Have you ever wondered how to determine the weight of angle iron for your next construction or metalworking project? Whether you’re a beginner in the world of metal fabrication or simply looking to enhance your knowledge, understanding the process of calculating the weight of angle iron is crucial. In this comprehensive guide, we’ll demystify the process with a step-by-step approach, ensuring you grasp the fundamental principles with ease.

We’ll start by introducing angle iron, explaining its definition, uses, and common applications. Then, we’ll delve into the essential tools required for measuring its dimensions accurately. Understanding the density of iron and its impact on weight calculations will be covered, along with typical density values. Ready to master the art of calculating the weight of angle iron? Let’s get started!

Angle iron, also known as an L-beam or angle bar, is a type of structural steel characterized by its L-shaped cross-section. This shape provides strength and stability in two different directions, making it an ideal choice for various construction and metalworking applications. The two legs of the angle iron can be of equal or unequal length, depending on the specific requirements of the project.

Angle iron is typically made from materials such as:

Equal angle steel, with legs of the same length, provides uniform strength and stability, making it ideal for structural components, framing, and reinforcement.

Unequal angle steel has legs of different lengths, offering more flexibility in design and load distribution. This type is often used in applications where varying load conditions are expected.

In construction, angle iron is widely used for framing, support structures, and reinforcement due to its strength and versatility. It is commonly found in building frames, bridges, and other infrastructure projects.

In bridge construction, angle iron is used to reinforce arches and girders, providing additional support and stability to withstand heavy loads and environmental stresses.

Angle iron is also employed in the manufacturing of machinery and industrial equipment. It is used to strengthen corners and joints, ensuring the structural integrity of the equipment.

In warehousing and storage facilities, angle iron is used to construct sturdy and durable shelving units. Its strength and ease of fabrication make it an ideal material for creating custom storage solutions.

When choosing angle iron, consider the material based on project needs like strength and corrosion resistance. Protect it from moisture to prevent rust, and store it properly to maintain its structural integrity and ease of use.

Angle iron is a versatile and essential material in construction and metalworking, offering strength, stability, and adaptability for a wide range of applications. Understanding its properties and uses can help you make informed decisions in your projects.

Accurate angle iron measurements are essential for weight calculations and ensuring a proper fit in construction projects. Here are the essential tools required for this task:

A ruler or tape measure is fundamental for measuring the length of the angle iron. Choose one that provides clear, precise markings for accurate measurements. When using a tape measure, ensure it is properly aligned along the length of the angle iron to avoid any discrepancies.

Calipers and micrometers are essential for measuring the width and thickness of the angle iron. These tools provide high precision, which is crucial for ensuring the correct dimensions. Calipers are useful for larger widths, while micrometers are ideal for measuring thicknesses down to the millimeter.

A protractor is used to verify the angle between the legs of the angle iron. Standard angle irons usually have a 90-degree angle; however, it’s important to verify this for proper alignment in your projects.

Angle iron dimensions are often noted in a specific format. This format indicates the width of the legs and the thickness. For instance, “2x2x1/4 inches” means each leg is 2 inches wide, and the thickness is 1/4 inch.

Be aware of manufacturing tolerances that may slightly affect the actual measurements. Always check the manufacturer’s specifications for tolerance levels.

Ensure the surface of the angle iron is clean and smooth before measuring. Dirt, rust, or uneven surfaces can impact the accuracy of your measurements.

Accurate measurements are essential for calculating the weight of angle iron and determining its suitability for various structural applications. Using the right tools and following precise measuring steps will help ensure reliable results.

Density is a fundamental property of materials that describes how much mass is contained within a specific volume. The formula to calculate density is:

Density is measured in units of mass per volume, like kilograms per cubic meter (kg/m³).

Iron, commonly used in construction and manufacturing, has a density of about 7,870 kg/m³ at room temperature, making it ideal for applications requiring strength and durability.

Iron’s density is key to calculating the weight of components like angle iron. Knowing the density helps you determine the weight of an iron piece from its volume. This is essential for ensuring structural integrity and for logistical purposes, such as transportation and installation.

