Have you ever looked at a gold-plated stainless steel item and wondered how to restore it to its original luster? Whether you’re dealing with worn-out plating or simply prefer the sleek look of stainless steel, knowing how to safely and effectively remove gold plating can be a valuable skill. In this comprehensive guide, we’ll walk you through the safest methods for removing gold plating, comparing chemical and mechanical techniques to help you make an informed decision. From essential safety precautions to step-by-step instructions, you’ll gain the confidence to tackle this task with precision and care. Ready to transform your gold-plated items back to their stainless steel glory? Let’s dive in.

Introduction to Gold Plating

Definition of Gold Plating

Gold plating involves depositing a thin layer of gold onto the surface of another metal. This technique enhances both the appearance and durability of items such as jewelry, electronics, and decorative pieces by providing a luxurious look and excellent resistance to corrosion and tarnishing.

Common Applications and Uses

Gold plating is used in several industries, including:

- Jewelry Making: It adds an elegant finish to jewelry pieces, making them more attractive and valuable.

- Electronics: Gold’s excellent conductivity makes it ideal for plating electrical connectors and components to improve performance and prevent oxidation.

- Watches: Many high-end watches feature gold-plated cases and bands for aesthetic appeal and durability.

- Decorative Items: Gold plating is used on various decorative objects, such as picture frames and statues, to enhance their visual appeal.

Importance of Removing Gold Plating

Despite its benefits, there are times when gold plating needs to be removed. This might be necessary for restoration, repurposing the base metal, or customizing an item’s appearance. Knowing how to remove gold plating properly is essential for anyone involved in jewelry repair, metalworking, or DIY projects.

