Soldering mild steel might seem like a daunting task, especially if you’re just starting out. But what if we told you that with the right guidance, you could master it with ease? Whether you’re looking to learn the best practices for a flawless solder, understand how to choose the right flux, or gather the necessary tools, you’re in the right place. This comprehensive guide will walk you through each step of the process, from preparing your materials to applying the final touches. By the end, you’ll be equipped with the knowledge and confidence to tackle any mild steel soldering project. Ready to dive in and discover the secrets to perfect soldering? Let’s get started!

When soldering mild steel, ensuring personal safety is crucial. Proper PPE is essential to protect against potential hazards.

Proper handling of soldering tools and materials reduces the risk of accidents.

Sustainability in soldering practices can help protect the environment.

Proper disposal of soldering materials is crucial for environmental protection.

Dispose of lead-containing solder waste as hazardous material per local regulations, and always clean your workspace thoroughly to remove flux residues and solder scraps.

Being mindful of environmental impacts in metalworking can contribute to a healthier planet.

Preparing the surface of mild steel is crucial for achieving a strong and reliable solder joint. Any contaminants or oxidation on the metal can prevent the solder from adhering properly, leading to weak joints.

To prepare mild steel for soldering, you will need a few essential tools:

Begin by scrubbing the mild steel with a wire brush in multiple directions to thoroughly remove any visible rust and debris.

After using the wire brush, sand the metal with fine – grit sandpaper. This step will remove any remaining oxidation and give the metal a smooth finish for the solder to adhere. Sand until the metal has a bright, silvery appearance.

Wipe the surface with a clean cloth soaked in acetone or alcohol to remove any grease or oil. When handling acetone or alcohol, ensure you are in a well – ventilated area, away from open flames or heat sources, as they are flammable. This step is essential as even small traces of grease can interfere with the soldering process.

Ensure that the surface is completely clean and free of any contaminants. The metal should appear bright and shiny, with no visible rust or grease. By following these steps, you will ensure that the mild steel is properly prepared for soldering, leading to stronger and more reliable joints.

Flux is essential in soldering, as it cleans metal surfaces by removing oxidation and impurities, which helps solder adhere properly. It also prevents re-oxidation during soldering, ensuring a strong and durable joint.

Inorganic acid fluxes are highly recommended for mild steel because they effectively remove tough oxides from the metal surface. Other types of flux, like rosin-based fluxes, are more commonly used for electronics rather than mild steel.

Silver solder is a type of solder that contains silver. Silver solder, especially those with high silver content (40% or 55%), is ideal for soldering mild steel.

Silver solder provides a strong bond, making it more effective than soft solder. It can withstand higher stress and temperature, ensuring a more durable joint in mild steel applications.

To apply silver solder, heat the mild steel with an oxy-acetylene or oxy-propane torch until it reaches 650-720°C. Apply the silver solder to the joint, allowing it to flow and bond the metal pieces together.

Various heat sources can be effectively used for soldering mild steel. Each heat source has its advantages and is suited to specific applications. This section will guide you through the use of various heat sources, focusing on the oxy – acetylene torch and the propane torch, and provide you with step – by – step instructions for their effective use.

An oxy – acetylene torch is a versatile and powerful tool ideal for soldering mild steel, particularly when using silver solder. It delivers high temperatures, making it suitable for both soldering and brazing.

Pros:

Cons:

A propane torch is a more accessible and user – friendly option for soldering mild steel, particularly for smaller projects or when less heat is required.

Pros:

Cons:

Here are some additional tips to help you achieve the best results when soldering mild steel with any heat source.

Proper positioning of the materials is crucial for effective soldering. Begin by aligning the pieces of mild steel that need to be joined. Ensure they are stable and in the correct position to avoid movement during the soldering process.

Applying the correct amount of heat is vital for successful soldering. The goal is to heat the metal to the right temperature without causing damage. Select an appropriate heat source like an oxy-acetylene or propane torch and begin heating the joint area evenly. Move the torch in a circular motion to distribute the heat uniformly. Heat the metal until it reaches a dull-red hue around 650-720°C, indicating it’s ready for soldering.

