Laser welding aluminum can seem daunting, but with the right approach, it transforms into an exciting and rewarding process. This detailed guide is designed to walk you through each step, making complex techniques more accessible. Whether you’re looking to understand the intricacies of laser welding, identify the necessary equipment, or navigate the unique challenges aluminum presents, you’ve come to the right place. We’ll cover everything from preparation to advanced techniques for specific alloys, ensuring you have the knowledge to achieve precise, high-quality welds. Ready to master the art of laser welding aluminum? Let’s dive in and illuminate the path to your next successful project.

Laser welding is an advanced technique that uses a focused beam of light to join metals and other materials. It offers high precision and control, making it an ideal choice for applications requiring minimal heat distortion and superior weld quality. This highly efficient process is extensively used in industries such as automotive, aerospace, and electronics.

Aluminum is popular in manufacturing because it is lightweight, strong, and resistant to corrosion. However, welding aluminum presents unique challenges due to its high thermal conductivity, low melting point, and the formation of aluminum oxide on its surface.

Laser welding aluminum offers several advantages, including precision control over heat input, which minimizes distortion, high-speed processing suitable for mass production, and the creation of strong, clean welds that need little post-processing. Additionally, it is versatile enough to be used on various aluminum alloys.

Aluminum’s high thermal conductivity means it dissipates heat quickly. This characteristic requires careful control of the laser’s power and speed to ensure a consistent weld without overheating or causing distortion.

It is crucial to remove the oxide layer from aluminum surfaces before welding, using methods like mechanical cleaning or chemical treatments, to prevent weak welds and porosity.

Contaminants such as lubricants or oils from machining processes can affect weld quality. Thorough cleaning of the aluminum surfaces is necessary to prevent contamination and ensure a strong, defect-free weld.

Laser welding is especially valuable in industries requiring high precision and efficiency, such as aerospace (for lightweight, strong components), automotive (for durable parts with minimal distortion), and electronics (for delicate components with minimal heat damage).

Laser welding is a high-precision welding process that employs a concentrated beam of light to join metal parts together. This method is known for its efficiency, accuracy, and ability to produce high-quality welds with minimal heat input and distortion.

Laser welding uses a focused laser beam to melt and join metal parts with high precision. The energy from the laser melts the material, which then solidifies to form a strong, precise weld. The process can be controlled very precisely, making it ideal for applications where accuracy is critical.

Several types of lasers can be used for welding, each with its own advantages:

Laser welding offers exceptional control over the welding process, allowing for precise adjustments to the laser’s power, speed, and focus. This leads to high-quality welds with minimal defects.

This process is efficient, enabling high-speed welding with minimal downtime. This makes it suitable for mass production and automated manufacturing environments.

Because the laser beam can be precisely controlled, the heat input is localized, reducing the risk of thermal distortion and damage to surrounding materials. This is particularly important for delicate or heat-sensitive components.

Laser welding produces clean welds with minimal contamination. The resulting welds are strong and often require little to no post-processing, reducing the overall production time and costs.

Laser welding is used to join various automotive components, including body panels, transmission parts, and exhaust systems. Its precision and speed are essential for the high-volume production in this industry.

In aerospace, laser welding is used to fabricate lightweight, strong components. The ability to produce precise, high-quality welds is critical for ensuring the safety and performance of aircraft parts.

The electronics industry benefits from laser welding’s precision and low heat input, which are essential for joining small, delicate components without causing damage.

Highly reflective materials like aluminum can make laser welding less efficient. Using fiber lasers with optimized wavelengths and absorptive coatings can help mitigate this issue.

Aluminum’s high thermal conductivity can lead to rapid heat dissipation, making it challenging to maintain a stable welding process. Techniques such as pulsed laser welding and the use of higher power lasers can address this challenge.

Aluminum naturally forms an oxide layer that can interfere with welding. Proper surface preparation, including cleaning and removing the oxide layer, is essential for achieving high-quality welds.