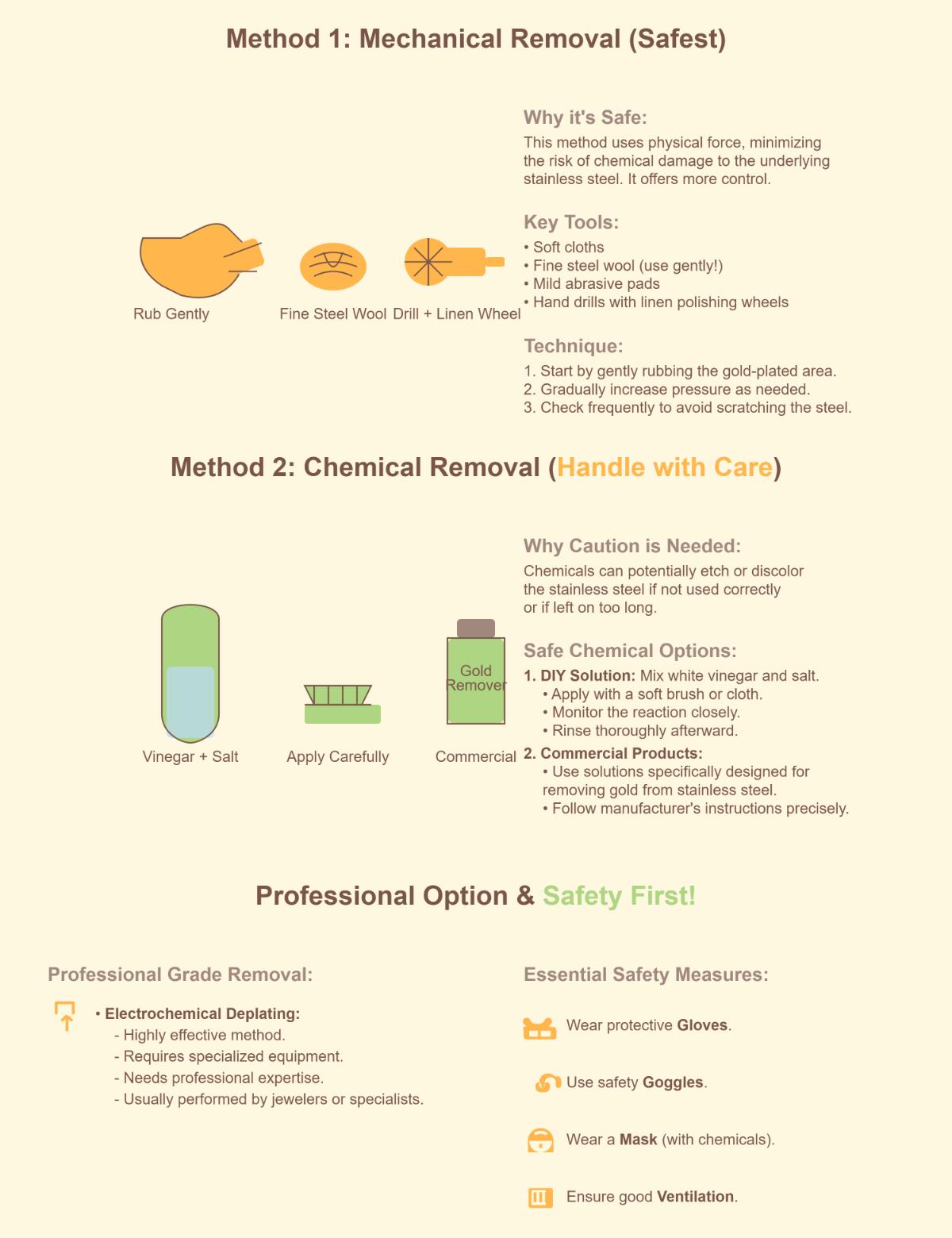

Safety Precautions for Chemical Removal

Chemical removal uses specific agents to dissolve or strip away gold plating from stainless steel surfaces. This method can be efficient but requires careful adherence to safety protocols to avoid damage to the base material and ensure personal safety.

Essential Protective Gear

When handling chemicals for removing gold plating, it is crucial to wear appropriate protective gear to minimize the risk of exposure and injury. The essential protective gear includes:

- Gloves: Use chemical-resistant gloves to protect your hands from corrosive substances.

- Goggles: Wear safety goggles to shield your eyes from splashes and fumes.

- Mask: A respirator mask is necessary to prevent inhalation of harmful vapors.

- Apron: A chemical-resistant apron can protect your clothing and skin from spills.

Safety Protocols and Regulations

Adhering to safety protocols and regulations is vital when performing chemical removal of gold plating. Key protocols include:

- Working in a Ventilated Area: Ensure your workspace is well-ventilated to disperse harmful fumes and reduce inhalation risks.

- Proper Labeling: Clearly label all chemical containers to prevent accidental misuse.

- Emergency Procedures: Have an emergency plan in place, including access to an eyewash station and safety shower in case of accidental exposure.

- Regulatory Compliance: Follow local and national regulations regarding the use and disposal of chemicals to ensure compliance and safety.

Handling and Disposal of Chemicals

Proper handling and disposal of chemicals are critical to prevent environmental contamination and health hazards. Follow these guidelines:

- Chemical Selection: Choose less hazardous chemicals, such as a mixture of white vinegar and salt, instead of highly toxic substances like sodium cyanide or sulfuric acid.

- Storage: Store chemicals in secure, labeled containers away from incompatible substances.

- Disposal: Dispose of chemical waste according to local regulations. Never pour chemicals down the drain. Use designated disposal sites or services.

- Spill Management: Have a spill kit on hand to manage accidental spills. This should include absorbent materials, neutralizing agents, and protective gear.

Preparation and Workspace Setup

Before beginning the chemical removal process, proper preparation and workspace setup are essential:

- Inspect the Item for Sensitive Components: Examine the stainless steel item to identify any sensitive components that may require extra protection during the process.

- Clean Workspace: Ensure your workspace is clean and free from clutter to reduce the risk of contamination and accidents.

- Safety Equipment: Set up all necessary safety equipment, including gloves, goggles, masks, and an emergency spill kit.

- Neutralizing Agents: Have neutralizing agents, such as baking soda or a neutralizing solution, ready to counteract any chemical spills.

Example Chemical Removal Method

Here’s a safer alternative for chemical removal using a mild acid solution of white vinegar and salt:

- Preparation: Ensure the workspace is well-ventilated and have all safety gear on hand.

- Application: Mix white vinegar and salt to create a mild acid solution. Apply the solution to the gold-plated area using a soft brush or cloth.

- Monitoring: Observe the reaction, allowing the gold plating to dissolve or peel off. This process may take some time, so be patient.

- Rinsing: Once the gold plating is removed, rinse the item thoroughly with lukewarm water to remove any residual chemicals.

- Drying: Dry the item completely to prevent tarnishing or corrosion.

By following these safety precautions and guidelines, you can effectively and safely remove gold plating from stainless steel using chemical methods.

Step-by-Step Chemical Removal Process

Preparation

Gather Materials

Before beginning the chemical removal process, ensure you have all the necessary materials and tools at hand. This includes:

- Protective Gear: Gloves and safety glasses to protect your hands and eyes from chemicals.

