Imagine a material that combines exceptional strength, corrosion resistance, and versatility—an engineer’s dream come true. This is the promise of 17-4 stainless steel, a martensitic precipitation-hardening alloy that has become indispensable in industries ranging from aerospace to chemical processing. But how does this remarkable material achieve its superior properties? The secret lies in the meticulous process of heat treating.

In this comprehensive guide, we will dive deep into the technical aspects of heat treating 17-4 stainless steel. You’ll learn about the critical steps involved, from solution annealing and precipitation hardening to the aging process. We will explore how each phase alters the microstructure and enhances the mechanical properties of the alloy. Along the way, we’ll also address common applications and real-world performance outcomes of heat-treated 17-4 stainless steel.

Ready to uncover the science behind this transformative process and understand why 17-4 stainless steel is a go-to material for high-performance applications? Let’s delve into the details and elevate your knowledge to the next level.

17-4 stainless steel, also known as SAE Type 630, is known for its combination of high strength, hardness, and excellent corrosion resistance. The composition of 17-4 stainless steel typically includes about 17% chromium and 4% nickel, along with smaller amounts of copper, niobium, and tantalum, which allow it to undergo heat treatment processes that enhance its mechanical properties.

17-4 stainless steel is very strong and hard, making it perfect for high-performance applications. The alloy can achieve a yield strength ranging from 1100 to 1300 MPa (160-190 ksi) after heat treatment. This high strength is attributed to the precipitation hardening process, which forms fine precipitates that hinder dislocation movement, thereby enhancing the material’s hardness.

Despite its high strength, 17-4 stainless steel maintains moderate ductility and good toughness. This balance of properties ensures that the material can withstand impact and shock loading without fracturing. It is capable of some cold forming, although care must be taken to avoid excessive work hardening.

The corrosion resistance of 17-4 stainless steel is comparable to that of 304 stainless steel. It works well in many environments, including those with exposure to chlorides and other corrosive substances. This makes it suitable for applications in harsh or marine environments where both strength and corrosion resistance are critical.

17-4 stainless steel is utilized across numerous industries due to its versatile properties:

Heat treating is a crucial process for optimizing the properties of 17-4 stainless steel. It involves a series of thermal cycles that modify the material’s microstructure to achieve desired mechanical properties. The heat treating process for 17-4 stainless steel typically includes solution annealing, quenching, and precipitation hardening (aging).

Solution annealing involves heating the steel to a high temperature (1038-1066°C or 1900-1950°F) to dissolve carbides and restore the austenitic structure. This step is followed by rapid cooling, usually in air, to retain the dissolved elements in solution.

Quenching is the process of rapidly cooling the steel, typically in oil, to form a martensitic structure. This step is critical for achieving the high strength characteristic of 17-4 stainless steel.

Precipitation hardening, also known as aging, involves heating the material to a lower temperature (482-760°C or 900-1400°F) for a specific duration to form intermetallic compounds that increase the steel’s hardness and strength.

These heat treating steps are essential for tailoring the properties of 17-4 stainless steel to meet specific application requirements, making it a highly valuable material in metalworking and manufacturing.

Solution annealing is a critical initial step in the heat treatment of 17-4 stainless steel. This process involves heating the material to a temperature range of 1,040-1,100°C (1,904-2,012°F) for about 30 minutes to dissolve chromium carbides and restore the austenitic structure. This step is essential for enhancing the material’s ductility and corrosion resistance.

Precipitation hardening, also known as aging, is a heat treatment process that increases the strength and hardness of 17-4 stainless steel by forming fine intermetallic compounds.

The precipitation hardening process forms fine intermetallic compounds within the steel, which obstruct dislocation movement, thereby increasing the material’s strength and hardness.

The aging process is essential for achieving the desired mechanical properties in 17-4 stainless steel by precipitating fine particles that enhance its strength.

By carefully controlling the heat treating processes, including solution annealing and precipitation hardening, manufacturers can tailor the properties of 17-4 stainless steel to meet specific application requirements. This makes 17-4 stainless steel an invaluable material in industries demanding high strength, toughness, and corrosion resistance.

Precipitation hardening, also known as age hardening, is a heat treatment technique used to increase the yield strength and hardness of certain alloys, including 17-4 stainless steel. This process involves the formation of very fine intermetallic particles within the metal’s matrix, which obstruct dislocation movement and enhance mechanical properties.

