When it comes to bending aluminum pipe, the path to success isn’t just about brute force—it’s an art form that requires precision and understanding. Whether you’re crafting a custom bike frame or a sleek piece of furniture, mastering the art of bending aluminum without kinking or cracking is essential. But how can you achieve those smooth curves without the luxury of specialized equipment? This guide is designed for the intermediate DIY enthusiast ready to dive into the nuances of pipe bending, offering a step-by-step walkthrough that covers everything from selecting the right aluminum alloy to choosing between cold forming and heat bending. Along the way, we’ll tackle common challenges like preventing kinks and explore budget-friendly tool options. Ready to bend aluminum like a pro? Let’s unfold the secrets behind those perfect arcs and discover the techniques that can transform your projects.

Aluminum alloys are broadly categorized into non-heat-treatable and heat-treatable groups, each offering distinct properties that affect their suitability for bending processes. Understanding these categories helps in choosing the best alloy for specific applications.

These alloys, such as the 3xxx and 5xxx series, are known for their excellent ductility and corrosion resistance. They are particularly suited for applications where bending is required without compromising material integrity.

These alloys can undergo heat treatment to enhance strength and other mechanical properties. The 6xxx series is a common choice for applications requiring both strength and formability.

The temper of an aluminum alloy significantly influences its bending performance. Understanding these temper states is essential for achieving desired bending results without compromising the material’s structural integrity.

The O-temper is the softest state of aluminum alloys, achieved through annealing. This state is optimal for intricate bends, especially in non-heat-treatable alloys like 3xxx and 5xxx, as it allows for maximum ductility.

The T4 temper, achieved by solution heat treatment and natural aging, is crucial for bending heat-treatable alloys like the 6xxx series. This temper provides a balance between formability and strength, making it suitable for applications requiring subsequent strengthening through aging.

H-tempers represent strain-hardened states, which provide increased strength through cold working. These tempers are suitable for moderate bends in non-heat-treatable alloys, where some degree of stiffness is beneficial.

When bending aluminum alloys, careful consideration of alloy type and temper state is crucial to prevent issues such as cracking or kinking.

Understanding these fundamental aspects of aluminum alloys and temper states will guide the selection and processing of materials to achieve optimal bending outcomes in various applications.

The bending radius is a key factor in pipe bending, as it determines how sharply the pipe can be curved without damaging the material. The minimum bending radius is typically expressed as a multiple of the pipe’s outer diameter (OD), and it varies based on the alloy and wall thickness. For example, softer aluminum alloys like 3003 can handle tighter radii, while harder alloys may require larger radii to prevent cracking. Ensuring the correct bending radius is vital for maintaining the integrity of the pipe and avoiding structural failures.

Material thickness significantly affects the bending process, especially when performed manually, as thicker materials require more force and are more prone to issues like kinking or collapsing. When manually bending aluminum pipes, the limitations are often dictated by the physical strength required and the tools available.

To optimize the bending process, careful consideration of both the bending radius and material thickness is essential. Choosing the right tools and techniques for the specific aluminum alloy and temper ensures more precise bends and fewer defects.

There are two main techniques for bending aluminum pipes: cold bending and heat bending. Each technique has its own applications, benefits, and drawbacks.

Cold bending shapes aluminum pipes using mechanical force at room temperature, without external heat.

Heat bending involves applying heat to the aluminum pipe to increase its malleability, making it easier to bend.

For those without access to specialized machinery, manual bending and the sand filling method offer practical alternatives.

This technique involves using basic tools and physical effort to achieve the desired bend.

Filling the pipe with sand before bending helps maintain its shape and prevent collapsing.

Selecting the appropriate bending technique depends on the specific requirements of your project, including the type of aluminum alloy, pipe dimensions, and desired bend complexity. By understanding and applying these techniques, you can ensure efficient and high-quality bends in aluminum piping.

A tube bender is essential for bending aluminum pipes accurately and efficiently, preventing issues like kinking or flattening. There are several types of tube benders available to suit different needs. Manual tube benders are portable and easy to use, perfect for small projects and softer aluminum alloys, though they require physical effort. Hydraulic tube benders offer more force with less manual input, ideal for thicker pipes and larger tasks. Electric tube benders provide precision and efficiency, making them suitable for high-volume production and complex bends.

