Chrome plating can give steel a shiny, durable finish, but sometimes, you need to remove it—whether it’s for restoration, repair, or simply a change in appearance. If you’re new to this process, don’t worry; we’ve got you covered. This comprehensive guide will walk you through the safest and most effective methods to strip chrome plating from steel, ensuring you understand each step clearly. From chemical stripping using common substances like sodium hydroxide and hydrochloric acid to mechanical methods such as grinding and sanding, we’ll explore all your options. Plus, we’ll discuss how to handle and dispose of chemicals responsibly. Ready to dive in and reclaim that steel? Let’s get started!

Introduction to Chrome Plating and Its Removal

Definition and Purpose of Chrome Plating

Chrome plating is an electrochemical process where a thin layer of chromium is deposited onto a metal surface. This process not only improves the metal’s appearance but also its functionality. The process includes cleaning, pretreatment, and immersing the metal in a chromic acid solution to deposit chromium ions onto it.

Why and When You Might Need to Remove Chrome Plating

There are several scenarios where removing chrome plating is necessary. Over time, chrome plating can deteriorate, compromising its qualities, and removing the old plating is crucial for repair or refurbishment. In some cases, you might also want to remove chrome plating to apply a different finish or to prepare the metal for welding or other fabrication processes.

Overview of Steel as a Substrate for Chrome Plating

Steel is commonly used for chrome plating because it is strong, durable, and widely used in many industries. Chrome plating on steel can significantly enhance its resistance to wear and corrosion, making it ideal for applications in machinery, automotive parts, and industrial equipment. However, removing chrome plating from steel requires careful method and material selection to avoid damaging the metal.

Methods for Removing Chrome Plating

Abrasive Blasting (Sandblasting)

Abrasive blasting, often called sandblasting, uses high-pressure air to propel abrasive particles against a chrome-plated surface, effectively stripping away the chrome layer. Abrasive blasting is effective for large surfaces and provides excellent preparation for re-plating. However, it requires protective gear and care to avoid damaging the base metal.

Ultrasonic Cleaning

Ultrasonic cleaning uses high-frequency sound waves to create bubbles in a cleaning solution, which help lift and remove chrome plating. This method is gentle on delicate items and suitable for small objects but is limited by the size of the ultrasonic cleaner and may not be cost-effective for one-time use.

Chemical Methods

Chemical methods, like using hydrochloric acid or sodium hydroxide, can dissolve chrome plating. Hydrochloric acid is highly corrosive and requires careful handling, while sodium hydroxide is less corrosive but still effective. Sulfuric acid is another option, preferred for sensitive base metals.

Manual Methods

Manual methods involve physically removing the chrome plating through abrasion. Sanding or grinding uses abrasive paper or grinding tools to manually remove chrome plating, providing precise control and suitability for small areas or detailed work. A baking soda paste, made by mixing baking soda and water, can be used to scrub away thin chrome plating, making it suitable for delicate items or thin chrome layers.

Reverse Electroplating

Reverse electroplating, which reverses the electroplating process to remove chrome, is complex and typically requires professional expertise due to hazardous chemicals involved.

Safety Considerations

Always use protective gear when handling chemicals or performing mechanical removal methods. Ensure proper ventilation and follow safety guidelines for chemical use to avoid damage to the base metal.

