Have you ever wondered how you can enhance the durability and wear resistance of mild steel right from the comfort of your home workshop? Case hardening is the answer, and it’s more accessible than you might think! In this guide, we’ll walk you through the fascinating process of transforming the surface properties of mild steel using simple, cost-effective materials you probably already have. Whether you’re a hobbyist or a budding metalworker, we’ll cover everything you need to know—from the essential materials and tools to the step-by-step process and crucial safety measures. Ready to dive into the art of case hardening and give your steel projects a professional edge? Let’s get started!

Case hardening is a heat treatment process that enhances the surface hardness of steel while preserving a softer, more ductile core. This process is particularly useful for low-carbon steels, which typically lack the necessary carbon content to be hardened throughout. By introducing additional carbon or nitrogen into the outer layer of the steel, case hardening creates a tough exterior capable of withstanding wear and impact, while the softer core provides the necessary toughness and flexibility to absorb shocks and prevent brittle failure.

Case hardening is crucial for components that need to be wear-resistant yet durable enough to absorb impacts without cracking. Here are some key benefits of case hardening mild steel:

Case hardening has a long history, from ancient blacksmiths using charcoal and bone to modern techniques like gas carburizing and nitriding. The process has evolved significantly over the centuries:

Several techniques are used in case hardening, each suited to different applications and materials:

Case hardening is widely used in various industries to enhance the performance and durability of components:

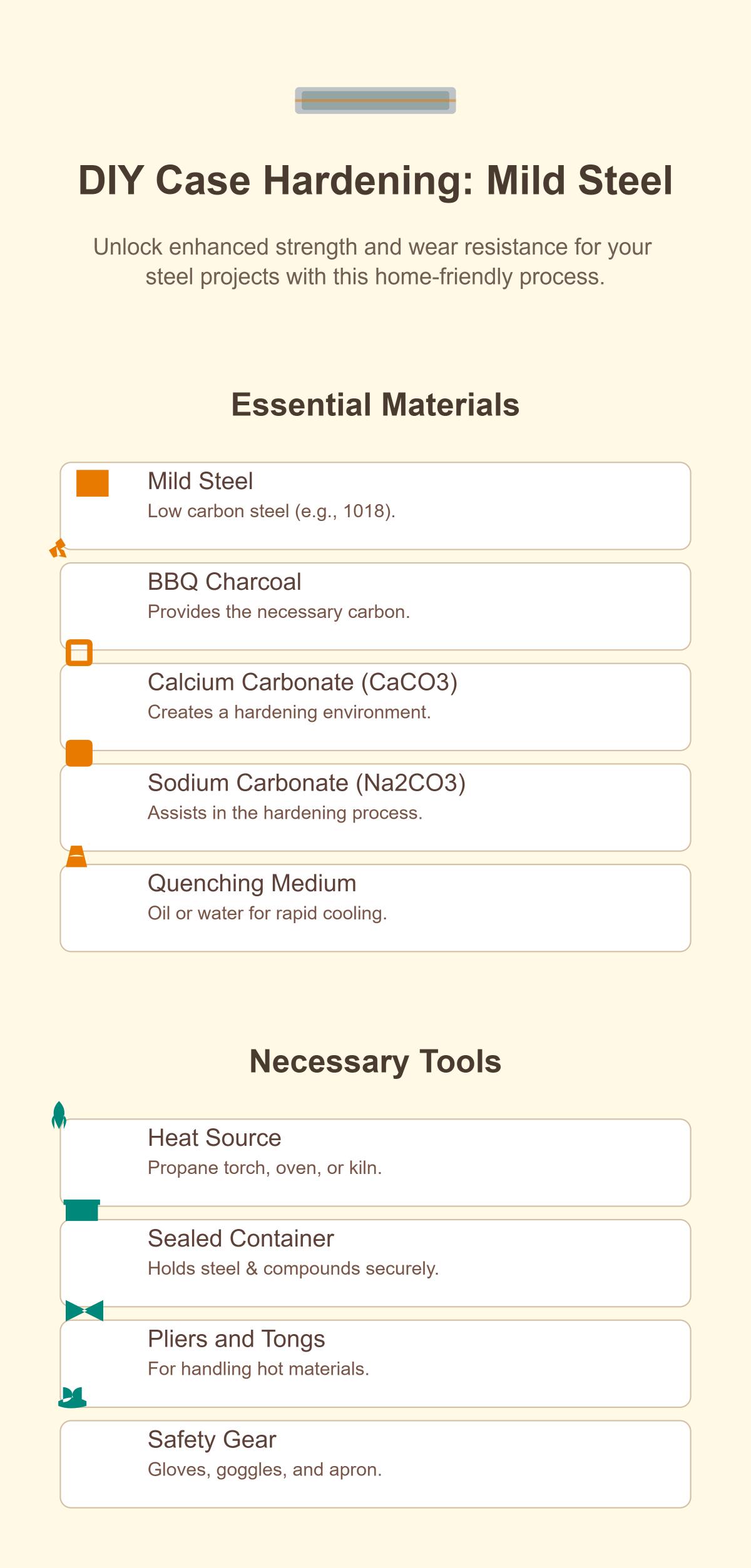

To successfully case harden mild steel at home, you’ll need several essential materials.

Choose mild steel with low carbon content, such as 1018 steel, which is ideal for case hardening. For the compound, mix 75% BBQ charcoal with 25% sodium carbonate. Alternatively, you can use charcoal with calcium carbonate or bone meal.

You will need a reliable heat source to achieve high temperatures. Suitable options include an acetylene torch, propane oven, or pottery kiln.

After heating the steel, it needs to be rapidly cooled to harden the surface. Water or oil are commonly used quenching mediums. Choose one based on availability and personal preference.

