Stainless steel is revered for its strength and durability, making it a staple in numerous industrial and domestic applications. However, there are times when its inherent hardness can become a challenge, particularly when machining or forming is required. If you’ve ever grappled with the difficulty of working with overly hard stainless steel, you’re not alone. Fortunately, there are effective methods to reduce its hardness, making the material more malleable and workable. In this article, we will delve into the principles of annealing, explore various heat treatment techniques, and provide practical steps for reducing the hardness of stainless steel. By the end, you’ll have a comprehensive understanding of how to achieve the desired softness without compromising the integrity of the material. Ready to transform your stainless steel projects? Let’s dive in.

Stainless steel is an alloy primarily made of iron and contains at least 10.5% chromium, which gives it excellent corrosion resistance. The chromium forms a thin, stable oxide layer on the steel’s surface, called the passive layer, which prevents further corrosion and stops it from penetrating deeper into the metal. Besides chromium, stainless steel may also contain other elements such as nickel, molybdenum, and titanium to enhance specific properties like strength, durability, and resistance to various environments.

Hardness is a critical property in stainless steel that affects its performance in various applications. Hardness refers to the material’s resistance to deformation, particularly permanent deformation, scratching, cutting, or abrasion. Understanding and managing the hardness of stainless steel is essential for several reasons:

Several factors contribute to the hardness of stainless steel, including its composition, heat treatment processes, and mechanical working. Understanding these factors helps in selecting the appropriate grade and treatment for desired hardness levels.

The elements added to stainless steel, like carbon, chromium, nickel, and molybdenum, affect its hardness. More carbon makes the steel harder and stronger but may reduce its resistance to rust. Chromium enhances corrosion resistance and contributes to overall hardness. Nickel adds toughness and improves corrosion resistance, while molybdenum increases strength and resistance to pitting corrosion.

Heat treatments like annealing, quenching, and tempering change the hardness of stainless steel. Annealing makes the steel softer and more flexible, while quenching and tempering make it harder and stronger.

Cold working methods like rolling, drawing, and forging make stainless steel harder by causing strain hardening. The more the steel is worked, the harder it becomes.

The hardness of stainless steel is commonly measured using various scales, such as Rockwell, Brinell, and Vickers. The Rockwell B and C scales are frequently used for stainless steel, where the B scale measures softer materials and the C scale measures harder materials. For example:

Understanding the hardness of stainless steel and how it can be manipulated through composition, heat treatment, and mechanical working is essential for optimizing its performance in various applications.

Annealing is a crucial heat treatment process that changes the physical and chemical properties of stainless steel. The primary aim is to reduce hardness, improve ductility, and relieve internal stresses. This process is essential for enhancing the machinability and overall workability of stainless steel, making it suitable for various industrial applications.

The first stage of annealing involves heating the stainless steel to a temperature above its recrystallization point, typically above 1040°C for austenitic stainless steels. The precise temperature may vary depending on the specific grade and desired properties of the stainless steel.

After reaching the target temperature, the material is held there for a period, called soaking. This allows the steel to fully recrystallize, which is crucial for achieving the desired reduction in hardness and improvement in ductility. The soaking time can vary based on the thickness and composition of the stainless steel.

In the final stage, the stainless steel is cooled slowly to avoid rapid temperature changes that can cause distortion or other issues. This slow cooling can be achieved by turning off the heating source and allowing the material to cool in the furnace or using insulation to control the rate of cooling.

One potential issue during annealing is sensitization. This happens if the cooling process is too slow, causing carbon atoms to become trapped and form chromium carbides. This reduces the chromium content available for forming the passive oxide layer, thus decreasing corrosion resistance.

Rapid cooling can lead to distortion, particularly in high-carbon stainless steels. To mitigate this risk, “L” grade stainless steels, which have low carbon content (less than 0.03%), are often used. These grades are less prone to distortion during cooling.

Full annealing involves heating the stainless steel to around 1080°C, followed by slow cooling. This method is comprehensive but may not be practical for large or complex workpieces due to the extended cooling times required.

This technique focuses on heating the steel to just above its recrystallization temperature. It aims to refine the grain structure, thereby improving the mechanical properties without the extensive cooling period required in full annealing.

