Are you looking to restore an old metal piece to its former glory by removing unsightly brass plating? Whether it’s a cherished antique or a practical project, stripping brass plating can seem daunting for beginners. But fear not—this guide will walk you through the best methods for safely and effectively removing brass plating without damaging the underlying metal. From chemical strippers to mechanical techniques, you’ll learn the pros and cons of each method, step-by-step instructions, and essential safety precautions. Ready to uncover the beauty beneath the brass? Let’s dive in and explore the most effective ways to achieve a pristine finish.

Brass plating is a process that applies a thin layer of brass to a metal object. This coating provides a distinct golden appearance and can enhance the aesthetic appeal of the object. Brass plating is commonly used for decorative purposes but also offers certain functional benefits, such as corrosion resistance.

The brass plating process typically involves electroplating, a method that uses electrical current to deposit the brass layer onto the metal surface. Here is a simplified overview of the steps involved in electroplating:

Brass plating is used in many industries for both decorative and functional purposes, such as in jewelry and household fixtures. Some common applications include:

Brass plating gives items a shiny, golden appearance that greatly enhances their visual appeal. It provides a protective layer that can help prevent rust and corrosion, extending the lifespan of metal objects. Compared to solid brass items, brass-plated objects are generally more affordable while still offering similar benefits.

Chemical methods are commonly used to remove brass plating, particularly when the plating layer is thin. These methods involve using specific chemicals that react with the brass layer, dissolving it and allowing it to be removed.

Ammoniacal strippers are powerful chemicals used primarily in industrial settings. They can effectively remove brass plating, but they require careful handling due to their strong fumes and potential health hazards. Due to safety and environmental concerns, these strippers are generally not recommended for home use.

Potassium cyanide-based solutions are highly effective at removing brass plating, but they are extremely dangerous and toxic. These solutions are strictly regulated and should not be used outside of professional settings. Handling potassium cyanide is risky, making it impractical for most people.

For a safer, more accessible option, vinegar or mild acid solutions can be used to remove brass plating. Soaking the item in vinegar or a diluted acid solution gradually dissolves the brass layer. This method is more suitable for thinner platings and can be performed with common household items, making it a popular choice for DIY enthusiasts.

Mechanical methods for removing brass plating involve physically abrading or scraping off the brass layer. These techniques are generally safer than chemical methods but can be more labor-intensive.

Sanding, using sandpaper or a sanding wheel, gradually wears away the brass plating and requires patience and a careful technique to avoid damaging the underlying metal. Different grits of sandpaper can be used to control the rate of removal and the smoothness of the final surface.

Grinding is similar to sanding but uses a grinding tool to remove the brass plating more quickly. This method is effective but requires a steady hand and caution to prevent gouging the base metal. Grinding is best suited for larger, flat surfaces where even pressure can be maintained.

A powered wire brush can be used to remove brass plating, particularly in hard-to-reach areas or on intricate surfaces. This method is slower than grinding but offers more control, reducing the risk of damaging the underlying metal. This method is ideal for items with intricate patterns or small crevices.

Some alternative methods can also be considered for removing brass plating or achieving a similar result without complete removal.

Using oven cleaner is another technique to dissolve and remove the brass finish. This method requires applying the oven cleaner to the plated item and letting it sit for a specified period. Proper ventilation and protective gear are essential due to the harsh chemicals involved.

Sandblasting uses high-pressure abrasive particles to strip the brass plating from the metal surface. This method is efficient for thicker platings but requires specialized equipment and safety precautions. Sandblasting is typically performed by professionals or in well-equipped workshops.

Instead of removing the brass plating, applying a tin or zinc coating over the brass can achieve a similar appearance to galvanizing. This method eliminates the need for removal and can provide additional protection to the underlying metal.

Chemical strippers are substances designed to dissolve the brass plating on metal surfaces. They are particularly effective for reaching intricate areas and require less physical effort compared to mechanical methods.

Alkaline strippers use a combination of sodium hydroxide and complexing agents to break down the brass coating. These strippers are highly effective but must be handled with care to avoid damaging the underlying metal.

While potassium cyanide-based strippers are mainly used for gold, they can also effectively remove brass plating. Due to their extreme toxicity, these chemicals are highly regulated and should only be used with proper safety measures.

Household items such as oven cleaner and acetone can also be used to strip brass plating. Oven cleaner’s high alkalinity makes it effective, but it should be used carefully to avoid damaging the base metal.