- Cleaning Supplies: Mild detergent and soft cloths for initial cleaning.

- Chemical Solutions:

- DIY Solution: Mix equal parts of white vinegar and salt, adding a few drops of acetone if needed for light gold layers.

- Commercial Products: Consider specialized gold removal solutions available in the market for more effective results.

Clean the Item

Thoroughly clean the stainless steel item to remove any dirt, grease, or contaminants. Use a mild detergent and a soft cloth to ensure the surface is clean, which helps the chemical solution to effectively reach the gold plating.

Application of the Chemical Solution

Apply the Solution

Use a soft sponge or brush to evenly apply the chemical solution over the gold-plated area. Be gentle to avoid scratching the underlying stainless steel surface.

Monitor the Reaction

Watch for signs like bubbling or discoloration to see if the gold plating is dissolving. This process may take several minutes, so patience is key.

Reapply as Necessary

If the gold plating remains, reapply the solution in small amounts, as thicker layers may require multiple applications.

Rinse and Clean the Item

Remove Residue

Once the gold plating has begun to lift, gently wipe away loosened particles and any chemical residues using a soft, damp cloth. Ensure all residues are removed to avoid potential damage.

Rinse with Water

Rinse the item with lukewarm water, focusing on grooves or hard-to-reach areas to ensure all chemicals are washed away.

Drying and Finishing

Dry the Item

Thoroughly dry the stainless steel item with a lint-free cloth to avoid water spots. Ensure the item is completely dry to prevent any risk of tarnishing or corrosion.

Polishing

To restore shine, apply a stainless steel polish like ‘Brasso’ or ‘Weiman’ with a soft cloth, using small, circular motions.

Final Inspection

Check for Remaining Gold

Inspect the item to ensure that all gold plating has been removed. If any gold remains, repeat the chemical application process on those specific areas.

Safety Considerations

- Always work in a well-ventilated area to avoid inhaling harmful fumes.

- Dispose of any chemical waste according to local regulations to mitigate environmental impact.

- If unsure about handling chemicals, consider consulting a professional for assistance.

