Are you ready to transform that rusty old metal piece into a gleaming work of art? Before you start painting, it’s crucial to clean the metal properly to ensure a flawless finish. If you’re a beginner looking for a straightforward guide, you’ve come to the right place. This article will walk you through each step of the process, from gathering essential materials like acetone and rust remover to applying a self-etching primer. You’ll learn how to inspect the surface, remove rust, and prepare the metal for painting with easy-to-follow instructions. So, grab your tools and let’s dive in—how do you think you can achieve that perfect, professional-looking paint job?

Metal surface preparation involves cleaning and treating metal surfaces before applying coatings such as paint or primer. This step is crucial to ensure that the coatings adhere properly and last longer by removing any contaminants, rust, or old coatings that might be present on the metal surface.

This step creates a clean, roughened surface that allows coatings to stick better, reducing the chances of peeling or flaking over time.

Removing rust, old paint, and other contaminants prevents issues that could compromise the new coating, extending the lifespan of the paint job.

A well-prepared surface ensures that the paint or primer applies smoothly and evenly, resulting in a professional and visually appealing finish. This is particularly important for projects where appearance is critical, such as in automotive or decorative metalwork.

By thoroughly preparing the metal surface, you can apply rust inhibitors and primers to protect the metal from future rust and corrosion, enhancing the longevity of the structure.

The first step in metal surface preparation involves cleaning the surface to remove dirt, grease, and other contaminants. This can be done using various cleaning agents, such as degreasers or specialized metal cleaners.

Once the surface is clean, the next step is to remove any rust or old paint. This can be achieved using mechanical methods like sanding or wire brushing, or chemical methods like rust removers.

After removing contaminants and old coatings, the surface needs to be profiled, typically through abrasive blasting or sanding. This step roughens the surface, enhancing the adhesion of the primer and paint.

When preparing to clean metal surfaces, it’s important to handle all cleaning materials with care to ensure safety and effectiveness.

Wearing the right protective gear is crucial when cleaning metal surfaces to safeguard against chemical exposure and physical injuries.

Proper disposal of chemicals is essential to prevent environmental contamination and health hazards.

Creating a safe working environment minimizes the risk of accidents and exposure to harmful substances.

Handling equipment safely is vital to prevent injuries and ensure effective cleaning.

To prevent moisture and rust, avoid water – based cleaners that can leave moisture behind, which may lead to rust or poor paint adhesion. Ensure the metal surface is completely dry before priming or painting.

