Bending steel pipes might sound like a task reserved for professionals, but with the right guidance and tools, even a complete beginner can master this skill. Whether you’re looking to create custom plumbing, unique metal furniture, or intricate DIY projects, understanding how to bend steel pipe opens up a world of possibilities. This comprehensive guide will walk you through the basic steps to bend a steel pipe correctly, from selecting the appropriate tools to ensuring your bends are smooth and accurate.

We’ll start by introducing the essential tools you’ll need, such as tube bending machines and hand pipe benders. Next, we’ll delve into the properties of different types of steel pipes and why these matter for bending. You’ll learn a step-by-step manual bending process, including measuring, marking, and using a hand bender. Additionally, we’ll cover advanced techniques like the sand filling method to prevent pipe deformation and ensure perfect bends.

By the end of this guide, you’ll not only know how to bend steel pipes with confidence but also how to avoid common pitfalls such as collapsing or wrinkling. Ready to get started? Let’s dive into the world of steel pipe bending and unlock your creative potential.

Steel pipe bending is a process in metal fabrication that shapes steel pipes into specific angles or curves while maintaining their structural integrity. This technique is essential in various industries, including construction, plumbing, automotive, and manufacturing, where pipes need to fit precise spatial configurations or design requirements. Steel pipe bending allows for the customization of pipes to meet specific design and functional needs, whether creating a seamless connection in plumbing systems, forming the framework for construction projects, or shaping automotive exhaust systems.

Understanding the fundamental concepts of steel pipe bending is crucial for anyone new to this process. Here are some key terms and ideas to get you started:

Nominal Pipe Size (NPS)

Nominal Pipe Size (NPS) is a standard way to size pipes, including their outside diameter (OD), wall thickness, and pipe schedule. These dimensions are crucial for determining how the pipe will behave during bending and what tools and techniques will be needed.

Bending Radius

The bending radius is the distance from the center of the bend to the centerline (axis) of the pipe. It is a critical measurement because it affects the pipe’s final shape and structural integrity. The smaller the bending radius, the tighter the bend.

Wall Thickness

The thickness of the pipe’s wall significantly impacts bending. Thinner walls are more prone to wrinkling and deformation, requiring careful handling and specific techniques to maintain the pipe’s shape.

There are several methods used to bend steel pipes, each suited to different applications and bend radii:

For beginners, the steel pipe bending process can be broken down into several clear steps:

Plan the Bend and Set Up the Bender

Determine the required shape or angle for the pipe, then adjust the bending equipment to match the pipe’s size and material thickness. Modern benders may feature mechanical, hydraulic, or CNC controls for enhanced accuracy.

Align the Pipe

Carefully position the steel pipe on the bender. Use additional tools like mandrels and wiper dies to support the pipe and prevent defects during bending.

Perform the Bend

Follow the machine’s instructions to execute the bend. The bending die moves the pipe around the centerline radius, ensuring the desired curvature.

Release and Inspect

After bending, disengage the pipe from the bender and check for any defects such as kinks, flattening, or cracks. Proper technique and tooling are essential to avoid these issues.

Several tools and accessories are commonly used in steel pipe bending to achieve precise and defect-free bends:

Tube bending machines are essential for shaping steel pipes into precise angles and curves, and they come in various types to suit different bending tasks and automation levels.

Manual tube benders are hand-operated, cost-effective, and easy to use, making them ideal for small-scale projects and beginners. These benders typically include a lever and a die set for manual bending.

Hydraulic tube benders use hydraulic pressure to bend pipes, offering more power and precision than manual benders. They are suitable for thicker pipes and more demanding projects, providing consistent results with less physical effort.

CNC tube benders are automated machines controlled by computer programming. They offer high accuracy and efficiency, making them perfect for large-scale production and complex bends.

Hand pipe benders are portable and easy to use, making them suitable for on-site work or small workshops. Designed for bending smaller pipes, they provide a straightforward solution for simple bends.

A deburring tool is crucial for cleaning up pipe edges after cutting or bending, removing burrs and sharp edges to ensure smooth and safe pipe ends. This tool helps maintain the pipe’s integrity and prevents damage during the bending process.

The bend die determines the radius of the bend with its concave channel fitting the pipe’s outer diameter, guiding it into the desired curve. Different bend dies are used based on pipe size and the required bend radius.

The clamp die holds the pipe firmly against the bend die during bending. It ensures the pipe stays in place, providing consistent and accurate bends without slipping.