Chemical stripping is an effective method for removing brass plating, offering precision and ease for intricate or delicate items. However, it is essential to handle these chemicals with care and follow safety guidelines to ensure a successful and safe process.

Mechanical removal techniques involve physically abrading or scraping off the brass plating from metal surfaces. These methods are typically safer than chemical methods and can be performed with commonly available tools. Below are some of the primary mechanical removal techniques.

Manual sanding is a simple and effective way to remove brass plating using abrasive materials like sandpaper.

Sandblasting uses high-speed abrasive particles to strip away brass plating.

Grinding uses rotary tools with abrasive wheels or discs to remove the brass plating.

Mechanical methods may leave scratches or require additional polishing to restore the base metal’s appearance.

Always wear protective gear and work in a well-ventilated area.

Clean the metal thoroughly and consider applying a protective coating to prevent corrosion, especially on steel or zinc substrates.

By understanding the advantages and disadvantages of both chemical and mechanical methods, you can make an informed decision that best suits your specific needs and resources.

To safely remove brass plating from metal, it’s crucial to set up your work environment properly.

Work in a well-ventilated area to disperse harmful chemical fumes and reduce respiratory risks. Adequate airflow helps disperse these fumes and reduces the risk of respiratory issues.

Use masking agents, plastic film, and tape to protect areas you don’t want stripped. This precaution prevents accidental damage and exposure to chemicals.

When using power tools for mechanical removal, ensure all electrical equipment is in good working condition. Keep electrical tools away from liquids and chemicals to avoid the risk of electrocution.

Wearing the right personal protective equipment (PPE) is essential for safety during the brass plating removal process.

Wear heavy-duty chemical-resistant gloves to protect your hands from corrosive chemicals and sharp debris during mechanical removal.

Safety goggles are necessary to shield your eyes from chemical splashes and dust particles. This protection is crucial to avoid serious eye injuries.

Use a dust mask or respirator, especially when sanding, grinding, or sandblasting. This equipment helps prevent the inhalation of metal dust and abrasive particles.

Wear an apron or suitable protective clothing to guard your skin and clothes against chemical splashes and metal particles. This precaution helps minimize skin contact with harmful substances.

Proper handling of chemicals is vital for safety and effectiveness.

Always read and follow the instructions and warnings on chemical products to ensure safe and correct use. Understanding the guidelines ensures correct and safe application.

Store chemicals in their original containers to maintain their integrity and keep them out of reach of children and pets to prevent accidental ingestion or exposure.

Never mix different chemicals unless explicitly stated safe by the manufacturer. Mixing can cause dangerous reactions and pose severe health risks.

Dispose of used chemicals responsibly according to local environmental regulations. Proper disposal prevents environmental contamination and keeps your work area safe.

Use containers made from neutral materials when mixing or submerging metal objects in chemical solutions. This precaution prevents unwanted reactions that could compromise safety and effectiveness.

Oven cleaners containing sodium hydroxide are effective for removing brass plating. Apply the cleaner carefully, leave it briefly on the surface, and rinse thoroughly to avoid damaging the base metal.

Hydrochloric acid and bleach are strong corrosive agents. Monitor exposure time closely to prevent damage to the underlying metal. Avoid skin or eye contact with these substances.

For metals plated with nickel underneath brass, specialized potassium cyanide-based strippers are recommended. Oven cleaner can damage nickel layers, so use appropriate chemicals for specific metal types.

Wear dust masks and goggles during sanding, grinding, or sandblasting to protect from airborne particles. This equipment helps maintain respiratory and eye health.

Perform sandblasting in a contained area to prevent abrasive spread and protect nearby objects. Containment ensures a safer and more efficient process.

Only use equipment designed for abrasive removal. Follow operational safety protocols to avoid injury and ensure effective brass plating removal.

After removing brass plating, thoroughly clean the metal to eliminate chemical residues and prevent corrosion or damage. Consider applying protective coatings or treatments to the exposed metal surface. These measures help prevent rust or tarnish and extend the lifespan of the metal object.

A common mistake in removing brass plating is not adequately preparing the surface. Thoroughly clean the metal with a mild detergent or solvent to remove dirt and grease, and ensure it is completely dry before starting the removal process.

Removing brass plating involves handling chemicals or using mechanical tools, which can pose safety risks if proper precautions are not taken. Always wear gloves, goggles, and a mask to protect yourself from chemicals and dust. Make sure to work in a well-ventilated area to avoid inhaling harmful fumes from chemical strippers.

