Drilling holes in aluminum might seem daunting, especially if you’re a beginner, but with the right guidance, it can become a straightforward task. Imagine transforming a simple piece of aluminum into a precise component for your DIY project—all it takes is the right tools, techniques, and a bit of know-how. In this comprehensive step-by-step guide, we’ll walk you through everything you need to know to drill holes in aluminum effectively. From selecting the appropriate drill bits and understanding aluminum’s unique properties to mastering speed control and lubrication techniques, we’ve got you covered. Ready to start your journey and avoid common pitfalls like overheating or damage? Let’s dive in and make your drilling experience smooth and successful!

Before starting any drilling project, it’s crucial to prioritize safety. Wear gloves to protect your hands from sharp edges and debris, safety goggles to prevent eye damage from flying particles, and ear protection to reduce noise exposure during drilling.

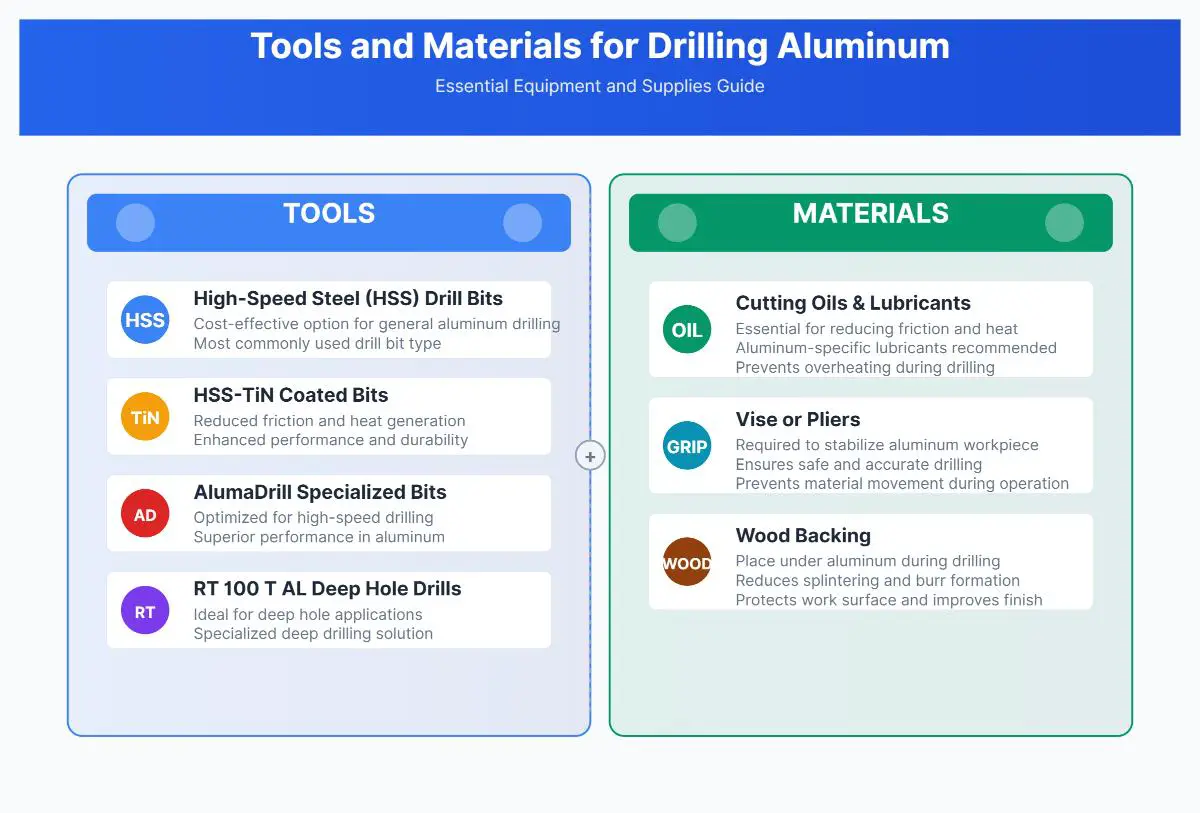

The right tools are essential for effectively drilling holes in aluminum. Below are the primary tools required:

