Have you ever wondered how to ensure the copper you’re working with is as pure as it claims to be? Whether you’re a hobbyist, jeweler, or involved in any industry that relies on high-quality copper, knowing how to test its purity can be crucial. In this beginner-friendly guide, we’ll walk you through the essential concepts of copper purity and why it matters. You’ll discover three common and reliable methods to test copper’s purity: spectrometer analysis, conductivity measurements, and electrodeposition. Each method will be broken down into easy-to-follow steps, ensuring you gain the confidence to perform these tests yourself. Ready to dive in and become a copper testing pro? Let’s get started!

Introduction to Copper Purity

Copper Purity

Copper purity refers to the percentage of pure copper in a sample. This measure is crucial because impurities can significantly alter copper’s physical and chemical properties, impacting its performance across various applications.

Importance of Testing Copper Purity in Various Industries

Electrical Industry

Copper’s high purity ensures excellent electrical conductivity. Impurities can reduce this efficiency, leading to energy losses and inconsistent performance in electrical components and wiring.

Plumbing Systems

High purity in copper ensures consistent performance in electrical components and wiring. Additionally, pure copper has natural antimicrobial properties, which are beneficial in maintaining water quality. It also resists corrosion, prolonging the lifespan of plumbing systems.

Industrial Applications

Copper’s purity directly impacts its strength, flexibility, and usability in industrial applications. Pure copper welds more consistently and with fewer defects, making it preferable for manufacturing processes.

Investment and Environmental Impact

Copper with higher purity is more valuable in the market. Furthermore, pure copper is easier to recycle, reducing environmental impact and promoting sustainability.