Using the wrong chemicals or not following the instructions can lead to ineffective removal or damage to the metal. Use the recommended chemicals and follow the manufacturer’s instructions carefully to avoid damaging the metal.

Using mechanical methods incorrectly can damage the underlying metal, especially if tools are used with excessive force. Use sanding, either manual or power, to remove the brass plating. Be sure to apply even pressure to avoid scratching the underlying metal.

After removing the brass plating, failing to protect the exposed metal can lead to corrosion or oxidation. Apply a protective treatment or coating to prevent corrosion on the exposed metal.

Different metals require different removal methods, and using the wrong method can damage the underlying material. For nickel surfaces, use potassium cyanide-based strippers to avoid damage and avoid using oven cleaner.

Attempting to remove brass plating from complex items without sufficient experience can lead to poor results and potential damage. If unsure or dealing with intricate items, consider consulting a professional plating service for safe and effective removal.

Below are answers to some frequently asked questions:

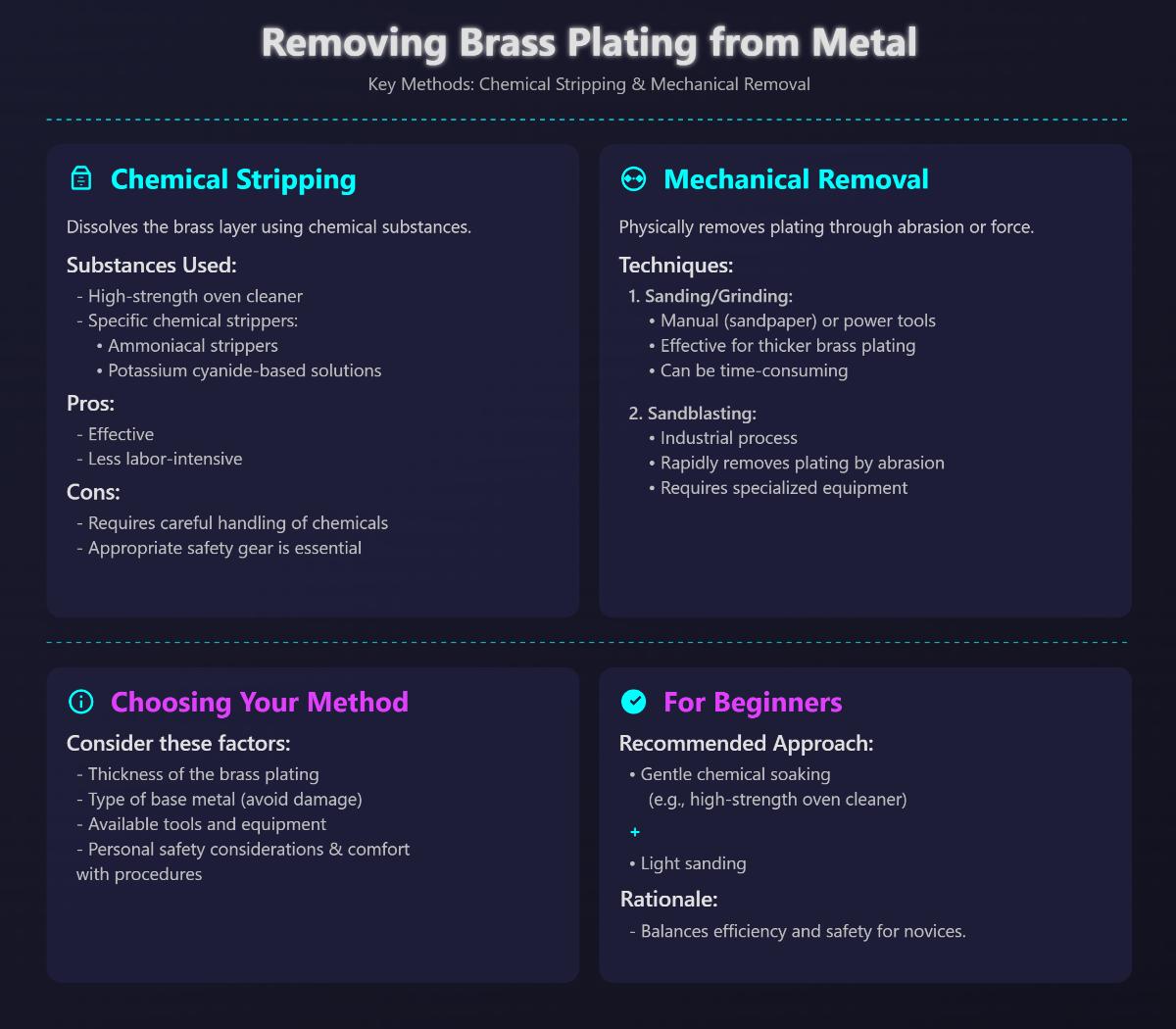

The best methods for removing brass plating from metal are chemical stripping and mechanical removal.

