In the world of electronic devices and industrial equipment, mastering the art of heat sink design is crucial for optimal thermal management. This comprehensive guide takes you on a step-by-step journey through the intricacies of heat sink design, revealing key principles and guidelines that are essential for intermediate-level enthusiasts. You’ll delve into the science behind thermal efficiency, explore strategies to optimize heat dissipation, and uncover the materials that drive performance excellence. Whether you’re curious about the pros and cons of aluminum versus copper, or eager to understand how fin designs impact thermal performance, this guide is tailored to enhance your understanding. Ready to elevate your heat sink design skills and ensure your devices stay cool under pressure? Let’s dive in!

Heat sink design is an engineering discipline focused on effectively managing the heat generated by electronic components and industrial equipment. The primary goal is to dissipate heat away from the components to ensure their optimal performance and longevity. This involves a deep understanding of thermal principles, material science, and fluid dynamics, combined with practical design strategies that maximize cooling efficiency.

Effective heat sink design begins with accurately understanding the thermal management needs of the component or device. This includes:

These parameters guide the design by dictating how efficiently the heat sink must transfer heat away from the component to maintain safe operating temperatures.

Choosing materials like aluminum and copper, which have high thermal conductivity, is crucial. Aluminum is lightweight and cost-effective, while copper offers superior conductivity but at a higher price and weight. The base plate and fins of the heat sink are typically made from these metals to ensure rapid conduction and dissipation of heat from the source.

Designing fins that maximize surface area is essential for efficient heat dissipation. Various shapes and arrangements help optimize airflow and prevent heat accumulation. This is achieved by:

Heat sinks dissipate heat through conduction (from component to fins), convection (from fins to air), and radiation (from surface to environment), with conduction and convection being the most significant.

To maximize conduction between the component and the heat sink base, Thermal Interface Materials (TIM) are applied. TIMs fill microscopic air gaps that would otherwise act as insulators. Common TIMs include:

These materials significantly reduce thermal resistance at the interface.

Heat pipes can be added to high-performance designs. These tubes contain fluid that vaporizes at the hot end and condenses at the cool end, efficiently transporting heat without adding much weight or volume. This mechanism enhances heat spreading and dissipation in compact designs.

Heat sink design is critical in thermal management, ensuring that electronic components operate within their safe temperature range. Effective heat sink design protects components from overheating, which can lead to failures and reduced lifespan. Proper thermal management also enhances the performance and reliability of electronic devices and industrial equipment.

Heat sinks play a vital role in various applications, including:

Adhering to thermal management standards and compliance is essential in heat sink design. These standards ensure that the heat sinks meet specific performance criteria, providing reliable and safe operation of electronic components and industrial equipment. Compliance with these standards is crucial for manufacturers to guarantee product quality and safety.

Thermal efficiency in heat sink design is crucial for effectively transferring heat away from electronic components, ensuring optimal temperatures and extending component lifespan. This efficiency influences the reliability and performance of electronic devices and industrial equipment.

Enhancing thermal efficiency involves several strategies focused on optimizing heat transfer and minimizing thermal resistance.

Selecting materials with high thermal conductivity, such as copper or aluminum, is vital for efficient heat transfer. While copper is more conductive, aluminum is lighter and less costly. Additionally, using thermal interface materials (TIMs) can enhance heat transfer by filling microscopic gaps between the heat source and the heat sink base.

Increasing the surface area of the heat sink by designing fins helps dissipate heat more effectively. Adjusting the height, thickness, and spacing of fins can improve airflow and enhance heat transfer.

Reducing thermal resistance involves ensuring effective contact between the heat sink and the component. Techniques like soldering fins to the base instead of using adhesives can significantly improve heat transfer.

Using both natural and forced convection methods can enhance heat dissipation. Forced convection, with fans or blowers, increases the rate of heat transfer. Optimizing airflow direction can further improve convective heat transfer by reducing thermal boundary layers.

These principles and techniques allow for designing heat sinks that maximize thermal efficiency, ensuring the reliability and performance of electronic systems in diverse applications.

The design of fin shapes in heat sinks is crucial for enhancing thermal performance and maximizing heat dissipation.

Inclined and convergent fins improve airflow distribution, reducing pressure drop and enhancing convective heat transfer compared to traditional straight fins. These designs improve airflow, which helps maintain consistent cooling efficiency.