Once the metal is heated properly, it’s time to add the solder. Silver solder is recommended for mild steel due to its strength and durability.

To create a strong bond, pay careful attention to detail throughout the soldering process.

Here are some additional tips to enhance your soldering technique:

Avoid these common mistakes to ensure a successful soldering process:

Below are answers to some frequently asked questions:

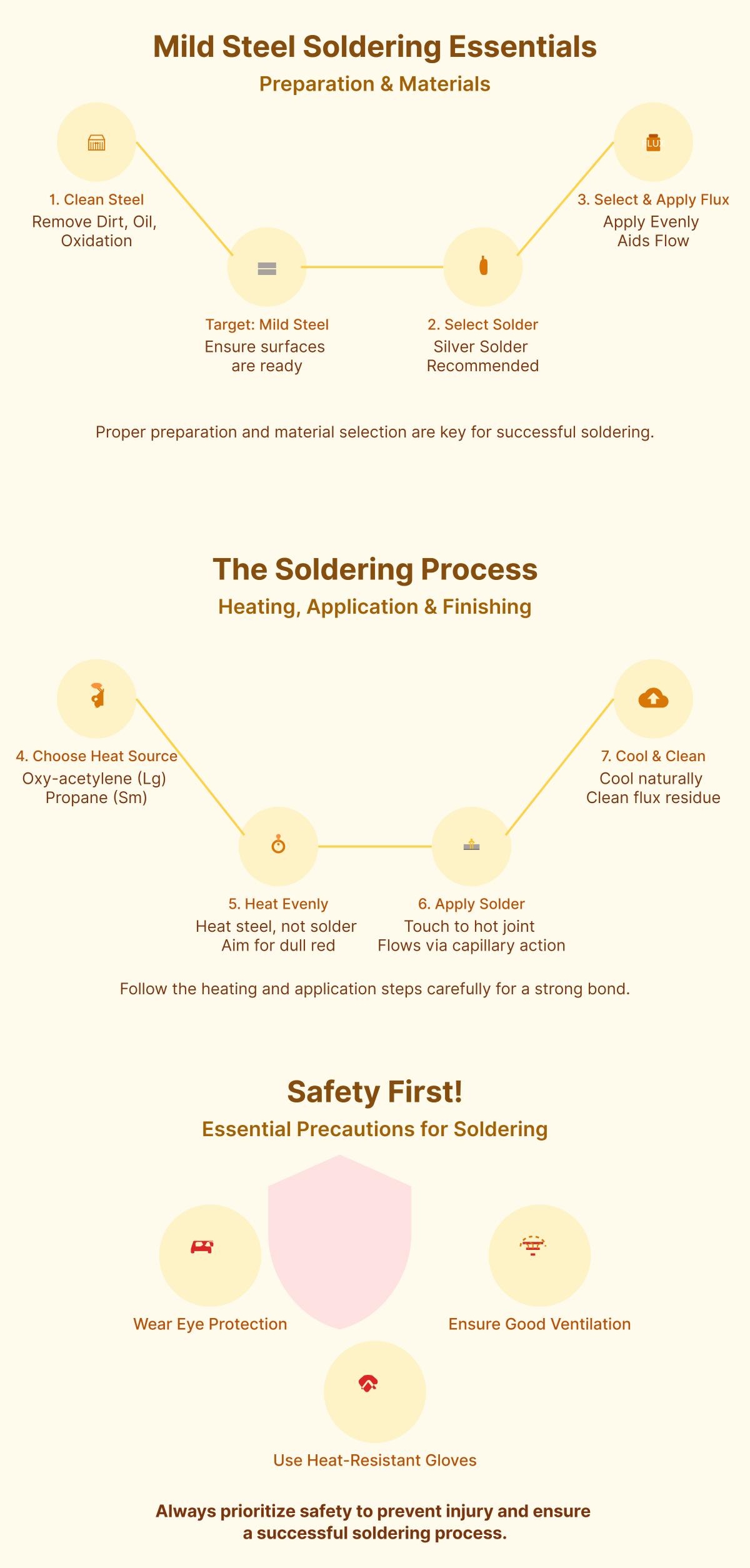

Best practices for soldering mild steel include several key steps to ensure a strong and reliable bond. Begin by thoroughly cleaning the mild steel surfaces using a wire brush or sandpaper to remove dirt, oil, and oxidation. This preparation is crucial for the solder to adhere properly.