Precipitation hardening in 17-4 stainless steel involves a series of heat treatments that modify the material’s microstructure at the atomic level. The process can be broken down into three main stages:

The precipitation hardening process induces significant changes in the microstructure of 17-4 stainless steel. During aging, the supersaturated solid solution breaks down, and fine intermetallic compounds, such as copper-rich phases, form within the matrix. New phases begin forming at nucleation sites like grain boundaries or dislocations. These precipitates grow as solute atoms diffuse from the matrix, and over time, smaller precipitates dissolve while larger ones grow. However, this coarsening stage is typically minimized to maintain optimal properties.

Precipitation hardening significantly increases the yield strength and hardness of the alloy. The fine precipitates formed during aging hinder the movement of dislocations, which are defects in the crystal structure that facilitate plastic deformation.

The specific aging conditions, such as temperature and time, are crucial in determining the alloy’s final properties. Common conditions for 17-4 stainless steel include H900 (900°F/482°C) for the highest strength and hardness, H1025 (1025°F/552°C) for a balance of strength and toughness, and H1150 (1150°F/621°C) for the best combination of toughness and ductility. These conditions tailor the material’s properties to meet specific application needs, making 17-4 stainless steel versatile for various industries.

Heat-treated 17-4 stainless steel is widely used in various industries due to its high strength, excellent corrosion resistance, and toughness. Here are some of the key applications across different sectors:

In the aerospace industry, 17-4 stainless steel is highly valued for its strength-to-weight ratio and resistance to corrosion. It is used in the manufacturing of structural parts, landing gear components, and engine parts. Its ability to retain strength and toughness after treatments such as H900 and H1100 makes it a top choice for critical aerospace components.

17-4 stainless steel is frequently employed in the chemical processing industry for the production of valves, pumps, and other equipment. Its resistance to corrosive environments ensures the longevity and reliability of components that operate under harsh conditions. The material’s ability to maintain structural integrity under stress is crucial for the safe and efficient operation of chemical processing plants.

The oil and gas industry utilizes 17-4 stainless steel in drilling equipment, valves, and wellhead components. Its resistance to saltwater and chemical corrosion is vital for offshore and subsea applications. The high strength-to-weight ratio of this material is particularly advantageous in environments where size and weight are critical factors, contributing to improved efficiency and safety in oil and gas operations.

17-4 stainless steel is also used in the medical field, particularly for surgical instruments and orthopedic implants. Its biocompatibility, corrosion resistance, and strength make it ideal for durable and safe medical applications. Proper heat treatment ensures that the alloy meets the mechanical property requirements necessary for medical devices.

In the food processing industry, 17-4 stainless steel is applied in equipment such as storage tanks and conveyor systems. Its resistance to corrosion and ease of cleaning ensure sanitary conditions are maintained. Additionally, the material’s magnetic properties are beneficial for contaminant removal, ensuring food safety and quality.

Automotive components like axles, shafts, and gears benefit from the use of 17-4 stainless steel. The material’s enhanced toughness and resistance to dynamic loads and corrosive environments make it suitable for high-performance automotive applications. Heat treatment processes like precipitation hardening improve the durability and performance of these critical parts.

The paper and pulp industry employs 17-4 stainless steel in equipment that processes pulp, such as tanks and valves. The material’s resilience under high temperatures and corrosive conditions ensures the longevity and reliability of equipment used in this demanding environment.

Solution annealing is a preliminary step in the heat treatment of 17-4 stainless steel. This process involves heating the material to dissolve alloying elements and create a uniform austenitic structure. The result is enhanced corrosion resistance and ductility, which are essential for many industrial applications.

Precipitation hardening involves heating the material to specific temperatures followed by aging to form copper-rich precipitates. This process greatly enhances the material’s strength and hardness. The H900 treatment is commonly used to achieve a balance of strength and toughness, while the H1100 treatment enhances toughness by introducing a ferrite fraction.

Welding 17-4 stainless steel can alter its microstructure, requiring careful control of the welding process and post-weld heat treatment to maintain desired properties. Machining the material is more straightforward in the annealed condition but becomes challenging after heat treatment, necessitating the use of appropriate tools and lubricants.

Refining heat treatment processes to balance strength, toughness, and corrosion resistance will be crucial for expanding its use in industries demanding high material reliability.

Below are answers to some frequently asked questions:

Heat treating 17-4 stainless steel involves two main processes: solution annealing and aging (precipitation hardening).