Start by thoroughly cleaning the aluminum surface to remove contaminants like oil, grease, and dirt for high-quality welds. Use organic solvents such as acetone, mild detergents, or vinegar, applying them with a lint-free cloth or paper towel, and ensure the surface is completely dry before proceeding.

Aluminum forms an oxide layer that can weaken the weld. Remove this layer using sanding, abrasive pads, or acid etching. Ensure the oxide layer is completely removed just before welding to prevent its reformation.

For optimal weld quality, the aluminum surface must be smooth and even. Use machining tools to level the surface, removing any irregularities that could affect the weld. A uniform surface ensures better laser penetration and weld consistency.

Cut aluminum pieces accurately using precision tools to ensure clean, straight edges for a proper fit during welding. Misaligned pieces can lead to poor weld quality and structural weaknesses.

Securely holding and aligning the aluminum pieces is essential to prevent movement during welding. Use clamps or custom fixtures to maintain the alignment of the pieces. This ensures a seamless joint and consistent weld quality.

Preheating aluminum to a temperature range of 150°C–200°C can help reduce thermal stress and minimize the risk of cracking. This step is particularly beneficial for certain aluminum alloys, as it reduces thermal gradients and improves weld integrity.

Before starting the welding process, inspect the aluminum surfaces to ensure they are free from moisture and contaminants. Any residual contaminants can lead to porosity and weaken the weld.

Perform a final wipe-down of the aluminum surfaces with a lint-free cloth and a suitable solvent. This last cleaning step removes any remaining contaminants, ensuring a clean surface for welding.

Select the appropriate laser type based on the aluminum alloy, material thickness, and application. Options include CO2, Nd:YAG, Fiber, and Diode lasers, each with specific advantages for different welding scenarios.

Choose pulsed mode for thin materials and continuous wave mode for deeper welds, based on the desired penetration and heat control.

Use inert gases like Argon to shield the weld pool from oxidation and atmospheric contamination. Proper shielding ensures a clean, strong weld.

Adjust laser parameters such as power, welding speed, and focal position according to the material thickness and desired weld quality. Fine-tuning these settings is critical for achieving optimal results.

When selecting equipment for laser welding aluminum, understanding the different types of lasers available is crucial. Each type offers unique advantages and disadvantages depending on the application.

Fiber lasers are highly precise, fast, and reliable, making them ideal for welding thin aluminum sheets. They can focus the laser beam with minimal heat-affected zones.

Diode lasers are compact and more affordable, offering better energy absorption for aluminum, making them suitable for small-scale or lighter-duty applications.

CO2 lasers are versatile and can produce high-quality welds. However, they suffer from reflectivity issues with aluminum, which can require additional maintenance.

Nd:YAG lasers penetrate deeply, making them good for thicker aluminum pieces, but they are less efficient due to reflectivity issues.

Selecting the appropriate welding mode is essential for achieving the desired weld quality.

Pulsed mode offers precise control over heat input. This mode is ideal for thin aluminum materials or applications that need high precision.

Continuous wave mode allows for deeper penetration, making it suitable for thicker materials and high-speed industrial applications.

Handheld laser welding machines provide flexibility and ease of use, making them suitable for small projects or repair tasks.

Understanding key specifications helps ensure the chosen equipment meets the requirements for aluminum welding.

Laser power requirements vary based on the thickness of the aluminum being welded.

Welding speed must be adjusted according to the thickness of the aluminum.

Using inert gases such as Argon is essential to prevent oxidation during the welding process.

A robust cooling system is necessary to manage aluminum’s high thermal conductivity, ensuring stable welding conditions.

For industrial applications, advanced features can enhance productivity and precision.

Automation can significantly improve productivity and reduce defects, ensuring consistent quality in high-volume production.

Choosing equipment that supports various joint types, such as butt, lap, and corner joints, is essential for versatility in different welding applications.

When selecting the right machine, consider the specific requirements of your project.

First, identify if your project involves only aluminum and consider the material’s thickness to choose the right laser type and power.

Ensure the machine offers the necessary power and laser type to meet the application’s demands, whether it involves thin or thick aluminum materials.

