Did you know that heat treatment can significantly transform the properties of 304 stainless steel? For intermediate-level enthusiasts seeking a technical deep-dive, understanding this process is crucial. Heat treatment encompasses methods like annealing, stress relieving, and solution annealing, which can enhance corrosion resistance, ductility, and hardness. These treatments not only improve the steel’s performance but also offer sustainability and cost-efficiency benefits. So, how exactly do these processes work and what specific impacts do they have? Let’s explore further.

304 stainless steel is an austenitic alloy. It mainly contains 18% chromium and 8% nickel. This composition gives it high corrosion resistance. But its austenitic structure means it can’t be easily hardened by traditional heat – treatment methods like ferritic or martensitic steels.

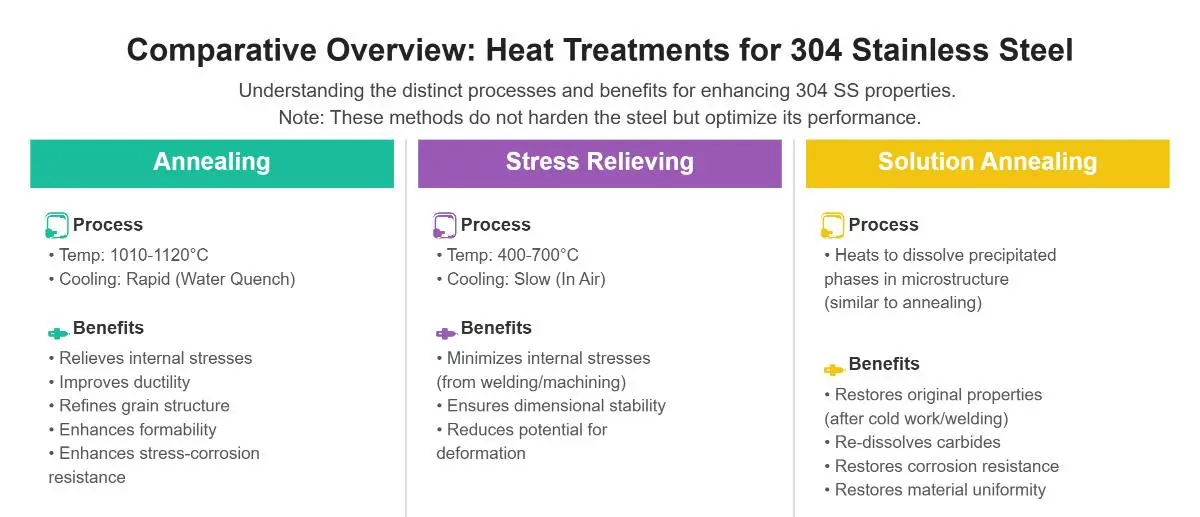

Annealing improves ductility, relieves internal stresses, and refines the grain structure. The steel is heated to 1010 – 1120°C (1850 – 2050°F). Then it’s rapidly cooled by water quenching. This treatment boosts formability and stress – corrosion resistance.

Stress relieving reduces internal stresses without majorly changing mechanical properties. The material is heated to 425 – 925°C (800 – 1700°F). Then it’s slowly cooled in air. This ensures dimensional stability, especially after welding or machining.

Normalization is less used for 304 stainless steel because of its stable austenitic structure. However, it can refine the grain structure when needed.

304 stainless steel can’t be effectively hardened by heat treatment. So, work hardening (cold working) is used to increase its strength and hardness. It involves plastic deformation below the recrystallization temperature.

A big challenge in 304 stainless steel heat treatment is sensitization. When the steel is exposed to 425 – 860°C for a long time, chromium carbide can form. This is like rust forming on a normal metal, reducing the steel’s corrosion resistance.

Precise temperature control is crucial during heat treatment. Correct temperatures prevent unwanted microstructural changes and ensure the steel gets the desired properties.

After heat treatment, 304 stainless steel is very versatile. Annealing, which improves ductility, relieves internal stresses, and refines the grain structure by heating to 1010 – 1120°C and water – quenching, also maintains formability and stress – corrosion resistance. This makes it suitable for complex applications in industries like food processing, medical instruments, and construction.

Annealing is an essential heat treatment process used to increase ductility and decrease the hardness of 304 stainless steel. The process involves three main steps: heating, holding, and cooling.