Microchannels with high aspect ratios significantly increase the surface area for heat dissipation. This technique is particularly effective in compact spaces and high-power applications, where efficient heat transfer is essential. Microchannel heat sinks are ideal for modern electronics with rising power densities.

Spatially adaptive fin arrangements balance thermal resistance and aerodynamic efficiency. By varying fin density, designers can optimize heat transfer in forced convection systems, ensuring better performance under different operating conditions.

Innovations in material science and hybrid cooling methods contribute to more effective heat sink designs.

Copper-aluminum composites offer a cost-effective solution that balances conductivity, weight, and performance. This hybrid material provides superior thermal performance, making it an ideal choice for various applications.

Heat pipes are integrated into heat sinks to transport heat rapidly to peripheral fins, reducing localized hot spots. This two-phase cooling system enhances heat dissipation in high-density layouts, making it suitable for compact electronic devices.

Emerging graphene-enhanced coatings improve surface emissivity and thermal interface conductivity. These advanced materials show promise in enhancing overall thermal performance by improving heat transfer efficiency at critical interfaces.

The use of computational techniques allows for precise and efficient heat sink design.

Using computational fluid dynamics (CFD), designers can refine fin shapes to improve thermal performance while considering manufacturing constraints. This algorithm-based approach ensures optimal thermal performance in real-world applications.

Multi-objective parametric studies balance competing factors like weight, pressure drop, and thermal impedance. Machine learning-assisted simulations enable designers to explore various configurations and identify the best trade-offs for heat sink designs.

Transient thermal modeling predicts heat sink performance under dynamic loads rather than steady-state assumptions. This approach ensures reliability and efficiency in real-world operating conditions, providing more accurate performance assessments.

Combining active and passive cooling methods can significantly enhance heat sink efficiency.

Piezoelectric fans are low-power vibrational air movers that enhance natural convection efficiency without traditional fan noise. These fans are ideal for applications requiring quiet operation and efficient cooling.

Liquid-cooled hybrid heat sinks, featuring microfluidic channels combined with air-cooled fins, achieve higher heat flux dissipation than air-only systems. This hybrid approach enhances cooling efficiency, especially in high-power applications.

Phase-change materials absorb transient thermal loads during peak operation, delaying critical temperature thresholds. PCMs provide an effective solution for managing sudden increases in heat generation, ensuring consistent performance.

Advances in manufacturing techniques enable the creation of more complex and efficient heat sink designs.

Additive manufacturing allows for the creation of complex lattice structures and conformal cooling channels that are impossible with traditional extrusion or stamping methods. This technology enables innovative designs that improve thermal performance.

Origami-inspired designs improve packing density for thermal solutions in space-constrained applications, such as foldable electronics. These designs offer flexibility and efficiency, making them suitable for modern electronic devices.

Bonded fin fabrication allows for material heterogeneity, such as combining copper bases with aluminum fins while maintaining structural integrity. This method provides the benefits of both materials, enhancing overall heat sink performance.

Effective fouling mitigation strategies are essential for maintaining heat sink performance in harsh environments.

Hydrophobic surface treatments reduce dust accumulation and moisture adhesion, ensuring consistent performance in challenging environments. These treatments help maintain the efficiency of heat sinks over time.

Self-cleaning vibrating fins use automated mechanical systems to periodically dislodge particulate buildup. This approach minimizes maintenance requirements and ensures reliable operation.

IoT-enabled sensors monitor performance and trigger maintenance when needed, helping keep heat sinks efficient. Predictive maintenance integration helps in maintaining optimal heat sink performance and prolonging the lifespan of electronic components.

Selecting the appropriate material for a heat sink is crucial for ensuring efficient heat dissipation and overall performance. Several critical factors must be considered to make an informed choice:

Thermal conductivity measures how well a material can transfer heat. Materials with higher thermal conductivity, such as copper and aluminum, are preferred because they transfer heat more effectively, ensuring efficient cooling of electronic components.

Cost plays a significant role in the selection of heat sink materials, especially for large-scale production. For example, while copper offers excellent heat transfer, its higher cost might make it less suitable for projects with tight budgets compared to aluminum, which is more cost-effective.

The density of the material affects the weight of the heat sink. Aluminum is advantageous for applications where reducing weight is essential, such as in portable electronic devices, due to its lower density compared to copper.

The ease of manufacturing is another important consideration. Aluminum is generally easier to work with and can be extruded into complex shapes more readily than copper, making it a popular choice for a variety of applications.