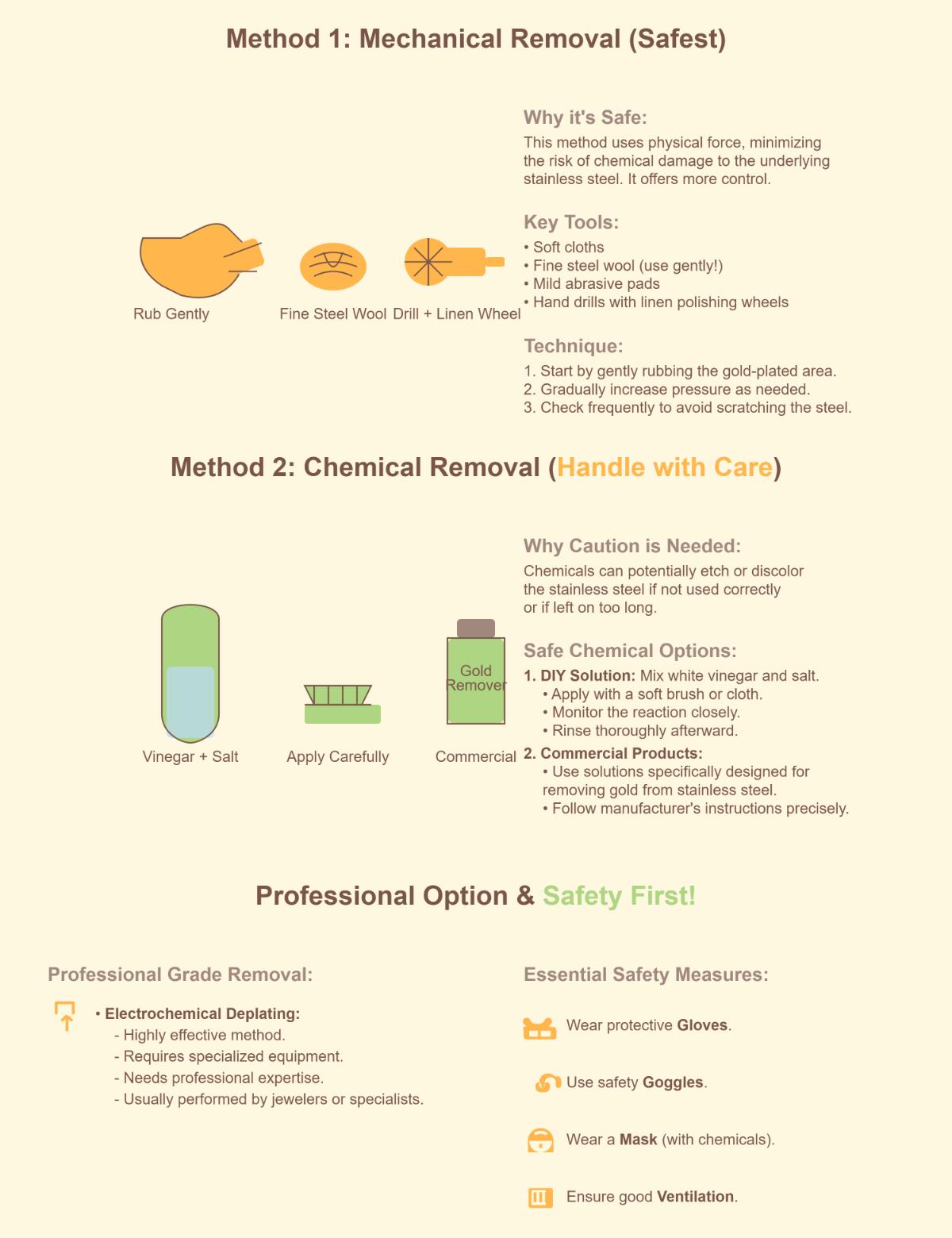

Step-by-Step Mechanical Removal Process

Thoroughly examine the stainless steel item to assess the condition of the gold plating. Identify any delicate components such as plastic or rubber parts that may require extra caution during the removal process. Prepare a clean, well-ventilated workspace. Ensure you have access to water and set up safety equipment including gloves, goggles, and a mask to protect yourself from dust and particles.

Mechanical Removal Techniques

Abrasive Tools

Use Mild Abrasive Pads

Start with mild abrasive pads or soft cloths combined with gentle detergents. Rub the gold-plated area gently to avoid damaging the underlying stainless steel.

Use Stronger Abrasives if Necessary

If the gold plating proves stubborn, switch to a slightly more abrasive pad or a muslin polishing wheel attached to a handheld drill. Apply gentle pressure and work gradually to avoid scratching the base material.

Fine Steel Wool

For tougher gold layers, use fine steel wool to gently scrape away the gold. Ensure you work in small sections to maintain control and precision.

Polishing Tools

Dremel with Muslin Polishing Wheel

For detailed work, use a Dremel tool fitted with a muslin polishing wheel. This setup allows for precise removal of thin gold layers, especially in intricate areas.

Small Files

Use small files to carefully remove gold plating from detailed sections. This method is particularly effective for reaching areas that abrasive pads or wheels may not access.

Safety Precautions

Protective Gear

Always wear gloves, safety glasses, and a mask to protect yourself from abrasive materials and particles.

Avoid Over-Pressure

Apply gentle pressure when using abrasive tools to avoid scratching or damaging the stainless steel surface.

Ventilation

Ensure your workspace is well-ventilated to prevent inhalation of dust and particles generated during the mechanical removal process.

Post-Removal Steps

Rinse with Lukewarm Water

After the gold plating is removed, thoroughly rinse the item with lukewarm water to eliminate any abrasive residues.

Dry and Inspect

Completely dry the item and inspect it to ensure all the gold plating is gone. Check for any remaining gold and repeat the removal process on specific areas if necessary.

Tips for Efficient and Safe Removal

- Work in Small Sections: Focus on small areas at a time to maintain control and precision.

- Be Patient: Mechanical removal can be time-consuming, especially for thicker gold layers. Take your time to avoid damaging the base material.

- Consult a Professional: If the process seems challenging or the gold plating is particularly thick, consider seeking professional assistance to ensure the integrity of the stainless steel.

Mechanical removal is a safe and environmentally friendly method for removing gold plating from stainless steel, making it ideal for delicate or intricate items.

Post-Removal Cleaning and Maintenance

Cleaning Techniques After Chemical Removal

Initial Inspection and Cleaning

Once the gold plating has been removed chemically, inspect the stainless steel surface for any leftover chemicals or damage. Begin by:

- Inspecting the Surface: Look for any remaining residues, discoloration, or chemical stains.

- Initial Cleaning: Use a soft sponge or cloth with mild soap and lukewarm water to gently clean the surface. This step helps remove any lingering chemical residues and prepares the surface for further treatment.