In addition to tools, certain materials and accessories are necessary to achieve clean and precise results:

Using the right techniques is as important as having the right tools and materials. Here are some techniques to consider:

Following best practices can significantly enhance your drilling results. Always clamp or vise the aluminum piece to prevent movement, ensuring safety and precision. Regularly clean drill bits to prevent clogging, which can cause overheating and reduce tool life.

To stay safe while drilling aluminum, it’s essential to use the right personal protective equipment:

A safe work environment prevents accidents and ensures smooth operation:

Proper drill setup and operation are crucial for effective and safe drilling:

Managing heat is critical to avoid damaging both the aluminum and the drill bit:

After completing the drilling process, follow these steps to ensure a safe and tidy workspace:

Aluminum is a versatile metal known for its unique properties, making it ideal for drilling and various other applications. Understanding these characteristics is essential for achieving optimal results.

One of the most notable features of aluminum is its lightweight nature. It is approximately one-third the weight of steel, making it easier to handle and work with. Aluminum’s softness facilitates easier cutting and shaping, although it can be easily scratched or dented if not handled with care.

Aluminum can be stretched into thin wires and shaped into various forms without breaking due to its high ductility and malleability. This property is beneficial during drilling as it allows the metal to deform slightly, reducing the risk of cracking or breaking.

Aluminum has excellent corrosion resistance due to the formation of a natural oxide layer on its surface. This layer protects the metal from environmental factors such as moisture and oxygen, which can cause rust and corrosion in other metals. However, this oxide layer can affect drilling precision, so it’s important to clean the surface before starting.

Aluminum has a relatively low melting point of around 660°C (1220°F). During drilling, the friction between the drill bit and the aluminum generates heat, which can quickly build up and cause the metal to soften or melt. This can lead to poor-quality holes, tool damage, and safety hazards.

Effective heat management during drilling requires cooling techniques like lubrication and controlled speeds. Lubricants such as cutting oil or WD-40 help reduce friction and heat, ensuring smoother and more precise drilling. Additionally, using moderate drilling speeds can prevent excessive heat buildup.

When drilling aluminum, the metal tends to produce long, stringy chips rather than small, broken ones. These chips can wrap around the drill bit and clog the flutes, leading to increased heat and reduced drilling efficiency.

Drill bits with wider flutes and higher helix angles can better remove chips during drilling. This design allows the chips to move away from the cutting area quickly, reducing the risk of clogging and improving Before drilling, it’s essential to clean the aluminum surface to remove any dirt, grease, or oxide layer. This can be done using a degreaser or a mild abrasive cleaner. A clean surface ensures better accuracy and prevents the drill bit from slipping.

Using a center punch and hammer or a sharp needle to create a small indentation at the drilling point helps guide the drill bit. This step is especially important for aluminum due to its smooth surface, which can cause the drill bit to wander if not properly marked.

By understanding these properties and characteristics of aluminum, you can make informed decisions and apply appropriate techniques to achieve clean, precise holes while drilling.

High-Speed Steel (HSS) drill bits are a basic and affordable option for drilling aluminum. They are widely available. However, they may not be the best choice for long – term or high – precision drilling. When using HSS drill bits on aluminum, the hole quality might not be as sharp and clean as with other types, and the bit may wear out faster.

Titanium-coated drill bits are highly recommended for drilling aluminum. The titanium coating reduces friction between the drill bit and the aluminum, making the drilling process smoother and extending the lifespan of the drill bit. You’ll notice that the bit stays sharper for longer, allowing you to create cleaner holes with less effort.

