Are you a beginner in metalworking, eager to learn how to remove nickel plating from steel safely? Nickel plating, commonly used in various metal applications, can sometimes need removal. There are several methods, like chemical, mechanical, and electrolytic stripping, each with its own safety aspects and environmental impacts. For instance, electrolytic stripping uses an electric current to separate the plating. In this guide, we’ll walk you through step – by – step processes for each method. So, are you ready to discover the best way to get that nickel plating off your steel?

Nickel plating involves coating a metal object with a thin layer of nickel through a process called electroplating. This technique enhances the physical and chemical properties of metal components, providing corrosion resistance, increased durability, aesthetic improvement, hardness, and good electrical conductivity.

Nickel plating is utilized in a wide range of applications due to its beneficial properties. Some of the common uses include:

First, the base metal is cleaned to remove any impurities that could affect the plating quality.

The cleaned metal is then treated with a mild acid bath to activate its surface. This step prepares the metal for optimal bonding with the nickel ions.

During electroplating, the metal part is submerged in a solution with nickel salts, and an electric current is applied, causing nickel ions to deposit onto the metal surface. The thickness of the nickel layer can be controlled by adjusting the current and the duration of the plating process.

Nickel plating is an essential technique in metal finishing, offering both functional and aesthetic benefits that enhance the performance and appearance of metal components.

Steel is an alloy primarily composed of iron and carbon, known for its high strength and durability. It serves as an excellent base material for various industrial applications due to its mechanical properties. Understanding the characteristics of steel is crucial when discussing nickel plating and its removal.

Nickel plating involves coating a base metal, such as steel, with a layer of nickel. This process enhances the metal’s properties and extends its usability in various applications.

Nickel plating provides a protective layer that shields the base metal from environmental factors, reducing the risk of rust and corrosion. Additionally, the bright, shiny finish of nickel plating improves the visual appeal of metal objects. This makes it popular in decorative applications, such as jewelry and household fixtures, where appearance is as important as functionality.

Nickel plating adds a hard surface layer to the base metal, improving its resistance to scratches and wear. This is beneficial for tools and machinery parts that undergo frequent use and abrasion.

Before nickel plating, clean the steel surface well to remove grease, dirt, or oxide layers. This helps the nickel layer stick properly.

The cleaned steel is put into an electrolytic solution with nickel salts. An electric current makes nickel ions stick to the steel surface. The process parameters, such as current density and plating time, control the thickness of the nickel layer.

After plating, the nickel-coated steel is rinsed to remove any remaining plating solution and then dried. This step ensures a clean, dry surface, ready for further processing or use.

Nickel-plated steel is used in many industries because of its improved properties. Some common applications include:

Nickel plating can be removed from steel using mechanical, chemical, or electrolytic techniques, each with distinct advantages and drawbacks.

Mechanical methods, such as sandblasting and grinding or sanding, involve physically removing the nickel plating using abrasive techniques. Sandblasting uses compressed air to propel abrasive media, while grinding and sanding involve using wheels or discs. These methods are effective but can be labor-intensive and may risk damaging the base metal if not performed carefully.

Chemical methods involve using solutions that dissolve the nickel plating without affecting the base metal. These methods can be more controlled and are often preferred for delicate items.

Proprietary nickel strippers are commercial solutions designed to dissolve nickel plating. They are safer and more environmentally friendly than strong acids but can be costly and require specific disposal methods.

Muriatic acid, also known as hydrochloric acid, can be diluted and applied to dissolve the nickel layer. This method is effective for thicker nickel layers but requires proper safety measures, including gloves and goggles, and the steel must be neutralized afterward to prevent rust.

Soaking the nickel-plated item in vinegar can slowly dissolve the nickel plating. This method is safe and readily available in most households, but it is a slow process and less effective for thicker nickel layers.

Electrolytic methods use an electric current to reverse the plating process. In reverse electroplating, the nickel-plated item acts as the anode in an electrolyte bath, and an electric current dissolves the nickel layer. This method offers precise control but requires specialized equipment and careful monitoring.

