Imagine a world where a single material could revolutionize industries ranging from packaging to construction, all while being incredibly durable and environmentally friendly. Enter High Density Polyethylene, or HDPE—a versatile thermoplastic polymer that has become a cornerstone in modern manufacturing and daily life. But what exactly is HDPE, and why is it so highly regarded? In this comprehensive guide, we’ll explore the origins and properties of HDPE, its wide-ranging applications, and the fascinating manufacturing processes behind it. Whether you’re curious about its role in the packaging industry or how it supports sustainability efforts, this article will provide all the answers. Ready to discover why HDPE is making such a big impact? Let’s dive in!

High-Density Polyethylene (HDPE) is a type of durable plastic made from petroleum. This material has long chains of ethylene molecules, giving it high density and strength. HDPE was first synthesized in the 1950s and has since become one of the most widely used plastics due to its versatility and durability.

Polyethylene (PE) is a family of polymers that includes several different types, each with distinct properties:

Thermoplastics, like HDPE, become moldable when heated and solidify when cooled. This makes them valuable in manufacturing because they can be easily reshaped. Thermoplastics are used in various industries, from packaging and automotive to construction and consumer goods.

Petroleum is essential for producing HDPE. The process starts with extracting ethylene from crude oil through cracking, then polymerizing the ethylene to form polyethylene. This reliance on petroleum highlights the importance of sustainable practices and recycling to reduce environmental impact.

High-Density Polyethylene (HDPE) stands out for its remarkable strength-to-density ratio. HDPE typically has a density ranging from 0.93 to 0.97 g/cm³, making it both strong and lightweight—a balance crucial for applications requiring durable yet lightweight materials like pipes and containers.

HDPE can flex without breaking, making it ideal for products that need to handle physical stress and impacts. Its impact resistance ensures that it can absorb and dissipate energy from impacts, preventing cracks and damage.

HDPE is highly resistant to a variety of chemicals, including acids, bases, and solvents. This resistance makes it an ideal material for containers and pipes that need to transport or store reactive substances without degrading.

The chemical inertness of HDPE ensures that it does not react with the substances it comes into contact with. This property is especially important in applications involving food and beverages, where contamination must be avoided.

HDPE’s durability allows it to withstand harsh environmental conditions such as extreme temperatures and UV radiation, making it suitable for outdoor applications.

One of the significant environmental benefits of HDPE is its recyclability. HDPE products can be recycled and repurposed, reducing waste and environmental impact. This makes HDPE a sustainable choice in various industries.

HDPE has very low moisture absorption, ensuring that it remains stable and retains its mechanical properties even in humid environments. This property is essential for applications like water pipes and storage tanks.

HDPE is an excellent electrical insulator, which makes it suitable for use in electrical and telecommunications industries. Its insulating properties protect against electrical leakage and short circuits.

HDPE’s unique combination of strength, flexibility, chemical resistance, and environmental friendliness makes it a versatile material for numerous applications across different industries.

HDPE is a preferred material for water and gas distribution pipes due to its durability and long lifespan. Its resistance to chemicals ensures these pipes won’t corrode when transporting various substances. The ease of installation reduces labor time and costs, making it a cost-effective solution for large-scale infrastructure projects. It is also used in sewage mains and natural gas distribution systems, where its reliability is crucial for public safety.

HDPE is used in geomembranes for hydraulic applications, acting as a barrier to prevent the leakage of water or other fluids. Its weather resistance and durability make it suitable for long-term use in building structures, protecting them from environmental factors and extending their lifespan.

As a good electrical insulator, HDPE protects wires and cables from moisture and chemicals. This protection reduces the risk of electrical leakage and short circuits, ensuring the safety and proper functioning of electrical systems.

HDPE is commonly used in blow-molded bottles for food and beverages. It doesn’t release harmful substances into food or drinks, ensuring consumer safety. It also provides a good moisture barrier, keeping the contents fresh for longer.