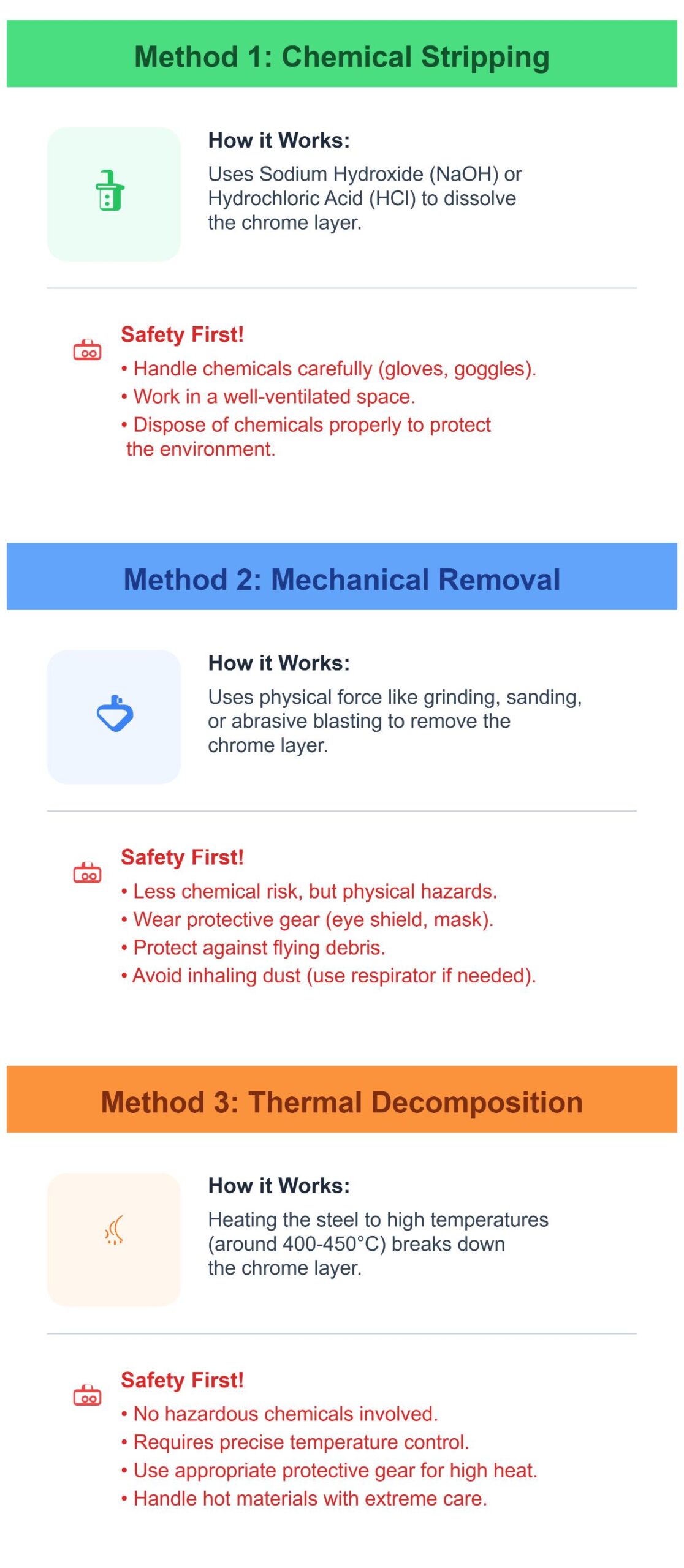

Chemical Stripping Method for Chrome Removal

Chemical stripping uses specific chemicals to remove chrome plating from steel substrates. Two common chemicals used for this purpose are sodium hydroxide (NaOH) and hydrochloric acid (HCl). Sodium hydroxide, also known as lye or caustic soda, is a strong alkaline compound that breaks down the bond between the chrome layer and the steel substrate. It is less corrosive to steel compared to acids. Hydrochloric acid, a strong acid, dissolves chrome plating quickly and is highly effective, though it requires careful handling due to its corrosive nature.

Step-by-Step Guide for Chemical Stripping

Step 1: Prepare Your Workspace and Gather Safety Equipment

- Workspace Preparation: Ensure your workspace is well-ventilated and free from flammable materials. Set up in an area where spills can be easily contained and cleaned.

- Safety Equipment: Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and a lab coat. If working with hydrochloric acid, use a face shield and acid-resistant apron.

Step 2: Mix the Chemical Solution

- For Sodium Hydroxide:

- Mix 50 grams of sodium hydroxide with 1 liter of water to create a 5% solution.

- Always add NaOH to water to prevent exothermic reactions.

- For Hydrochloric Acid:

- Dilute hydrochloric acid with water to achieve a 30-40% concentration.

- Add acid to water slowly to avoid splashing and heat generation.

Step 3: Apply the Solution to the Chrome-Plated Steel

- Submersion Method: Submerge small items completely in the chemical solution, ensuring the entire chrome-plated surface is in contact.

- Brush-On Method: For larger items, use a brush to apply the solution evenly over the chrome-plated surface.

Step 4: Wait for the Chemical Reaction to Occur

- Allow the solution to react with the chrome plating, which may take a few minutes. Bubbling and color change indicate the chemical is working. Avoid prolonged exposure to prevent damage to the steel substrate.

Step 5: Rinse and Neutralize the Steel Surface

- Rinsing: Once the chrome plating is removed, rinse the steel thoroughly with cold water to remove any residual chemicals.