Decide whether pulsed or continuous wave mode is needed based on the desired weld quality and application requirements.

By carefully evaluating these factors, you can select the appropriate equipment for laser welding aluminum, achieving high-quality welds with precision and efficiency.

Start by thoroughly cleaning the aluminum surface to remove any oil, dirt, and oxide layers. Use mechanical methods like grinding or chemical cleaning agents to ensure the surface is spotless. This step is crucial as contaminants can lead to defects in the weld.

Cut and shape the aluminum sheets to the required dimensions, ensuring a precise fit and alignment during the welding process. Accurate cutting and shaping are essential for achieving a seamless weld.

Preheat the material to 150°C–200°C for certain aluminum alloys like the 7000 series to reduce the risk of cracking and improve weld quality.

Choose the right laser for your application, such as CO2, Nd:YAG, Fiber, or Diode lasers, with Fiber lasers being ideal for aluminum due to their precision and efficient energy transfer.

Choose between pulsed and continuous wave (CW) modes. Pulsed mode offers better control over heat input, making it ideal for thin materials, while CW mode is suitable for deeper penetration in thicker materials.

Use inert gases such as Argon or Helium to shield the weld area from oxidation. Proper shielding is essential to maintain weld integrity and quality.

Adjust laser power based on material thickness. Thicker sections may need 2KW to 3KW or more.

Set the welding speed based on the material thickness. Thinner materials generally require faster speeds (50-60 inches per minute) to prevent overheating, while thicker materials need slower speeds (20-30 inches per minute).

Optimize the beam diameter and focus for efficient energy transfer. Focus the laser slightly below the surface of the aluminum to enhance absorption and ensure a strong weld.

Turn on the laser and the shielding gas, ensuring the laser beam is properly aligned with the weld seam. Proper alignment is critical for achieving a consistent weld.

Move the laser along the seam at a steady and controlled speed, maintaining a consistent heat input throughout the welding process. This helps in creating uniform and strong welds.

Allow the weld to cool naturally, forming a solid and strong bond between the aluminum components. Avoid any abrupt cooling methods as they can cause thermal stress and potential defects.

Carefully inspect the weld for defects like porosity, cracks, or incomplete fusion using non-destructive testing methods to ensure the weld meets quality standards.

Perform grinding or polishing if necessary to enhance the appearance and quality of the weld. This step helps in removing any surface imperfections and achieving a smooth finish.

Consider additional surface treatments, such as anodizing, to improve the corrosion resistance and durability of the material.

Aluminum’s high reflectivity can reduce the efficiency of the laser welding process. Apply absorptive coatings to the surface to improve energy absorption and reduce reflectivity.

Porosity and cracking are common issues in aluminum welding. Ensure thorough cleaning of the material and adjust laser parameters to minimize these defects. Proper surface preparation and parameter optimization are key to preventing these problems.

Laser welding aluminum is challenging because of its physical properties and specific welding requirements. Understanding these challenges is crucial for achieving high-quality welds.

Porosity, a common defect in laser welding aluminum, is mainly caused by gas entrapment during solidification due to rapid cooling rates and the aluminum oxide layer trapping moisture and gases.

Aluminum alloys can crack when they cool quickly after welding. This issue arises when low melting point eutectics form at grain boundaries, leading to cracks as the weld cools. The risk of hot cracking increases with higher welding speeds and significant thermal gradients.

Low laser power or incorrect focus can cause aluminum welds to blacken. This occurs when the laser energy fails to penetrate the oxide layer completely, causing a mixture of aluminum with air and impurities, leading to a darkened weld area.

Aluminum’s high thermal conductivity causes it to dissipate heat rapidly. This rapid expansion and contraction during welding can create stress points, leading to distortion.

Addressing these challenges requires specific strategies and adjustments in the welding process to ensure high-quality welds.

Implementing best practices can significantly improve the quality and consistency of laser welds on aluminum.

By addressing these challenges and following best practices, manufacturers can achieve high-quality aluminum welds suitable for various industrial applications.