The pressure die applies force to the pipe, pushing it against the bend die. This pressure helps the pipe conform to the desired shape, preventing deformation and ensuring a smooth bend.

The wiper die is positioned inside the bend to support the pipe wall and prevent wrinkles or creases. It is especially important for maintaining a smooth inner surface during tight bends.

A mandrel is inserted inside the pipe during bending to support the inner wall, preventing collapse or kinking, which is essential for maintaining the pipe’s structural integrity during tight bends.

Understanding and using these essential tools will help achieve accurate and high-quality bends in steel pipes, ensuring successful outcomes for various projects.

Knowing the various types of steel pipes is crucial for successful bending. Various steel compositions and manufacturing processes result in pipes with distinct properties suitable for specific applications.

Carbon steel pipes are widely used due to their strength and durability. They contain varying amounts of carbon, which influences their hardness and ductility. Low-carbon steel is more malleable and easier to bend, while high-carbon steel is harder but more brittle, requiring careful handling during bending. Stainless steel pipes are known for their corrosion resistance and strength. They are more challenging to bend than carbon steel due to their higher strength and lower ductility. However, they are ideal for applications where corrosion resistance is crucial.

Alloy steel pipes contain additional elements like chromium, nickel, and molybdenum, which enhance their mechanical properties. These pipes offer improved strength, toughness, and resistance to wear and corrosion. The specific alloy composition affects the pipe’s bending characteristics.

Steel pipe properties greatly affect how they bend. Key properties to consider include malleability, ductility, carbon content, and the phenomena of springback and radial growth.

Malleability refers to a material’s ability to deform under compressive stress. Highly malleable materials can be shaped easily without cracking or breaking. This property is crucial for achieving smooth bends in pipes.

Ductility is the ability of a material to stretch without breaking under tensile stress. Ductile materials, such as mild steel, can undergo significant deformation before fracturing. This makes them ideal for bending processes, as they can accommodate the stresses involved without compromising structural integrity.

The carbon content in steel determines its hardness and brittleness. Low-carbon steel is softer and more ductile, making it easier to bend cold. High-carbon steel, on the other hand, is harder and more prone to cracking, often requiring heating to achieve the desired bend.

Springback is when a pipe tries to revert to its original shape after being bent. Radial growth refers to the increase in diameter at the bend due to material stretching. Both phenomena must be accounted for to ensure precise and accurate bends.

Different pipe materials exhibit unique bending properties, making them suitable for various applications:

Selecting the appropriate bending technique and equipment is crucial for achieving accurate and high-quality bends:

Mandrel bending involves inserting a mandrel inside the pipe to guide the bending process. This technique is ideal for achieving tight radii and smooth bends with minimal ovality.

Cold bending retains material properties better than hot bending and is more versatile, accommodating various metal types and thicknesses. It is particularly suitable for materials that are prone to losing strength when heated.

Before starting the manual pipe bending process, gather the following tools and materials:

Accurate bends start with proper preparation:

Select the bending shoe that matches your pipe’s diameter exactly (e.g., ½ inch shoe for ½ inch pipe) to ensure the bend matches your pipe’s diameter:

To set up the pipe, open the bender handles, place the pipe on the bending shoe, and secure it with the clamp. Align the mark on the pipe with the angle markers on the bender.

Start bending the pipe by slowly pulling the handles down (lever bender) or squeezing the ratchet trigger (ratchet bender). Continue bending until you reach the desired angle, checking the handle angle markers for confirmation.

Once the bend is complete, carefully release the handles to open the bender. Remove the pipe by pulling it out of the former and clamp assembly.

For best results: use a bender that matches your pipe size, bend slowly and steadily, use angle markers for precision, measure and mark each bend point carefully, and wear safety gear to protect your hands and eyes.

Using sand filling is a reliable way to prevent steel pipes from deforming during bending. This method ensures that thin-walled pipes maintain their structural integrity and shape, reducing the risk of collapsing or buckling. Here are some key reasons to use the sand filling method:

Start by cleaning the pipe thoroughly to remove any debris or contaminants. Inspect the pipe for any defects or damage that could affect the bending process.

Use dry, fine sand to fill the pipe completely. Make sure the sand is free of large particles for even distribution.

Densely pack the sand inside the pipe using a rod or mechanical device. This crucial step ensures the sand provides solid internal support.

Cap or plug both ends of the pipe securely to keep the sand in place during the bending process. This prevents the sand from spilling out and ensures uniform support throughout the pipe length.