Outdoor toys and playground equipment made of HDPE benefit from its UV resistance. This property ensures that the equipment won’t degrade quickly under the sun’s rays, providing a long-lasting and safe play environment for children.

HDPE’s chemical resistance makes it ideal for storing chemicals like laundry detergent, shampoo, and motor oil. It can safely hold these substances without reacting with them, preventing spills and leaks that could be hazardous.

HDPE is commonly used for medical tubing, implants, and packaging. Its biocompatibility means it can be in contact with the human body without causing adverse reactions. The moisture and chemical resistance also ensure the sterility and integrity of medical products.

Medical supplies need to be stored in a safe and durable environment. HDPE medical containers provide this, protecting the supplies from damage and contamination.

In the automotive industry, HDPE is used for fuel tanks and other parts. Its durability and chemical resistance make it suitable for holding fuel and withstanding the harsh conditions inside a vehicle.

For boat components and pool equipment, HDPE’s UV resistance and durability are key. It can withstand constant exposure to sunlight and water, ensuring a long service life in these marine environments.

HDPE geomembranes are used in landfills to prevent soil and groundwater pollution. Their chemical resistance stops harmful substances from seeping into the environment, protecting the ecosystem.

In agriculture, HDPE is widely used in irrigation systems and greenhouse films. Its durability and resistance to environmental factors make it suitable for withstanding the rigors of outdoor use, helping to improve agricultural productivity.

The manufacturing process of High-Density Polyethylene (HDPE) starts with preparing the raw material, which is derived from petroleum-based hydrocarbons. Initially, these hydrocarbons are broken down into ethylene molecules through a process known as cracking. This process involves heating the hydrocarbons to high temperatures until they decompose into simpler molecules like ethylene gas, which is then collected for the next stage.

Polymerization is a critical step where ethylene molecules are transformed into polyethylene. Catalysts such as Ziegler-Natta, metallocene, or activated chromium oxide (Phillips catalyst) play a vital role in this process. These catalysts facilitate the bonding of ethylene monomers into long polymer chains with minimal branching. The catalysts ensure that the polyethylene formed is dense and strong, resulting in high-quality HDPE.

After polymerization, the mixture contains both polyethylene and the solvent used during the process. The separation involves using a centrifuge or a decanter to isolate the polyethylene from the solvent. The wet HDPE powder is then dried, often using a drying oven or a fluidized bed dryer. The solvent is recycled for future use, ensuring efficient resource utilization and minimal waste.

The dried HDPE powder is melted and extruded into long strands, which are then cut into small, uniform pellets. These pellets are the raw material for various HDPE products and are easy to transport and handle. For applications requiring HDPE sheets, the pellets are re-melted and extruded through a flat die to form a continuous sheet. The thickness and width of the sheet are carefully controlled during this process.

The molten HDPE is forced through a flat die to create a continuous sheet. After exiting the die, the sheet is cooled using air and water to solidify it. The cooling process ensures that the sheet maintains its shape and properties.

Once the HDPE sheet has solidified, it is pulled off the extrusion line using rollers or a conveyor system. The edges of the sheet are trimmed to achieve the desired dimensions, ensuring uniformity and precision in the final product.

To enhance dimensional stability and relieve internal stresses, the HDPE sheet may undergo annealing. This process involves heating the sheet to a specific temperature range, typically between 120°C and 150°C, and then allowing it to cool slowly at a controlled rate. Annealing improves the mechanical properties of the HDPE sheet, making it more durable and reliable for various applications.

The final stage of the HDPE manufacturing process involves rigorous quality control checks. The sheets are inspected for consistency in thickness, dimensions, and overall surface quality. Any defects or irregularities are identified and addressed to ensure that the final product meets the required standards. Once the quality control checks are completed, the HDPE sheets are carefully packaged to prevent any damage during transportation.