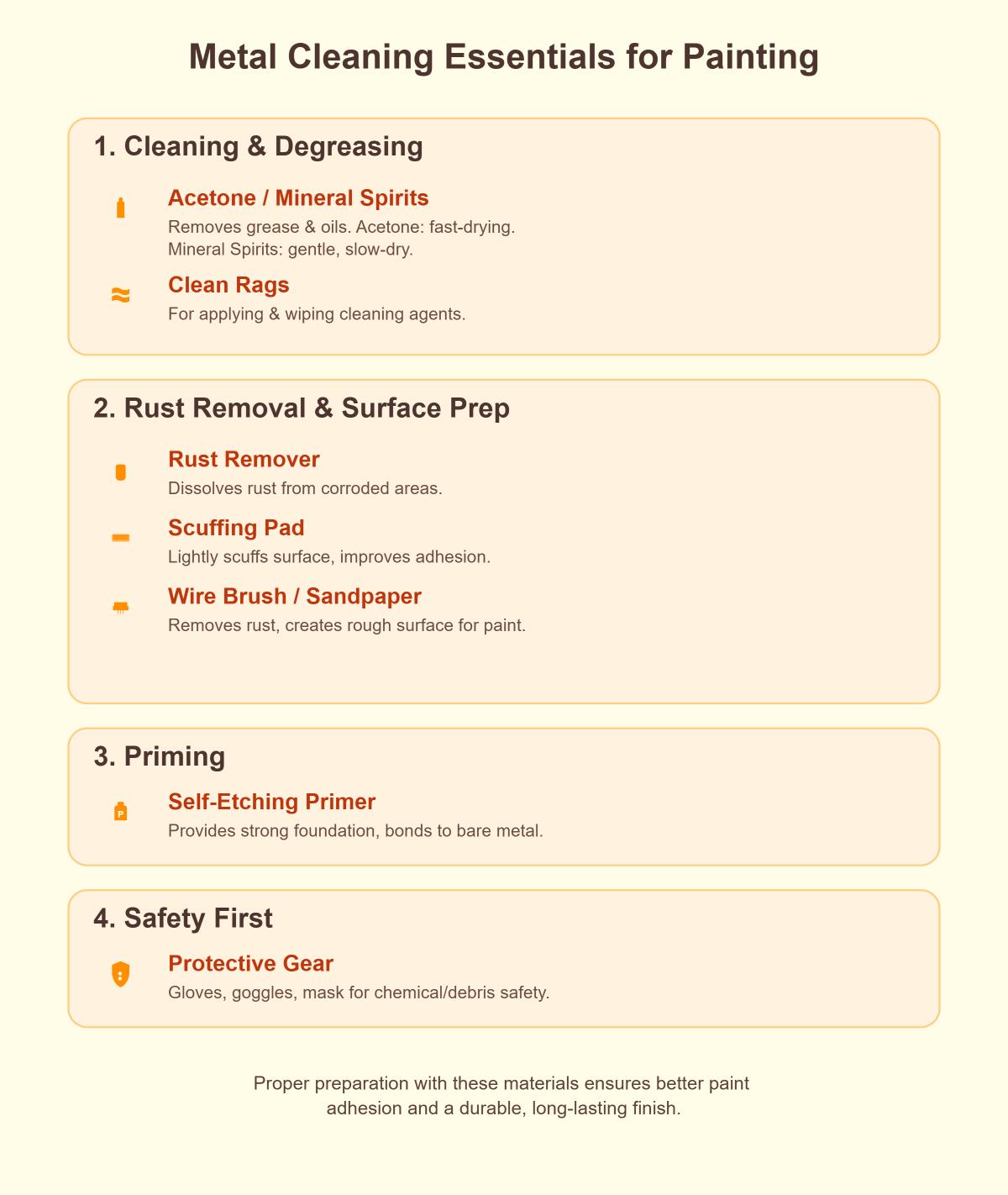

Acetone and mineral spirits are essential for effectively removing grease and oils from metal surfaces. Acetone offers a quick and deep clean, perfect for removing tough grease and oils from metal surfaces. Mineral spirits, on the other hand, are a safer choice for new metal surfaces.

Rust removers are crucial for eliminating rust; household vinegar works for minor cases, while specialized products like CLR or naval jelly tackle heavier rust.

A self – etching primer is designed to bond directly to bare metal. It provides a strong base for paint adhesion, ensuring a long – lasting paint job.

When dealing with mild steel surfaces, a mixture of mild soap or detergent and warm water is ideal. It can remove dirt and grime without causing damage to the metal.

Rags are used to apply cleaning agents and wipe metal surfaces clean, preparing them for the next step.

Scuffing pads or sandpaper are used to lightly scuff the metal surface. This creates texture, which improves primer adhesion. Coarse sandpaper is great for removing old paint and rust.

Wire brushes and wire brush drill attachments are useful for removing loose or flaking paint and surface rust. They can quickly clear the metal surface.

Always wear protective gloves to shield your hands from harsh chemicals. Safety goggles protect your eyes from chemical splashes and debris, while a dust mask or respirator prevents inhalation of harmful fumes and dust.

If you have extensive rust or need more thorough surface preparation, an angle grinder, orbital sander, or bristle blaster can be very helpful. These tools are used for rust removal and surface texturing, with the bristle blaster providing a more uniform finish.

A heat gun can be used to soften old paint, making it easier to remove. This can save a lot of time and effort.

Understanding the advantages and limitations of different cleaning agents is crucial for effective metal surface preparation. Here, we delve into the most commonly used solvents and their characteristics.

Mild soap or detergent is ideal for removing light contaminants such as dirt and grime without damaging the metal surface. It is non-toxic, generally safe for most metal surfaces, and easily accessible and inexpensive. However, it can’t effectively remove grease, oil, or heavy dirt and may leave a residue that needs to be rinsed off thoroughly.

Mineral spirits are excellent for removing grease, oils, and other organic contaminants, providing ample working time for thorough cleaning due to their slower evaporation. On the downside, they are flammable, need careful use and proper storage, and emit fumes that necessitate good ventilation during use.

Acetone dries rapidly, leaving no residue behind, and is highly effective at removing grease, oils, and some types of adhesives. However, it is highly flammable, requiring extreme caution, and its fumes can be harmful, necessitating proper ventilation and protective gear.

Rust removers are specifically designed to remove rust and corrosion from metal surfaces and are available in different forms, including gels, liquids, and sprays, catering to varying levels of rust severity. However, some rust removers have strong chemicals that need careful use and disposal, and additional steps may be required to neutralize the surface before painting.

Selecting the appropriate cleaning agent depends on the specific requirements of your project. Here are some guidelines to help you make the right choice:

Identify whether the surface has dirt, grease, oil, or rust, and determine if the metal is new, lightly tarnished, or heavily corroded.

Choose an agent with the strength to remove the specific contaminants present on the metal, ensure it can be handled safely considering its flammability and toxicity, and confirm it is suitable for your preferred application method (e.g., wiping, spraying, soaking).