1000 series aluminum alloys are highly pure, resist corrosion well, and conduct electricity excellently. However, they exhibit low strength, making them suitable for applications where these properties are advantageous.

The 6000 series alloys offer good strength, excellent weldability, and corrosion resistance, making them a popular choice for structural applications.

The 7000 series alloys, known for their high strength-to-weight ratio due to their high zinc content, are ideal for aerospace and high-performance applications.

By applying these advanced techniques, you can overcome the specific challenges associated with laser welding various aluminum alloys and achieve high-quality welds suitable for a wide range of industrial applications.

This guide comprehensively covers the fundamentals of laser welding, such as the physics of laser-material interaction, various laser types, and practical applications. It is an excellent resource for those looking to deepen their understanding of laser welding techniques and best practices.

This book provides an in-depth look at welding aluminum, addressing the unique challenges associated with this material. It includes sections on preparation, equipment selection, and troubleshooting common issues, making it a valuable resource for both beginners and experienced welders.

Offered by various online platforms, these courses cover the basics of laser welding, including the principles of laser operation, material interactions, and hands-on welding techniques. These courses often feature video demonstrations, quizzes, and hands-on assignments to reinforce learning.

This specialized course focuses on the advanced techniques required for welding different aluminum alloys. Topics include parameter optimization, dealing with high reflectivity, and advanced surface preparation methods. It is ideal for those looking to master aluminum welding.

This international standard provides guidelines for the qualification of welding procedures for aluminum and its alloys. Covering various welding processes, including laser welding, it ensures that welds meet quality and safety standards.

Published by the American Welding Society, this code outlines the requirements for welding aluminum structures. It includes specifications for materials, design, fabrication, and inspection, providing a comprehensive reference for ensuring high-quality aluminum welds.

AWS offers a wealth of resources, including technical papers, standards, and certification programs, while membership provides access to industry news, professional development opportunities, and a network of welding professionals.

An online community where welders of all levels share their experiences, ask questions, and provide support. It is a great place to find practical advice, troubleshooting tips, and discussions on the latest trends and technologies in laser welding.

This software allows users to simulate the laser welding process, helping to optimize parameters and predict weld quality before actual welding. It includes features for modeling heat input, thermal cycles, and material properties, making it a powerful tool for both education and practical applications.

This application helps welders select the right laser settings for various materials and thicknesses. It provides recommendations for laser power, speed, and shielding gas, based on empirical data and industry best practices.

This research paper explores the specific challenges associated with laser welding aluminum, such as porosity and reflectivity. It presents various solutions and innovations that have been developed to address these issues, providing valuable insights for welders and engineers.

This case study examines the application of laser welding in the production of automotive components. It highlights the benefits of laser welding, such as increased precision and reduced production times, and discusses the specific techniques used to overcome the challenges of welding aluminum in this context.

Below are answers to some frequently asked questions:

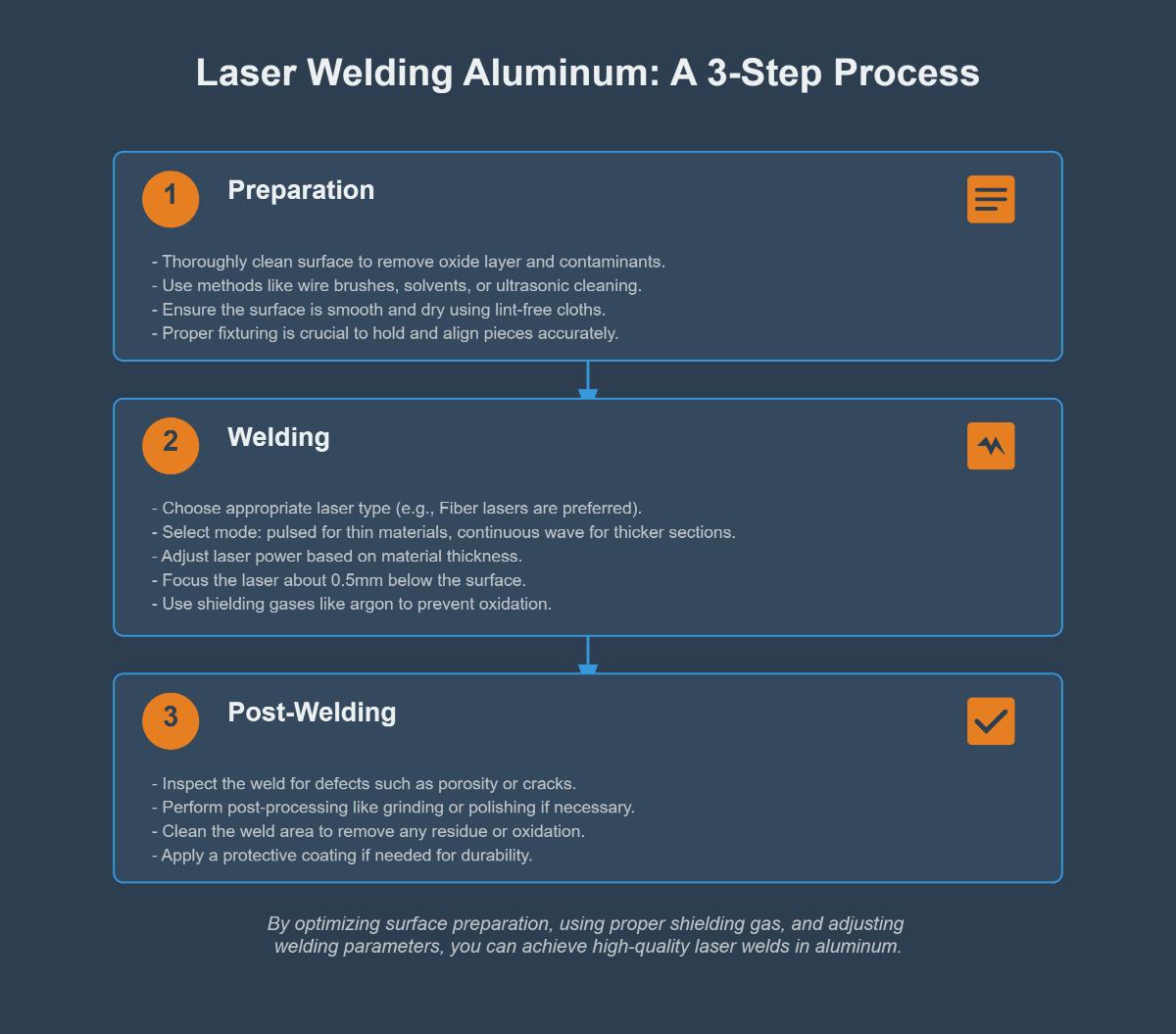

To laser weld aluminum effectively, follow these steps:

By optimizing surface preparation, using proper shielding gas, and adjusting welding parameters, you can achieve high-quality laser welds in aluminum.

Laser welding aluminum presents several challenges due to its distinct material properties. One major issue is aluminum’s high thermal conductivity, which can lead to rapid cooling, gas entrapment, and porosity, weakening the weld. Preheating and adjusting laser power can help mitigate these effects. Aluminum’s high reflectivity also poses a problem by scattering the laser beam, reducing efficiency. Using higher power levels can counteract this.

Another challenge is the formation of an oxide layer on aluminum’s surface, which hinders bonding and introduces impurities. Thorough cleaning and the use of shielding gases like argon can prevent oxidation. Additionally, aluminum is sensitive to rapid temperature changes, potentially causing cracking or distortion. Fine-tuning welding parameters and preheating are essential to address this.

To laser weld aluminum effectively, several key pieces of equipment are required due to aluminum’s unique properties. Firstly, a laser welder is essential, with options typically including fiber lasers or CO2 lasers. The power source for these welders generally ranges from 500W to 3000W, tailored to the thickness of the aluminum being welded; for instance, a 2kW laser can weld aluminum up to 6mm thick in one pass. Handheld laser welders are also available for more flexible applications.

