Imagine the frustration of watching a sturdy steel structure slowly succumb to the relentless forces of corrosion. Mild steel, a material celebrated for its versatility and strength, is particularly susceptible to this silent destroyer. Whether you’re a construction professional, a manufacturer, or an engineer, understanding how to protect mild steel from corrosion is crucial to maintaining the integrity and longevity of your projects.

In this article, we’ll delve into the most effective methods to safeguard mild steel, including the science behind galvanization, the nuanced technique of bluing, and the robust approach of cathodic protection. You’ll discover the strengths and limitations of each method, helping you make informed decisions for your specific applications. So, what are the best strategies to shield mild steel from the ravages of time and elements? Let’s explore the options and find the solution that best fits your needs.

Mild steel, or low carbon steel, is widely used in engineering and construction due to its versatility. It features a low carbon content, typically between 0.16% and 0.29%, which contributes to its ductility and malleability, making it easy to work with.

The low carbon content of mild steel provides it with unique properties such as ductility and malleability, which make it easy to work with. These characteristics, combined with its affordability, make mild steel a popular choice in various industries:

Despite its many advantages, mild steel is prone to corrosion. This happens because the iron in mild steel reacts with oxygen and moisture, forming rust. This reaction is accelerated in harsh environmental conditions such as high humidity, saltwater exposure, and industrial atmospheres.

Protecting mild steel from corrosion is essential to ensure its strength and longevity. Corrosion can lead to structural failures, reduced efficiency, and increased maintenance costs. Thus, using effective corrosion protection methods is vital for the durability and reliability of mild steel across different uses.

Corrosion is a natural process that causes the deterioration of materials, especially metals, due to chemical reactions with elements like oxygen and moisture. Mild steel, widely used in construction and manufacturing, is susceptible to rust formation, making corrosion protection essential to maintain its structural integrity and lifespan. Implementing effective corrosion protection methods is crucial to preserving the functionality and longevity of mild steel.

Several strategies can be employed to protect mild steel from corrosion, each with unique mechanisms and applications. Below are some of the most widely used methods:

Barrier coatings act as a physical shield that stops corrosive agents from reaching the steel surface. These coatings include paints, plastics, and powder coatings that are directly applied to the steel. They are cost-effective and provide initial protection against moisture and oxygen.

Hot-dip galvanization involves immersing steel into molten zinc, forming a protective zinc alloy layer. This coating acts as a barrier and a sacrificial layer, corroding in place of the steel underneath.

By alloying steel with elements like nickel and chromium, stainless steel forms a passive layer that resists corrosion. This method is highly effective in preventing rust formation but comes with a higher production cost.

Cathodic protection uses a sacrificial anode to divert corrosion away from the mild steel. This method is especially useful for large structures like pipelines and marine installations. There are two types: sacrificial anode systems and impressed current systems.

Bluing involves a chemical treatment that creates a thin layer of magnetite on the steel surface, offering mild corrosion resistance. This method is often used for aesthetic purposes and smaller applications.

Using multiple corrosion protection methods together can enhance effectiveness. For example, applying barrier coatings along with galvanization or cathodic protection can offer comprehensive protection against specific environmental challenges.

Recent developments in corrosion protection focus on sustainability and cost-efficiency. Innovations in coating technologies and the adoption of environmentally friendly materials are paving the way for more effective and sustainable protection solutions. Advances in cathodic protection techniques continue to play a vital role in safeguarding infrastructure across diverse industries.

Galvanization is a common method for protecting mild steel from corrosion by coating it with zinc. This process involves either hot-dip galvanization or electro-galvanization, where the zinc layer acts as a barrier, preventing corrosive substances from reaching the steel surface. Additionally, zinc provides electrochemical protection through the sacrificial anode effect.

The primary advantage of galvanization is its effectiveness in preventing rust. The zinc coating serves as a physical barrier, protecting the steel from moisture and oxygen, which are the main causes of corrosion. Furthermore, zinc has a lower electrochemical potential than steel, meaning it will corrode in place of the steel. This sacrificial anode effect ensures that even if the zinc coating is damaged, the surrounding zinc will continue to protect exposed steel areas, maintaining the steel’s integrity over time.

Galvanized steel is durable and lasts a long time. In typical environments, galvanized coatings can last over 50 years without significant maintenance. Even in more aggressive conditions, such as coastal or industrial environments, galvanized steel can provide reliable protection for 20 years or more. This durability reduces the need for frequent replacements and repairs, making it a cost-effective choice for long-term applications.

Compared to other protective coatings, galvanizing steel is initially inexpensive. The long-term savings from reduced maintenance and extended service life further enhance its economic appeal. This makes galvanization a preferred choice for large-scale projects where cost efficiency is critical.