Annealing softens the material, relieves internal stresses, increases ductility, and refines the grain structure, improving the material’s machinability and overall performance. This treatment enhances the steel’s ability to undergo further forming and shaping processes without the risk of cracking or other forms of failure.

Stress relieving is another essential heat treatment process for 304 stainless steel, aimed at reducing residual stresses without significantly altering its mechanical properties.

Stress relieving mainly improves the material’s dimensional stability, especially after welding or machining. This treatment ensures that the material remains stable and less prone to distortion or cracking during use.

Solution annealing is specifically used for austenitic stainless steels like 304 to restore their original properties after cold working or welding.

The main goal of solution annealing is to dissolve any precipitated phases and restore the material’s uniformity. This process is crucial for maintaining the corrosion resistance and mechanical properties of the steel.

By understanding and applying these heat treatment processes, manufacturers can optimize the properties of 304 stainless steel for a variety of industrial applications.

Heat treatment processes significantly influence the corrosion resistance of 304 stainless steel. Proper annealing can enhance the material’s resistance to various forms of corrosion, including intergranular corrosion and stress-corrosion cracking. This is done by dissolving chromium carbides and ensuring an even distribution of alloying elements, which is essential for maintaining the protective film that shields the steel from corrosive environments.

Heat treatments like annealing and stress relieving improve the ductility of 304 stainless steel. By reducing internal stresses and refining the grain structure, these processes make the material easier to shape and form into complex configurations without cracking. Enhanced ductility is especially useful for applications that involve extensive forming and bending operations.

Although traditional heat treatment methods are not effective for hardening 304 stainless steel, work hardening through cold working can increase its hardness. This process involves plastic deformation below the recrystallization temperature, which strengthens the steel by creating dislocation movements. However, increasing hardness through work hardening comes with a reduction in ductility, requiring a careful balance based on the intended application.

The austenitic structure of 304 stainless steel, which has a stable crystal lattice at all temperatures up to its melting point, is key to its mechanical properties. Heat treatment processes like solution annealing are designed to maintain this structure while eliminating harmful phases that may form during welding or cold working. Preserving the austenitic structure is essential for maintaining the material’s toughness and impact resistance.

A critical consideration during heat treatment is the risk of sensitization. This occurs when the steel is held within the temperature range of 425°C to 860°C, causing chromium carbides to form at grain boundaries and deplete the surrounding areas of chromium. This makes the material susceptible to intergranular corrosion. To prevent sensitization, solution annealing followed by rapid cooling ensures chromium remains in solid solution.

Heat treatment processes are tailored to optimize the mechanical properties of 304 stainless steel for specific applications. Annealing can improve the metal’s ductility, relieve internal stresses, and restore its corrosion resistance by eliminating the effects of work hardening. This process involves heating the stainless steel to a temperature range of 1,000–1,100°C (1,832–2,012°F) followed by slow cooling, typically in air. Proper annealing ensures that the 304 stainless steel maintains its desirable balance of strength and formability, making it suitable for a wide range of industrial and commercial applications, such as kitchen equipment, chemical processing, and structural components.

Recent research has focused on refining heat treatment techniques to further enhance the properties of 304 stainless steel. Innovations in controlled atmosphere annealing and advanced quenching methods aim to achieve better consistency in mechanical properties and corrosion resistance. These advancements are driven by the need to meet increasingly stringent industry standards and application requirements.

304 stainless steel is a preferred material for equipment in chemical processing plants and oil refineries. Its superior corrosion resistance allows it to withstand the harsh chemical environments and aggressive substances commonly found in these industries. Whether it’s handling acids, alkalis, or other corrosive agents, 304 stainless steel ensures the longevity and reliability of equipment, reducing the need for frequent replacements and maintenance.

The non-reactive nature of 304 stainless steel makes it ideal for food processing equipment. It doesn’t react with food products, which helps maintain the hygiene and quality of the food. Additionally, its easy-to-clean nature is crucial in an industry with strict sanitation standards. From large-scale industrial food processing machinery to common kitchen appliances and utensils, 304 stainless steel is widely used due to its aesthetic appeal and functionality.

In the automotive sector, 304 stainless steel is used for trim and decorative features. Its rust and stain resistance ensure that these features stay attractive over time, even in different environmental conditions. In aerospace, the strength and corrosion resistance of 304 stainless steel are valuable assets. Components made from this material can withstand the high-stress environments and harsh conditions encountered during flight, contributing to the safety and reliability of aircraft.