Bend the pipe using the appropriate method, such as rotary draw bending. The sand inside the pipe will support the walls internally, helping maintain the pipe’s shape and preventing deformation.

Once the bending is complete, remove the sand from the pipe by flushing it with water or using a vacuum. Make sure to remove all the sand to avoid any leftover material that could impact the pipe’s functionality.

Tube and pipe bending machines come in various types, each designed to cater to different bending needs and applications. Here are the main types:

Manual tube benders are easy-to-use, cost-effective tools operated by hand. They are ideal for small-scale projects and beginners. These benders typically consist of a lever and a set of dies to shape the pipe manually.

Hydraulic tube benders use hydraulic pressure to bend pipes, providing more power and precision than manual benders. They are suitable for thicker pipes and more demanding projects, delivering consistent results with less physical effort.

CNC (Computer Numerical Control) tube benders are automated machines that use computer programming to control the bending process. They offer high accuracy and efficiency, making them perfect for large-scale production and complex bends.

Tube and pipe bending machines operate by applying force to the pipe to bend it around a fixed radius or die. Key components play a crucial role in the bending process:

The bend die is a stationary part that defines the radius and shape of the bend. It is crucial for ensuring the pipe conforms to the desired curve without collapsing.

The clamp or holding block secures the pipe in place during bending to prevent movement. This ensures the pipe remains accurately positioned against the bend die.

The roller or compression die glides along the pipe’s outer side, pressing it against the bend die to shape the curve. This component is essential for achieving a smooth and uniform bend.

The pipe feeding mechanism moves the pipe forward during the bending process, allowing for continuous shaping. This ensures the pipe bends progressively without interruptions.

It’s essential for beginners to understand the key components of tube bending machines:

The rocker’s arm controls the bending radius to meet specific requirements. It adjusts the position of the bend die relative to the pipe.

The clamping seat restricts the pipe’s spring-back effect, maintaining the bend shape once the bending force is removed.

The pump station provides hydraulic power for various machine operations, including clamping and pushing the pipe.

Guide wheels ensure horizontal bending and keep the pipe aligned during the process. They prevent the pipe from deviating from its intended path.

The straightening wheel prevents vertical deformation and maintains the pipe’s shape. It ensures the pipe remains straight after bending.

The pushing device moves the pipe through the machine, enabling it to bend progressively. It ensures the pipe is fed smoothly and consistently during the bending process.

Various industries rely on tube and pipe bending machines for their precision and uniformity in creating bends. Common applications include:

While tube and pipe bending machines are highly effective, they do have limitations:

Understanding these limitations helps in selecting the right machine and setting up the process correctly to achieve optimal results.

Bending steel pipes at home can be a straightforward and rewarding process with the right techniques and tools. Here are some simple methods that beginners can use to achieve effective bends without the need for professional equipment.

A hand bender is a portable and easy-to-use tool that is ideal for bending small-diameter pipes. Follow these steps to use a hand bender:

If you don’t have a hand bender, a pipe vice can also be used to bend steel pipes. This method is suitable for creating simple bends:

When bending steel pipes at home, it’s essential to have the right tools to ensure safety and accuracy. Consider using a hand pipe bender for smaller pipes, a pipe vice to secure your work, a heat gun or propane torch for heating, measuring tools for precision, and protective gear like gloves and safety glasses.

To achieve the best results when bending steel pipes at home, consider the following tips:

By using these techniques and tools, you can successfully bend steel pipes at home, creating custom shapes for various DIY projects.

Choosing the correct steel grade and thickness is essential for precise and safe bends. Different steel materials have unique bending properties; for instance, low-carbon steel bends more easily than high-carbon steel because of its greater ductility. Always select a material that aligns with your project’s requirements to ensure optimal results.

Before bending, know the steel pipe’s nominal size, wall thickness, and schedule. These factors influence the bending technique and the tools needed. Understanding these properties aids in planning the bending process and selecting the appropriate equipment.

Make sure your bending equipment is properly calibrated for the material and technique you are using. Incorrect calibration can lead to pipe distortion or damage. Regularly check and adjust your equipment to maintain accuracy and prevent any bending issues.

Use the right tools for the job, including pipe benders, mandrels, bending dies, and clamps. Each tool plays a vital role in achieving precise bends and preventing damage to the pipe. For example, mandrels can prevent the pipe from collapsing or wrinkling during the bending process.

Mandrel bending is ideal for pipes that are prone to distortion. A mandrel inserted inside the pipe supports the walls, preventing collapse and ensuring a smooth bend. This technique is particularly useful for tight radii bends.