Stress relieving is performed at temperatures below the critical point of the steel. This method targets the reduction of internal stresses without fully annealing the material, making it suitable for complex fabrications where maintaining dimensional stability is crucial.

Recent research has focused on optimizing annealing techniques to balance hardness reduction with maintaining desirable mechanical properties. Studies have highlighted the importance of precise temperature control and cooling rates to achieve specific hardness levels while preserving corrosion resistance and structural integrity. These advancements are particularly relevant in applications requiring stringent material performance criteria.

Understanding the principles of annealing stainless steel is essential for manufacturers and metalworkers looking to enhance the material’s workability and performance in various applications. By carefully controlling the annealing process, it is possible to achieve a balance between reduced hardness and improved ductility, ensuring the material meets the specific requirements of each application.

Heat treatment techniques are essential for modifying the hardness, ductility, and overall properties of stainless steel. Precise heat treatment processes help manufacturers tailor the characteristics of stainless steel to specific applications.

Annealing is a crucial heat treatment process designed to soften stainless steel, improve its ductility, and relieve internal stresses. This involves heating the metal to a specific temperature, holding it there (soaking), and then cooling it slowly.

Solution Annealing is particularly effective for austenitic stainless steels. This technique involves heating the metal to a high temperature, typically between 1850-2100°F, and then rapidly cooling it through water quenching. Rapid cooling dissolves unwanted carbides, restoring corrosion resistance and strength.

Stress Relieving is used to maintain dimensional stability and reduce the risk of stress corrosion cracking. It involves heating the stainless steel to just below its critical point, which helps in reducing residual stresses without significantly altering the hardness. This process is especially beneficial for complex fabrications where maintaining structural integrity is crucial.

To effectively reduce the hardness of stainless steel, it is essential to avoid processes that increase hardness, such as hardening or quenching. These processes are typically used to enhance strength and wear resistance but can make the steel brittle if not followed by appropriate tempering.

Choosing the right equipment, like kilns, ovens, and furnaces, is vital for achieving desired results due to their various temperature control capabilities. Precise temperature control is essential for ensuring that the stainless steel undergoes the correct heat treatment process to achieve the intended properties.

Understanding these heat treatment techniques and their specific applications allows manufacturers to tailor the properties of stainless steel to meet the requirements of various industrial applications. Each method offers unique advantages, making it essential to select the appropriate technique based on the desired outcome.

Annealing is the primary method used to reduce the hardness of stainless steel. Annealing involves heating stainless steel above its recrystallization point, typically above 1040°C for austenitic grades, to alter its microstructure, enhance ductility, and reduce internal stresses.

Ensure precise temperature control and slow cooling rates to avoid grain growth, unwanted phases, and the formation of hard phases like martensite.

Stress relieving is another method to reduce hardness, focusing on reducing residual stresses without fully softening the metal.

Cold working and machining increase hardness by strain hardening. To mitigate this:

| Method | Temperature Range | Effect on Hardness | Advantages | Limitations |

|---|---|---|---|---|

| Full Annealing | Above recrystallization (~1040°C+) | Significant softening | Maximum hardness reduction, stress relief | Time-consuming, may cause distortion |

| Partial/Recrystallization Annealing | Slightly lower than full annealing | Moderate softening | Less distortion, faster | Less effective on heavily hardened steel |

| Stress Relieving | Below critical temperature (~550-700°C) | Moderate stress relief, slight hardness reduction | Preserves dimensional stability | Does not fully soften steel |

| Mechanical Surface Removal | N/A | Removes hardened surface layer | Quick localized hardness reduction | Does not affect bulk hardness |

By implementing these controlled heat treatment processes, manufacturers and engineers can effectively reduce the hardness of stainless steel, improving its performance, machinability, and longevity in demanding applications.

Reducing stainless steel hardness improves its machinability, ductility, and overall workability. Techniques to achieve this can be broadly classified into mechanical methods and chemical (heat treatment) methods. Each technique has specific mechanisms and applications suited to different types of stainless steel and industrial requirements.

Annealing, the primary heat treatment for reducing stainless steel hardness, involves heating the steel above its recrystallization temperature (typically above 1040°C for austenitic stainless steels), soaking it at this temperature, and then cooling it slowly. This process dissolves hard phases, relieves internal stresses, and creates a softer, more ductile microstructure. Precise control of temperature, soaking time, and cooling rate is critical to avoid grain growth or residual hard phases, thereby achieving an optimal balance between hardness reduction and mechanical integrity.