When selecting a removal method, consider the type of base metal, the thickness of the nickel layer, available tools and equipment, and safety precautions. Prioritize safety by using appropriate protective equipment and working in a well-ventilated area.

Adhering to safety protocols is crucial when removing nickel plating from steel to prevent accidents and ensure success.

Wear chemical-resistant gloves and safety goggles to protect your hands from corrosive chemicals and your eyes from splashes and fumes. A mask or respirator helps protect against inhalation of harmful fumes and dust, and a chemical-resistant apron protects your clothing and skin from spills.

Work in a well-ventilated area to reduce exposure to toxic fumes. Use an exhaust fan or fume hood to direct fumes away from your workspace.

Always read and understand the labels and Material Safety Data Sheets (MSDS) for all chemicals you use. Store chemicals in clearly labeled, appropriate containers, and keep them out of reach of children and pets. Have materials like baking soda and water ready to neutralize spills and splashes immediately.

Inspect electrical equipment for damage and secure connections before use. Follow the manufacturer’s instructions for setting up and using electrical equipment like power supplies for electrolytic stripping. Keep electrical equipment away from water to prevent shocks and short circuits.

These solutions are designed to dissolve nickel plating safely and effectively. Muriatic acid, a strong acid, can be diluted and used to remove nickel but requires careful handling and neutralization. Nitric acid is another option for dissolving nickel, mainly used in industrial applications.

A blasting cabinet provides a controlled environment for sandblasting, containing the abrasive media and debris. An air compressor powers the blasting process, providing the necessary pressure. Abrasive media such as glass beads or aluminum oxide are used to mechanically remove the nickel layer.

A bench grinder is useful for flat surfaces and larger items, while an angle grinder is ideal for intricate shapes and hard-to-reach areas. Aluminum oxide or silicon carbide grinding wheels are effective for grinding away nickel plating.

A power supply provides the necessary electrical current for reverse electroplating. A sulfuric acid solution is typically used as the electrolyte to facilitate the electrolysis process. An anode (the nickel-plated item) and a cathode (usually steel) are required for the setup.

Exhaust fans help remove fumes from the workspace, and fume hoods capture and direct fumes away from the operator, improving safety.

Choose the removal method based on the thickness of the nickel plating, the type of steel, and the desired outcome. Adhere to the manufacturer’s guidelines for chemical products and equipment to ensure safe and effective use. Always handle chemicals and electrical equipment with care to avoid accidents.

After successfully removing the nickel plating from steel, it is crucial to clean the surface thoroughly to ensure it is free from any contaminants that could affect the new plating. Follow these steps to achieve a clean and prepared surface:

Begin by rinsing the steel thoroughly with water. This step is crucial to remove any leftover chemicals from the nickel plating removal. Use clean water to ensure all traces of the previous substances are washed away, preventing any contamination that might impact the new plating.

If you used chemical stripping methods, it is important to neutralize the steel surface. Make a mild alkaline solution like baking soda and water. Submerge the steel in this solution or apply it generously to the surface to neutralize any remaining acid residue. This helps to prevent corrosion and ensures a clean base for new coatings.

Remove any oils or grease from the surface using a commercial degreaser or a soap solution as this step is vital for new plating adhesion. Rinse the steel again with clean water to remove any degreasing agents and dry it thoroughly.

Once the steel is clean, the next step is to prepare it for new plating. Proper preparation ensures the new plating adheres well and provides a durable, high-quality finish.

Use mechanical methods such as sanding or polishing to smooth out the steel surface. This step is important for achieving a uniform finish. Employ fine-grit sandpaper or a polishing wheel to gently smooth the surface, removing any imperfections or remaining residues. A smooth surface enhances the adhesion of the new plating.

For a more thorough preparation, especially if there are any remaining impurities, consider using a chemical cleaning solution. A common option is a mild muriatic acid or a special pickle solution for metal prep. Apply the solution according to the manufacturer’s instructions and follow all safety guidelines when handling acids. This step ensures the steel is free from any microscopic contaminants.