304 stainless steel is commonly used for outdoor structures like bridges, walkways, and architectural elements. Its strength, corrosion resistance, and aesthetic appeal make it suitable for both functional and decorative applications. In architectural paneling and interior design, 304 stainless steel can add a modern and sophisticated look while also providing durability.

304 stainless steel is favored for medical instruments and equipment due to its biocompatibility and durability. Biocompatibility ensures that it doesn’t cause adverse reactions when in contact with the human body, making it safe for use in surgical instruments and implants. In pharmaceutical manufacturing, its corrosion resistance and ease of cleaning are essential for maintaining a sterile environment.

Below are answers to some frequently asked questions:

304 stainless steel undergoes several heat treatment methods to enhance its properties, although it cannot be hardened like other steels. The primary methods include:

These methods optimize the performance of 304 stainless steel in various applications, enhancing its properties without altering its fundamental austenitic structure.

304 stainless steel cannot be hardened by traditional heat treatment methods such as quenching and tempering. This is due to its austenitic structure, which remains stable at typical heat treatment temperatures and does not transform into a harder phase. Instead, processes like annealing, stress relieving, and solution annealing are used to enhance other properties of 304 stainless steel, such as improving ductility, relieving internal stresses, and restoring original properties after welding. However, 304 stainless steel can be significantly hardened through cold working, which involves deforming the material at low temperatures to increase strength and hardness while reducing ductility.

Heat treatment significantly influences the properties of 304 stainless steel, an austenitic alloy known for its excellent corrosion resistance and formability. The main heat treatment processes include annealing, stress relieving, and solution annealing.

Annealing improves ductility and reduces internal stresses by heating the steel to 1010°C to 1120°C and then rapidly cooling it. This process also enhances formability and stress-corrosion resistance. Stress relieving, conducted at 400°C to 700°C, minimizes residual stresses without altering the material’s microstructure, ensuring dimensional stability.

Solution annealing, which involves heating to high temperatures and rapid cooling, restores the material’s properties after cold working or welding by dissolving carbide precipitates. This maintains corrosion resistance and prevents sensitization, a condition that can reduce corrosion resistance due to chromium carbide formation.

Although 304 stainless steel cannot be hardened by traditional heat treatment due to its austenitic structure, cold working can increase its hardness and strength.

Solution annealing is a vital heat treatment process for 304 stainless steel, aimed at restoring the material’s properties after processes like cold working or welding. The primary purpose of solution annealing is to dissolve any precipitated phases within the steel’s microstructure, ensuring a uniform single-phase structure. This is crucial for preventing sensitization, which can reduce the steel’s corrosion resistance.

The process involves heating the steel to a temperature range between 1010°C and 1150°C, followed by rapid quenching to prevent the reformation of precipitates during cooling. Solution annealing also relieves internal stresses that may have developed during manufacturing, enhancing the material’s ductility and making it more formable and less prone to cracking under stress. Additionally, it improves machinability by reducing hardness and removing hard spots, thereby reducing tool wear and associated costs.

Heat treatment contributes significantly to the sustainability of stainless steel, especially for alloys like 304 stainless steel. By enhancing the material properties through processes such as annealing, stress relieving, and solution annealing, the treated stainless steel becomes more durable and resistant to wear and corrosion. This extended lifespan reduces the frequency of replacement and minimizes waste.

Furthermore, heat treatment can improve the workability of stainless steel, making manufacturing processes more efficient and less energy-intensive. This efficiency leads to cost savings and reduces the Additionally, the improved corrosion resistance from heat treatment decreases the need for protective coatings, which can have harmful environmental effects. The durability achieved through heat treatment also supports the recyclability of stainless steel, ensuring that it can be reused multiple times, thus reducing the demand for new raw materials.

Several industries benefit significantly from heat-treated 304 stainless steel. In aerospace and engineering, it’s used for its enhanced ductility and corrosion resistance. The chemical and oil & gas sectors rely on its improved corrosion resistance in harsh environments. The food and beverage industry values it for hygienic properties after annealing. Architectural and construction applications prefer it for outdoor use due to durability. In laboratory and medical settings, it withstands sterilization. Manufacturers also benefit from its ease of fabrication and weldability after heat treatment.