Bending dies play a critical role in shaping and securing the pipe during the bending process. Bend dies determine the bend radius, while clamp dies secure the pipe to prevent slippage. Pressure dies apply the necessary force to maintain the pipe’s shape, ensuring precise bends without damage.

Mandrels support thin-walled pipes internally, preventing collapse during bending. They come in various forms, such as plug mandrels for standard bends and ball mandrels, which allow for flexibility in complex bending scenarios.

Wiper dies are used to prevent wrinkles on the inside of the bend, which is particularly important when working with softer aluminum alloys to maintain surface quality.

Lubricants are crucial for reducing friction and protecting the pipe surface, ensuring smooth bends and prolonging tool life. Regular lubrication enhances the efficiency of the bending process and extends the lifespan of the equipment.

For those seeking cost-effective solutions, DIY jigs can be customized for specific needs, though they require manual operation and are less precise. CNC machines offer high precision and repeatability, suitable for large-scale production, providing an efficient and accurate option despite their higher initial cost.

Before you begin the cold bending process, it’s essential to thoroughly prepare the aluminum pipe. Start by assessing the pipe’s condition, ensuring it is free from any damage such as cracks or folds that could compromise the bending quality. Determine the thickness and alloy type, as these aspects will dictate the tools required and the ease of bending.

Clean the pipe thoroughly to remove any contaminants like dirt or oil that may interfere with the bending process. Once clean, accurately mark the locations where the bends are intended. This marking ensures precision and helps guide the bending process, preventing errors and material wastage.

Use a tube bender designed for aluminum pipes to ensure precise bends without damage. For thin-walled aluminum pipes, utilize mandrel and wiper dies, which are crucial for supporting the interior of the pipe during bending, preventing wrinkles, and maintaining the pipe’s structural integrity. Place the marked aluminum pipe into the tube bender, ensuring it is aligned correctly with the die. Secure the pipe firmly to prevent movement during the bending process, which can cause inaccuracies or damage.

Gradually apply force to guide the pipe around the die, ensuring it follows the marked points and achieves the desired bend. Aluminum tends to spring back slightly after bending, so bend slightly beyond the desired angle, release, and check the angle. Adjust accordingly until achieving the precise bend required. To prevent kinking or wrinkling, especially with thin-walled pipes, employ mandrel bending techniques by inserting a solid rod into the pipe during bending, offering internal support and maintaining the pipe’s shape.

After bending, inspect the pipe for any signs of damage or deformation. Use precise tools to check the bend angle and adjust as needed to meet specifications. This step ensures the quality and functionality of the bent pipe in its intended application.

Applying heat is a key technique in bending aluminum pipes, as it makes the material more flexible and less likely to crack. By carefully controlling the heat, the microstructure can be altered, enhancing the pipe’s pliability while maintaining its integrity.

Annealing involves heating the aluminum pipe to a specific temperature and then allowing it to cool slowly. This reduces hardness and increases ductility, making the material suitable for complex bends.

An oxyacetylene torch with a rosebud tip is ideal for manually applying heat. This setup provides broad and even heat distribution, which is crucial for achieving uniform ductility across the bend area.

Induction heating systems offer precise temperature control and rapid heating, making them suitable for both small-scale and industrial applications. Equipment like the 3.5 kW EASYHEAT system can quickly reach target temperatures, facilitating efficient bending processes.

Effective temperature monitoring ensures the aluminum does not overheat, which can degrade its properties. Utilize infrared thermometers for accurate readings and consistent results.

By understanding and applying these heat application techniques, the bending of aluminum pipes can be optimized for quality and efficiency, reducing the risk of common bending problems such as cracking and kinking.

Maintaining the shape and integrity of aluminum pipes during bending is essential to avoid kinks that can compromise their strength and appearance. To prevent kinking, fill the aluminum pipe with oil dry (fuller’s earth) to provide internal support and reduce kinking risk. Ensure the filler is packed tightly and evenly to distribute stress along the pipe’s length. Additionally, using mandrel benders with bullet alignment helps maintain a consistent shape by providing backpressure against the bending force. Gradually and consistently apply bending force to prevent sudden or uneven stress that could cause the pipe to buckle or kink.