Overview of Common Methods for Testing Copper Purity

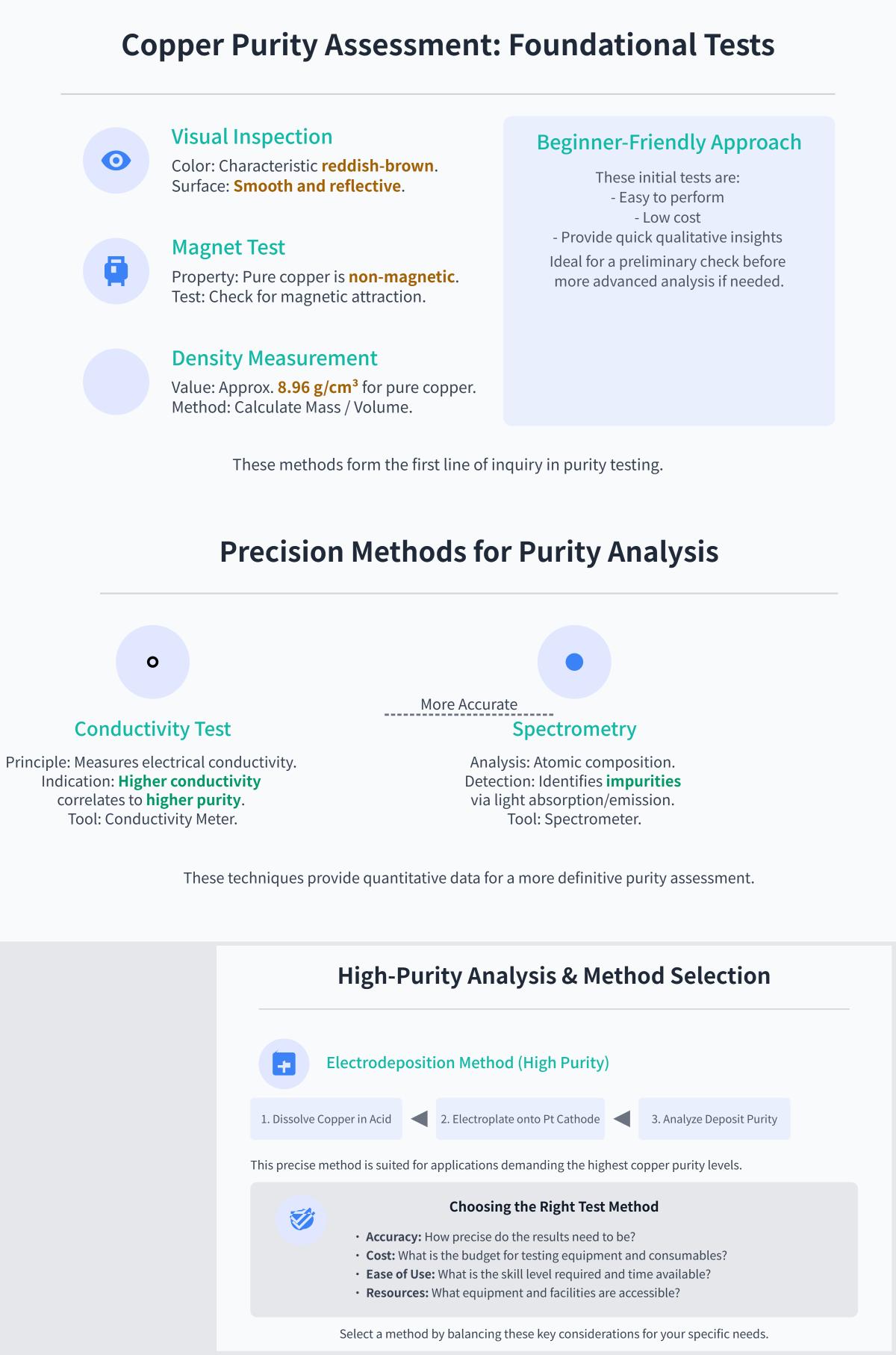

Visual Inspection

- Color: Pure copper has a distinct reddish-orange color.

- Texture: It should be smooth and uniform without any noticeable impurities.

- Patina: Over time, pure copper develops a greenish-blue patina, indicating oxidation.

Physical Properties Testing

- Density: Pure copper has a density of approximately 8.96 g/cm³.

- Electrical Conductivity: Measured in terms of specific resistivity, pure copper should have a value around 1.68 × 10⁻⁸ ohm-meters.

- Magnetism: Pure copper is non-magnetic, so it should not be attracted to a magnet.

Specialized Physical Tests

- Acoustic Testing: When struck, pure copper produces a characteristic dull sound.

- Surface Examination: Using magnification tools to check for a smooth, waxy surface.

Resistance Testing

- Multimeter Use: Measuring electrical resistance with a multimeter can help determine purity by comparing it against known values for pure copper.

Chemical Testing

- Lab Equipment: Involves using chemical reagents and lab equipment to analyze the chemical composition and detect impurities.

Laboratory Analysis

- Spectroscopy: Spectroscopy techniques offer detailed insights into copper’s purity by detecting and measuring impurities.

Basic Concepts of Copper Purity and Its Measurement

Understanding copper purity involves knowing how to measure and interpret various properties. The measurement techniques can range from simple visual inspections to complex laboratory analyses, each providing different levels of accuracy and detail. By combining several methods, one can achieve a comprehensive assessment of copper purity, ensuring its suitability for specific applications.

Overview of Testing Equipment

Introduction to Testing Equipment

Testing copper purity involves various methods, each using specific equipment. Knowing these tools is crucial for accurate results. Below, we explore some common testing equipment used to assess copper purity.

Spectrometers

Spectrometers are sophisticated instruments that measure the light absorbed or emitted by a sample to precisely identify its elements.

Types of Spectrometers

- Optical Emission Spectrometers (OES): Use an electrical arc or spark to excite the sample, causing it to emit light at characteristic wavelengths.

- X-ray Fluorescence (XRF) Spectrometers: Use X-rays to excite the atoms in a sample, leading to the emission of secondary (fluorescent) X-rays.

Conductivity Meters

Conductivity meters measure the electrical conductivity of copper, which correlates with its purity, as pure copper has high conductivity.

Types of Conductivity Meters

- Benchtop Conductivity Meters: Typically used in laboratories for precise measurements.

- Handheld Conductivity Meters: Portable and easy to use, suitable for field testing.

Electrodeposition Apparatus

Electrodeposition deposits copper ions from a solution onto a cathode, forming a layer of pure copper that can be tested for purity.

Components of Electrodeposition Apparatus

- Electrolyte Solution: Contains copper ions necessary for the deposition process.

- Cathode and Anode: Electrodes where the reduction and oxidation reactions occur.

- Power Supply: Provides the electrical current needed for the deposition.

Multimeters

Multimeters are versatile tools used to measure various electrical properties, including resistance, voltage, and current. In copper purity testing, they primarily measure resistance, as pure copper has very low resistance.