Chemical stripping involves using substances like high-strength oven cleaner or specific chemical strippers, such as ammoniacal strippers or potassium cyanide-based solutions, to dissolve the brass layer. This method can be effective and less labor-intensive but requires careful handling of chemicals and appropriate safety gear.

Mechanical removal includes techniques like sanding, grinding, or sandblasting. Sanding or grinding manually with sandpaper or using power tools can effectively remove thicker brass plating, though it can be time-consuming. Sandblasting, an industrial process, rapidly removes plating through abrasion but requires specialized equipment.

Choosing between these methods depends on factors like the thickness of the brass plating, the type of base metal, available tools, and personal safety considerations. For beginners, a combination of gentle chemical soaking (like using oven cleaner) and light sanding is often recommended for efficiency and safety.

To safely remove brass plating from metal without damaging the underlying surface, you can use either chemical or mechanical methods, depending on the metal type and thickness of the plating.

For chemical methods, citric or phosphoric acid solutions are gentle options that effectively dissolve brass without harming the base metal. Apply the solution with a brush, let it sit for a few minutes, and then scrub off the loosened brass with a non-abrasive pad. Oven cleaners can also be used, but ensure you have proper ventilation and protective gear, as they can be harsh.

Mechanical methods include manual sanding with fine to medium grit sandpaper, which offers precise control, or using electric sanding tools for faster results. Sandblasting is another option for larger or intricate items, but it requires careful execution to avoid damaging the base metal.

Always work in a well-ventilated area, wear protective gloves, goggles, and a respiratory mask, and follow all safety guidelines to ensure a safe and effective brass plating removal process.

Chemical methods for removing brass plating offer several advantages, including effective and selective removal without excessive physical effort. They provide uniform removal across the entire surface, even reaching hard-to-access areas. However, they come with significant disadvantages, such as the hazards associated with handling chemicals, potential damage to the base metal if used incorrectly, and the need for proper disposal of chemical waste to prevent environmental harm.

Mechanical methods, on the other hand, allow precise control over the removal process, making them suitable for targeting specific areas. Tools like sandpaper and sandblasters are widely accessible and avoid the risks associated with chemical exposure. However, these methods can be labor-intensive and time-consuming, with a higher risk of damaging the underlying metal if not handled carefully. Additionally, mechanical removal generates dust and debris, requiring cleanup and dust control measures.

When removing brass plating from metal, using the right protective gear is essential for safety. Here are the key items you should consider:

By using this protective gear, you can safely remove brass plating while minimizing health risks and accidents.

Yes, you can use household items to remove brass plating from metal. One common method involves using oven cleaner. Apply the oven cleaner to the brass-plated surface and let it sit for a while before rinsing it off. This method requires caution as oven cleaner can be harsh, so ensure proper ventilation and wear protective gloves. Another approach is sanding or scrubbing with sandpaper or a scrubber. Start with coarse grit sandpaper and gradually move to finer grits to remove the brass plating. Citric acid, found in lemon juice or as a powder, can also be used. Soak the brass-plated item in a citric acid solution to gently strip the plating. Always prioritize safety by working in a well-ventilated area and using protective gear.

The duration of the brass plating removal process can vary significantly depending on the method used. Chemical methods typically take from a few hours to up to 24 hours, depending on the thickness of the brass plating and the effectiveness of the chemical stripper. Some chemical strippers require objects to soak for a prolonged period, such as 16 hours, to effectively dissolve the brass layer. On the other hand, mechanical methods such as sanding or grinding can be quicker, often taking about 15-30 minutes for small, thinly plated items. Sandblasting may take longer due to the need for specialized equipment. Overall, the removal process duration ranges from 15 minutes to several hours, with chemical methods generally being more time-consuming. Safety precautions should always be followed, as discussed earlier in the article.