Compression bending is suitable for bends that do not require tight radii. In this method, the bending die remains stationary while the pipe is pushed against it. This technique minimizes distortion and is effective for simpler bends.

Roll bending uses rollers to create smooth, large-radius bends. This technique is beneficial for applications requiring gradual curves and is less likely to cause deformation compared to other methods.

Use precise measuring tools such as protractors, angle finders, and even lasers to ensure your bends are accurate. Accurate measurements are crucial for achieving the desired bend angle and maintaining consistency across multiple bends.

Apply a uniform speed and the correct amount of force during the bending process. Inconsistent speed or force can lead to irregularities like ripples or flattening of the pipe. Consistency helps in maintaining the structural integrity of the pipe.

Springback is the tendency of a pipe to partially revert to its original shape after bending. To counteract this, overbend slightly beyond the desired angle. This compensation ensures that the final bend is accurate.

Always wear protective gear such as gloves, goggles, and protective clothing to reduce the risk of injury. Following safety guidelines is essential to ensure a safe working environment.

Regularly check your equipment for damage and inspect the bends for quality. Look for defects such as kinks, cracks, or flattening. Ensuring the structural integrity and precision of each bend is crucial for the overall quality of your project.

Below are answers to some frequently asked questions:

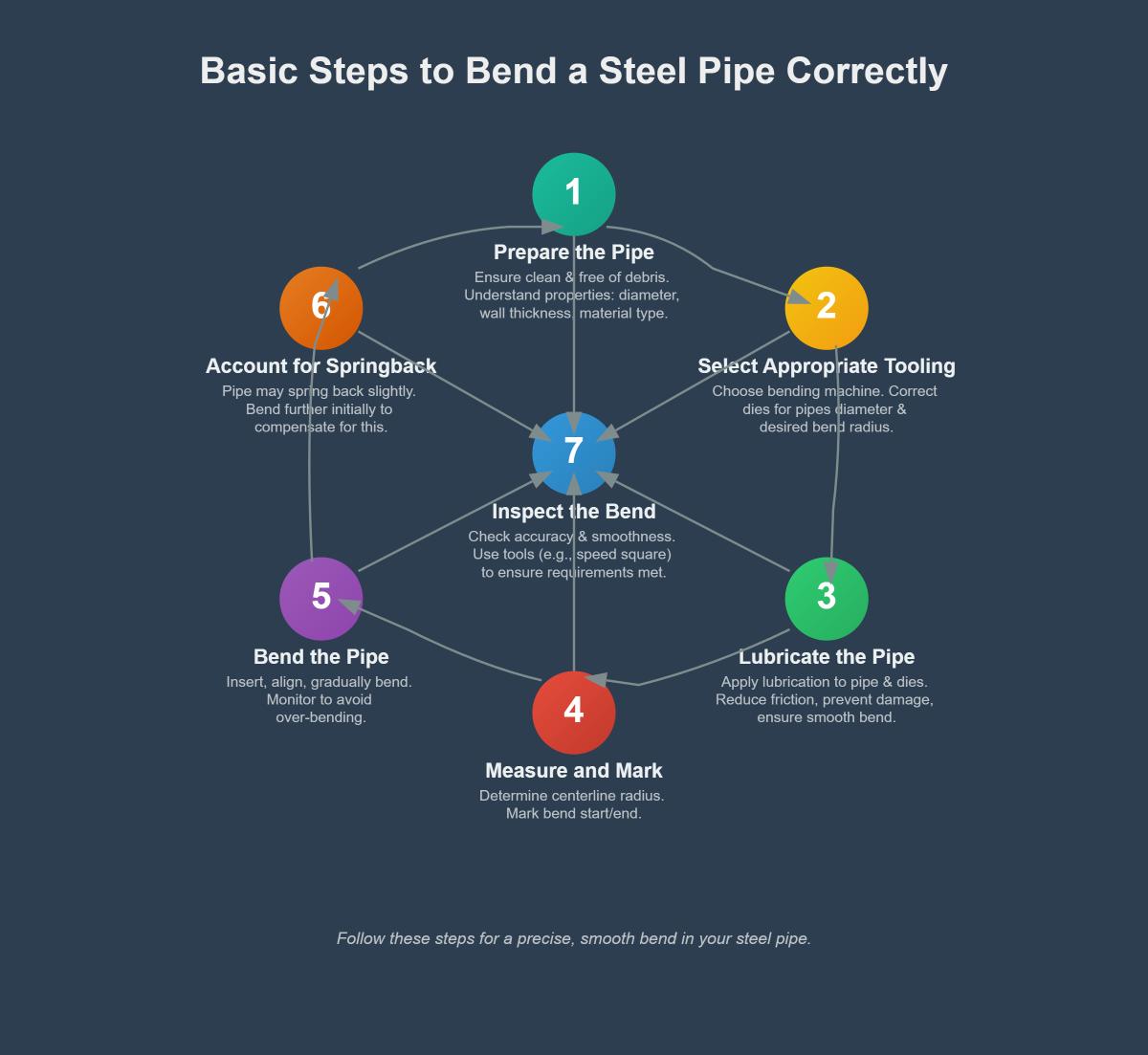

To bend a steel pipe correctly, follow these basic steps:

By following these steps, you can achieve a precise and smooth bend in your steel pipe.

To bend steel pipes at home, you will need several basic tools and materials to ensure effective and accurate bending. Firstly, a manual pipe bender is essential as it provides the leverage required to bend the pipe smoothly without kinking or collapsing it. If a manual bender is not available, you can use the sand filling method, which involves filling the pipe with sand to maintain its shape during bending. You will also need a sturdy lever or a long pipe to increase the bending force, making it easier to bend thicker pipes.

Measuring and marking tools, such as a protractor or angle gauge, are necessary to measure and mark the bend angle accurately. Clamps or a bench vise are useful for holding the pipe securely while bending, preventing it from slipping and ensuring even force application.

For more advanced bending, a hydraulic tube bender can be used, especially for thicker or larger diameter pipes, though it requires more skill and parts. Custom bending dies can also help create smooth bends matching the pipe size.