Choosing non-toxic and environmentally friendly materials, such as aluminum and aluminum nitride, is crucial for meeting safety standards and sustainability goals.

Different materials offer distinct advantages, and their selection depends on the specific requirements of the application.

Aluminum is widely used in heat sink manufacturing due to its excellent balance of thermal conductivity, cost-effectiveness, and lightweight nature. It is also highly machinable and can be anodized to improve corrosion resistance.

Copper is renowned for its high thermal conductivity, making it ideal for high-performance applications where maximum heat dissipation is required. However, it is heavier and more costly, which can limit its use in weight-sensitive or cost-sensitive projects.

Emerging materials like aluminum nitride and boron nitride are gaining attention for their high thermal conductivity and unique properties. These materials are particularly suited for specialized applications where traditional metals may not meet all performance criteria.

In designing heat sinks, achieving a balance between performance and practicality is crucial. Engineers must weigh the benefits of high thermal conductivity against factors like cost, weight, and ease of manufacturing. This balance ensures that the selected materials meet both thermal requirements and practical constraints. By carefully evaluating these factors, it is possible to select materials that align with both performance needs and economic considerations.

Choosing the right fin design is essential for maximizing the efficiency of heat sinks in dissipating heat. Different fin configurations impact heat dissipation efficiency based on the cooling conditions and specific application requirements.

Straight fins are one of the most common and straightforward designs. Characterized by their parallel, evenly spaced structure, they allow for efficient heat dissipation through natural or forced convection.

Pin fins feature an array of cylindrical pins, offering a large surface area for heat transfer. This design is particularly effective in enhancing airflow and promoting turbulent flow, which increases heat transfer rates.

Flared fins are designed with a slight outward angle, which helps to increase airflow and reduce resistance. This design boosts heat dissipation by improving how effectively air moves over the fins.

Choosing the right fin design involves evaluating factors like heat dissipation capability, space availability, and cooling conditions to ensure optimal thermal performance. The available space for the heat sink significantly influences the fin design choice. Compact devices may require more intricate designs, such as pin fins or microchannels, to maximize surface area without increasing the overall size. Understanding the cooling environment is crucial. For instance, natural convection scenarios may benefit from straight or rectangular fins, while forced convection systems can leverage designs like pin fins or wavy fins for enhanced performance. The ease of manufacturing plays a role in selecting the fin design. Simple designs like straight fins are easier and less costly to produce, while more complex designs may require advanced manufacturing techniques, impacting cost and production time.

Balancing surface area and space constraints is critical in fin design. Larger surface areas improve heat dissipation but may not fit in compact devices. Optimizing fin geometry and spacing helps achieve the best trade-off.

The choice of fin design directly affects the thermal performance of the heat sink. Properly designed fins can significantly improve heat transfer efficiency, ensuring that electronic components remain within safe operating temperatures and extending their lifespan.

Heat sinks are indispensable in various industries, ensuring the efficient dissipation of heat from electronic components and mechanical systems. Here are some notable applications:

Power amplifiers, used in audio equipment and communication devices, often produce a lot of heat while functioning. Heat sinks are essential to prevent thermal runaway in transistors, which can lead to performance degradation and component failure. By maintaining a stable temperature, heat sinks ensure consistent signal quality and longevity of the amplifier.

Central Processing Units (CPUs) and Graphics Processing Units (GPUs) are critical components in computers, responsible for executing complex calculations and rendering graphics. These components produce substantial heat, which must be managed effectively to prevent thermal throttling and ensure optimal performance. Efficient heat sink designs, often combined with fans or liquid cooling systems, help maintain temperatures within safe operating limits, enhancing the reliability and lifespan of these processors.

Similarly, LED lights are widely used for their energy efficiency and long life. However, they are highly sensitive to temperature variations, which can affect their brightness and lifespan. Heat sinks are crucial in LED applications to manage heat dissipation, ensuring that the LEDs operate efficiently and maintain their performance over time.

A leading electronics manufacturer integrated heat pipes into the heat sink design of their high-power LEDs. This approach reduced heat flow by up to 50%, significantly improving heat dissipation. The U-shaped heat pipes transported heat away from the LED chips to the peripheral fins, maintaining optimal temperatures even under high loads. This innovation resulted in longer LED lifespan and more stable light output.

An automotive electronics company used Computational Fluid Dynamics (CFD) analysis to optimize the heat sink design for their engine control units (ECUs). By simulating various fin geometries and airflow patterns, they identified a design that enhanced heat dissipation while minimizing airflow reduction. This CFD-driven approach enabled the company to achieve superior thermal performance without extensive physical prototyping, reducing development time and costs.