Once galvanized, steel is ready for immediate use. There is no need for additional surface preparation or coatings, which streamlines the construction process and reduces downtime. This immediate readiness is particularly advantageous in time-sensitive projects.

It’s important to have a consistent zinc coating thickness for proper corrosion protection. Variations in coating thickness can result in areas with less protection, potentially leading to premature corrosion. Ensuring consistent application requires careful control of the galvanization process.

While the sacrificial anode effect provides some level of protection for damaged areas, significant damage to the zinc coating can compromise the overall effectiveness of the protection. Regular inspections and maintenance are necessary to ensure the integrity of the coating and address any areas of damage promptly.

The effectiveness of galvanization can be influenced by environmental conditions. For instance, high salinity or extreme pH levels can accelerate the corrosion of zinc, reducing the lifespan of the coating. In such environments, additional protective measures may be required to ensure long-term durability.

The appearance of galvanized steel may not be suitable for all applications, particularly where aesthetics are a priority. Additionally, galvanized steel may not be compatible with certain materials or finishes required in specific industries. This limitation necessitates careful consideration of the intended application before choosing galvanization as the protective method.

Cathodic protection is a technique used to prevent corrosion in mild steel by transforming it into the cathode within an electrochemical cell. This method effectively preserves steel structures in various environments by redirecting the corrosion process away from the steel itself.

There are two primary approaches to cathodic protection: sacrificial anode systems and impressed current systems. Sacrificial anode systems utilize more reactive metals, like aluminum, zinc, or magnesium, which corrode instead of the mild steel, making them suitable for smaller or isolated structures such as water heaters and marine components. On the other hand, impressed current systems employ a DC power source to provide a continuous flow of current, ideal for large infrastructures like pipelines and storage tanks. This system allows for adjustable current output based on environmental conditions, ensuring optimal protection.

The effectiveness of cathodic protection depends on the surrounding conditions, like how conductive the soil or water is, the acidity level, and the temperature. These factors influence the choice of anode materials and the necessary current levels to maintain protection. Complex shapes and large structures may require multiple anodes or distributed current sources to ensure uniform protection, avoiding unprotected areas.

Continuous monitoring using reference electrodes is crucial to verify protection levels. Maintaining a voltage of -0.85 V against a Cu/CuSO4 electrode is typically recommended for effective protection. This ensures that the steel remains safeguarded from corrosion, with adjustments made as needed to account for environmental changes.

Exciting advancements in aluminum-based alloys have improved their efficiency and lifespan, especially in salty environments. These innovations enhance the performance of sacrificial anodes. Additionally, the integration of smart sensors offers real-time data on corrosion, optimizing maintenance schedules and ensuring continuous protection. These developments make cathodic protection an increasingly robust strategy for safeguarding mild steel in diverse applications.

Bluing is a chemical treatment that forms a protective magnetite layer on mild steel, enhancing its resistance to rust and corrosion. This process involves controlled oxidation, creating a barrier that reduces exposure to oxygen and moisture.

Bluing transforms the steel surface into magnetite, a stable iron oxide, through controlled oxidation. This magnetite layer acts as a shield against corrosive elements like oxygen and moisture.

The microporous nature of the blued surface allows it to absorb oils. Applying oils, such as 3-in-1 oil, to the blued surface creates a hydrophobic barrier that repels moisture, extending the lifespan of the steel.

Bluing can be combined with other protective methods, such as galvanizing or powder coating, to provide a multi-layered defense. This is especially beneficial in harsh environments where additional protection is needed.

There are two main methods for applying bluing, each with its own advantages depending on the scale and type of the steel components.

Cold bluing is a straightforward method suitable for small-scale applications. The process involves cleaning the steel with acetone to remove contaminants, then applying a selenium-dioxide-based solution at room temperature. This results in the formation of a thin black oxide layer. After rinsing, the surface is oiled and allowed to cure. Cold bluing is advantageous due to its simplicity and lack of requirement for specialized equipment, making it ideal for small repairs and precision parts.

Hot bluing involves heating the steel to temperatures between 150°C and 300°C, followed by quenching in oil. This method produces a thicker and more durable oxide layer than cold bluing, offering superior corrosion resistance and longevity. However, hot bluing requires heat sources and appropriate safety measures, making it better suited for larger items like tools and high-wear components.

To boost the protective qualities of bluing, use high-quality oils after treatment. This creates a moisture-resistant barrier, and combining bluing with other protective strategies can improve durability in harsh environments.