Cobalt drill bits are usually used for harder metals like stainless steel, but they can also be effective for aluminum. If you’re planning to drill a large number of holes in aluminum or need to drill through thicker sections, cobalt drill bits can withstand the stress better than some other types.

Different aluminum alloys vary in hardness. For softer aluminum alloys, you can use a wider range of drill bits, including HSS. But for harder aluminum alloys, titanium – coated or cobalt drill bits are better options as they can handle the increased resistance without dulling quickly.

If you need precise, clean holes for your project, such as in a DIY furniture piece or an industrial part, titanium – coated drill bits are your best bet. They cut through the aluminum smoothly, leaving minimal burrs or rough edges. For less critical applications where hole quality is not as important, HSS drill bits may be sufficient.

If you’re only drilling a few holes, an HSS drill bit might be adequate. However, for large – scale projects with a high volume of drilling, investing in titanium – coated or cobalt drill bits will save you time and money in the long run, as you won’t have to replace the bits as often.

Drill bits with a split – point or pilot point tip are ideal for drilling aluminum. These tip designs help the drill bit start the hole accurately and prevent it from wandering on the smooth surface of the aluminum.

Ensure the drill bit is the correct size for your needs. A bit that is too small may break easily, while a bit that is too large can cause the aluminum to deform or result in an oversized hole. Measure the required hole diameter carefully before selecting the drill bit.

Ensure you wear safety goggles, gloves, and ear protection to protect yourself from flying debris, sharp aluminum shavings, and loud noise.

Use clamps or a vise to firmly hold the aluminum piece to prevent slipping, ensuring accurate drilling. Carefully measure and mark the spot where you want to drill, then use a center punch and hammer to create a small guiding dimple.

Choose high-speed steel (HSS), cobalt, or titanium-coated drill bits with a 118° or 135° split point to reduce wandering and enhance precision. Bits with larger flutes and faster spirals help evacuate aluminum chips, preventing clogging.

Begin by using a smaller drill bit to create a small pilot hole. This step increases the accuracy of the final hole and reduces bit slippage.

Lubrication reduces friction between surfaces, which is essential when drilling aluminum to prevent the material from sticking to the drill bit and generating excessive heat.

Generously apply cutting oil, WD-40, kerosene, or specialized lubricants to the drill bit and aluminum surface to reduce friction and heat buildup, extend the drill bit’s life, and produce cleaner holes.

Reapply the lubricant as needed during the drilling process, especially when drilling deeper or larger holes. Continuous lubrication keeps the drill bit cool and stops aluminum chips from sticking to the bit.

Use a slower drill speed to avoid overheating. For thin aluminum sheets, medium speeds work well, while thicker pieces require slower speeds. Typical recommended speeds range from 2,000 to 3,000 RPM, depending on the thickness and drill bit size.

Apply moderate, consistent pressure on the drill. Avoid pushing too hard, as this can cause excessive heat and damage the bit or material. Let the drill bit do the cutting work smoothly.

Keep the drill bit and the hole lubricated throughout the process. When using a drill press or hand drill, stop occasionally to add more lubricant if necessary.

Use a deburring tool or a slightly larger drill bit twisted by hand to remove sharp edges or burrs around the hole, ensuring safety and a clean finish.

Blow away or brush off metal shavings. If you plan to tap the hole, apply any required anti-corrosion treatment or thread sealant.

Creating a pilot hole is a crucial step when drilling aluminum. It involves drilling a small, initial hole that serves as a guide for the final hole. This method helps in preventing the drill bit from wandering and ensures accuracy.

Managing the speed of your drill is crucial to avoid overheating and damaging both the drill bit and the aluminum.

Excessive speed can generate heat, which may warp the material and dull the drill bit. Monitor the temperature and reduce speed if the aluminum heats up too much.

Lubrication is essential to reduce friction and heat. Use cutting oil, WD-40, or kerosene, and apply generously to both the drill bit and aluminum surface. This helps in achieving a cleaner cut and extends the life of the drill bit.

