Ever wondered how a simple piece of steel can transform into a high – performance component? Heat treatment is the key. For intermediate enthusiasts looking to master the art, this guide is your go – to resource. Heat treatment involves a series of processes like hardening, tempering, and annealing, each altering steel properties such as hardness, ductility, and toughness. These processes are crucial in manufacturing, aerospace, and automotive industries. So, are you ready to discover the step – by – step journey of heat treating steel?

Heat treatment is the process of heating and cooling metals in a controlled way to change their physical and mechanical properties without altering their shapes. This process is crucial in metalworking as it improves properties like hardness, strength, ductility, and wear resistance, which are vital for various industrial applications.

Steel, an alloy of iron and carbon, is the most commonly heat-treated material due to its versatility and wide range of applications. The amount of carbon in steel can significantly influence its properties. Higher carbon content generally increases hardness and strength, while lower carbon content enhances ductility and toughness. Adjusting the heat treatment process allows these properties to be finely tuned to meet specific needs, making steel essential in industries such as manufacturing, aerospace, and automotive.

In manufacturing, heat-treated steel is used to produce high-strength tools and machinery components. For example, drill bits and cutting tools require high hardness to maintain their edge during use. Heat treatment ensures these parts can withstand the demanding conditions of manufacturing processes.

The aerospace industry relies on heat-treated steel for critical components such as landing gear, engine parts, and structural elements. For instance, landing gear must endure extreme stress during takeoff and landing. The high strength-to-weight ratio achieved through heat treatment is vital for ensuring safety and performance in aerospace applications.

In the automotive sector, heat-treated steel is used for engine components, gears, and suspension systems. For example, crankshafts and camshafts need to be hard and wear-resistant to function effectively over time. The enhanced durability and resistance to wear provided by heat treatment processes contribute to the longevity and reliability of vehicles.

Several key processes are involved in heat treatment, each with its own specific purpose and methodology:

Each of these processes plays a crucial role in tailoring the properties of steel for specific applications, making heat treatment an indispensable technique in modern metalworking.

Carbon steel is one of the most widely used types of steel, primarily due to its versatility and cost-effectiveness. It is classified based on the amount of carbon content, which significantly influences its mechanical properties.

Alloy steels are steels that are alloyed with a variety of elements in addition to carbon to enhance specific properties. Common alloying elements include chromium, nickel, molybdenum, and vanadium.

Stainless steel is a type of high-alloy steel that contains at least 10.5% chromium, which gives it its remarkable corrosion resistance. It is further classified into several categories based on its crystalline structure.

Tool steels are specially formulated steels designed to make tools. They are characterized by their hardness, resistance to abrasion, and ability to retain a cutting edge. High-Speed Steel (HSS) contains significant amounts of tungsten, molybdenum, and vanadium. It can withstand high temperatures without losing hardness, making it ideal for cutting tools like drill bits and saw blades. Hot-Work Steel, alloyed with chromium, tungsten, and molybdenum, maintains strength and hardness at high temperatures and is resistant to thermal fatigue, suitable for hot forging and extrusion dies.

Heat treatment processes are critical in manipulating the mechanical properties of steel to meet specific application requirements. These processes involve controlled heating and cooling to alter the microstructure of steel, enhancing properties such as hardness, strength, ductility, and toughness.

Annealing involves heating steel to a specific temperature above its recrystallization point and then allowing it to cool slowly to room temperature. This process can be conducted in a furnace where the temperature is carefully controlled.

Annealing relieves internal stresses from processing and softens the steel, improving its machinability and ductility. Additionally, it refines the grain structure to enhance mechanical properties.

Normalizing is similar to annealing but involves cooling the steel in still air rather than a furnace. The steel is heated to a temperature slightly above its critical point and then allowed to cool naturally.

Normalizing aims to refine the grain structure, homogenize the steel composition, and improve toughness and strength.

Quenching involves heating the steel to a high temperature and then rapidly cooling it in a quenching medium such as water, oil, or air. Rapid cooling during quenching changes the steel’s microstructure into a hard and brittle phase called martensite.

The purpose of quenching is to increase hardness and strength, and enhance wear resistance.

Tempering follows quenching and involves reheating the quenched steel to a lower temperature, then cooling it at a controlled rate. This process reduces the brittleness imparted by quenching.

Tempering is used to reduce brittleness, increase toughness, and achieve a balance between hardness and ductility.