In addressing issues like cracking and springback, heat treatment is a useful technique. For alloys like 6063, carefully heat the pipe until a soap marker blackens, indicating the right temperature. This process enhances ductility, minimizing the risk of cracking. To manage springback, bend slightly beyond the desired angle, using angle finders to measure accurately. Consider choosing alloys with better formability, such as 6061-T6, for more complex bends.

When tackling wall collapse issues, internal support is key. For instance, using sand filling has proven effective in maintaining the pipe’s shape during bending. Ensure tools are correctly aligned and adjusted to the pipe’s diameter and wall thickness, including using the right-sized bending dies and mandrels. Apply heat uniformly across the bending area, rotating the pipe under a steady heat source to prevent localized weaknesses.

After bending, inspect the pipe for defects. Look for surface irregularities or cracks, and smooth out any rough edges to enhance both appearance and durability. Perform localized heat treatment to relieve stress in bent areas, particularly for thicker or more complex bends, to reduce residual stresses that could lead to future cracking.

Below are answers to some frequently asked questions:

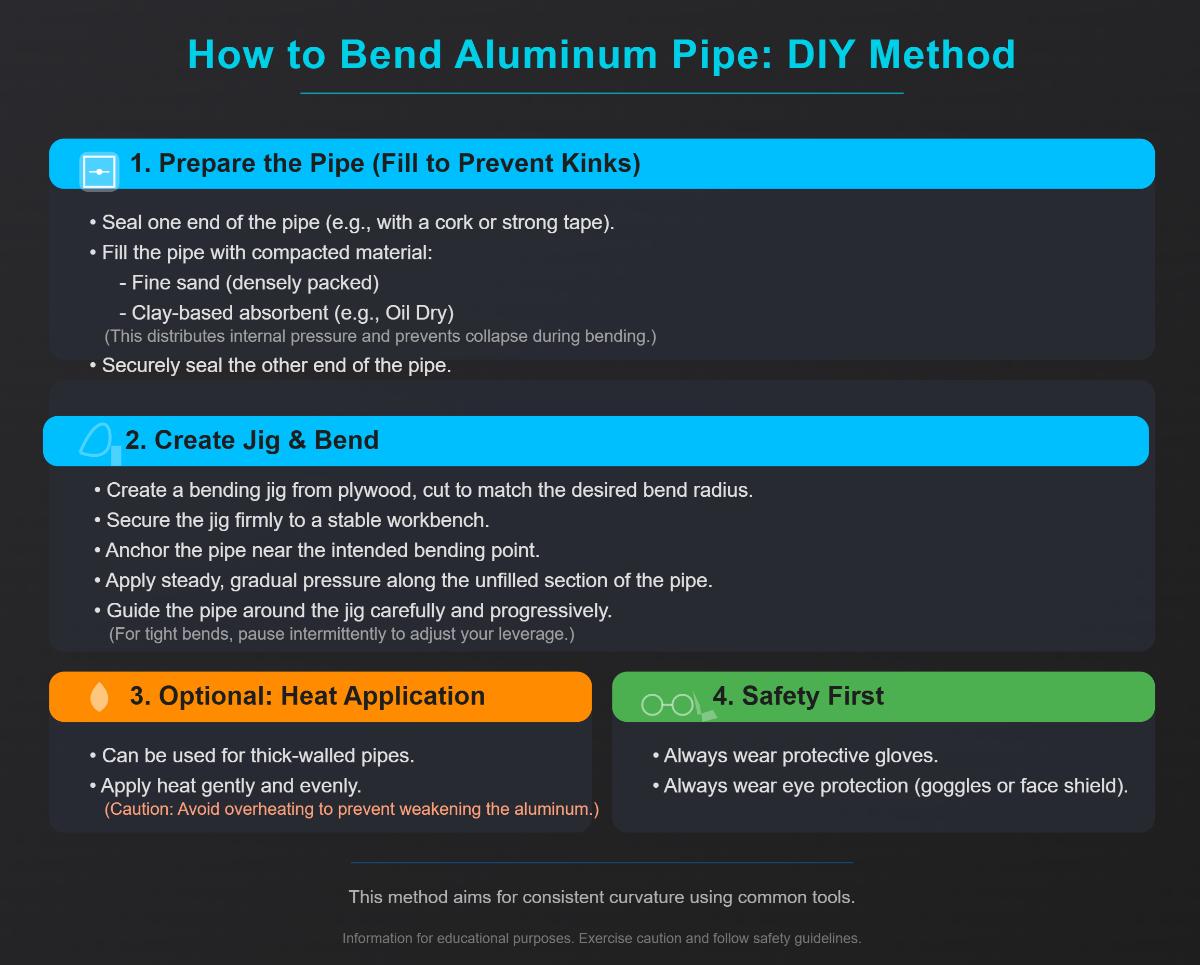

The easiest way to bend aluminum pipe without special tools involves using a filling method to prevent kinking. Start by sealing one end of the pipe with a cork or tape. Fill the pipe with compacted sand or a clay-based absorbent like Oil Dry. This filling material helps distribute internal pressure and avoids collapse during bending. Seal the other end of the pipe securely.

Create a bending jig from plywood, cutting it to match the desired bend radius, and secure it firmly to a workbench. Anchor the pipe near the bending point and apply steady pressure along the unfilled section, guiding the pipe around the jig gradually. For tight bends, pause intermittently to adjust leverage.

Optional heat application can be used for thick-walled pipes, but avoid overheating to prevent weakening the metal. This method ensures consistent curvature and replicates professional results using household tools. Wear gloves and eye protection for safety during the process.

To prevent kinking when bending aluminum tubing, several techniques can be employed to ensure the tubing maintains its shape and integrity. Firstly, using mandrels is highly effective; plug mandrels provide internal support during the bending process, preventing flattening or buckling. Additionally, filling the tube with compacted sand before bending can offer similar support, keeping the tube’s shape intact. Employing proper bending techniques is also crucial—smooth and gradual bends are recommended to distribute stress evenly across the tubing. It’s essential to use appropriate tube benders designed for aluminum to maintain control over the bending process. Choosing a thicker tube can also help resist kinking, as it provides more structural support. By following these methods, you can effectively avoid kinking and ensure the tubing’s functionality and durability.