After completing the chemical cleaning or pickling, rinse the steel thoroughly with clean water to remove any remaining chemicals. This step is key to stop leftover chemicals from harming the new plating. Dry the steel completely, ensuring there are no water spots or moisture left on the surface. The steel should be completely dry and clean, ready for the new plating application.

When performing post-removal cleaning and preparation for new plating, always prioritize safety:

By following these steps, you can effectively clean and prepare your steel surface for new plating, ensuring a durable and high-quality finish.

When removing nickel plating from steel, it’s crucial to consider the environmental impact of the chemicals used. Strong acids like nitric acid and hydrochloric acid (muriatic acid) are commonly employed for chemical stripping. These chemicals can be hazardous if not managed properly, leading to soil and water contamination.

The chemicals used in nickel plating removal can pose significant health risks, including exposure to toxic fumes, skin contact with corrosive substances, and accidental ingestion. These risks can lead to serious health issues.

The process of extracting and processing metals for plating has a considerable environmental footprint. Implementing sustainable practices can help mitigate this impact and promote environmental responsibility.

Adhering to local and international environmental regulations is crucial for responsible nickel plating removal. Regulations ensure that hazardous chemicals are handled and disposed of properly to protect the environment and public health.

Removing nickel plating from steel can present several challenges, especially for beginners. Recognizing and addressing these issues can ensure successful nickel plating removal.

One of the primary concerns when removing nickel plating is avoiding damage to the underlying steel. Mechanical methods, such as grinding and sanding, can scratch or gouge the steel if not performed carefully.

Chemical stripping involves hazardous substances that can pose health risks if not handled properly. For instance, muriatic acid can cause burns and respiratory problems.

Ensuring complete removal of nickel plating can be challenging, particularly with thick layers or complex surfaces.

If not disposed of properly, the chemicals used in nickel removal can harm the environment. This includes acids and other hazardous substances.

Electrolytic stripping involves handling electrical equipment and chemicals, which can be dangerous if not managed correctly.

Even with precautions, issues can arise during the nickel plating removal process. Here are some common problems and their solutions.

Symptom: The base metal starts getting damaged.

Symptom: Residual nickel remains after stripping.

Symptom: Skin or eye irritation, respiratory issues.

Symptom: Electrical shock or equipment malfunction.

Select the removal method based on the thickness of the nickel layer and the complexity of the part. Reverse electroplating is effective for thick layers, while grinding and sanding are better for simpler geometries.

Always prioritize safety by wearing protective gear and ensuring proper ventilation when using chemicals. This helps to prevent accidents and exposure to hazardous substances.

Opt for eco-friendly methods where possible and dispose of waste responsibly. This minimizes the environmental impact of the nickel removal process.

A common mistake in removing nickel plating from steel is neglecting safety precautions, which can result in serious injuries from handling chemicals and tools without proper protection.

Always wear appropriate personal protective equipment (PPE), including chemical-resistant gloves, safety goggles, and a mask or respirator. Ensure good ventilation in your workspace to avoid inhaling fumes. Use an exhaust fan or work in a well-ventilated area to minimize exposure to harmful chemicals.

Proper surface preparation is crucial; failing to clean the steel surface both before and after the removal process can lead to incomplete removal and poor results.

Thoroughly clean the steel surface before starting the removal process. Use a degreaser to remove any oils or contaminants. After the nickel plating is removed, clean the surface again to ensure it is free of any residues that could affect the final finish.

Using undiluted or highly concentrated acids can damage the steel underneath the nickel plating. This is a common mistake, especially for beginners.

Always dilute acids as recommended. For instance, mix one part muriatic acid with three parts water, and always add acid to water to prevent dangerous reactions. Test the diluted solution on a small area first to ensure it does not harm the steel.

Choosing the wrong removal technique based on the nickel layer’s thickness or the part’s shape can be ineffective. Mechanical methods may not suit intricate shapes, while chemical methods might be too slow for thick layers.