A data center operator adopted a hybrid cooling solution combining air-cooled heat sinks with liquid cooling for their server CPUs. This setup used microfluidic channels within the heat sink to achieve higher heat flux dissipation. The hybrid design allowed the data center to handle higher computational loads while maintaining efficient thermal management, leading to improved server performance and energy efficiency.

A consumer electronics company applied graphene-enhanced coatings to the heat sinks of their latest smartphone model. These advanced coatings improved surface emissivity and thermal interface conductivity, resulting in better heat transfer from the processor to the heat sink. The enhanced thermal management allowed the smartphone to maintain high performance during intensive tasks, such as gaming and video editing, without overheating.

Innovations in material science have led to the development of copper-aluminum composites that balance thermal conductivity, weight, and cost. These composites are being increasingly adopted in applications where traditional materials like pure copper or aluminum may not provide the optimal combination of properties.

Additive manufacturing, or 3D printing, is revolutionizing heat sink design by enabling the creation of complex geometries that were previously impossible with conventional methods. Imagine the intricate designs possible with 3D printing as similar to a delicate lace pattern, showcasing the complexity and innovation in heat sink structures. This technology allows for the fabrication of intricate lattice structures and conformal cooling channels, improving the overall thermal performance of heat sinks.

Combining active cooling methods, such as piezoelectric fans, with passive heat sinks has shown significant improvements in thermal management. Hybrid systems are especially beneficial for applications that demand quiet, efficient cooling, like medical devices and premium electronics.

By exploring these practical applications and case studies, engineers can gain valuable insights into effective heat sink design strategies and stay abreast of the latest advancements in thermal management technology.

Start by accurately defining the thermal management requirements for your heat sink design. Determine key parameters, such as the heat dissipation requirement (Q). For example, if an electronic component generates 20 W of heat, then Q = 20 W. Identify the ambient temperature (Ta), typically around 30°C. Establish the maximum junction temperature (Tj), such as 85°C. Compute the desired temperature rise (ΔT) as the difference between the junction temperature and ambient temperature, ΔT = Tj – Ta = 55°C.

Selecting the right materials for the heat sink is crucial for efficient thermal management. Copper offers excellent heat dissipation due to its high thermal conductivity, but it is more costly. Aluminum is a cost-effective alternative with good thermal performance. Choose the heat sink type based on space constraints and cooling demands, considering options such as plate-fin and pin-fin configurations.

The design of the fins significantly impacts heat dissipation efficiency. Ensure the heat sink fits the component perfectly and optimize its surface area to enhance heat dissipation through convection and radiation. Decide the number and type of fins based on the heat dissipation requirements and available space. Common fin types include straight fins, pin fins, and flared fins.

Calculating the heat transfer mechanisms is essential to ensure the heat sink performs as expected. Calculate the heat dissipated through convection using the formula ( Qc=2hA(Tcomponent–Tambient)). For radiation, calculate the heat dissipated using ( Qr=2ϵσA(T4component–Tambient4) ). Ensure a good thermal interface between the component and the heat sink using thermal paste or other thermal interface materials (TIMs).

Manufacturing and testing the heat sink prototype are critical steps to validate the design. Utilize metal stock (aluminum or copper), a hacksaw or jigsaw, a metal file, sandpaper, and thermal adhesive or epoxy. Smooth the edges and, if needed, apply a protective coating to boost durability and performance. Monitor temperature changes under load conditions to ensure the heat sink meets the required specifications.

Based on the test results, refine the design parameters to improve efficiency and reduce thermal resistance. Adjust fin configuration, material selection, or other design aspects based on performance data to optimize the heat sink’s efficiency.

Below are answers to some frequently asked questions:

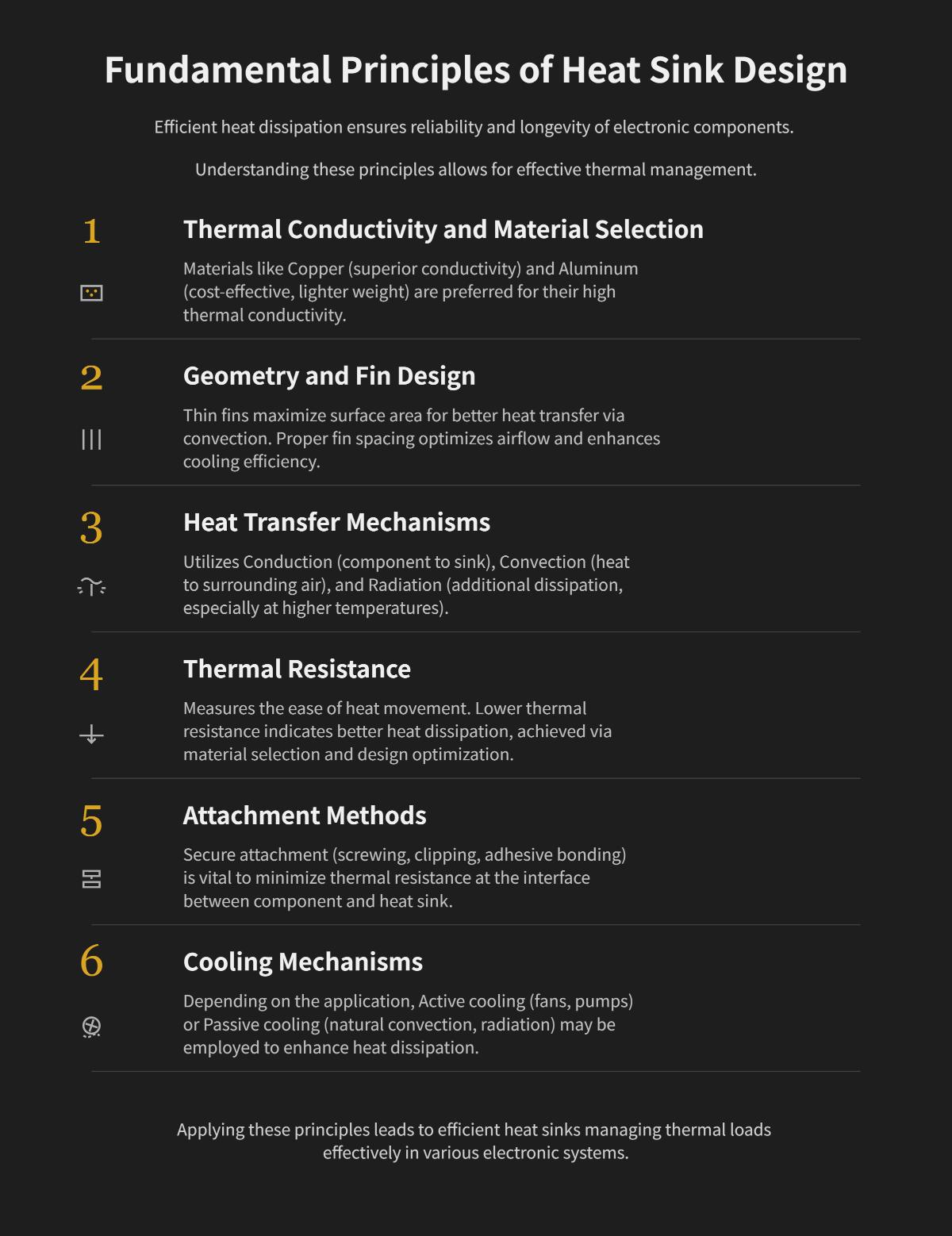

The fundamental principles of heat sink design revolve around efficient heat dissipation to ensure the reliability and longevity of electronic components. Key principles include:

Understanding and applying these principles allows for the design of efficient heat sinks that manage thermal loads effectively in various electronic systems.

Enhancing the efficiency of a heat sink involves optimizing its design, material selection, airflow management, and thermal interface. Firstly, the fin design and configuration are crucial; inclined fins or complex shapes like W-type fins can improve airflow and uniform temperature distribution, leading to better heat transfer. Optimizing fin height, thickness, and spacing also balances surface area and airflow resistance, facilitating efficient heat dissipation.

Material selection plays a significant role in performance; high thermal conductivity materials like copper and aluminum alloys are ideal. Surface finishing techniques such as anodization can improve emissivity and protect the heat sink from corrosion, maintaining efficiency over time.

Improving airflow mechanisms through active cooling methods like fans or blowers can significantly enhance convective heat dissipation. In high-power applications, integrating liquid cooling systems or heat pipes can transfer heat more effectively than air cooling alone. Ensuring smooth and unobstructed airflow paths also contributes to better cooling performance.