Aluminum pipes can be bent manually if they are up to about 1/8 inch (3 mm) in thickness. This thickness allows for relatively easy manual bending using basic hand tools, such as pipe benders or vices, without excessive force. Thicker pipes present more resistance and are more challenging to bend manually, often necessitating specialized equipment like hydraulic benders for effective results. When manually bending, it’s essential to consider the aluminum alloy’s ductility and the bend radius, as maintaining a bend radius of at least 1.5 to 3 times the material thickness helps prevent damage like kinking or cracking. For successful manual bending, ensure the aluminum type is suitable and the tools are appropriate for the pipe size, applying even force to achieve smooth bends.

Cold forming and heat bending are two primary methods for bending aluminum pipes, each with distinct characteristics. Cold forming involves bending the pipe at room temperature using mechanical force, often with tube bending machines like CNC devices. This method preserves the aluminum’s original properties, such as strength and surface treatments, and is generally less expensive. However, it typically results in larger bending radii and may reduce ductility at the bend points, making it less suitable for tight or complex bends.

Heat bending, on the other hand, requires heating the aluminum to make it more pliable. This technique can achieve tighter bends and distribute stress more evenly, maintaining ductility. However, it risks altering the material properties, potentially requiring post-bend treatments to restore strength, and demands specialized equipment.

For aluminum pipes, cold forming is usually preferred due to its preservation of material properties and simpler equipment requirements. Heat bending might be considered for more complex bends, but it requires careful control to mitigate heat exposure risks.

Budget-friendly options for bending aluminum pipes include DIY tools and affordable commercial products. For those interested in a hands-on approach, creating a DIY metal bending tool can be economical and effective. Basic materials like zinc hinges, machine screws, washers, and a metal saw can be sourced from local hardware stores at a low cost, typically between $25 and $29. This homemade tool allows you to manually bend softer metals, including aluminum, with simple assembly steps.

For those seeking more precision without breaking the bank, affordable commercial tools are available. Companies like Affordable Benders offer tube benders with die sets at competitive prices, though the dies can be an additional cost. Rogue Fabrication provides reliable tube and pipe benders designed for more extensive use, offering a balance between cost and functionality.

When choosing a tool, consider the size and type of bends required, material compatibility, and the desired precision to ensure optimal results within your budget constraints.

To effectively enhance your understanding of bending aluminum pipe, visual aids play a crucial role. Here are some recommendations:

By incorporating these visual aids, you can enhance your comprehension and execution of precise bends in aluminum pipes.