If the surface is lightly dirty, start with mild soap or detergent and then try stronger cleaners if needed. Use mineral spirits for new metal, ideal for degreasing without the rapid evaporation of acetone. Reserve acetone for tough grease, using it when you need a powerful solvent to tackle stubborn grease and oils. Apply rust removers as needed, choosing one based on the severity of corrosion and following the manufacturer’s instructions for best results.

By understanding the pros and cons of each cleaning agent and evaluating the specific needs of your project, you can effectively prepare metal surfaces for painting, ensuring a professional and durable finish.

Begin by inspecting the metal surface to identify rust, old paint, and contaminants. Use a wire brush or sandpaper (120-240 grit) to remove loose rust and debris, focusing on areas with visible rust and flaking paint.

Apply a rust remover to stubborn rust spots, following the manufacturer’s instructions. Let it sit for the recommended time, then remove the loosened rust with a wire brush or sandpaper.

Clean the entire metal surface with a rag dampened with acetone to remove grease, oil, and dirt.

Lightly scuff the surface with a scuffing pad or fine-grit sandpaper to help the primer adhere better, then wipe away any dust with a clean rag.

A self-etching primer is crucial for metal surfaces because it has acidic ingredients that etch the metal surface, creating a rough texture for the paint to adhere to. This type of primer also helps prevent rust and provides a strong foundation for the topcoat.

Select paint made for metal surfaces. It will adhere well and protect against corrosion for a long time.

Selecting the appropriate primer for metal surfaces is crucial for achieving a durable and smooth paint finish. Here, we will review the different types of primers and their characteristics to help you make an informed decision.

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

When selecting a primer for your metal surface, consider the specific requirements of your project, such as the type of metal, exposure conditions, and desired finish.

When evaluating primers, it’s essential to balance cost and performance to ensure you achieve the best results for your project.

By understanding the different types of primers and their respective advantages and disadvantages, you can select the best primer for your metal surface preparation, ensuring a durable and professional finish.

Below are answers to some frequently asked questions:

To clean metal before painting, you will need the following materials:

These materials are essential for ensuring proper preparation of the metal surface, leading to better paint adhesion and a longer-lasting finish.

To remove rust before painting metal, follow these steps:

By following these steps, you ensure that the metal surface is properly prepared, which will lead to a durable and high-quality paint finish.

Metal surface preparation is important because it ensures that the paint adheres properly, leading to a smooth, even finish. This preparation involves cleaning the metal to remove any rust, grease, dirt, and old paint, which are common contaminants that can prevent the paint from sticking. Properly preparing the surface also helps prevent future corrosion by eliminating rust, thus enhancing the durability of the paint job. By creating a clean, stable surface, you can avoid common issues like peeling, blistering, and flaking, ensuring that the paint lasts longer and maintains its aesthetic appeal.

While it is possible to skip using a self-etching primer, it is generally not recommended, especially for beginners. Self-etching primer contains acids that etch the metal surface, creating a strong bond for the paint and providing excellent adhesion. Without this primer, the paint may not adhere properly, leading to peeling or chipping. Additionally, self-etching primers offer some corrosion protection by embedding zinc particles into the metal, which helps prevent rust. Skipping this step could result in rust forming under the paint, compromising the finish over time. Therefore, for the best results and a durable, professional finish, it is advisable to use a self-etching primer as part of your metal surface preparation process.

When choosing a scuffing pad for cleaning metal before painting, consider the grit level and material. For heavy oxidation or old paint removal, use a coarse pad (P150 – P320). A medium (P600) pad is good for general surface preparation, and a fine (P800 – P1200) pad is best for final prep before painting. Look for pads made with aluminum oxide abrasive or nylon fibers as they cut consistently without rusting or splintering. Popular options include Dura – Gold Scuff Pads with different grits and Scotch – Brite Scuffing Systems, known for flexibility and paint – prep effectiveness.

When cleaning metal before painting, it is essential to follow safety precautions to protect yourself and ensure a successful project. First, wear personal protective equipment (PPE) such as gloves to prevent skin contact with chemicals, goggles to shield your eyes from splashes and debris, and a mask to avoid inhaling dust or fumes.

Ensure your work environment is well-ventilated to dissipate harmful vapors and keep the workspace clean and clutter-free to avoid accidents. Handle chemicals like acetone in well-ventilated areas and dispose of them responsibly to minimize environmental impact.

When using tools such as wire brushes or sandpaper, operate them carefully to prevent injury. Avoid touching cleaned metal surfaces with bare hands to prevent recontamination with oils from your skin. Finally, make sure the metal surface is completely dry before applying primer or paint to avoid rust and ensure proper adhesion.