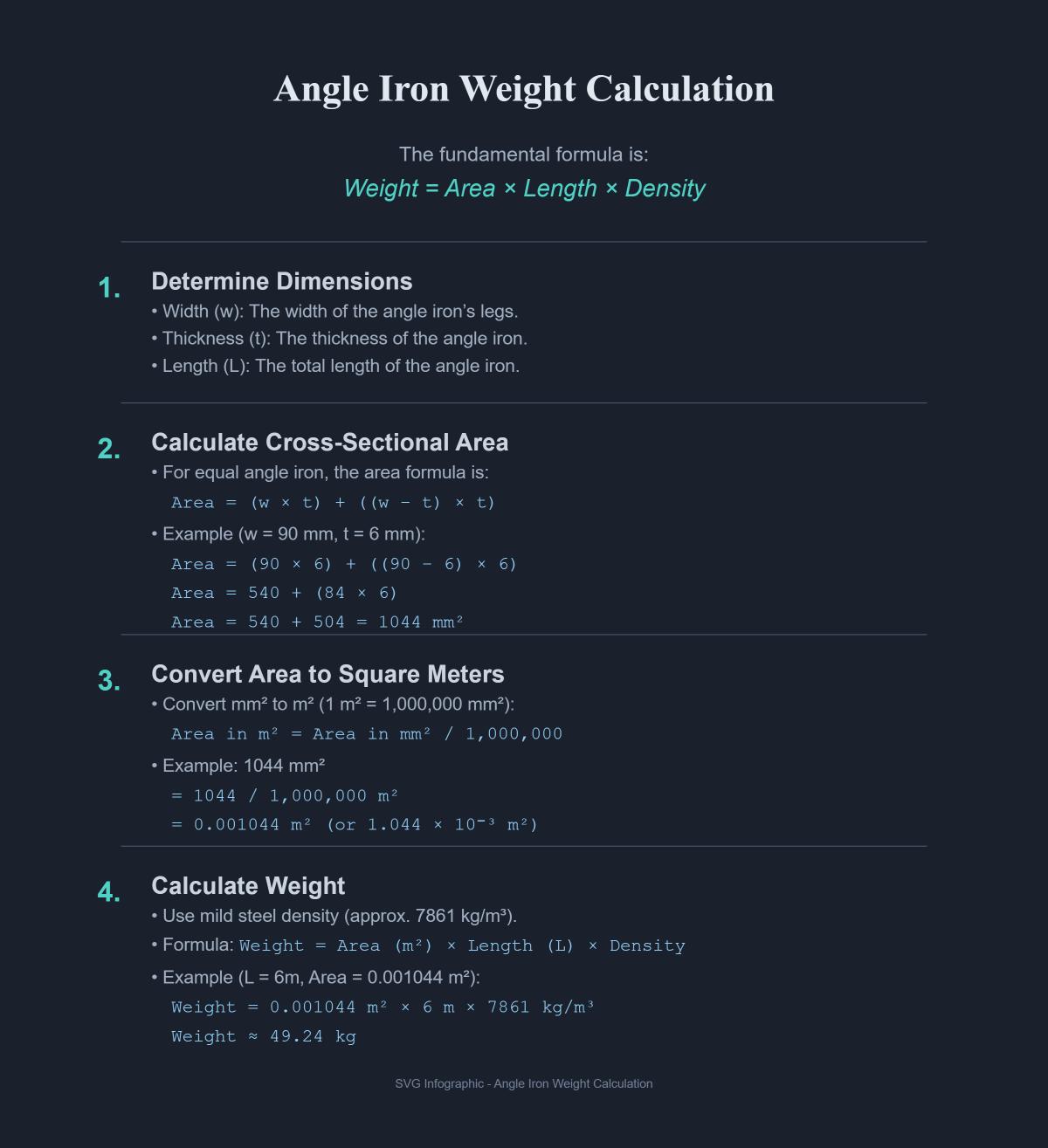

To calculate the weight of an iron component, you need to know its volume. The formula for calculating weight is:

Here’s a step-by-step example:

The density of iron can change slightly with temperature due to thermal expansion. At higher temperatures, iron expands, causing a slight decrease in density.

The presence of impurities or alloying elements in iron can also affect its density. For instance, adding carbon to iron to make steel can change the density slightly, depending on the carbon content and other alloying elements.

Understanding the density of iron is crucial for various applications in construction and engineering. Accurate weight calculations ensure that structural components like beams, columns, and angle iron can support the intended loads without failure. It also aids in planning for material handling, transportation, and installation logistics.

By mastering the concept of density and its application in weight calculations, you can make informed decisions in your projects, ensuring safety and efficiency.

Knowing how to calculate the weight of angle iron is essential for construction and engineering projects. Accurate weight calculations ensure proper material estimation, cost management, and structural integrity. This section will guide you through the basic principles and necessary steps to calculate the weight of angle iron effectively.

To calculate the weight of angle iron, you need the following parameters:

The weight of angle iron can be calculated using the following formula:

This formula is derived from the principle that weight equals volume times density, taking into account the cross-sectional area and the length of the angle iron.

If your steel has a different density, adjust the formula to reflect this.

Ensure the length measurement is in meters to maintain consistency in the formula. If the length is in centimeters, convert it to meters by dividing by 100.

Different steel grades may have slight variations in density, which can affect the weight calculation. Always verify the density of the specific material you are using.

Actual weights may vary due to corner arcs or inconsistent thicknesses in the angle iron. Consider these factors when performing weight calculations.