Advanced Chemical Analysis Equipment

Advanced chemical testing equipment provides more detailed and precise analysis.

Types of Chemical Analysis Equipment

- Atomic Absorption Spectroscopy (AAS): Measures the concentration of copper by analyzing the light absorbed by the sample.

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS): A highly sensitive technique that can detect trace impurities in copper samples.

Visual Inspection Tools

Visual inspection tools help identify impurities through the physical examination of the copper sample.

Common Visual Inspection Tools

- Magnifying Glasses: Enhance the visibility of surface imperfections.

- Microscopes: Provide a more detailed view of the sample’s surface at a microscopic level.

Common Methods for Testing Copper Purity

Spectrometer Analysis

A spectrometer is a sophisticated tool that analyzes copper purity by identifying impurities.

How Spectrometer Analysis Works

- Sample Preparation: Clean the copper sample to remove any surface contaminants.

- Excitation: The sample is excited using an energy source, such as an electric arc or laser, causing it to emit light.

- Detection: The emitted light is collected and passed through a diffraction grating or prism.

- Analysis: The light is split into different wavelengths, and a detector measures each wavelength’s intensity.

- Interpretation: The resulting spectrum is analyzed to identify the elements present and their concentrations.

Advantages

- High precision and accuracy.

- Ability to detect trace impurities.

Disadvantages

- Expensive equipment and operation.

- Requires skilled operators.