To prevent steel pipes from collapsing or wrinkling during bending, there are several effective techniques to consider. First, using a mandrel, a device inserted inside the pipe, provides internal support and prevents collapse or pinching. This is particularly useful for tight-radius bends. Second, employing rotary draw bending with a proper die helps maintain the pipe’s shape. The die supports the pipe’s exterior, preventing it from becoming oval-shaped. It is crucial to apply the correct clamping pressure to avoid wrinkling or thinning of the pipe walls. Third, following the minimum bend radius rule, which suggests that the bend radius should be at least four times the pipe diameter, reduces stress on the pipe walls and maintains structural integrity. Lastly, for tougher pipes, heat induction bending softens the steel, making it more pliable and reducing the risk of cracks or wrinkles. By combining these techniques, you can achieve smooth and precise bends in steel pipes.

Pipe bending machines come in several types, each suited to different applications:

Each type of pipe bending machine has its own advantages and is chosen based on the specific needs of the project, such as material type, bend complexity, and production volume.

Yes, you can bend steel pipes without professional equipment using several accessible DIY methods. One common method is the sand filling technique, where you fill the pipe with dry sand to prevent it from collapsing or wrinkling during bending. After securely plugging one end and filling the pipe with sand, you can manually bend it around a form or jig to achieve the desired curve. This works best for pipes with thinner walls.

Another method is heat bending using a blow torch. By heating the pipe at the bend point until it becomes malleable, you can carefully bend it around a form or jig. This method is suitable for thicker pipes or when a tighter bend radius is needed. Always use heat-resistant gloves and ensure safety when handling high temperatures.

For thinner pipes, manual bending with protective wrapping can be effective. Wrapping the ends of the pipe with leather strips or thick cloth helps protect your hands and provides better grip. Apply steady, even pressure and bend slowly to avoid kinks or flattening.

These methods are practical for home use and can yield satisfactory results with proper technique and care.

When bending steel pipes, it’s crucial to follow safety precautions to prevent injuries and ensure a smooth process. Firstly, always wear personal protective equipment (PPE), including safety goggles or face shields, gloves, and closed-toe shoes. Avoid wearing loose clothing or jewelry that could get caught in the machinery.

Before starting, inspect your tools and machines. Ensure the dies are compatible with the pipe’s diameter and thickness, and that all components are securely fastened. Check hydraulic systems for any leaks or irregularities.

During operation, align the pipes correctly with the dies to prevent slippage and maintain a safe bending radius, typically not tighter than 10 times the pipe’s outer diameter. Keep your hands away from clamping zones and moving parts to avoid crush injuries.

In case of any unusual noises or malfunctions, shut down the machine immediately and power off before making any adjustments. Always stay within reach of the emergency stop switch.

After bending, clean up any debris and report any defects or issues with the equipment. Following these safety measures will help prevent accidents and ensure successful steel pipe bending.