Accurate weight calculation aids in procurement planning, cost estimation, and ensuring that the structural components meet the required specifications.

Several online tools and calculators are available to simplify the weight calculation process. Websites like wCalcul and GIGACalculator offer metal weight calculators that can handle various metal types and shapes, including angle iron. These tools often require input of dimensions and material type to provide a precise weight calculation.

Using these tools can save time and reduce the risk of manual calculation errors.

Calculating the weight of angle iron is crucial for various construction and manufacturing projects. By understanding its dimensions and applying a straightforward formula, you can ensure accurate material planning and budgeting.

First, measure the side width (W), thickness (T), and length (L) of the angle iron. Next, use these measurements to calculate the volume with the formula:

This formula accounts for the cross-sectional area and length.

To convert the volume from cubic millimeters to cubic meters, multiply by ( 10−6):

Utilize online calculators like GIGACalculator and wCalcul, or create a spreadsheet to automate weight calculations for multiple pieces of angle iron.

One common mistake in calculating the weight of angle iron is using the wrong material density. The density of steel is typically around 0.00785 g/cm³, but other materials like cast iron have different densities. Using the incorrect density will lead to inaccurate weight calculations.

Always verify the density of the specific material you are working with before performing any calculations.

Incorrect or incomplete measurements of the angle iron’s dimensions, such as side width, thickness, and length, can lead to significant errors. Even a small error in measurement can result in a significant deviation in the calculated weight.

Double-check all measurements to ensure accuracy. Use precise measuring tools such as calipers, micrometers, and tape measures, and ensure they are properly calibrated.

When calculating the weight of angle iron, the volume of the corner intersection is often counted twice, which can result in an overestimation.

Calculate the volume of the corner intersection and subtract it once from the total volume to avoid double-counting.

Applying an incorrect formula or misunderstanding the calculation process is another common mistake. The weight of angle iron is calculated using a specific formula that takes into account the side widths, thickness, and length.

Use this formula to calculate the weight of angle iron:Weight=(side width1+side width2−thickness)×thickness×length×density, Adjust the formula for equal or unequal angles as needed.

Different grades of steel or other materials can have slightly different densities. Not considering these variations can lead to errors in weight calculations.

Be aware of the specific density of the material you are using, including any variations due to different grades. Adjust your calculations accordingly if necessary.

By following these guidelines and avoiding common mistakes, you can accurately calculate the weight of angle iron for construction and engineering projects. Utilize online calculators or software for more complex shapes and to streamline the process.

Below are answers to some frequently asked questions:

To calculate the weight of angle iron, you need to use the following formula:

Here’s how you can apply this formula step-by-step:

This formula helps you accurately determine the weight of angle iron based on its dimensions and material density.

The density of iron significantly affects the weight of angle iron, which is commonly used in construction and metalworking projects. Density is defined as the mass per unit volume of a substance. For iron, this density is approximately 7,847 kg/m³.

To calculate the weight of angle iron, you need to determine its volume and multiply it by the density of the iron. The formula for this calculation is: Weight = Density × Volume.

For instance, if you have an angle iron with a specific volume, you would multiply this volume by the density of iron to find its weight. The higher the density, the heavier the angle iron will be for the same volume. This is why knowing the exact density of the material you are using is crucial for accurate weight calculations. Different types of iron, such as pure iron or wrought iron, may have slightly different densities, so it’s important to use the correct value for your specific material.

To measure the dimensions of angle iron accurately, you will need a few essential tools. A ruler or tape measure is necessary for measuring the length and width of the angle iron’s legs. To measure the thickness of the material, a caliper or micrometer is recommended for precision. Additionally, a protractor can be used to verify the angle between the legs, which is typically 90 degrees for standard angle iron. These tools ensure that you can capture all necessary dimensions accurately, which is crucial for weight calculation and ensuring the angle iron meets your project requirements.

Yes, there are several online calculators available for calculating the weight of angle iron. These tools can simplify the process by allowing you to input the dimensions and material properties of the angle iron, such as leg length, thickness, and length.

These online resources are user-friendly and particularly helpful for beginners, ensuring accurate and quick calculations without the need for complex manual computations.

To ensure accuracy in weight calculations for angle iron, follow these steps:

By meticulously following these steps, you can achieve precise weight calculations essential for engineering and construction projects.

Common mistakes to avoid in weight calculations for angle iron include inaccurate measurements of dimensions, incorrect material density, math errors in volume calculation, improper unit conversions, neglecting material variations, rounding errors, and lack of verification. To ensure precision, use reliable measuring tools for accurate dimensions, reference correct density charts, double-check volume calculations, maintain consistent units, account for material characteristics, delay rounding until final steps, and verify calculations using multiple methods or tools. By being mindful of these errors, you can achieve accurate and reliable weight calculations for angle iron.