- Neutralizing: Apply a mild acidic solution (e.g., diluted vinegar) if sodium hydroxide was used, or a mild alkaline solution (e.g., baking soda solution) if hydrochloric acid was used. Rinse again with water.

Step 6: Dispose of the Chemicals Safely

- Dispose of used chemicals following local regulations for hazardous waste. Clean your workspace and tools thoroughly, ensuring all chemical residues are neutralized and safely discarded.

Safety Precautions

- Handling Chemicals: Always handle chemicals with care, following the manufacturer’s safety instructions. Work in a well-ventilated area and avoid inhaling fumes.

- Protective Gear: Wear appropriate PPE to protect your skin and eyes from chemical splashes. Use gloves that are resistant to the chemicals you are handling.

- Emergency Procedures: Have an emergency wash station nearby. In case of contact with skin or eyes, rinse immediately with plenty of water and seek medical attention if necessary.

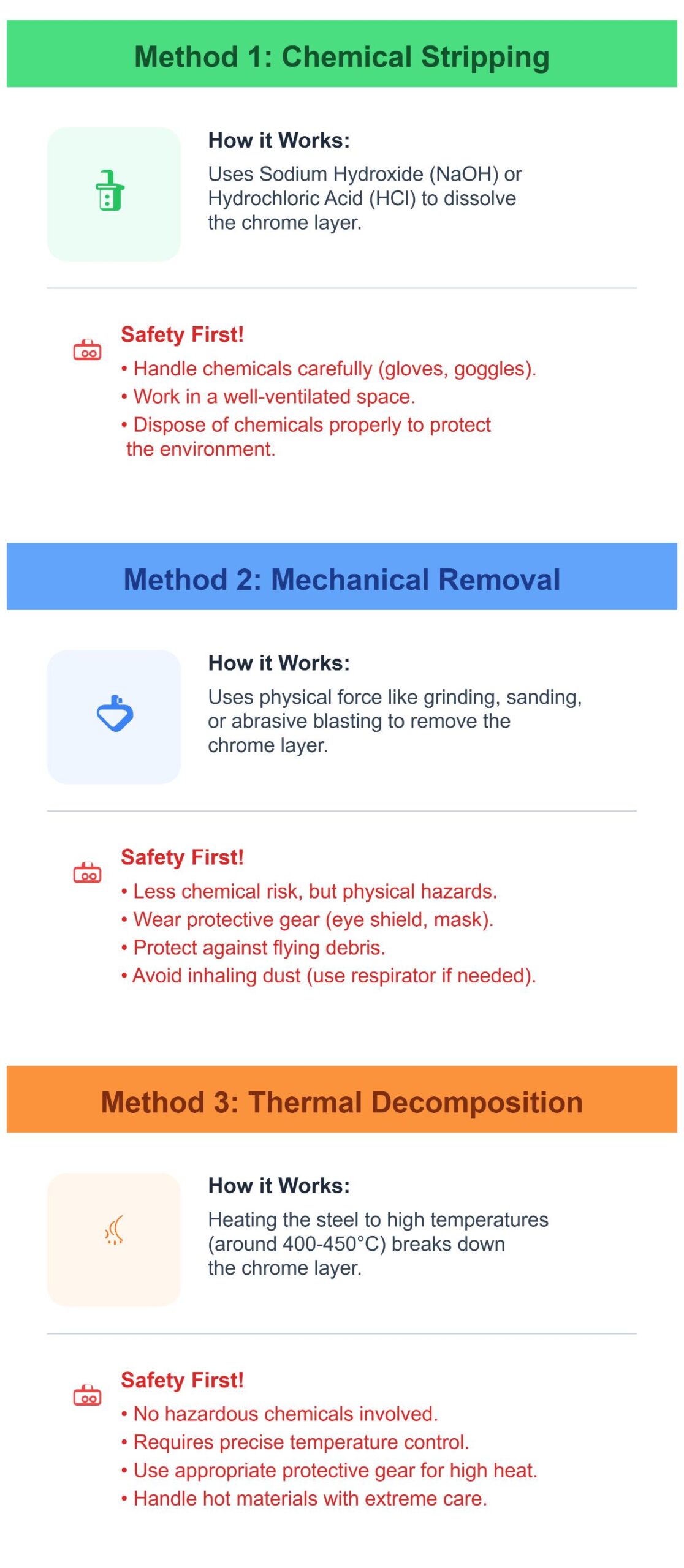

Mechanical Removal Method for Chrome Removal

Mechanical Removal Method for Chrome Removal

Mechanical removal is a simple and effective method for removing chrome plating from steel. This approach uses physical tools and abrasive materials to wear away the chrome layer. Below are the common techniques used in mechanical removal, along with a step-by-step guide to ensure safe and effective chrome removal.