Choose the removal method based on the specific requirements of the job. For thick nickel layers, chemical stripping or electrolytic methods may be more effective. For intricate shapes, sandblasting or using a rotary tool with a wire brush attachment can help reach difficult areas.

Not thoroughly inspecting the surface during the removal process can result in incomplete removal of the nickel plating. This can affect the final finish and performance of the steel part.

Regularly inspect the workpiece during the removal process to ensure all nickel plating is being removed. Use good lighting and magnification if necessary to check for any remaining nickel. Be patient and allow enough time for the process to complete thoroughly.

Improper disposal of chemical waste poses a major environmental risk. Dumping chemicals down the drain or in regular trash can contaminate water sources and soil.

Follow local regulations for the disposal of chemical waste. Use certified hazardous waste disposal facilities to ensure chemicals are handled safely and do not harm the environment. Keep a log of the chemicals used and disposed of to maintain compliance with environmental regulations.

By understanding and avoiding these common mistakes, beginners can effectively and safely remove nickel plating from steel, ensuring the integrity of the base metal and achieving high-quality results.

Below are answers to some frequently asked questions:

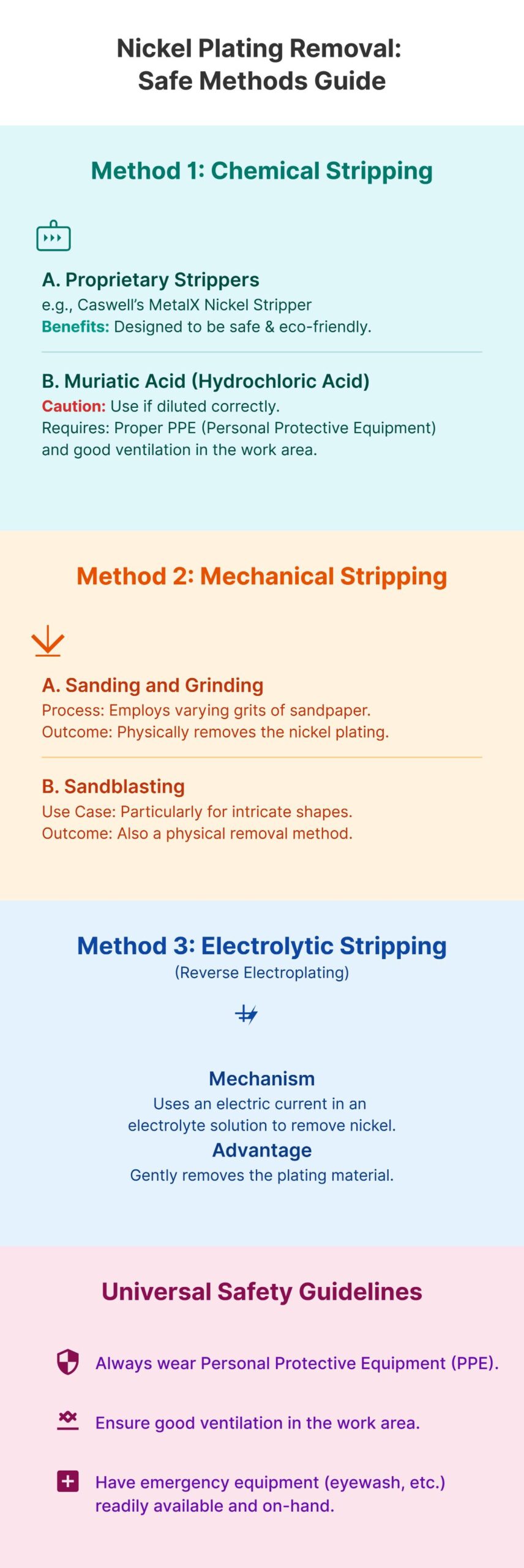

When removing nickel plating from steel, a few safe methods are available. Chemical stripping can use proprietary strippers like Caswell’s MetalX Nickel Stripper, which are designed to be safe and eco – friendly. Muriatic acid (hydrochloric acid) can also be used if diluted correctly, but requires proper PPE and ventilation. Mechanical stripping, such as sanding and grinding with varying grits of sandpaper, or sandblasting for intricate shapes, physically removes the plating. Electrolytic stripping, or reverse electroplating, uses an electric current in an electrolyte solution to gently remove the nickel. Always wear PPE, ensure good ventilation, and have emergency equipment on – hand.