Case hardening involves hardening the surface layer of the steel while maintaining a softer core. This is achieved through carburizing or nitriding, where the surface is enriched with carbon or nitrogen, respectively.

Case hardening enhances surface wear resistance and improves fatigue strength by hardening the surface layer while keeping a softer core.

Induction hardening uses electromagnetic induction to heat specific areas of the steel rapidly, followed by immediate quenching. This process is highly localized and controlled.

Induction hardening is utilized to harden specific areas without affecting the entire component and minimize distortion and stress.

Precipitation hardening heats the steel to a temperature where precipitates form in the microstructure, then cools and ages it in a controlled way.

Precipitation hardening aims to increase strength and hardness without significantly reducing ductility.

Hardening is a vital heat treatment process that improves the mechanical properties of steel, especially its hardness and strength. This process is essential for applications requiring high wear resistance and durability, such as cutting tools, gears, and machine parts. By transforming the steel’s microstructure, hardening can significantly improve its performance in demanding industrial environments.

Tempering is a heat treatment process applied to steel and other alloys to enhance their mechanical properties, specifically aiming to reduce brittleness while maintaining hardness. After steel has been hardened, it can become quite brittle due to the formation of martensite. Tempering alleviates this brittleness by modifying the microstructure, balancing toughness with strength.

Involves heating the steel to a specific temperature and cooling slowly to achieve optimal toughness and hardness. This type is commonly used for general applications where a balance between the two properties is essential.

Performed at lower temperatures, it enhances toughness while maintaining considerable hardness. It is suitable for components requiring high strength and moderate ductility.

Used for alloys that form precipitates during tempering, which improve strength by altering the crystalline structure. This technique is often applied in specialized applications requiring high durability.

Involves two tempering cycles to maximize toughness without excessively reducing hardness. This method is useful for applications requiring high impact resistance.

Retains maximum hardness while slightly improving toughness, making it ideal for tools and components that need to maintain a sharp edge.

Maximizes toughness at the expense of hardness, suitable for applications requiring high ductility and resistance to cracking.

Annealing is a vital heat treatment process used to improve the microstructure of steel, thereby enhancing its physical and chemical properties. The primary goals of annealing are to relieve internal stresses, increase ductility, and improve machinability. By carefully managing the heating and cooling phases, the steel’s grain structure can be refined, leading to enhanced mechanical characteristics.

The annealing process begins with careful preparation and heating. First, select the appropriate steel alloy, as each has distinct critical temperatures and responses to annealing. Clean the steel thoroughly to remove dirt, oil, or contaminants, ensuring uniform heating and preventing unwanted oxide formation. The heating phase involves raising the steel to a high temperature below its critical transformation point to relieve internal stresses and improve ductility. Gradually increase the temperature to facilitate recrystallization, forming a new, stress-free grain structure. Optionally, maintain or slightly adjust the temperature to promote grain growth, which results in a more uniform microstructure but must be controlled to avoid reduced strength.

Once the desired temperature is reached, hold the steel at this temperature for a specified period. This soaking time allows for complete transformation and homogenization of the microstructure. The duration depends on the steel’s thickness and composition, ranging from 30 minutes to several hours.

Controlled cooling is crucial after soaking. This step significantly influences the final grain size and properties of the steel. Controlled cooling is usually achieved by turning off the heat source and allowing the steel to cool inside the furnace. For certain types of annealing, such as stress-relief annealing, cooling can occur in still air, whereas complete annealing requires a slower cooling rate within the furnace.

Precise temperature control is essential throughout the annealing process to ensure correct microstructure transformation and optimal mechanical properties. Use reliable temperature measurement devices, such as thermocouples, for accuracy. The cooling rate should be tailored to the type of annealing and steel alloy to avoid internal stresses and ensure desirable final properties. Safety precautions, including appropriate personal protective equipment and proper ventilation, are necessary when working with high-temperature processes. Familiarity with relevant ASTM standards is crucial for ensuring compliance and maintaining quality control. Document the annealing process meticulously, including temperature profiles, soaking times, and cooling rates, for quality assurance and standard adherence.

Heat-treated steel plays a crucial role in manufacturing, providing the strength and durability needed for high-performance tools and machinery components. Processes like hardening and tempering enable steel to achieve the necessary toughness and wear resistance essential for demanding manufacturing environments. For instance, drill bits and cutting tools require exceptional hardness to maintain their effectiveness over time. Heat treatment ensures these parts are robust enough to endure continuous use and resist wear, thus enhancing productivity and longevity.