Polishing

If the stainless steel appears dull or discolored after the initial cleaning, use a buffing tool with a polishing compound to enhance the shine and smooth out any imperfections:

- Choose a Polishing Compound: Select a stainless steel polishing compound such as Brasso or Weiman Stainless Steel Cleaner.

- Application: Apply the polishing compound with a microfiber cloth, using small circular motions to evenly polish the surface.

Addressing Corrosion and Imperfections

In cases where there are signs of corrosion or minor scratches:

- Use Gentle Abrasives: Opt for a gentle abrasive pad to smooth out the surface. Avoid harsh materials that could cause further damage.

- Rinse Thoroughly: After using abrasive pads, rinse the item with lukewarm water to remove any residue from the polishing compound or abrasive materials.

Cleaning Techniques After Mechanical Removal

Removing Abrasive Residues

Mechanical removal often leaves abrasive particles and dust:

- Initial Rinse: Rinse the item with lukewarm water to remove any loose particles.

- Detailed Cleaning: Use a soft brush to clean hard-to-reach areas and ensure that all residues are thoroughly removed.

Polishing

To restore the luster of the stainless steel:

- Polishing Compound: Use a soft cloth to apply a stainless steel polishing compound.

- Buffing: Use small circular motions with a microfiber cloth or a buffing tool to achieve a high shine.

Drying and Storage

Thorough Drying

Ensuring the stainless steel is completely dry is crucial to prevent water spots and corrosion:

- Use a Lint-Free Cloth: Dry the item thoroughly with a lint-free cloth.

- Ensure Complete Dryness: Pay special attention to crevices and detailed areas to ensure they are completely dry.

Proper Storage

Keep the cleaned stainless steel item in a dry place, away from moisture and direct sunlight:

- Dry Environment: Store in a dry environment away from moisture and direct sunlight.

- Protection: Consider using a lined box or soft pouches to protect the item from scratches and damage.

Maintenance Tips to Prevent Future Issues

Regular Maintenance

Regular maintenance can help prevent future issues such as corrosion and tarnishing:

- Periodic Cleaning: Regularly clean the stainless steel with mild soap and water to maintain its appearance.

- Inspection: Frequently inspect the item for signs of corrosion or discoloration and address any issues promptly.

Applying Protective Coatings

For items exposed to harsh environments:

- Protective Coatings: Apply a protective coating or wax to enhance the stainless steel’s resistance to corrosion.

- Reapplication: Reapply the protective coating periodically as needed.

Handling Tips

- Clean Gloves: Always handle stainless steel items with clean gloves to prevent oils from your skin from causing tarnish.

- Avoid Harsh Chemicals: Keep the item away from chemicals or substances that could cause damage or discoloration.

Comparison of Chemical and Mechanical Methods

Advantages and Disadvantages of Chemical Removal

Advantages

- Effectiveness on Intricate Surfaces: Chemical solutions can effectively dissolve gold plating in hard-to-reach areas, making them ideal for intricate designs or detailed components.

- Preservation of Base Material: When used correctly, chemical methods are gentle on the stainless steel, preserving the integrity and appearance of the underlying metal.

- Availability of DIY and Commercial Solutions: Both DIY solutions (like vinegar and salt) and specialized commercial products are available, providing flexibility in terms of cost and accessibility.

Disadvantages

- Risk of Damage: Using strong acids or incorrect chemical solutions may damage the stainless steel. Careful selection and application are crucial to avoid this risk.

- Safety Concerns: Handling chemicals requires following safety protocols, including wearing protective gear and ensuring good ventilation.

- Time-Consuming: The chemical process can be slow, requiring patience as the solution gradually dissolves the gold plating.

Advantages and Disadvantages of Mechanical Removal

Advantages

- Efficiency for Thick Plating: Mechanical methods, such as using abrasive pads or fine steel wool, can quickly remove thicker layers of gold plating, making them efficient for certain items.

- Control and Precision: With the right tools, mechanical removal allows for precise control, particularly useful for detailed or small areas.

- Minimal Chemical Exposure: This method eliminates the need for hazardous chemicals, reducing the risk of chemical burns or inhalation of toxic fumes.

Disadvantages

- Risk of Scratching: There’s a higher risk of scratching or damaging the stainless steel surface, especially if too much pressure is applied or if inappropriate tools are used.

- Physical Effort: Mechanical removal can be physically demanding and time-consuming, particularly for large items or surfaces with intricate details.

- Dust and Debris: The process generates dust and debris, necessitating a well-ventilated workspace and thorough cleanup afterward.