The peck drilling method involves drilling in short bursts and retracting the drill bit frequently to clear chips and allow cooling. This process helps in removing chips from the hole and prevents clogging.

When drilling, apply steady and moderate pressure. Let the drill bit do the cutting naturally. Avoid forcing the drill, as this can cause overheating and damage the material and bit.

Using a drill press ensures that the holes are perpendicular and consistent in depth. It provides stability and precision, especially for larger projects.

After drilling, deburr the edges of the hole to remove any sharp edges or burrs. This can be done using a deburring tool or fine sandpaper, ensuring a smooth finish and safe handling.

Below are answers to some frequently asked questions:

To drill aluminum, you’ll need specific tools and materials. For tools, high-Speed Steel (HSS) drill bits are cost-effective, while HSS-TiN coated bits reduce friction and heat. Specialized drills like AlumaDrill work well for high-speed drilling, and RT 100 T AL deep hole drills are ideal for deep holes. As for materials, cutting oils or aluminum-specific lubricants are essential to reduce friction and prevent overheating. You’ll also need a vise or pliers to stabilize the aluminum and a piece of wood to place under it to reduce splintering.

To avoid overheating or damaging aluminum while drilling, follow these key techniques:

By following these steps, you can drill aluminum efficiently without overheating or causing damage.

When drilling aluminum, it’s crucial to take several safety precautions. First, wear appropriate personal protective equipment (PPE) like safety goggles to protect your eyes from flying debris, thick gloves to prevent cuts, and ear protection to guard against noise. If there’s fine dust, consider a respiratory mask, and avoid loose clothing and jewelry. Secure the aluminum workpiece with clamps or a vise to prevent movement. Use drill bits designed for metal, ensure they’re sharp and properly seated. Start with a pilot hole for accuracy. Apply steady, moderate pressure and use the recommended drill speed. Use a lubricant to prevent overheating. Keep your workspace clean and well-lit, and always handle the drill with both hands, keeping fingers away from the bit. Check the drill and cord for damage before use.

When drilling aluminum, several types of drill bits are suitable. High-Speed Steel (HSS) drill bits are a great starting option as they’re affordable and commonly available, suitable for general aluminum drilling. Titanium-coated HSS drill bits reduce friction and heat, staying sharper longer and drilling cleaner holes for aluminum and other soft metals. Cobalt drill bits are harder and dissipate heat quickly, ideal for tougher aluminum alloys like 6061 or 7075. Black Oxide-Coated drill bits have a corrosion-resistant finish and better durability than basic HSS bits, also performing well on aluminum. Choose a bit with a 118-degree point angle, a size slightly smaller than the required hole, and consider hex shanks for better grip in cordless drills.

Lubrication is important when drilling aluminum because it reduces friction and heat, preventing the aluminum from welding or sticking to the drill bit and avoiding overheating. It also stops drill bit welding and galling, allowing chips to evacuate cleanly. Lubrication extends the drill bit’s life by reducing wear and tear, improves hole quality by creating cleaner holes with smooth edges, and facilitates chip removal, preventing drill flute clogging. Using the right lubricant and proper drilling techniques makes aluminum drilling easier and more precise.

Aluminum’s properties significantly affect the drilling process. Firstly, aluminum is softer and more ductile than many metals, which means it can easily adhere to the cutting edges of drill bits, causing chip buildup and clogging. This requires the use of specialized drill bits, such as cobalt or titanium-coated bits, which resist wear and reduce sticking. Secondly, aluminum heats up quickly during drilling. Excessive heat can warp the material and dull the drill bit, so it’s essential to manage heat through proper speed control and the use of lubricants. Lastly, aluminum’s smooth surface can cause the drill bit to slip, making it crucial to start with a pilot hole for accuracy. Understanding these properties helps in selecting the right tools and techniques to achieve clean, precise holes in aluminum.