Here’s a comparison of cold bluing and hot bluing to help you decide which method best suits your needs.

| Aspect | Cold Bluing | Hot Bluing |

|---|---|---|

| Durability | Moderate | High |

| Equipment | Brush, solution | Torch, oil bath |

| Best For | Small parts, repairs | Tools, high-wear items |

Understanding the various corrosion protection methods available for mild steel is essential for selecting the most effective solution based on specific needs and environmental conditions. This section compares galvanization, bluing, and cathodic protection, providing insights into their advantages, limitations, and suitable applications.

Process: Galvanization coats mild steel with a zinc layer using hot-dipping or electro-galvanizing techniques, providing both a physical barrier and sacrificial protection.

Advantages:

Limitations:

Process: Bluing applies a selenium-dioxide compound that forms a magnetite layer on the steel surface, enhancing rust resistance.

Advantages:

Limitations:

Process: Cathodic protection turns mild steel into the cathode of an electrochemical cell, using sacrificial anodes or impressed current systems.

Advantages:

Limitations:

Cost considerations play a significant role in selecting the appropriate corrosion protection method. Below is a comparative analysis of the expenses associated with each method:

Choosing the right corrosion protection method involves considering several factors, including environmental conditions, budget constraints, and specific application requirements. Here are some best practices:

Case Study 1: Coastal Infrastructure

A coastal infrastructure project employed a combination of galvanization and cathodic protection to safeguard against the harsh marine environment. The zinc coating provided immediate protection, while the impressed current system ensured long-term durability despite high salinity levels.

Case Study 2: Industrial Equipment

An industrial facility utilized bluing for small precision parts and galvanization for larger structural components. This approach balanced cost-efficiency with effective corrosion prevention, ensuring the longevity of both small and large-scale elements.

Case Study 3: Marine Applications

A marine application involving pipelines and storage tanks implemented sacrificial anode cathodic protection. The system provided robust defense against corrosion, with regular monitoring and adjustments ensuring optimal performance.

Each case highlights the importance of tailoring corrosion protection strategies to specific needs and conditions, leveraging the strengths of different methods to achieve the best results.

Below are answers to some frequently asked questions:

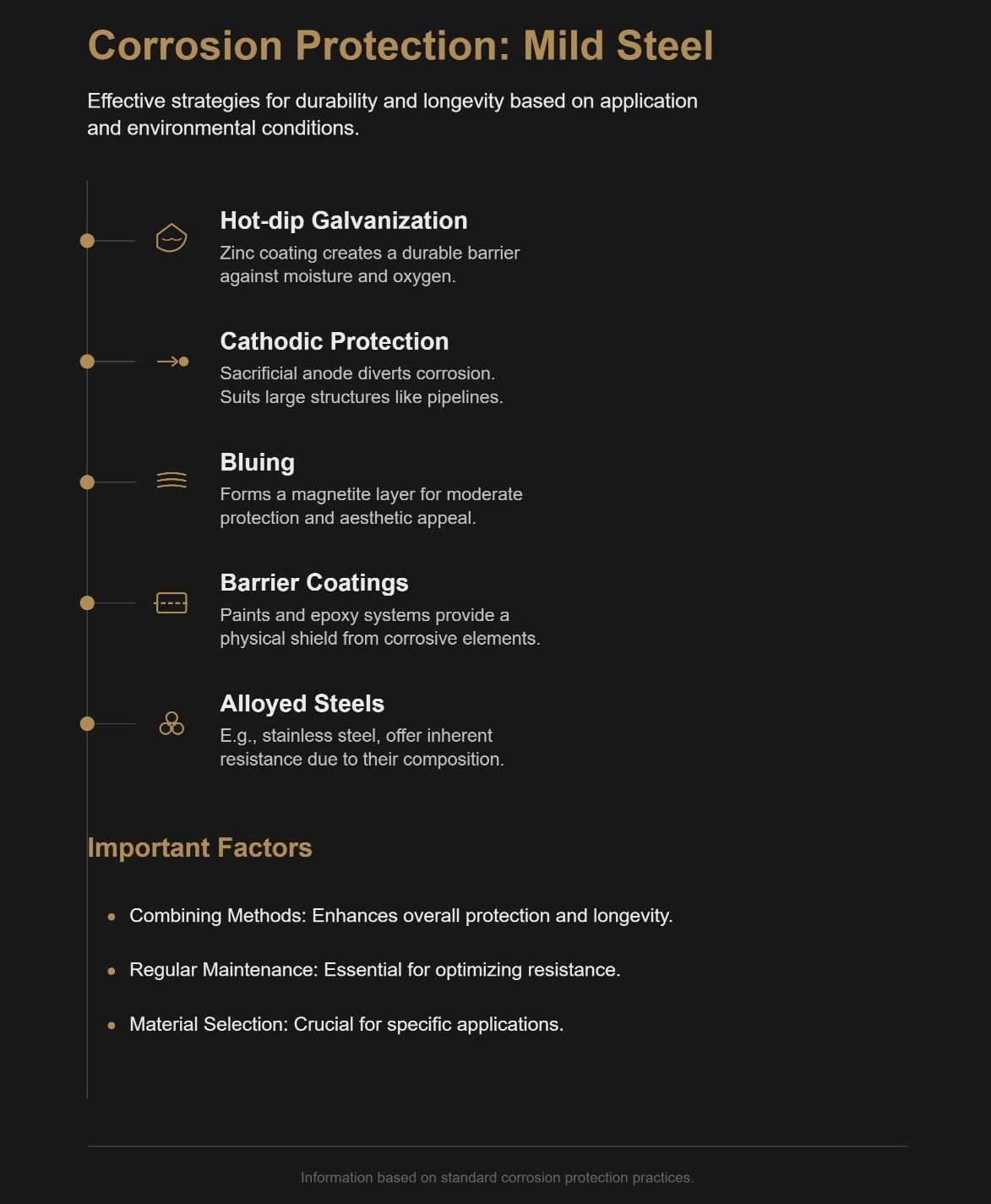

To effectively protect mild steel from corrosion, several strategies can be employed based on the application and environmental conditions. Hot-dip galvanization is a popular method, involving the coating of steel with zinc to create a durable barrier against moisture and oxygen. Cathodic protection is another effective approach, especially for large structures like pipelines, where a sacrificial anode diverts corrosive reactions away from the steel. Bluing offers aesthetic benefits and moderate protection by forming a magnetite layer on the steel’s surface. Barrier coatings, including paints and epoxy systems, provide physical protection by preventing direct contact with corrosive elements. Additionally, using alloyed steels, such as stainless steel, can inherently resist corrosion due to their composition. Combining these methods can enhance protection and ensure the longevity of mild steel structures, as discussed earlier. Regular maintenance and material selection adjustments are also crucial in optimizing corrosion resistance.

Galvanization prevents corrosion in mild steel through the application of a protective zinc coating. This process, typically executed via hot-dip galvanizing, involves immersing the steel in molten zinc, which forms a robust, multi-layered barrier. The zinc coating provides three main protective mechanisms:

These synergistic mechanisms make galvanization a highly effective method for protecting mild steel from corrosion, offering durability and cost-efficiency in various environments.

Bluing is a corrosion protection method for mild steel that involves creating a magnetite (Fe₃O₄) layer through controlled oxidation. This layer acts as a barrier to moisture and oxygen, offering partial rust resistance.

Advantages:

Limitations:

Bluing is best suited for indoor, low-moisture environments or projects where aesthetics are important. For enhanced protection, it can be paired with oil coatings or other methods like galvanizing.

Cathodic protection (CP) works by converting active corrosion sites on mild steel into passive cathodes through the introduction of a protective electrical current. This process counteracts the natural electrochemical reactions that cause corrosion. There are two primary methods of CP: galvanic anode and impressed current.

CP is particularly useful for buried or submerged infrastructure, reinforced concrete exposed to harsh conditions, and marine environments. It is often legally required for oil and gas pipelines and helps extend the lifespan of structures by significantly reducing corrosion rates.

The most cost-effective method for protecting mild steel from corrosion largely depends on the application and environment. Hot-dip galvanization is typically favored for its durability and long-term cost efficiency, especially in industrial or outdoor settings. It provides both a physical barrier and sacrificial cathodic protection, making it ideal for environments prone to moisture and pollutants. While the initial cost is higher compared to paints, the extended lifespan and reduced maintenance needs often justify the investment.

For less demanding conditions, oil-enriched organic coatings offer a low-cost solution, although they require more frequent reapplication. In high-moisture settings, polymer-ceramic coatings demonstrate excellent ROI despite higher initial costs, with proven long-term maintenance savings. Combining methods, such as galvanization with powder coating, can also enhance cost-effectiveness by optimizing protection and durability.

Yes, combining multiple methods can indeed enhance corrosion protection for mild steel. Integrating strategies such as galvanization with organic inhibitors, cathodic protection with environmental control, or bluing with oiling can address diverse environmental and operational challenges effectively. For example, galvanization provides a sacrificial zinc layer, while organic inhibitors slow down acidic corrosion, making the combination highly effective in industrial settings. Similarly, cathodic protection can be complemented with desiccants to reduce humidity-driven corrosion. Ensuring compatibility between different methods and maintaining them properly can maximize their protective benefits while balancing costs and maintenance needs. This holistic approach allows for tailored solutions that meet specific requirements and extend the lifespan of mild steel components.