Select the appropriate flux and solder for the job. Silver solder is highly recommended for its strength and durability, and it works well with mild steel. Apply the flux evenly to the joint areas to remove oxidation and promote solder flow.

Choose the right heat source for your project. An oxy-acetylene torch is effective for larger jobs, while a propane torch can be sufficient for smaller tasks. Heat the steel evenly until it reaches the correct temperature, indicated by a dull red color, before applying the solder.

Position the materials securely, apply heat evenly, and introduce the solder once the flux starts to melt. Allow the solder to flow into the joint through capillary action. After soldering, let the joint cool naturally to avoid thermal stress and clean off any excess flux.

Always follow safety measures, such as wearing protective gear and working in a well-ventilated area, to ensure a safe and effective soldering process. By adhering to these best practices, you can achieve strong, durable solder joints in mild steel.

When choosing the right flux for soldering mild steel, a type of low-carbon steel, you should first understand its role. Flux removes oxidation from the metal surface, prevents new oxidation during heating, and improves solder flow. There are several types of flux: inorganic acid fluxes are good at removing tough oxides but require post-soldering cleaning; rosin fluxes, common in electronics, may not be ideal but alcohol-based ones can work in some cases; water-soluble fluxes offer good performance but need extra cleaning. Key considerations include effective oxidation removal, prevention of re-oxidation, improved solder flow, and compatibility with your chosen solder, like silver solder. Also, ensure the mild steel surface is clean before applying a thin layer of flux, and apply solder right after heating the flux for a strong bond.

To effectively solder mild steel, several tools are necessary to ensure strong and reliable joints. Firstly, a soldering iron is useful for small-scale tasks, providing precise control at lower temperatures. For larger projects requiring higher heat, a soldering torch is essential, as it can reach temperatures around 600°C or higher, suitable for thicker metal parts. A soldering station with adjustable temperature controls can be versatile for maintaining consistent heat during complex tasks.

Cleaning and preparation tools are also crucial. Abrasive tools like wire brushes or sandpaper are needed to clean the steel surface, ensuring it is free of contaminants. Flux is another essential material that prevents oxidation and promotes proper adhesion of the solder. Different types of fluxes are available depending on the specific soldering task.

For the solder itself, silver solder is recommended for mild steel due to its ability to form stronger bonds at higher temperatures (around 650-720°C). Lastly, safety gear such as protective goggles and gloves is necessary to prevent injuries, and a well-lit, stable workspace is important for precision and safety.

To prepare mild steel for soldering, follow these essential steps to ensure a strong and reliable bond:

By following these steps, you ensure the mild steel is properly prepared for soldering, leading to a durable and effective joint.

When soldering mild steel, the choice between an oxy-acetylene torch and a propane torch involves considering factors like heat requirements, cost, safety, and technique.

An oxy-acetylene torch produces a higher temperature, reaching up to 5720°F (3177°C), making it suitable for tasks requiring intense heat, such as welding and cutting thick metals. It provides high precision and speed but is more expensive and requires careful handling due to acetylene’s unstable nature.

In contrast, a propane torch burns at a lower temperature, around 5112°F (2822°C) in an oxygen-propane setup. It is less costly, widely available, and safer due to its narrower flammability range. Although it releases most of its heat in the outer flame cone, making it less efficient for precision tasks, it can still be effective for soldering with the right technique.

When soldering mild steel, several common mistakes can hinder the quality of your work. Here are some key errors to avoid:

By addressing these common mistakes, you can achieve stronger, more reliable solder joints on mild steel.