Stress relieving heats stainless steel just below its critical temperature, reducing residual stresses from fabrication processes like machining and rolling without significantly altering hardness. This method is more practical for complex or large parts where full annealing is not feasible.

Tempering is used primarily to reduce brittleness and improve toughness after hardening but can also help modulate hardness by reducing stresses in martensitic stainless steels.

Cold working increases the hardness of stainless steel through strain hardening. To reduce this hardness, subsequent annealing or stress relieving is applied. Mechanical deformation alone doesn’t reduce hardness but prepares the microstructure for effective softening through heat treatment.

While carburizing and carbonitriding are typically used to increase surface hardness, mechanical polishing or grinding can remove hardened surface layers, reducing effective hardness locally. These methods are useful for managing surface hardness but do not change the bulk properties.

By integrating these chemical (heat treatment) and mechanical approaches, engineers can effectively tailor stainless steel hardness to meet specific application requirements, balancing hardness, ductility, and corrosion resistance.

Below are answers to some frequently asked questions:

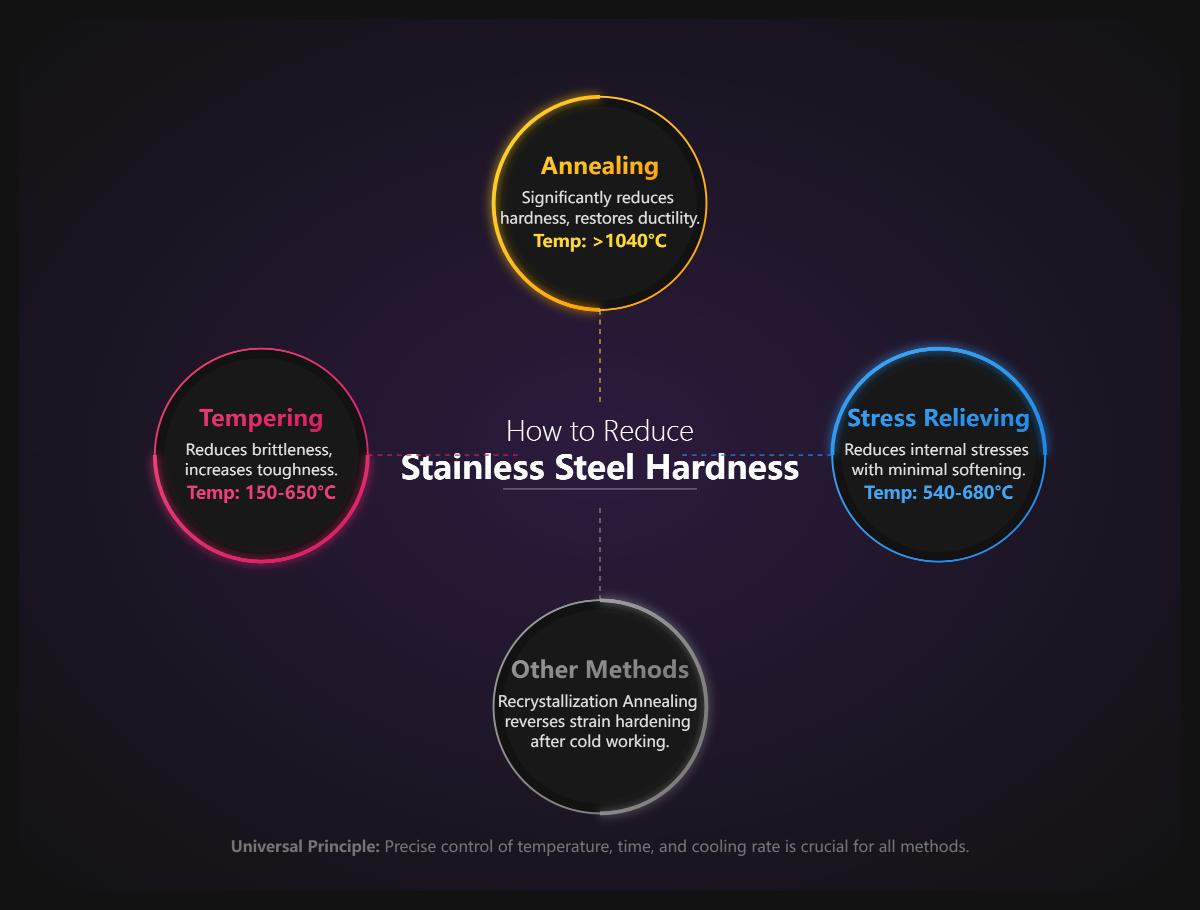

The most effective methods to reduce the hardness of stainless steel involve controlled heat treatment processes, primarily annealing, tempering, and stress relieving. Annealing is the primary method, which involves heating the stainless steel above its recrystallization temperature (typically above 1040°C for austenitic types), soaking it at this temperature, and then cooling it slowly. This process significantly reduces hardness by allowing the microstructure to reform without hard phases, thereby restoring ductility and improving workability.

Tempering, used after hardening, involves reheating the steel to a temperature below its critical point (150°C to 650°C) and then cooling it. This method reduces brittleness and moderately decreases hardness while increasing toughness.

Stress relieving involves heating the material to just below its critical transformation temperature (540°C to 680°C) and cooling it slowly. This process reduces residual stresses without significantly softening the steel.

Additionally, mechanical processes like recrystallization annealing after cold working can effectively reduce hardness by reversing strain hardening effects, restoring malleability. Each method must be precisely controlled in terms of temperature, soaking time, and cooling rate to achieve the desired hardness reduction without compromising the material’s integrity.

Annealing is a critical heat treatment process that significantly impacts the hardness and workability of stainless steel. During annealing, stainless steel is heated to a specific temperature (typically between 1,100°C and 1,150°C) and then cooled slowly. This process alters the material’s microstructure by relieving internal stresses and reducing dislocations within the crystal structure.

