Have you ever wondered how to effectively strip away that stubborn layer of nickel plating from a metal surface without damaging the underlying material? Whether you’re a DIY enthusiast or tackling a specific project, learning how to safely and efficiently remove nickel plating can open up a world of possibilities for restoration and customization. In this article, we’ll walk you through five straightforward steps to remove nickel plating using beginner-friendly methods. From chemical and electrolytic stripping to essential safety tips, we’ve got you covered. Ready to transform your metal pieces with ease? Let’s dive into the process and discover the best techniques to achieve a pristine, nickel-free finish.

Nickel plating involves depositing a layer of nickel onto a metal surface, typically through electroplating, where an electric current transfers nickel ions from a source onto the metal object. Nickel plating is widely used in various industries because it enhances the appearance, durability, and corrosion resistance of metal components.

Removing nickel plating is often necessary for restoration projects, manufacturing quality control, or repair processes. Various methods can be employed to remove nickel plating, each with its own advantages and suitable applications.

Chemical stripping uses solutions that react with the nickel plating, dissolving it from the metal surface. This method is effective for intricate shapes and delicate items where mechanical methods might cause damage.

Electrolytic stripping reverses the electroplating process by using an electrolytic cell to dissolve the nickel layer. It is particularly useful for thicker nickel coatings and provides a controlled removal process that minimizes damage to the underlying metal.

Mechanical methods involve physically removing the nickel plating using abrasive tools such as sandpaper, grinding wheels, or blasting media. These methods are suitable for thicker coatings and robust items that can withstand abrasive forces.

Each method has specific applications, benefits, and limitations. The appropriate method depends on factors like the thickness of the nickel plating, the type of underlying metal, and the desired outcome of the removal process.

Chemical stripping involves using specialized solutions to dissolve nickel plating from metal surfaces, making it ideal for intricate or delicate items. This method is particularly effective for items with complex designs or delicate structures where mechanical methods might cause damage. Common chemicals for this method include commercial nickel strippers, muriatic acid, and vinegar for thinner layers.

This approach is advantageous because it effectively handles complex geometries without harming the base metal and is suitable for softer metals or parts with detailed designs. However, it requires careful handling of chemicals and may necessitate specialized solutions.

Mechanical methods use abrasive tools to physically remove nickel plating, suitable for thicker layers and robust metals. These methods are more fitting for thicker layers of nickel and sturdy base metals that can endure abrasive forces. Tools required for this process include angle grinders, sanding blocks, and abrasive wheels and sandpaper.

The advantages of mechanical methods are their affordability and accessibility for DIY applications, making them suitable for large items where chemical methods are impractical. On the downside, they are labor-intensive and may result in a rough finish, with a risk of scratching or damaging the base metal if not done carefully.

Electrolytic stripping, also known as reverse plating, uses an electric current to dissolve the nickel plating. This method offers precise control over the removal process and minimizes damage to the base metal. The procedure involves connecting the nickel-plated item as the anode in an electrolytic cell and using an electrolyte solution like sulfuric acid.

This method is highly effective for thick nickel coatings and gentle on the base metal. However, it requires specialized equipment and safety precautions, and it may be slow for large or heavily plated items.

Vibratory finishing is used to polish and smooth the surface after the initial stripping process. This method is ideal for small or detailed parts and can handle bulk processing efficiently.

The advantages include leaving a polished finish and being effective for small or bulk processing. However, it is less effective for thick plating layers and requires specialized equipment.

Before starting the chemical stripping process, ensure you have all necessary materials and follow safety precautions to protect yourself and your workspace.

Before starting the electrolytic stripping process, it is essential to gather all necessary materials and follow safety precautions to ensure a smooth and safe operation.

Setting up the electrolytic cell correctly is crucial for the success of the stripping process.

Mix 5% sulfuric acid with water to create the electrolyte solution. If needed, add ammonia to enhance the stripping process.

The actual stripping process involves connecting the nickel-plated item and carefully monitoring the electrolytic reaction.

Set the current density to 3-5 amps per square inch and continuously monitor the process. Adjust the current or the solution as needed to achieve uniform removal of the nickel plating, avoiding excessive current to prevent damage to the base metal.

After the nickel plating has been removed, it is important to clean and inspect the item to ensure all residues are eliminated and the surface is intact.

Rinse the item thoroughly with clean water to remove any electrolyte residue. Dry the item with a soft cloth or towel to prevent rust or corrosion.

Carefully inspect the item to ensure all nickel is removed and the base metal is undamaged. Apply additional treatments if necessary to protect the base metal from future corrosion or damage.

Maintain an appropriate current density to avoid surface damage and regularly check the concentration and temperature of the electrolyte solution for optimal efficiency.

Chemical stripping is a popular method for removing nickel plating due to its effectiveness and ability to handle intricate designs without damaging the base metal.