Below are answers to some frequently asked questions:

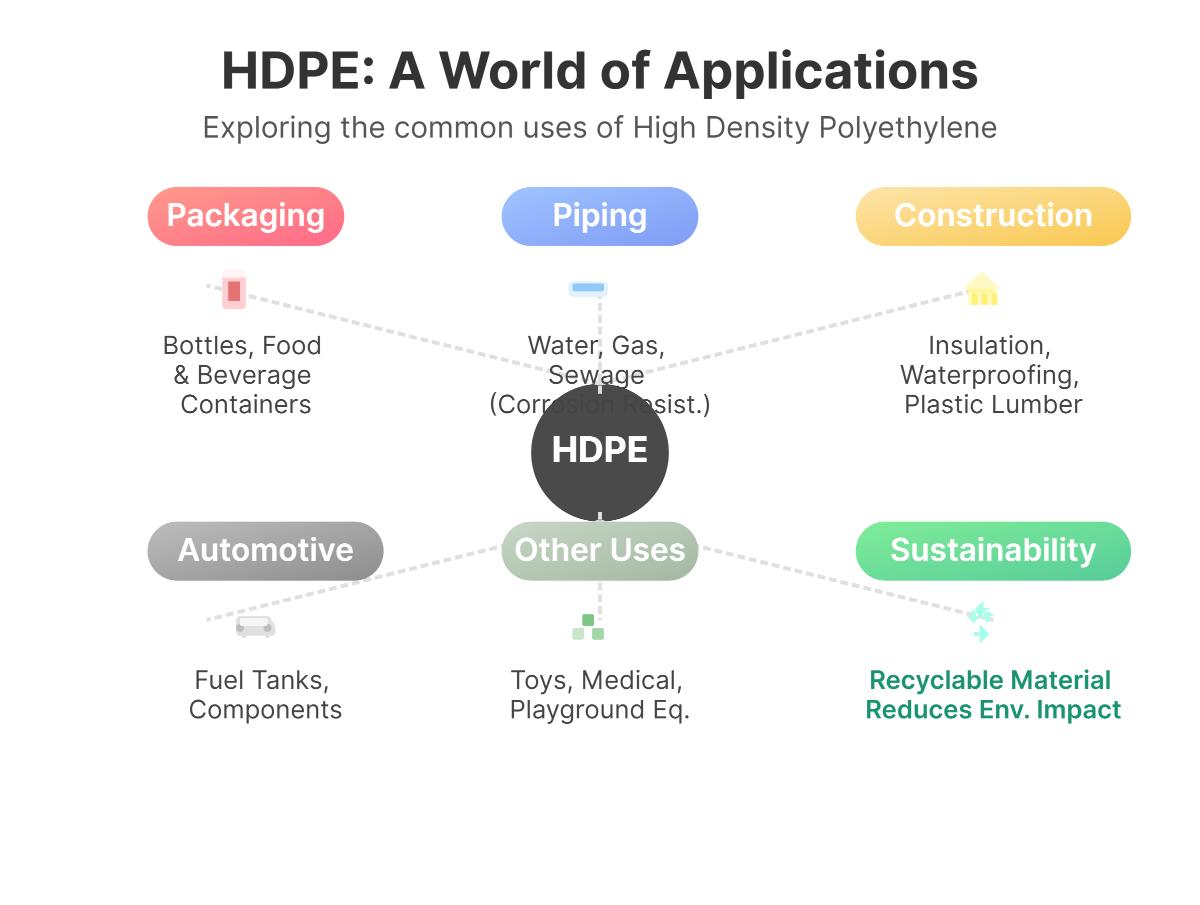

High Density Polyethylene (HDPE) is a versatile thermoplastic polymer with a wide range of common uses due to its high strength, impact resistance, and chemical inertness. In the packaging industry, HDPE is widely used to produce plastic bottles for milk, detergents, and other liquids. It is also used for food and beverage containers because it meets food-grade standards. In the piping and plumbing sectors, HDPE is valued for its resistance to corrosion and is used for water, gas, and sewage systems. The construction industry utilizes HDPE for building insulation, waterproofing materials, and plastic lumber, which is used for outdoor decking and structures. Additionally, HDPE finds applications in the automotive industry for fuel tanks and other components, and it is used to manufacture durable toys, playground equipment, and medical devices. Its recyclability also supports sustainability efforts by reducing environmental impact.