Safety is paramount when working with high temperatures and chemicals. Ensure you have the following protective gear:

Using a steel container to hold the steel and case hardening compound can provide more controlled heating. This is especially useful if you are using a muffle furnace.

Pliers and tongs are essential for handling hot components safely. Ensure they are sturdy and heat-resistant to avoid accidents.

If you want to save money, consider these cost-effective alternatives:

Having these materials on hand will prepare you for the case hardening process, ensuring you can achieve the desired results safely and efficiently.

Begin by selecting a suitable mild steel, like 1018 steel. This type of steel is ideal for case hardening due to its low carbon content, which makes it easier to enhance its surface hardness while retaining a tough core.

Thoroughly clean the steel using a degreaser or soap and water, then dry it completely to remove any oils, dirt, or coatings that could interfere with the case hardening process.

Make sure your workspace is well-ventilated and equipped with all necessary tools and safety gear. Gather the following items:

Begin by heating the mild steel to a temperature between 870°C and 980°C (1600°F to 1800°F). This high temperature is crucial for the carbon to diffuse into the steel surface.

Prepare the case hardening compound by mixing BBQ charcoal powder with additives such as calcium carbonate or sodium carbonate in a ratio of 75% charcoal to 25% additive. Place the steel in a sealed container filled with this mixture, ensuring the steel is fully surrounded.

Add the calcium carbonate and sodium carbonate to the charcoal mixture. These additives help to facilitate the carburizing process by enhancing the carbon absorption into the steel’s surface.

Keep the steel at this high temperature for several hours to allow the carbon to diffuse into its surface. The duration of this step depends on the desired depth of the hardened layer. Generally, a longer duration results in a deeper hardened layer.

After the heating period, allow the container to cool slowly, either inside the oven or in ambient air. This gradual cooling helps in the carbon diffusion process. Once cooled, remove the steel part from the container and clean off any remaining compound.

To further harden the surface, reheat the steel to a lower temperature and then quickly cool it in oil or water (quenching). This step can be followed by tempering to reduce brittleness and improve toughness by heating the steel to between 350°C and 450°C (662°F and 842°F).

When case hardening mild steel, wear the right personal protective equipment to stay safe:

Setting up a safe work environment is critical for the case hardening process:

Fire safety is crucial when working with high temperatures and flammable materials:

Proper handling of hot materials is essential to prevent injuries:

When using chemicals for case hardening, follow these safety measures:

Regular maintenance of your equipment is necessary to ensure safety:

Be prepared for emergencies by having the necessary protocols in place:

Case hardening mild steel at home is a practical way to enhance the surface hardness of steel while keeping its core tough.

Start by selecting mild steel with low carbon content, such as 1018 steel, and clean it thoroughly to remove any oils, dirt, or coatings.

Mix BBQ charcoal powder with additives like calcium carbonate or sodium carbonate, which will donate carbon during heating.

Place the steel in a sealed container with the case hardening compound. Heat the container to a temperature between 1600°F and 1800°F (870°C to 980°C) and maintain this temperature for several hours to allow the carbon to diffuse into the steel’s surface.

Allow the container to cool slowly, or quench the steel in oil immediately after heating to lock in the hardness. Quenching is crucial for achieving a hard outer layer.

For applications requiring reduced brittleness, temper the steel by reheating it to between 350°C and 450°C (662°F and 842°F). This step balances hardness and toughness.

Below are answers to some frequently asked questions:

To case harden mild steel at home, you’ll need the following materials and tools:

These materials and tools will help you successfully case harden mild steel, enhancing its surface hardness while retaining its core toughness, making it more wear-resistant.

To case harden mild steel at home, follow these steps:

Throughout the process, always wear appropriate personal protective equipment (gloves, safety goggles, apron) and ensure proper ventilation in your workspace to handle materials safely.

When case hardening mild steel at home, safety is paramount due to the high temperatures and potentially hazardous materials involved. Key safety measures include:

By following these safety measures, you can minimize risks and safely conduct the case hardening process at home.

Yes, you can use alternative materials for case hardening mild steel at home. While the traditional method involves using BBQ charcoal, calcium carbonate, and sodium carbonate, there are other options available. One common alternative mixture is charcoal combined with sodium carbonate, which effectively substitutes commercial case hardening compounds. Additionally, bone charcoal mixed with leather or other organic materials can also create a carbon-rich environment necessary for case hardening. Another option is using a mixture of calcium carbonate and bone meal instead of sodium carbonate. These alternatives are cost-effective and can be used to achieve similar results, enhancing the surface hardness of mild steel for improved durability and wear resistance.

The case hardening process for mild steel at home typically involves several steps: heating, applying a carbon source, maintaining the temperature, and then cooling. The entire process can take several hours to complete. Specifically, heating the mild steel in a carbon-rich environment, such as with BBQ charcoal and compounds like calcium carbonate and sodium carbonate, generally requires maintaining a temperature between 870°C and 980°C for several hours, often overnight, to achieve a sufficient case depth. After this, quenching and tempering the steel are relatively quick processes but require careful handling and setup.

For case hardening mild steel at home, there are several cost-effective alternatives to traditional materials. Instead of commercial case hardening compounds, you can use a mixture of BBQ charcoal and calcium carbonate, which are both affordable and easily accessible. Another option is aquarium charcoal, available at pet stores, which can also achieve deep hardening. Additionally, bone meal is a natural alternative that provides a significant hardening effect. For a homemade mix, you can combine hardwood charcoal, barium carbonate, sodium carbonate, and calcium carbonate. These alternatives allow for effective case hardening while keeping costs low and materials readily available.