Abrasive Blasting (Sandblasting)

Abrasive blasting is a powerful method that uses high-pressure air to propel abrasive particles against the chrome-plated surface.

- Prepare Your Workspace and Set Up Equipment:

- Ensure your workspace is well-ventilated and free from flammable materials.

- Wear protective gear such as a mask, gloves, and safety goggles.

- Choose an abrasive material like sand, aluminum oxide, or garnet, and load it into the blasting machine.

- Remove the Chrome Plating:

- Direct the high-pressure air and abrasive mixture at the chrome-plated surface.

- Move the nozzle in a consistent pattern to evenly strip away the chrome layer.

- Inspect and Clean the Steel Surface:

- Check the steel surface to ensure all chrome plating has been removed.

- Clean the surface to remove any remaining abrasive particles.

- Dispose of Debris Safely:

- Collect and dispose of used abrasive materials according to local regulations to prevent environmental contamination.

Mechanical Polishing

Mechanical polishing involves using sandpaper, grinders, or polishers to manually wear away the chrome layer.

- Prepare Your Workspace and Gather Safety Equipment:

- Ensure your workspace is well-lit and free from obstructions.

- Wear gloves and safety goggles to protect your hands and eyes from sharp edges and abrasive particles.

- Select the Appropriate Tools:

- Choose coarse grit sandpaper (e.g., 80-grit) for initial removal, and finer grits (e.g., 150-grit) for smoothing the surface.

- Alternatively, use a handheld grinder or polisher with appropriate abrasive attachments.

- Remove the Chrome Plating:

- Begin with coarse grit sandpaper to strip most of the chrome.

- Apply steady pressure and work evenly.

- Use finer grits to smooth the surface and remove any leftover chrome.

- Inspect and Clean the Steel Surface:

- Examine the steel surface for any remaining chrome.

- Wipe the surface clean with a cloth to remove dust and debris.

- Dispose of Used Materials Safely:

- Collect and dispose of used sandpaper, grinding discs, and debris according to local regulations.

Grinding

Grinding is a precise method for removing chrome plating, especially suitable for small or intricate areas.

- Prepare Your Workspace and Gather Safety Equipment:

- Set up in a well-ventilated area with good lighting.

- Wear appropriate protective gear, including gloves, safety goggles, and a dust mask.

- Select the Appropriate Grinding Tool:

- Use a handheld grinder with a suitable abrasive attachment for the specific area you are working on.

- Remove the Chrome Plating:

- Gently grind away the chrome layer, working on small sections at a time.

- Use controlled pressure to prevent damaging the steel underneath.

- Inspect and Clean the Steel Surface:

- Check the surface to ensure all chrome has been removed.

- Clean the area thoroughly to remove any grinding residue.

- Dispose of Debris Safely:

- Collect and dispose of grinding debris in compliance with local environmental regulations.

Key Considerations for Mechanical Removal

- Material Sensitivity: Handle non-ferrous metals like aluminum with care, as they are more easily damaged.

- Safety Equipment: Always use protective gear to prevent injuries from abrasive particles and sharp edges.

- Environmental Concerns: Ensure proper disposal of abrasive materials and dust to avoid environmental contamination.

Thermal Decomposition as an Alternative Removal Method

Introduction to Thermal Decomposition

Thermal decomposition is a technique used to remove chrome plating from metal surfaces by applying high temperatures. This method is particularly effective for heat-resistant metals and is commonly utilized in industries where maintaining the mechanical properties of the metal is crucial, such as aerospace.

Key Points of Thermal Decomposition

Temperature Range

This process usually requires heating the chrome-plated metal to temperatures between 400°C and 450°C. Within this range, the chrome plating breaks down and can be easily removed from the surface without damaging the underlying metal.

Advantages of Thermal Decomposition

- Minimal Damage: This method preserves the mechanical characteristics of the metal, making it ideal for sensitive materials.

- Effective for Thick Layers: Suitable for removing thick chrome layers, which can be challenging with other methods.