Additionally, a specialized welding gun is necessary to control the laser beam’s focus and intensity. Modern welding guns often feature digital interfaces for real-time parameter adjustments. Protective equipment is vital, including safety goggles designed for laser work, heat-resistant gloves, and appropriate clothing to shield against heat and sparks.

Filler material might be needed depending on the joint design and aluminum thickness, with filler wire typically matching the aluminum alloy and ranging from 0.8mm to 1.2mm in diameter. Cleaning equipment is crucial to remove the oxide layer on aluminum surfaces, using chemical cleaners or mechanical methods.

Optionally, shielding gas such as argon can be employed to protect the weld from contamination, particularly in environments with poor air quality. Proper preparation and calibration of this equipment are fundamental to achieving high-quality laser welds in aluminum.

Preparing aluminum for laser welding involves several critical steps to ensure high-quality welds with minimal defects. First, thoroughly clean the aluminum surface to remove contaminants such as oil, grease, and dirt. This can be done using organic solvents like acetone or mild detergents. Additionally, it’s essential to remove the oxide layer that naturally forms on aluminum, which can interfere with the welding process. This can be achieved through sanding or mechanical grinding.

Next, ensure the aluminum pieces are smooth and even by employing gentle machining techniques. Proper alignment of the pieces is crucial, so use fixtures or clamps to secure them in place for a seamless joint. Preheating the aluminum to a temperature between 150°C and 200°C can improve laser absorption and reduce thermal stress, which helps minimize porosity and prevent cracking. Also, make sure the surface is free of moisture, as water vapor can lead to porosity in the weld.

When laser welding aluminum, it is crucial to follow specific safety precautions to prevent injuries and ensure a safe working environment. First, wear appropriate personal protective equipment (PPE), including laser safety glasses or goggles that block the specific laser wavelengths and meet industry standards, flame-resistant clothing, long sleeves, pants, and leather gloves. A welding helmet with laser-safe glass adds an extra layer of protection.

Establish a designated laser-controlled area (LCA) with clear warning signs and ensure proper ventilation to remove any harmful fumes generated during welding. Only trained and authorized personnel should operate the laser equipment, understanding all safety protocols and risks involved.

Ensure the laser equipment has built-in safety features such as key switches, emergency stop buttons, and interlocks. Regular maintenance and inspection of the equipment are essential to prevent malfunctions.

Conduct regular risk assessments to identify and mitigate potential hazards. Comprehensive training on laser safety, PPE use, and emergency procedures is vital for all personnel involved.

Follow the manufacturer’s guidelines for starting and stopping the laser machine, avoiding frequent on/off cycles and ensuring proper cooling times. Never look directly at the laser beam, even with protective eyewear, and avoid directing the beam onto skin or reflective surfaces. Adhering to these precautions will help minimize risks and ensure a safe laser welding process.

Advanced techniques for laser welding specific aluminum alloys focus on managing the unique properties and challenges associated with different alloy compositions.

For the 1000 series (pure aluminum), which has high purity and excellent corrosion resistance but low strength, it is advisable to use low-power, high-speed settings to minimize heat input and distortion. This technique helps maintain the integrity of the weld while preventing excessive heat buildup.

When dealing with the 6000 series (6061 alloy), known for good weldability, strength, and corrosion resistance, a pulsed laser is recommended. Pulsed lasers allow for precise control over heat, thereby reducing the risk of hot cracking, which is a common issue in aluminum welding.

For the 7000 series (7075-T6 alloy), which offers high strength but is prone to hot cracking and porosity, high-power fiber laser welding with low heat input is effective. This method minimizes defects and preserves the mechanical properties of the alloy.

Additional advanced techniques include using pulsed lasers for better heat management and reducing thermal stress, employing inert shielding gases like Argon or Helium to prevent oxidation, and ensuring thorough surface preparation by removing oxide layers and contaminants. Automation and precision control are also crucial for achieving consistent, high-quality welds, particularly in complex geometries.

By carefully selecting the appropriate laser type and parameters based on the specific aluminum alloy, manufacturers can optimize the welding process, achieving superior weld quality and enhanced mechanical properties.