Aerospace engineering relies on heat-treated steel for components that must endure extreme conditions, including stress and temperature fluctuations. These applications demand materials with high strength-to-weight ratios and the ability to withstand harsh environments. Heat treatment processes such as hardening and case hardening optimize the mechanical properties of steel, making it suitable for critical components like landing gear, engine parts, and structural elements. These components must exhibit superior durability and reliability to ensure safety and performance during flight operations.

The automotive industry extensively relies on heat-treated steel for various components, including engine parts, gears, and suspension systems. Heat treatment enhances the durability and wear resistance of steel, making it ideal for parts like crankshafts and camshafts that face repetitive stress, thus contributing to the vehicle’s reliability and efficiency. The process ensures these components maintain their structural integrity over time, which is crucial for the safety, performance, and longevity of the vehicle.

Heat treatment refines the microstructure of steel, improving its machinability and ensuring components like barrels and firing mechanisms are durable and reliable. In the firearms industry, precision and durability are paramount. The heat treatment process enhances the hardness and wear resistance of steel components, ensuring firearms can withstand repeated use without compromising accuracy or safety.

Heat-treated steel is preferred in heavy machinery for its ability to perform efficiently under stress. Components such as gears, shafts, and bearings require high strength and wear resistance to function effectively in harsh industrial environments. Heat treatment processes, including quenching and annealing, optimize these properties, making steel suitable for demanding applications. The enhanced durability and toughness of heat-treated steel help prevent equipment failure, reduce maintenance costs, and extend the lifespan of machinery.

Advancements in heat treatment technologies have broadened the applications of steel in emerging industries. For example, induction heat treating offers precise control over heating and cooling, minimizing distortion and improving efficiency in component manufacturing. Cryogenic treatment further enhances the strength and durability of steel used in high-performance applications, such as aerospace and automotive industries. These innovations allow for the tailoring of steel properties to meet specific industry needs, facilitating the development of more efficient and resilient products.

Warping typically results from uneven heating or cooling, which generates internal stresses within the steel.

Rapid cooling or inconsistent temperatures during heat treatment can lead to the formation of cracks and fractures in the steel.

Heating steel to temperatures above 1200°C can damage its structure, making it brittle and potentially unusable.

Excessive heat during the heat treatment process can make the steel brittle, which may affect its performance.

Exposure to oxygen during heat treatment can cause the steel to lose carbon from its surface, weakening the material.

Variability in the heating and cooling process can lead to uneven hardness across the steel piece.

Surface oxidation or scale can occur if the steel is not properly prepared or if the furnace atmosphere is not controlled.

Below are answers to some frequently asked questions:

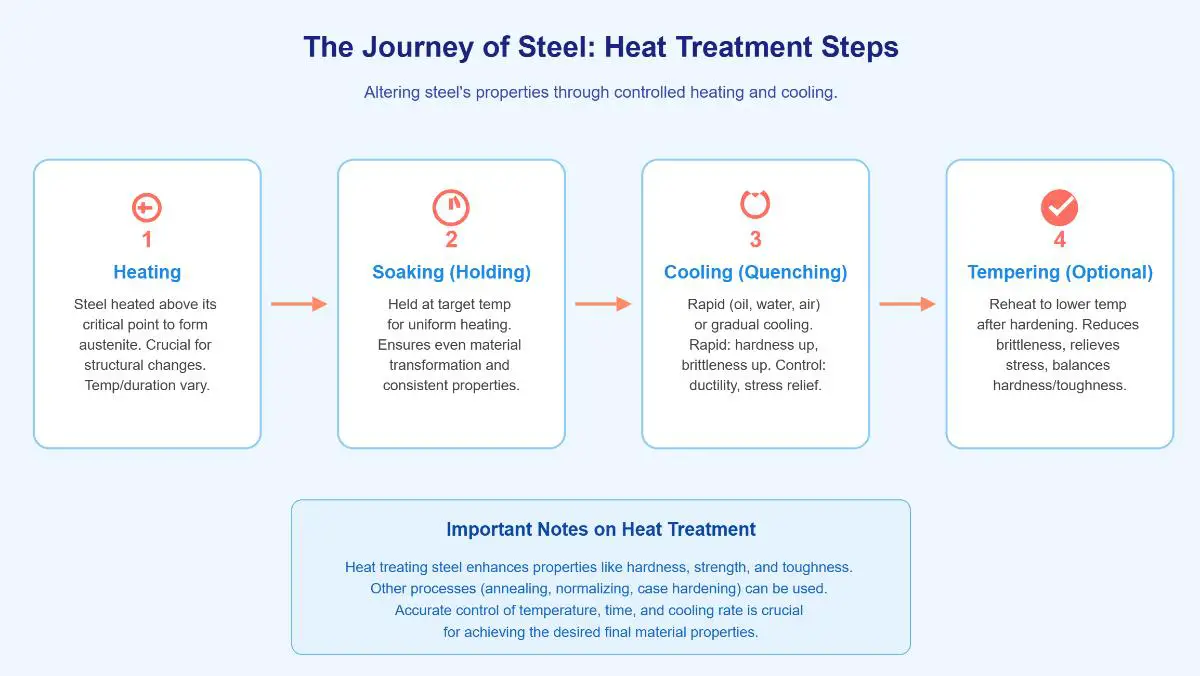

Heat treating steel involves several critical steps to alter its mechanical properties, enhancing characteristics such as hardness, strength, and toughness. Here are the essential steps:

Additional processes like annealing, normalizing, and case hardening can be applied based on specific requirements. Accurate control over temperature, time, and cooling rate is vital for achieving the desired material properties.

Heat treatment significantly alters the properties of steel by changing its microstructure through controlled heating and cooling cycles. Key processes such as hardening, tempering, annealing, and normalizing each target different mechanical properties to suit specific applications.

Hardening, which includes quenching, increases hardness and strength by rapidly cooling steel from high temperatures to form a martensitic structure. This results in a harder but more brittle material. Tempering follows quenching to reduce brittleness while improving toughness, achieving a balance between hardness and ductility.

Annealing, on the other hand, enhances ductility and relieves internal stresses by heating steel and cooling it slowly, allowing larger grains to form. This process makes steel more flexible and easier to work with. Normalizing, similar to annealing, refines the grain structure and improves strength and toughness by cooling steel in air.

These heat treatment processes also improve wear resistance and fatigue strength, essential for components subjected to constant friction and stress, such as those used in automotive and aerospace industries. Techniques like case hardening create a wear-resistant surface layer while maintaining a tough core.

There are several methods of heat treating steel, each designed to modify the material’s properties to suit specific applications:

Each method serves a unique purpose and is selected based on the desired properties and the specific application of the steel.

To apply heat treatment processes in your workshop, follow these steps:

By following these steps, you can effectively apply heat treatment processes in your workshop to enhance the properties of steel for various applications.

The latest advancements in industrial ovens for steel heat treatment focus on improving energy efficiency, smart controls, and customization. Modern industrial ovens now integrate advanced insulation and energy recovery systems, significantly reducing operational costs and environmental impact. Additionally, the use of renewable energy sources, such as solar or thermal technologies, is becoming more common to lower carbon footprints.

Smart controls and automation are another major advancement, with industrial ovens incorporating IoT features for real-time monitoring and predictive maintenance. This integration helps in reducing downtime and optimizing resource allocation. The modular design of these ovens offers greater flexibility, catering to both small-batch operations and large-scale manufacturing needs.

In terms of new steel alloys and techniques, recent developments focus on enhancing the precision of heat treatment processes. For example, rapid tempering techniques using continuous conveyor ovens allow for faster processing times and increased productivity. Customization of heat treatment processes enables the tailoring of steel properties to meet specific industry requirements, such as those in aerospace and automotive sectors.

Future trends in industrial ovens may include further integration with Industry 4.0 technologies, such as AI for predictive analytics, and the use of hybrid heating systems combining traditional and alternative energy sources to adapt to changing energy costs and sustainability goals.

ASTM standards play a crucial role in heat treating steel to ensure consistent quality and desired properties. ASTM A757/A757M – 15 applies to carbon and alloy steel castings for pressure – containing applications, especially for low – temperature service. It requires castings to be heat – treated by normalizing and tempering or liquid quenching and tempering, with a tempering temperature of at least 1100°F (595°C), except for grades B4N and B4Q which need 1050°F (565°C). ASTM F3301 – 18, mainly for metal parts from powder bed fusion, outlines thermal post – processing requirements, showing ASTM’s approach to thermal treatments. To implement these standards, select the right steel, follow the recommended heat treatment sequence, and verify the process, such as measuring hardness using ASTM E18.