- No Chemicals Required: Avoids the use of corrosive chemicals, reducing environmental and health risks.

Equipment Needed

- Industrial Ovens or Heat Guns: These tools are commonly used to apply the necessary heat.

- Temperature Control Systems: Essential for maintaining the correct temperature to prevent damage to the substrate.

Step-by-Step Guide for Thermal Decomposition

Step 1: Prepare Your Workspace and Gather Equipment

- Workspace Preparation: Ensure your workspace is well-ventilated and free from flammable materials.

- Safety Equipment: Wear appropriate personal protective equipment (PPE) such as heat-resistant gloves, safety goggles, and a face shield.

Step 2: Preheat the Equipment

Preheat the industrial oven or set the heat gun to the required temperature range of 400°C to 450°C.

Step 3: Apply Heat to the Chrome-Plated Surface

- Using an Industrial Oven: Place the chrome-plated item in the oven and allow it to heat until the chrome layer begins to break down.

- Using a Heat Gun: Direct the heat gun at the chrome-plated surface, moving it evenly across the area to ensure consistent heating.

Step 4: Monitor the Decomposition Process

- Visual Inspection: Watch for changes in the chrome layer, such as discoloration or peeling, indicating that the decomposition process is occurring.

- Temperature and Time Control: Monitor the temperature and exposure time closely to prevent damage to the base metal.

Step 5: Remove the Chrome Residue

- Mechanical Assistance: Use a brush or scraper to remove the decomposed chrome layer from the metal surface.

- Rinse and Clean: After removing the chrome residue, rinse the metal thoroughly with water to remove any remaining particles.

Considerations for Thermal Decomposition

- Temperature and Time Control: Precise control is essential to prevent damage to the substrate.

- Material Compatibility: First, test a small area to ensure the method is suitable for the base material.

Comparison with Other Methods

- Chemical Stripping: Uses acids or alkaline solutions, which can be corrosive and require careful handling. Effective but may damage sensitive substrates if not managed correctly.

- Mechanical Methods: Techniques like grinding or abrasive blasting provide precision but can be time-consuming and may damage the surface if not done carefully.

- Ultrasonic Cleaning: A gentle, non-toxic method ideal for small, delicate items but can be expensive for large-scale use.

Thermal decomposition is a valuable alternative for preserving heat-resistant metals while effectively removing chrome plating, especially in specific industrial applications.

Safety Considerations and Precautions

Work Environment Safety

Creating a safe work environment is essential when removing chrome plating from steel. Here are some key considerations:

- Ventilation: Ensure the workspace is well-ventilated to prevent the buildup of hazardous fumes from chemicals or dust from mechanical methods. This can be achieved by using exhaust fans or working in an open area.

- Flammable Materials: Keep the workspace free of flammable materials to minimize the risk of fires. Store all chemicals away from heat sources and open flames.

- Emergency Plan: Have an emergency plan in place, including first aid kits, fire extinguishers, and a clear evacuation route. Ensure all personnel are familiar with emergency procedures.

Protective Gear

Wearing appropriate protective gear is essential to safeguard against potential hazards:

- Gloves and Goggles: Wear chemical-resistant gloves and safety goggles to shield your hands and eyes from harmful chemicals and debris.

- Respirator and Protective Clothing: Wear a respirator to protect your respiratory system and long sleeves and durable pants to safeguard your skin from chemical exposure and abrasives.

- Clothing: Consider using an apron or lab coat for additional protection.

Chemical Safety

Handling chemicals requires careful attention to safety protocols:

- Handling Chemicals: Always handle chemicals in a well-ventilated area and avoid direct skin contact.

- Acid and Alkali Use: Dilute hydrochloric acid or sodium hydroxide properly and follow safety guidelines to avoid burns and respiratory problems.

- Waste Disposal: Dispose of chemical waste according to local regulations to avoid environmental contamination. Use designated containers for hazardous waste and label them clearly.

Mechanical Method Safety

Mechanical methods for removing chrome plating also come with specific safety considerations:

- Abrasive Blasting: Wear protective gear, including a mask and goggles, to avoid inhaling particles. Use appropriate abrasive materials to prevent excessive wear on the steel.

- Grinding: Ensure grinding machines are in good condition and use appropriate safety gear to prevent injury from debris. Secure the workpiece firmly before grinding to avoid accidents.