HDPE, or High Density Polyethylene, is manufactured through a process that starts with the preparation of raw materials. Ethylene, derived from petroleum, serves as the primary building block. The manufacturing process typically includes several key steps:

This process ensures the production of a strong, chemically resistant, and versatile plastic used in numerous applications.

High-density polyethylene (HDPE) is known for several notable properties that make it a versatile and widely used material. It has a high strength-to-density ratio, providing excellent durability while remaining lightweight. This makes HDPE suitable for applications that require both sturdiness and ease of handling. HDPE also exhibits exceptional chemical and corrosion resistance, allowing it to withstand exposure to various acids, bases, oils, and solvents without degrading.

Another significant property is its moldability; HDPE can be easily shaped into different forms when heated, making it useful for manufacturing diverse products like bottles and plastic lumber. It is also non-leaching and approved for food contact, ensuring safety for food and beverage storage. Additionally, HDPE is highly recyclable, promoting environmental sustainability.

HDPE is known for its impact resistance and durability, making it less prone to dents and scratches, which is ideal for heavy-duty uses. Its low moisture absorption is beneficial in marine applications, and it has a melting point of around 131.8°C, allowing it to endure moderate temperatures. These properties collectively contribute to HDPE’s widespread application in packaging, construction, automotive, and various other industries.

HDPE, or High Density Polyethylene, is favored over other materials for several reasons. First, it boasts a high strength-to-weight ratio, making it both strong and lightweight, which is particularly advantageous in applications where reducing weight is crucial. Additionally, HDPE has excellent chemical resistance, meaning it can withstand exposure to various chemicals without degrading, making it ideal for packaging and storing food, beverages, and chemicals.

Its durability and impact resistance allow it to endure heavy impacts without breaking, which is essential for construction and piping applications. HDPE is also highly processable; it can be easily molded, welded, and shaped using various manufacturing techniques, enhancing its versatility. Moreover, it can be made UV-resistant with the addition of stabilizers, extending its lifespan in outdoor environments.

Lastly, HDPE is environmentally friendly as it is recyclable, reducing its environmental footprint. These properties collectively make HDPE a preferred material in numerous industries, including packaging, construction, automotive, and more.

HDPE supports sustainability efforts in multiple ways. It has a high recycling rate, which can be transformed into various new products like bottles and pipes, reducing landfill waste and promoting a circular economy. Its production requires less energy, cutting down on carbon emissions and resource consumption compared to other materials. The material’s durability and long lifespan mean fewer replacements and less waste. Being lightweight, it reduces carbon emissions during transportation. Moreover, its chemical resistance and non – toxicity make it suitable for food packaging and medical equipment, and it can maintain performance in different environments, extending its useful life.

HDPE (High Density Polyethylene) is a widely used plastic known for its strength and durability. However, several challenges arise with its usage.

Environmentally, HDPE is non-biodegradable, persisting in the environment for centuries and contributing to pollution. Improper disposal can lead to soil infertility and water pollution, impacting marine life. Additionally, incinerating HDPE releases harmful greenhouse gases, exacerbating global warming.

Material-wise, HDPE is highly flammable and sensitive to stress cracking, especially when exposed to certain chemicals. It also has poor weathering resistance, becoming brittle and degrading under UV light, which limits its use in outdoor applications.

Recycling HDPE presents its own set of difficulties. Contamination with other plastics like polypropylene can degrade the quality of recycled HDPE, making it unsuitable for certain applications. The current recycling infrastructure often struggles with the size and weight of HDPE products, and sorting HDPE from mixed waste streams can be labor-intensive and costly.

Despite these challenges, advancements in recycling technologies and increased public awareness can help mitigate some of these issues.