Efficiency and Risk Comparison

Efficiency

- Chemical Methods: Best suited for items with intricate designs or delicate components where preserving the base material is crucial. The process can be slower but is effective for thin or evenly applied gold layers.

- Mechanical Methods: Mechanical methods are more efficient for thicker gold plating and larger surfaces, but they require careful handling to avoid damaging the stainless steel.

Risk

- Chemical Methods: The primary risks involve potential chemical burns, inhalation of fumes, and damage to the stainless steel if incorrect solutions are used. Strict safety protocols must be followed.

- Mechanical Methods: The main risks are scratching the stainless steel and physical strain from manual effort. Proper tool selection and technique are essential to minimize these risks.

Decision-Making Factors

Item Complexity and Detail

- For items with intricate designs or hard-to-reach areas, chemical removal is generally more effective.

- For larger, less detailed items, mechanical removal may be faster and more practical.

Thickness of Gold Plating

- Thicker gold plating is more efficiently removed using mechanical methods.

- Thin or evenly applied gold layers are best addressed with chemical solutions.

Safety and Environmental Concerns

- If safety and environmental impact are primary concerns, mechanical removal avoids the use of hazardous chemicals.

- Chemical removal should be chosen with strict adherence to safety protocols and proper disposal methods to mitigate risks.

Personal Skill and Comfort Level

- Individuals comfortable and experienced with handling chemicals may prefer chemical methods for their precision.

- Those who prefer hands-on, tool-based approaches may find mechanical methods more suitable.

Both chemical and mechanical methods have their unique advantages and challenges. The choice between them should be based on the specific requirements of the item being treated, the user’s skill level, and safety considerations.

Frequently Made Mistakes and How to Avoid Them

Insufficient Preparation

Thoroughly inspect the item before starting the gold plating removal process.

Failing to inspect the stainless steel item for delicate components such as plastic or rubber parts can lead to damage during the removal process. Always inspect the item beforehand to identify any sensitive components. Ensure that all parts can withstand the chosen removal method, whether chemical or mechanical.

Incorrect Removal Method

Choosing the wrong removal method, such as aggressive chemicals or improper tools, can damage the stainless steel and be ineffective. Using aggressive chemical methods that can harm the stainless steel base or attempting mechanical removal with inappropriate tools should be avoided. Use mechanical methods like fine steel wool or polishing pads for thin plating. For thicker plating, consider professional assistance or use mild chemical solutions such as white vinegar and salt.

Inadequate Safety Measures

Safety should never be compromised when removing gold plating, especially when chemicals are involved. Failing to wear gloves, safety glasses, and masks can expose you to harmful chemicals and physical injury. Always wear appropriate protective gear. Gloves, safety glasses, and masks should be used to protect your skin, eyes, and respiratory system. Work in a well-ventilated area to avoid inhaling fumes.

Inefficient Rinse Process

Properly rinsing the item after the removal process is crucial to ensure no harmful residues remain. Inadequate rinsing can leave harmful residues or particles that cause further damage. Rinse the item immediately with lukewarm water after the removal process. Pay special attention to grooves and hard-to-reach areas to ensure all residues are removed.

Using Inappropriate Chemicals

Incorrect chemicals can damage stainless steel and pose serious safety risks. Employing strong acids like sulfuric acid or sodium cyanide, which are highly dangerous and can damage the stainless steel, should be avoided. Opt for mild DIY solutions like a mixture of white vinegar and salt or use commercial products specifically designed for gold plating removal. Always follow the manufacturer’s instructions for safe use.

Applying Excessive Force

Applying too much force during mechanical removal can scratch or damage the stainless steel surface. Using excessive pressure or inappropriate tools during mechanical removal can lead to scratches and other damage. Use gentle, controlled movements and appropriate tools like fine steel wool or a Dremel with a muslin polishing wheel. Apply minimal pressure to avoid damaging the base material.

Incomplete Removal

Failing to completely remove the gold plating can leave the item looking uneven and unfinished. Stopping the process too soon can result in patches of remaining gold plating. Ensure that the gold plating is completely removed by reapplying the removal method as necessary. Thoroughly inspect the item after each stage to identify any areas that require additional attention.

Visual Aids

Step-by-Step Images

Visual aids are essential for clearly showing the process of removing gold plating from stainless steel. Including step-by-step images can significantly enhance the clarity and understanding of each step involved in both chemical and mechanical removal methods.