Electrolytic Methods

Safety precautions for electrolytic methods include:

- Electrical Safety: Avoid electrical shocks by ensuring all equipment is properly grounded and insulated. Follow proper setup and operation guidelines for reverse electrolysis to prevent accidents.

Post-Removal Care

After removing chrome plating, proper care of the steel is necessary:

- Rinsing and Drying: Thoroughly rinse the item with water to remove any residual chemicals and dry it completely to prevent corrosion.

- Protective Coatings: Apply protective coatings or paints to the steel surface to protect it from corrosion after the chrome plating has been removed.

Cost Analysis and Environmental Impact

Cost Analysis

When choosing a method to remove chrome plating from steel, it’s crucial to consider the costs involved. These costs can vary depending on the materials, equipment, and labor required.

Materials and Equipment Costs

- Abrasive Blasting: Requires abrasive materials like aluminum oxide or sand and an abrasive blaster. These materials are relatively inexpensive; however, additional equipment may be needed to smooth the surface afterward.

- Chemical Stripping: Uses chemicals such as hydrochloric acid or sodium hydroxide. The cost of these chemicals can be high, especially if large quantities are needed. Additional equipment, such as containers for mixing and applying the solution, may also be required.

- Electrochemical Stripping: Involves specialized equipment like a DC power supply and an electrolyte solution. The initial investment in equipment can be substantial, but the process is precise and efficient.

- Thermal Decomposition: Requires industrial ovens or heat guns, which can be costly to purchase and operate. The energy consumption for maintaining high temperatures adds to the

Labor Costs

- Abrasive Blasting: This method can be particularly labor-intensive for large or complex surfaces. Skilled labor is needed to operate the equipment and ensure even removal of the chrome layer.

- Chemical Stripping: Generally requires less manual labor, as the chemical reaction does the work. However, proper handling and disposal of chemicals require skilled personnel.

- Electrochemical Stripping: This process can be more automated, reducing labor costs. However, setting up the equipment and monitoring the process requires technical expertise.

- Thermal Decomposition: The labor cost is relatively low once the equipment is set up, but constant monitoring is necessary to prevent damage to the base metal.

Environmental Costs

- Abrasive Blasting: Generates hazardous dust that must be properly ventilated and disposed of to prevent environmental contamination. This adds to the cost of waste management.

- Chemical Stripping: Involves toxic chemicals that need careful handling and disposal. Following environmental regulations can raise disposal and cleanup costs.

- Electrochemical Stripping: Generally safer for the environment but still requires proper disposal of electrolyte solutions. The environmental cost is lower compared to chemical stripping.

- Thermal Decomposition: Consumes significant energy, contributing to greenhouse gas emissions. However, it minimizes chemical waste, which can be beneficial for the environment.

Environmental Impact

The environmental impact of chrome plating removal methods is an important consideration, especially with increasing regulations on hazardous waste and emissions.

Abrasive Blasting

- Dust Generation: Produces dust that can be harmful if inhaled and must be controlled with proper ventilation systems.

- Waste Disposal: The abrasive materials and removed chrome must be disposed of according to environmental regulations to prevent contamination.

Chemical Stripping

- Toxic Chemicals: The use of hydrochloric acid and sodium hydroxide poses risks to both human health and the environment. Proper handling, storage, and disposal are essential to mitigate these risks.

- Water Pollution: Rinsing the chemicals off the steel can lead to water contamination if not managed correctly.

Electrochemical Stripping

- Electrolyte Disposal: The electrolyte solutions used in this method need to be disposed of properly to avoid environmental damage. This method is generally considered safer but still requires careful waste management.

Thermal Decomposition

- Energy Consumption: The high energy consumption contributes to carbon emissions, affecting the environment. However, this method reduces the need for hazardous chemicals, which can be an advantage.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the safest methods to remove chrome plating from steel?

The safest methods to remove chrome plating from steel include chemical stripping, mechanical removal, and thermal decomposition.

- Chemical Stripping: This involves using solutions like sodium hydroxide or hydrochloric acid. Sodium hydroxide is effective but must be handled with care to avoid skin and eye contact. Hydrochloric acid is highly corrosive and requires protective gloves and goggles. Both chemicals should be used in well-ventilated areas, and proper disposal is crucial to avoid environmental harm.

- Mechanical Removal: This method includes grinding, sanding, or abrasive blasting. These techniques physically remove the chrome layer and are safer in terms of chemical exposure but require protective gear to prevent injury from flying debris and dust inhalation.