Minimizing thermal resistance at interfaces is another critical factor. Using high-quality thermal interface materials (TIMs), preparing smooth mating surfaces, and applying TIMs correctly ensures optimal thermal contact and reduces resistance.

By incorporating these strategies, you can significantly enhance heat sink efficiency, meeting the increasing thermal management demands of modern electronics and high-power devices.

When selecting materials for heat sinks, aluminum and copper are the most commonly used due to their favorable properties. Aluminum is lightweight, cost-effective, and has a thermal conductivity of approximately 205 W/mK, making it suitable for a wide range of applications. It is particularly popular for extruded heat sinks due to its malleability and ease of fabrication. Copper, on the other hand, offers superior thermal conductivity at around 398 W/mK, nearly double that of aluminum, making it ideal for high-demand applications where performance is critical despite its higher weight and cost.

Advanced ceramics like aluminum nitride (AlN) also offer high thermal conductivity and are lightweight, making them suitable for specialized applications requiring both thermal efficiency and structural integrity. However, these materials are typically more expensive than metals.

Advanced heat sink design techniques involve several innovative approaches to enhance thermal management. One key technique is the use of microchannel integration, where fluidic pathways within the heat sink facilitate efficient phase-change cooling, significantly improving heat flux management compared to traditional air-cooled designs. Another method is the incorporation of micro-fins and porous structures, which increase the surface area-to-volume ratio, boosting convection efficiency, particularly in compact electronic devices.

Material advancements also play a crucial role. For example, embedding heat pipes within the heat sink can effectively transfer heat from hotspots to fins, reducing thermal gradients. Additionally, graphene-enhanced metals and additive-manufactured alloys offer superior thermal conductivity and enable complex geometries that traditional machining cannot achieve.

Computational optimization techniques, such as Computational Fluid Dynamics (CFD) simulations, are employed to optimize fin spacing, base thickness, and fluid dynamics to minimize thermal resistance. Topology optimization algorithms help in removing non-critical material, reducing weight while maintaining thermal performance.

Active cooling synergies, including integrated piezoelectric fans and thermoelectric coolers (TECs), provide localized airflow and augment passive cooling methods, respectively. Lastly, fouling mitigation strategies, such as hydrophobic and self-cleaning coatings, prevent dust accumulation and particulate adhesion, ensuring consistent airflow and heat dissipation in industrial environments.

These advanced techniques collectively contribute to more efficient and effective heat sink designs, addressing the increasing thermal demands of modern electronic devices and industrial equipment.

Choosing the right fin design for your heat sink application involves several critical factors. First, consider the airflow characteristics. For high, directional airflow, plate fins, including straight, louvered, wavy, or offset strip fins, are ideal due to their large surface area and streamlined shape that maximizes heat dissipation. Conversely, pin fins are better suited for multidirectional or low airflow conditions, as they promote better air circulation and are less prone to clogging.

Next, evaluate space constraints and thermal performance requirements. Plate fins are more space-efficient and have a lower profile, making them suitable for compact designs. However, pin fins can offer superior cooling performance per unit volume in certain airflow regimes.

Environmental considerations also play a role. In dusty or debris-prone environments, pin fins are preferable due to their open structure, which resists clogging and eases cleaning. Plate fins may trap particulates more easily and require more frequent maintenance.

Lastly, balance mechanical constraints and manufacturing feasibility. Thin fins increase surface area but may compromise mechanical strength. Typical fin height-to-gap aspect ratios should be within extrusion limits, and serrated or cross-cut fins can enhance heat transfer but may increase manufacturing complexity.

By analyzing these factors—airflow type, space constraints, environmental conditions, and manufacturability—you can select the optimal fin design to maximize heat dissipation and reliability for your application.

Heat sink designs have practical applications across various industries due to their critical role in thermal management. In the electronics and computing sector, heat sinks are essential for cooling CPUs, GPUs, power supplies, and telecommunication equipment, ensuring optimal performance and preventing overheating. In LED lighting, heat sinks help maintain brightness and efficiency by managing heat dissipation, thus extending the lifespan of LEDs. The automotive industry uses heat sinks to cool power electronics in electric and hybrid vehicles and to manage heat in internal combustion engines. Industrial equipment relies on heat sinks for maintaining optimal temperatures in motor drives and power supplies. Additionally, in renewable energy, heat sinks are vital for the efficient operation of solar inverters and wind turbine controllers. Lastly, consumer electronics such as gaming consoles and audio amplifiers also benefit from heat sinks to prevent overheating and ensure consistent performance.