Electrolytic stripping works by reversing the electroplating process to remove nickel plating from steel. This method involves placing the nickel-plated steel item as the anode in an electrolytic bath, with a counter electrode (typically steel or stainless steel) serving as the cathode. When a direct electric current is applied, the nickel layer oxidizes and dissolves into the electrolyte solution, detaching from the steel surface.

Key components for this process include an electrolyte solution, often composed of acids like sulfuric acid or non-cyanide alkaline solutions, and specialized equipment to apply the electric current safely. Monitoring the electrolyte’s concentration, pH, and temperature is crucial to ensure effective stripping without damaging the steel. Electrolytic stripping provides precision and control, making it an environmentally friendly option compared to some chemical methods. However, it requires specialized equipment and strict adherence to safety protocols.

When removing nickel plating from steel, environmental considerations are crucial to minimize harm to the environment and ensure safety. Chemical stripping, which often uses muriatic acid or alkaline solutions, can generate hazardous waste. This waste must be handled and disposed of properly to prevent soil and water contamination. The fumes from these chemicals can also contribute to air pollution if not managed with proper ventilation.

Electrolytic stripping, which uses an electric current to dissolve the nickel layer, produces less chemical waste but requires careful handling of the equipment to avoid environmental hazards. Mechanical methods, like sandblasting, do not involve chemicals but can produce particulate matter that needs to be managed to avoid environmental contamination.

To mitigate these impacts, it’s important to follow best practices such as using protective gear, ensuring proper ventilation, and disposing of chemical waste according to environmental regulations. Opting for more environmentally friendly methods, like non-cyanide alkaline solutions, can also reduce toxicity and environmental harm. By considering these factors, you can effectively remove nickel plating while minimizing environmental impact.

If the nickel plating does not come off completely, you can take several steps to address the issue. First, review the chemical stripping method you’ve used. Ensure the exposure time in the chemical solution is adequate and adjust the concentration of the solution if necessary, following the manufacturer’s guidelines. If chemical methods are insufficient, enhance the process with mechanical techniques like sandblasting or grinding. These methods can effectively remove remaining nickel but require careful handling to avoid damaging the steel.

Alternatively, consider electrolytic stripping, which uses an electric current to dissolve the nickel plating. This method is effective for durable metals like steel but requires precise control to avoid damaging the base material. After removal, thoroughly clean the surface to remove any contaminants and prepare it for new plating. Always follow safety protocols when handling chemicals and using mechanical tools.

Beginners should avoid several common mistakes when removing nickel plating from steel. Firstly, insufficient safety precautions can lead to injuries; always use personal protective equipment like gloves, goggles, and masks, and ensure proper ventilation. Secondly, selecting the incorrect method can damage the base material; choose chemical methods for thick layers and mechanical methods for delicate surfaces. Electrolytic methods require specialized knowledge and are not recommended for beginners. Improper chemical handling, such as incorrect dilution or excessive exposure time, can also harm the steel. Inadequate surface preparation before and after removal can lead to uneven results and affect future coatings. Lastly, ignoring environmental and safety regulations regarding chemical disposal can have serious consequences. By avoiding these mistakes, beginners can achieve effective and safe nickel plating removal.

To prepare steel for new plating after removing nickel, follow these steps to ensure a clean and smooth surface:

Always work in a well-ventilated area and use appropriate protective gear. Follow proper disposal protocols for chemicals to minimize environmental impact and ensure the new plating material is compatible with the steel substrate. By adhering to these steps, you can prepare steel effectively for new plating, ensuring a high-quality and durable finish.