Chemical Removal

- Preparation: Show an image of all the necessary materials, including protective gear, chemical solutions, and cleaning supplies.

- Application of Solution: Display the application of the chemical solution on the gold-plated area using a soft brush or cloth, and include close-up images of the gold plating reacting with the solution, highlighting signs like bubbling or discoloration.

- Rinsing: Show the rinsing process with lukewarm water to remove chemical residues.

- Drying and Polishing: Capture the final steps of drying the item with a soft cloth and applying a stainless steel polishing compound to restore shine.

Mechanical Removal

- Tool Selection: Show images of the tools needed, like fine sandpaper, nylon pads, and a Dremel with a muslin polishing wheel.

- Abrasive Process: Show the process of gently rubbing the gold-plated surface with an abrasive tool.

- Detail Work: Include images of using a Dremel or small files to remove gold plating from intricate areas.

- Cleaning and Finishing: Display the cleaning process to remove loosened gold particles and the final polishing to restore the stainless steel finish.

Safety Equipment

Visual aids emphasizing the importance of protective gear are essential to ensure safety during the removal process. Include images or illustrations of the following safety equipment:

- Gloves: Highlight the use of chemical-resistant gloves to protect hands.

- Goggles: Show safety goggles to shield eyes from splashes and particles.

- Mask: Display a respirator mask to prevent inhalation of harmful fumes or dust.

- Apron: Include an image of a chemical-resistant apron for protecting clothing and skin.

Before and After Comparisons

Show the impact of the removal process with before and after comparison images:

- Initial Condition: Show the stainless steel item with the gold plating intact.

- Post-Removal: Display the item after the gold plating has been successfully removed, highlighting the restored stainless steel surface.

Warning Symbols

Using warning symbols or captions can help alert viewers to potential risks or necessary precautions during the removal process. Include visual aids such as:

- Chemical Hazard Symbols: Indicate the presence of hazardous chemicals and the need for protective gear.

- Warning Labels: Highlight areas where extra caution is required, such as during the application of chemical solutions or the use of abrasive tools.

- Emergency Equipment: Show the location of emergency equipment like eyewash stations and safety showers.

Diagrams for Detailed Processes

Diagrams can be particularly useful for illustrating detailed steps and techniques involved in both chemical and mechanical removal methods. Consider including the following types of diagrams:

- Chemical Application Diagram: Show the correct technique for applying the chemical solution and the expected reaction process.

- Abrasive Technique Diagram: Illustrate the proper method for using abrasive tools, including the angle and pressure to apply.

- Polishing Process Diagram: Detail the steps for applying polishing compounds and buffing the stainless steel to achieve a high shine.

Incorporating Visual Aids in Tutorials

Integrate visual aids directly into the step-by-step instructions to make tutorials more effective. For each step, provide corresponding images, diagrams, or videos to guide the user through the process. This approach ensures that the user can follow along more easily and understand each step’s intricacies.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the safest methods to remove gold plating from stainless steel?

To safely remove gold plating from stainless steel, you can use either mechanical or chemical methods.

Mechanical removal is often considered the safest because it involves minimal risk of damaging the stainless steel. This method uses physical tools such as soft cloths, fine steel wool, mild abrasive pads, or hand drills with linen wheels. Gently rub the gold-plated areas, gradually increasing pressure to avoid scratching the stainless steel.

Chemical removal is another option, but it requires careful handling to prevent damage to the stainless steel. A safe approach involves using a white vinegar and salt solution. Apply the solution with a soft brush or cloth, monitoring the reaction closely. Commercial gold removal solutions specifically designed for stainless steel can also be used.

For professional-grade removal, electrochemical deplating is effective but typically requires specialized equipment and expertise. Always wear protective gear like gloves, goggles, and masks, and ensure good ventilation when using chemicals.

How do I choose between chemical and mechanical removal methods?

Choosing between chemical and mechanical removal methods for gold plating from stainless steel depends on several factors:

- Thickness of the Gold Plating: For thin layers of gold plating, mechanical removal is often sufficient and effective. It involves using tools like fine steel wool, fine sandpaper, or handheld grinding wheels. Thicker layers may require the efficiency of chemical removal, which can dissolve the gold more quickly.

- Type of Item: Delicate or intricately designed items benefit from mechanical methods to avoid damage to the underlying stainless steel. In contrast, simpler or more robust items can withstand the chemical process.

- Safety and Environmental Concerns: Mechanical removal is safer and more environmentally friendly since it doesn’t involve hazardous chemicals. Chemical methods, while faster and more efficient, require careful handling and proper disposal to avoid health risks and environmental damage.