- Thermal Decomposition: This method involves heating the steel to high temperatures (around 400-450°C) to break down the chrome layer. It is safer in terms of chemical use but requires precise temperature control and appropriate protective equipment to handle high heat.

Each method should be chosen based on the specific requirements of the job and the safety measures available. Always prioritize safety equipment and follow proper procedures to minimize risks.

How do I handle and dispose of chemicals used in chrome removal?

When handling and disposing of chemicals used in chrome removal, it’s essential to follow safety guidelines to protect both health and the environment. First, always wear personal protective equipment (PPE) such as gloves, goggles, and masks to prevent exposure to harmful substances like sodium hydroxide or hydrochloric acid. Ensure your workspace is well-ventilated to avoid inhaling fumes.

For disposal, chemicals must be treated as hazardous waste. Do not pour them down drains or dispose of them with regular trash. Instead, neutralize the chemicals if possible (e.g., neutralizing acids with a base), and then store them in clearly labeled, appropriate containers. Contact a certified hazardous waste disposal service to handle the final disposal, ensuring compliance with local environmental regulations. Always keep a record of the disposal process to maintain transparency and adherence to legal requirements.

What are the most effective chemicals for removing chrome plating?

The most effective chemicals for removing chrome plating from steel include hydrochloric acid and sodium hydroxide. Hydrochloric acid, also known as muriatic acid, is highly effective due to its strong corrosive properties, which allow it to dissolve chrome plating efficiently. Typically, a concentration of 30–40% is used for this purpose. Sodium hydroxide, also known as lye or caustic soda, is another strong chemical that can dissolve chrome plating. It is a potent base and should be handled with care due to its caustic nature. Both chemicals require careful handling, including the use of protective gear and working in well-ventilated areas, to ensure safety. These chemicals are preferred for their precision and ability to remove chrome plating without damaging the underlying steel.

How can I ensure I am following safety protocols during chrome removal?

To ensure you are following safety protocols during chrome removal, start by using personal protective equipment (PPE) such as acid-resistant gloves, safety goggles, and a respirator to protect against harmful chemicals and fumes. Work in a well-ventilated area to avoid inhaling toxic vapors. Keep a fire extinguisher nearby and avoid working near flammable materials.

When handling chemicals like sodium hydroxide or hydrochloric acid, follow the recommended mixing ratios and procedures to prevent excessive corrosion. Store chemicals safely and dispose of waste according to local regulations to minimize environmental impact.

Prepare an emergency plan to address spills or accidents promptly. Continuously monitor the chrome removal process to prevent over-corrosion or damage to the steel. After removal, neutralize and thoroughly rinse the steel surface, then apply a protective coating to prevent rusting. Following these steps ensures a safe and effective chrome removal process.

What are the cost implications of different chrome removal methods?

The cost implications of removing chrome plating from steel depend on the method chosen. Mechanical methods, such as grinding or abrasive blasting, are generally cost-effective but labor-intensive, requiring manual effort and specialized equipment. Chemical methods, like using hydrochloric acid or sodium hydroxide, can be efficient but involve costs for chemicals and safety gear, along with the need for proper handling and disposal. These methods also vary in cost based on the specific chemicals used, with hydrochloric acid being more expensive than sodium hydroxide.

Electrochemical methods, such as reverse electroplating, are precise but expensive due to the need for specialized equipment and higher safety risks. Thermal decomposition is another option, effective for thick chrome layers but costly because it requires industrial ovens. Each method’s cost is influenced by factors like the thickness of the chrome layer, the complexity of the part, and the need for safety precautions. Generally, mechanical methods are more affordable but labor-intensive, while chemical and electrochemical methods balance efficiency with higher costs and safety considerations.

How do different chrome removal methods impact the environment?

Different chrome removal methods impact the environment in various ways. Chemical stripping, involving substances like sodium hydroxide and hydrochloric acid, can produce hazardous waste that requires careful handling and disposal to prevent environmental contamination. Mechanical methods such as grinding, sanding, and abrasive blasting generate physical waste and dust, which are less harmful than chemicals but still need proper management to avoid air and soil pollution.

Thermal decomposition, which uses high temperatures to break down chrome plating, can emit harmful gases and requires effective ventilation and emission controls to minimize air pollution. Each method has its environmental trade-offs, with chemical methods being more harmful due to hazardous waste, while mechanical and thermal methods pose less chemical risk but still require responsible waste and emission management.