The primary effect of annealing on stainless steel is the reduction of hardness. By decreasing internal stresses and dislocations, the steel becomes more ductile and less brittle, enhancing its overall mechanical properties. This makes the material easier to shape, bend, and machine without cracking.

Moreover, annealing improves the plasticity and formability of stainless steel, making it more suitable for various forming operations such as rolling, bending, and drawing. The process also enhances dimensional stability, which is crucial for achieving precise dimensions in applications requiring high accuracy, like aerospace and medical equipment.

When performing heat treatment to reduce the hardness of stainless steel, several safety precautions are essential:

By adhering to these safety precautions, you can ensure a safe and effective heat treatment process while reducing the hardness of stainless steel.

Yes, there are alternative methods to heat treatment for reducing the hardness of stainless steel, although they are generally less effective for bulk hardness reduction compared to annealing. Mechanical processes like stress relieving through vibration can help reduce hardness to some extent, but this effect is limited. Shot peening and surface rolling can alter surface hardness and residual stresses, but they primarily affect the surface properties rather than the bulk material.

Chemical methods such as electrochemical polishing and chemical etching can reduce surface hardness by removing hardened layers. However, these techniques do not significantly impact the overall hardness of the material.

Cold processing techniques like stretching or bending might induce work softening under specific conditions, but this is rare and highly dependent on the material and processing parameters.

To ensure the quality of stainless steel after hardness reduction, follow a comprehensive approach that includes precise process control, thorough testing, and rigorous documentation.

By following these steps, you can ensure the stainless steel retains its essential properties and meets application-specific performance requirements.

Softened stainless steel, achieved through annealing or other heat treatment methods, is used in various applications that require enhanced formability and ductility. Common applications include deep drawing and punching processes, which are essential for manufacturing kitchen sinks, cookware, and automotive body panels. Softened stainless steel is also utilized in producing fasteners and hardware components like bolts, nuts, screws, and bushings, where ease of machining and forming is crucial. Additionally, it is employed in industrial parts such as pump and valve components, steam and gas turbine parts, and furnace elements due to its moderate corrosion resistance and ease of fabrication. Electromechanical devices, including fuel injectors and solenoids, benefit from the material’s balanced magnetic properties and workability after softening. Furthermore, medical and culinary equipment, such as surgical instruments and certain cookware, rely on softened stainless steel for precise forming and a good surface finish. These applications demonstrate the versatility of softened stainless steel in various industries.