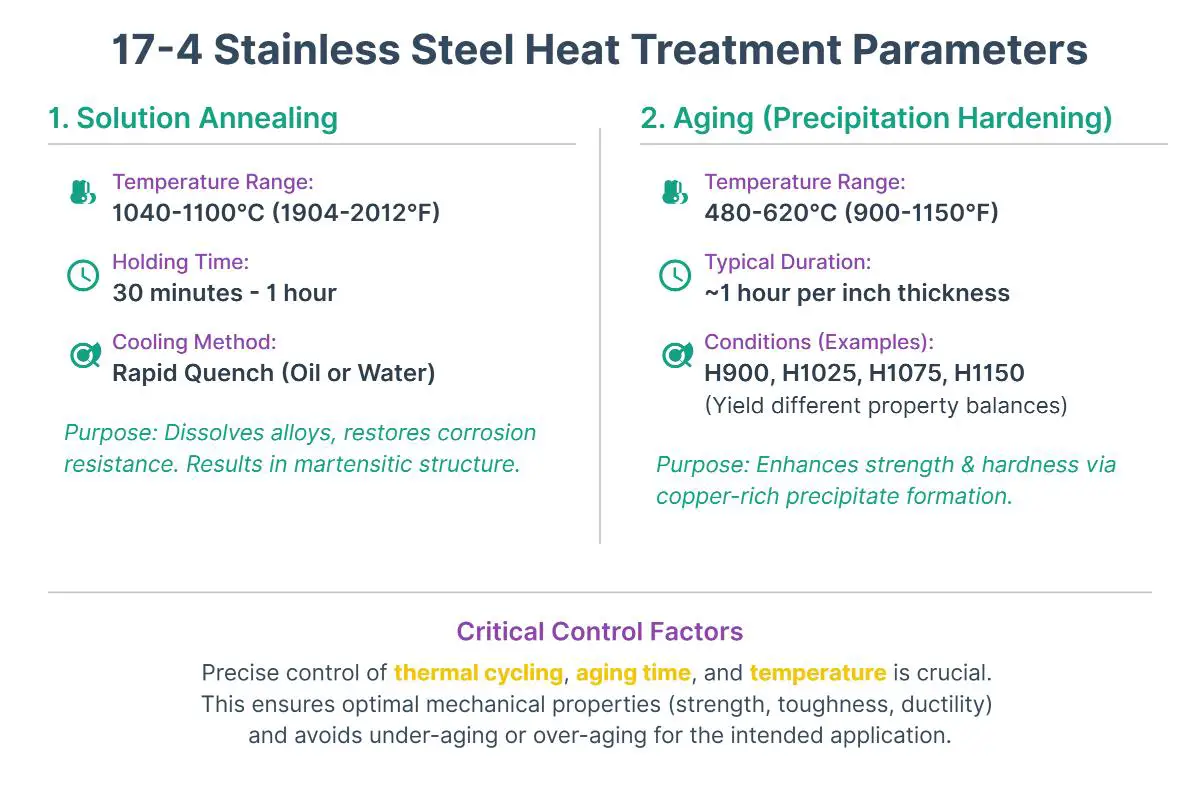

First, in solution annealing, the material is heated to a temperature range of 1,040-1,100°C (1,904-2,012°F) and held for approximately 30 minutes to 1 hour. This step dissolves alloying elements and restores corrosion resistance. After holding, the material is rapidly quenched in oil or water to achieve a martensitic structure, preparing it for further treatment.

Next, the aging process, also known as precipitation hardening, involves heating the material to a temperature between 480-620°C (900-1150°F). The duration of this step depends on the desired condition and thickness, typically about 1 hour per inch. This process enhances the mechanical properties by forming copper-rich precipitates that increase strength and hardness.

Specific aging conditions, such as H900, H1025, H1075, and H1150, vary in temperature and duration, each yielding different balances of strength, toughness, and ductility to suit various applications. Proper control of thermal cycling, aging time, and temperature is crucial to avoid under-aging or over-aging, ensuring the material achieves optimal properties for its intended use.

Precipitation hardening significantly affects the properties of 17-4 stainless steel by enhancing its mechanical strength and hardness. This process involves heating the alloy to specific temperatures, typically between 480°C and 620°C (900°F to 1150°F), to form strengthening precipitates within the material. These precipitates, primarily copper-rich, increase the ultimate tensile strength and yield strength of the steel. For instance, in the H900 condition, 17-4 stainless steel can achieve a yield strength of up to 1,300 MPa (190 ksi) and a Rockwell C hardness of approximately 44.