- Experience and Expertise: Mechanical removal is generally straightforward and safer for those with limited experience. Chemical removal should ideally be performed by those with knowledge of handling corrosive substances or under the guidance of a professional.

Evaluate these factors to decide the most appropriate method for your specific situation.

What protective gear is necessary for chemical removal?

For the chemical removal of gold plating from stainless steel, it is crucial to use the appropriate protective gear to ensure safety. Essential protective gear includes waterproof gloves made of nitrile or rubber to protect your hands from chemical exposure. Safety goggles are necessary to protect your eyes from splashes; they should be chemical-resistant and provide a tight seal around the eyes. Respiratory protection, such as a half-face respirator with organic vapor cartridges, is recommended to prevent inhalation of harmful fumes. Wearing long-sleeved shirts, pants, and a lab coat or apron made of chemical-resistant materials can minimize skin exposure. Additionally, a face mask can offer extra protection against splashes and vapors. Always inspect your protective gear for damage before use, ensure a proper fit, and follow appropriate decontamination or disposal procedures after use.

Are there any risks associated with mechanical removal?

Yes, there are several risks associated with mechanical removal of gold plating from stainless steel.

Firstly, improper use of abrasive tools can damage the underlying stainless steel surface. This includes scratches, which can compromise both the aesthetic and functional properties of the material, and discoloration, where excessive abrasion dulls the surface and can be difficult to restore.

Secondly, achieving a uniform removal is challenging; uneven application can result in patchy areas where some gold plating remains while other areas are stripped completely, leading to an inconsistent appearance and surface roughness.

Thirdly, mechanical removal generates metal dust and particulates, posing health risks if inhaled. It is essential to work in a well-ventilated area and use appropriate respiratory protection.

Lastly, the choice of tools is critical; overly abrasive tools can remove not only the gold plating but also thin layers of stainless steel, affecting the integrity of the piece. Residual materials from polishing compounds can interfere with subsequent finishes or treatments.

To minimize these risks, use the least abrasive tools necessary, apply even pressure, work in a controlled environment, and frequently inspect the surface during the process. Following these best practices ensures effective removal while preserving the stainless steel’s quality.

How do I dispose of chemicals used in the removal process?

To dispose of chemicals used in the gold plating removal process, follow these steps to ensure safety and compliance with environmental regulations. First, identify the types of chemicals you are using, such as strong acids like nitric or sulfuric acid, and any solutions containing cyanide. Understanding the chemical composition is crucial for proper disposal.

Next, adhere to local hazardous waste disposal regulations by contacting relevant authorities to learn the specific guidelines in your area. If you have a significant quantity of hazardous chemicals, consider hiring a professional hazardous waste disposal service to handle them safely and environmentally responsibly.

For smaller quantities, check if local recycling centers accept such chemicals in limited amounts, often with monthly restrictions. Ensure that chemicals are stored in sealed, clearly labeled containers and transported with necessary safety measures to prevent leaks or accidents.

Always prioritize environmental responsibility by choosing eco-friendly disposal methods and ensuring all residual materials are handled correctly to prevent water and soil contamination. Proper education and training on hazardous waste disposal are also vital to minimize health risks and environmental impact.

What should I do if I make a mistake during the removal process?

If you make a mistake during the process of removing gold plating from stainless steel, follow these steps to address and rectify the issue:

- Evaluate the Damage: Assess the extent of the mistake, whether it is minor, such as a small scratch, or more severe, like extensive chemical or mechanical damage. Identify any residual chemicals or physical abrasions.

- Immediate Action:

- For chemical residues, promptly rinse the affected area with plenty of water to neutralize and remove any lingering chemicals. Use a soft cloth to gently dry the surface.

- For mechanical damage, such as scratches, consider using a fine polishing compound or microcrystalline wax to restore the surface’s finish.

- Safety Measures: Always wear appropriate protective gear, including gloves, safety goggles, and a mask, to prevent injury from chemicals or debris. Ensure your workspace is well-ventilated to avoid inhaling harmful fumes.

- Seek Professional Advice: If the damage is significant or you’re unsure how to proceed, consult a professional to avoid further harm to the stainless steel.

- Learn and Prevent: Document the error to avoid repeating it in the future. Improve your techniques based on this experience and select safer, more effective methods for future tasks.

By following these steps, you can effectively manage and correct mistakes during the gold plating removal process, ensuring better outcomes in future attempts.