational disruptions.

While Hardox 500 may have a higher initial cost than some other abrasion-resistant steels, its long-term benefits in terms of reduced maintenance, extended service life, and improved performance often outweigh the upfront investment. This cost-effectiveness is particularly evident in industries where equipment downtime and maintenance costs can significantly impact overall productivity and profitability.

To aid in the selection process, interactive comparison tools and property calculators can be utilized. These tools allow engineers and procurement specialists to compare key properties, such as hardness, yield strength, and impact toughness, across different abrasion-resistant steels, facilitating informed decision-making based on specific application requirements.

Below are answers to some frequently asked questions:

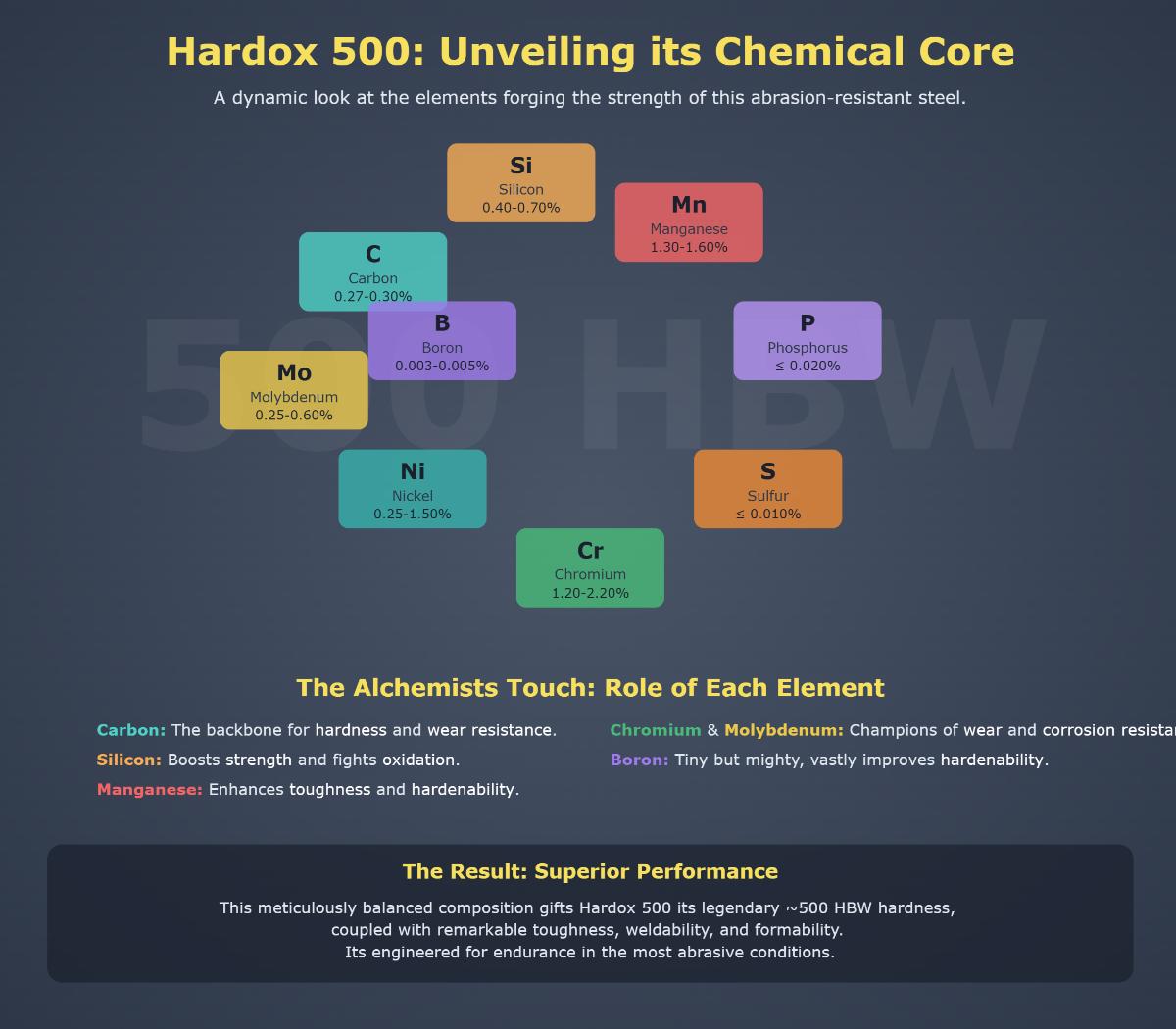

Hardox 500 steel is an abrasion-resistant steel plate known for its high hardness and excellent wear resistance. The chemical composition of Hardox 500 includes a combination of elements that contribute to its superior properties. The typical chemical composition, expressed as maximum or range percentages by weight, is as follows:

Each element in this alloy serves a specific purpose: carbon enhances hardness and wear resistance, silicon improves strength and oxidation resistance, manganese contributes to toughness and hardenability, and chromium and molybdenum enhance wear and corrosion resistance. The small addition of boron significantly improves hardenability. This balanced composition ensures Hardox 500 achieves its nominal hardness of approximately 500 HBW while maintaining good toughness, weldability, and formability.

Hardox 500 steel plate is known for its exceptional hardness, high yield strength, and impressive impact resistance. With a nominal hardness of 500 HBW (Brinell hardness), it offers superior abrasion resistance, making it ideal for demanding applications in industries like mining, construction, and transportation. The yield strength of Hardox 500 typically measures around 1400 MPa, providing robust structural support. Additionally, it exhibits good impact resistance, with an impact energy of 37 J at -40°C, ensuring durability under harsh conditions. The steel plate is also highly formable and weldable, allowing for versatile processing and fabrication. These properties contribute to its extended service life, reduced maintenance needs, and reliable performance in abrasive and corrosive environments.

Hardox 500, a high-performance abrasion-resistant steel, finds applications across multiple industries. In construction and heavy machinery, it’s used for dump trucks, bulldozers, and crane buckets. Mining and quarrying benefit from it in crusher liners and conveyor belts. Recycling and demolition use it in shredders and balers. In agriculture, it’s applied to ploughs and harvesters. Transportation relies on it for truck bodies and trailers. Industrial machinery and material handling use it for liner plates and crushers. Defense and military applications also employ it for body armor and vehicle armor due to its high toughness and impact resistance.

Hardox 500 stands out among abrasion-resistant steels due to its unique balance of hardness, toughness, and weldability. With a nominal hardness of 500 HBW, it offers superior wear resistance compared to other steels like NM500 and EH500. One of its key advantages is its low carbon equivalent, which enhances weldability without the need for preheating—a significant benefit over some other wear-resistant steels that require more stringent welding conditions.

In terms of toughness, Hardox 500 performs well even at low temperatures, maintaining its structural integrity and resistance to impact forces. This makes it suitable for applications in cold environments. Additionally, the inclusion of elements like chromium and nickel not only improves hardness but also provides enhanced corrosion resistance, extending the service life of components used in harsh conditions.

Hardox 500 is also highly bendable and available in a wide range of thicknesses and dimensions, making it versatile for various industrial applications. Its consistent performance in terms of wear resistance, ease of fabrication, and durability makes it a preferred choice over other abrasion-resistant steels for demanding environments such as mining, construction, and heavy machinery.

Yes, Hardox 500 steel is both weldable and bendable. It’s designed for weldability using standard procedures, but requires appropriate consumables and techniques. Precautions like following health and safety protocols are necessary, and prolonged exposure to high temperatures during welding should be avoided to prevent altering its mechanical properties. Its through-hardened structure maintains wear resistance post-welding. For bendability, it offers optimized performance in plate and sheet formats, complying with Hardox® Bending Guarantees Class F for plates and Class C for sheets, with bendability influenced by thickness.

Hardox 500 complies with several standards related to its mechanical properties and processing. For hardness, it adheres to EN ISO 6506-1, ensuring a nominal hardness of 470–540 HBW, depending on the thickness. The steel’s flatness and dimensional tolerances meet stricter-than-EN 10 029 Class N standards, while its thickness tolerance complies with AccuRollTech, surpassing EN 10 029 Class A. Impact testing is conducted per ISO EN 148, with typical values showing 27 J at 0°C for transverse tests and 37 J at -40°C for longitudinal tests. These standards ensure Hardox 500’s high performance in terms of wear resistance, toughness, and dimensional accuracy, making it suitable for demanding industrial applications.