However, while precipitation hardening improves strength, it can reduce ductility, making the steel more brittle under high-strength conditions. Aging at higher temperatures, such as H1025 or H1150, can enhance toughness and ductility, though it may slightly lower the strength. The careful control of the aging process is essential to achieve the desired balance of mechanical properties for specific applications, ensuring that 17-4 stainless steel remains suitable for high-performance environments like aerospace and chemical processing.

Heat-treated 17-4 stainless steel, also known as 17-4 PH, is widely used in various industries due to its high strength, excellent corrosion resistance, and enhanced mechanical properties through precipitation hardening. In the aerospace industry, it is used for turbine blades, fasteners, and structural components, where durability and a high strength-to-weight ratio are crucial. In the oil and gas sector, it is utilized in valves, pumps, and wellhead components due to its resistance to corrosive environments. The chemical and petrochemical industries benefit from its use in equipment that must withstand harsh chemical conditions, such as valves and pumps. Medical applications include surgical instruments and orthopedic implants, leveraging its strength and corrosion resistance. Marine applications involve critical components like valves and pumps that face corrosive sea environments. Additionally, it is used in the food processing industry for equipment requiring corrosion resistance and sanitation, and in the paper and pulp industry for components that endure high temperatures and corrosive conditions. These applications demonstrate the material’s versatility and reliability in demanding environments.

When heat treating 17-4 stainless steel, several safety precautions are essential to protect workers and ensure proper handling of the material.

Firstly, wear appropriate protective clothing, including heat-resistant attire, gloves, and safety glasses, to prevent burns and protect against hot material splashes. Utilizing face shields can provide additional protection, especially during high-risk operations like salt baths.

Comprehensive training on the specific heat treatment processes, including emergency response protocols, is crucial. Ensure the workspace has adequate room for safe movement around equipment, with clear signage marking high-temperature zones and emergency exits.

Temperature monitoring is vital; use remote sensors to track ambient temperatures in real-time and maintain precise control to avoid adverse microstructural changes in the steel. Regular equipment maintenance, including scheduled inspections and repairs, helps prevent malfunctions.

Proper material handling involves segregating materials based on heat treatment requirements and securely storing combustible materials in fire-resistant containers. For 17-4 stainless steel, perform welding before heat treatment to minimize impacts on the material’s properties and apply solution annealing post-welding to restore corrosion resistance.

Lastly, ensure a trained first aid team is available to handle potential heat-related injuries, and keep emergency contact numbers easily accessible.

Following these precautions can significantly enhance safety and the quality of the heat-treating process.

While it is technically feasible to heat treat 17-4 stainless steel at home, the process requires precise control over temperature and cooling rates, which can be challenging without professional equipment. Essential equipment includes a high-temperature oven capable of reaching 1,040°C to 1,100°C for solution annealing and 480°C to 760°C for aging, with precise temperature control. A thermocouple is necessary for accurate temperature monitoring, and a quenching medium, typically oil, is needed for rapid cooling. Safety equipment such as heat-resistant gloves and safety glasses is also crucial.

Challenges include maintaining exact temperatures and cooling rates, which significantly affect the material’s final properties. Therefore, while home heat treatment is possible, achieving consistent, optimal results is difficult without specialized equipment, and professional facilities are generally recommended.

To troubleshoot common issues in heat treating 17-4 stainless steel, it is essential to address challenges such as warping, cracking, corrosion resistance, dimensional changes, and welding effects. Warping can be mitigated by maintaining precise temperature control and pre-machining the material in condition A to reduce thermal stress. Cracking and brittleness, particularly in high-strength conditions like H900, can be prevented by inspecting for residual stresses and applying stress relief treatments when necessary. To preserve corrosion resistance, ensure proper solution annealing before precipitation hardening and maintain clean, uncontaminated working conditions. Dimensional changes, such as shrinkage, require careful design planning to account for predictable variations during heat treatment. For thermal cycling effects from welding, perform welding prior to final heat treatment and follow up with solution annealing and precipitation hardening to restore mechanical properties. By adhering to best practices, including temperature management, contamination prevention, and tailored machining parameters, these issues can be effectively resolved.