Electrolytic stripping, also known as reverse electroplating, uses an electric current to dissolve the nickel plating. This method is known for its precision and control.

Mechanical removal involves physically stripping the nickel plating using abrasive tools. This method is straightforward but requires more manual effort.

| Method | Effectiveness | Safety Considerations | Environmental Impact |

|---|---|---|---|

| Chemical Stripping | Highly effective | Requires protective gear, ventilation | Chemical waste management necessary |

| Electrolytic Stripping | Precise and controlled | Specialized equipment required, electric safety | Less toxic but needs proper disposal |

| Mechanical Removal | Fast for thick layers | Risk of scratching, particulate matter | No chemical waste but generates dust |

Selecting the appropriate method for removing nickel plating depends on several factors:

Removing nickel plating can significantly impact the environment if not done responsibly. Understanding these concerns is crucial for minimizing harm to both human health and the environment.

Common methods for removing nickel plating often involve hazardous chemical strippers or acids, such as muriatic acid (hydrochloric acid) and sulfuric acid, which pose risks like:

Proper disposal of chemical waste is essential to prevent environmental damage. Here are some key points to consider:

Adopting sustainable practices can help reduce the environmental footprint of nickel plating removal. Here are some eco-friendly approaches:

For small-scale projects, using common household items like a mixture of vinegar and salt can be a more sustainable and less hazardous alternative to strong acids. This method is suitable for thin nickel layers and small items.

Mechanical methods such as sanding and grinding avoid the use of chemicals altogether, providing a sustainable option for removing nickel plating:

Ensuring safety during the nickel plating removal process is paramount. Here are some precautions to take:

Proper cleaning and disposal after removing nickel plating are crucial for safety and environmental protection:

Below are answers to some frequently asked questions:

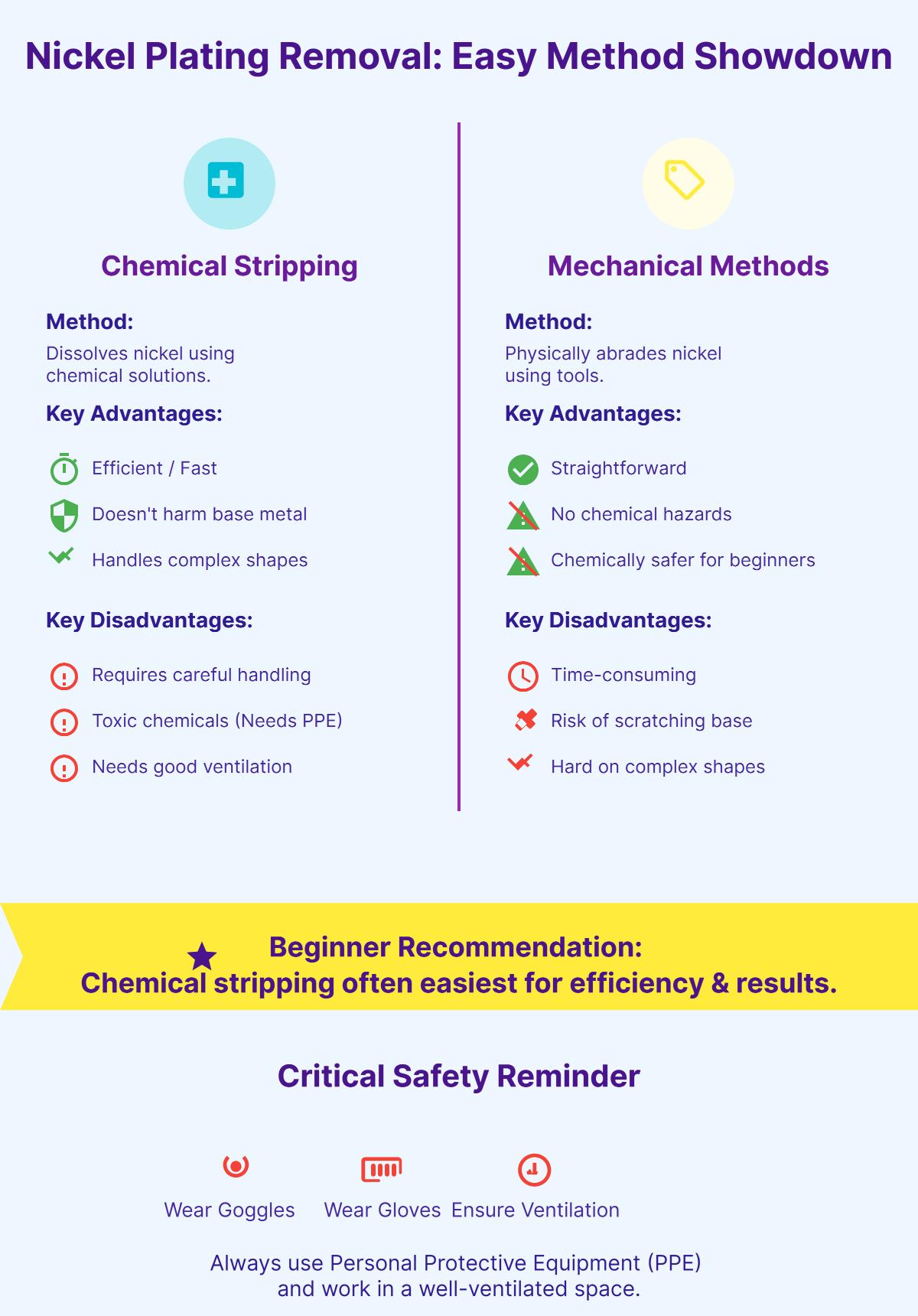

The easiest methods to remove nickel plating are chemical stripping and mechanical methods.

Chemical stripping involves using specialized solutions, such as commercial nickel strippers or household acids like vinegar (for thin layers) or hydrochloric acid. This method is efficient and doesn’t damage the base material, but requires careful handling and safety precautions due to the toxicity of the chemicals.

Mechanical methods include physically abrading the nickel layer using tools like sandpaper, grinding wheels, or abrasive pads. This approach is straightforward and doesn’t involve chemicals, making it safer for beginners. However, it can be time-consuming and may risk scratching the underlying material if not done carefully.

For most beginners, chemical stripping might be the easiest due to its efficiency and the ability to handle complex shapes without damaging the base material. Always ensure to use proper personal protective equipment and work in a well-ventilated area.

To safely remove nickel plating, you can use chemical stripping or electrolytic stripping methods. For chemical stripping, gather necessary materials like a specialized chemical stripper (e.g., Caswell’s MetalX Nickel Stripper), protective gear (gloves, goggles), and ensure proper ventilation. Apply the stripper following the manufacturer’s instructions, monitor the reaction, and remove the dissolved nickel. Neutralize any chemical residue and thoroughly clean the metal surface with water and mild detergent.

For electrolytic stripping, set up an electrolytic cell with the appropriate electrolyte solution, such as sulfuric acid. Connect the item anodically and control the current to avoid damaging the base metal. After stripping, rinse and dry the metal, inspecting for any remaining nickel.

Always prioritize safety by wearing PPE, ensuring good ventilation, and properly disposing of waste according to local regulations. This ensures an effective and safe nickel plating removal process.

Yes, you can use household items to remove nickel plating, but it requires caution. One common method is using white vinegar, which contains acetic acid that can react with the nickel plating to dissolve it. To do this, immerse the plated item in a container filled with white vinegar, ensuring it is fully covered. Allow it to soak for several hours or overnight, depending on the thickness of the plating. Periodically check the progress and use a soft brush or sponge to gently scrub the surface. Once the plating is removed, rinse the item thoroughly with water to neutralize any vinegar residue and dry it to prevent rust.

Another method involves using hydrochloric acid (found in some household cleaners), but this is more dangerous and requires proper protective equipment and good ventilation due to the strong fumes. Always follow safety precautions such as wearing gloves and goggles.

While these methods can be effective, they should be approached with care to avoid damaging the underlying material or exposing yourself to harmful chemicals.

The environmental impacts of nickel plating removal can be significant due to the chemicals and processes involved. Chemical stripping often utilizes strong acids such as hydrochloric acid or sulfuric acid. If these chemicals are not disposed of properly, they can contaminate water sources and soil, leading to environmental pollution. Additionally, the fumes and gases produced during the removal process can contribute to air pollution, potentially harming both the environment and human health.

To mitigate these impacts, it is crucial to choose safer chemical alternatives, follow proper waste disposal regulations, ensure good ventilation during the process, and use personal protective equipment (PPE). Sustainable practices, such as using electrolytic stripping methods that reduce chemical usage, can also help minimize the environmental footprint of nickel plating removal.

When removing nickel plating, beginners should be aware of several common mistakes to avoid:

By avoiding these mistakes, you can effectively and safely remove nickel plating without damaging the underlying material.

The time required to remove nickel plating varies depending on the method used and the thickness of the nickel layer. For chemical stripping, using an acidic or alkaline solution, the process can take anywhere from 20 minutes to a few hours. Electrolytic stripping, which reverses the plating process using an electric current, typically takes about an hour but may require multiple cycles for thicker layers. Mechanical methods, such as sanding or abrasive blasting, depend on the operator’s efficiency and the thickness of the nickel layer, making the duration more variable. Each method has its own advantages and considerations, so the choice of technique will influence the overall time required for nickel plating removal.