Conductivity Measurements

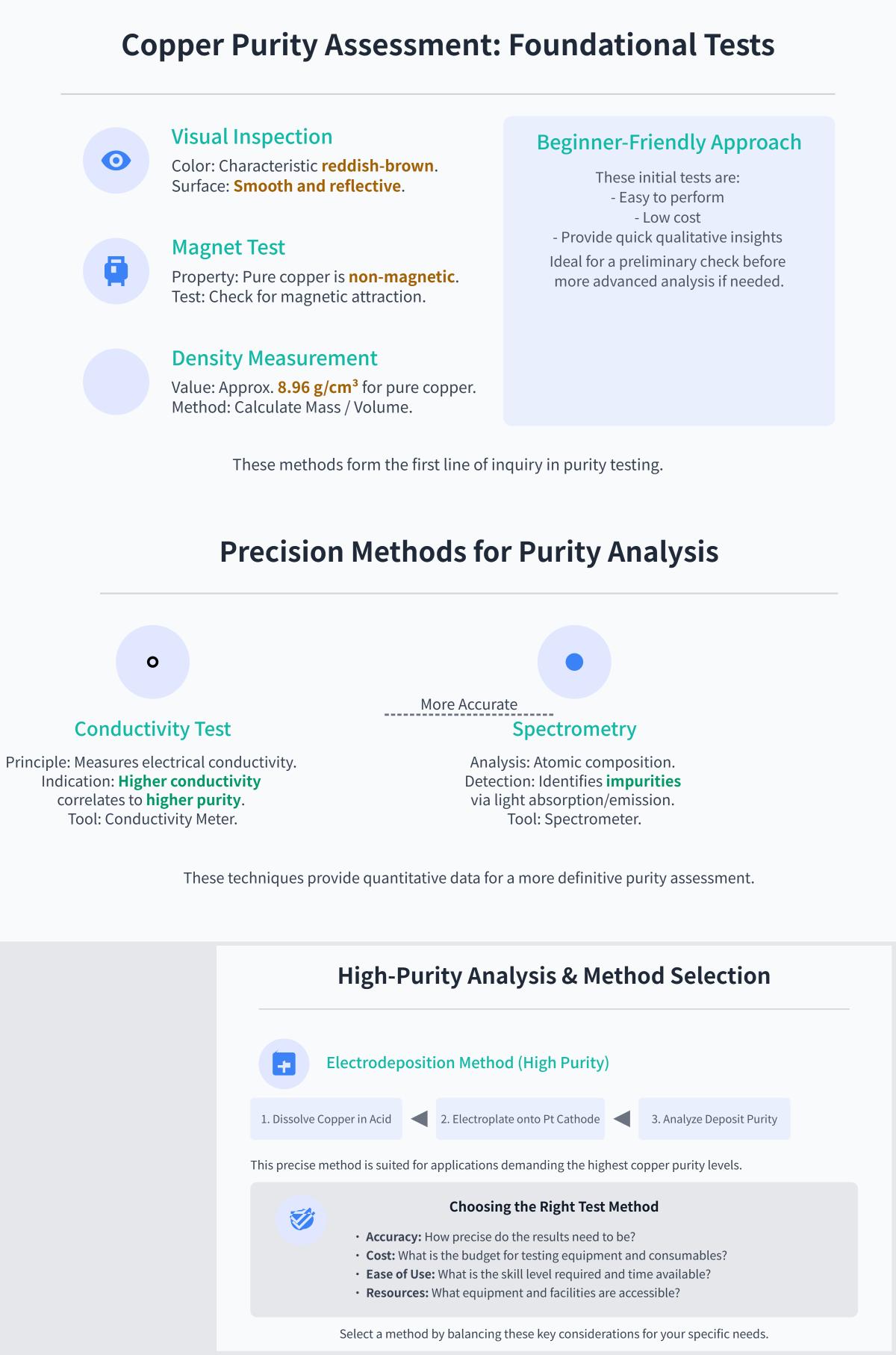

Conductivity meters measure copper’s electrical conductivity, which correlates with its purity, as pure copper has high conductivity.

How Conductivity Measurements Work

- Setup: Connect the conductivity meter to the copper sample.

- Measurement: The meter applies a small voltage and measures the resulting current.

- Calculation: The device calculates conductivity based on the current and voltage.

- Comparison: Compare the measured conductivity to the known value for pure copper (around 58 MS/m).

Advantages

- Quick and easy to perform.

- Non-destructive testing method.

Disadvantages

- Less precise than spectrometry.

- External factors like temperature can affect readings.

Electrodeposition Technique

Electrodeposition involves depositing copper from a solution onto a cathode, which can then be analyzed for purity.

How Electrodeposition Works

- Preparation: Prepare an electrolyte solution containing copper ions.

- Electrodes Setup: Place a pure copper anode and a platinum cathode in the solution.

- Power Supply: Apply a direct current to drive the deposition process.

- Deposition: Copper ions migrate to the cathode and form a layer of pure copper.

- Analysis: The copper layer is then analyzed for impurities.

Advantages

- Effective for high-purity analysis.

- Can be used for small and large samples.

Disadvantages

- Time-consuming process.

- Requires precise control of experimental conditions.

Visual Inspection

Visual inspection involves examining the physical appearance of copper to detect impurities.

How Visual Inspection Works

- Color Check: Observe the color of the copper; pure copper has a reddish-orange hue.

- Texture Examination: Inspect the texture for uniformity and smoothness.

- Patina Observation: Check for the development of a greenish-blue oxide layer over time.

Advantages

- Simple and cost-effective.

- No specialized equipment needed.

Disadvantages

- Subjective and less precise.

- Only suitable for surface impurities.

Physical Properties Tests

Physical properties tests involve measuring properties like density, magnetism, and sound to assess copper purity.

How Physical Properties Tests Work

- Density Test: Measure the sample’s volume and mass to calculate density (pure copper ~8.96 g/cm³).

- Magnetism Test: Check if the sample is attracted to a magnet (pure copper is non-magnetic).

- Sound Test: Strike the sample and listen for a dull, muted sound indicative of pure copper.

Advantages

- Easy to perform.

- Non-destructive methods.

Disadvantages

- Less precise than laboratory methods.

- Can be influenced by external factors.

Chemical Tests

Chemical tests use reagents to react with impurities in copper, indicating purity.

How Chemical Tests Work

- Salt and Vinegar Test: Rub the copper with a salt and vinegar mixture and observe the formation of a green patina.

- Flame Test: Hold the copper in a flame and observe the color (pure copper burns with a blue-green flame).

Advantages

- Inexpensive and simple.

- Can be performed at home.

Disadvantages

- Qualitative rather than quantitative.

- Limited to detecting certain impurities.

Understanding these methods allows you to effectively test copper purity, ensuring quality and performance in your projects.

Step-by-Step Guide to Using a Spectrometer

A spectrometer analyzes material composition by measuring the light spectrum that a sample emits or absorbs. It is particularly useful for determining the purity of metals like copper by identifying and quantifying the presence of impurities.

How a Spectrometer Works

Spectrometers excite atoms in a sample, causing them to emit light at specific wavelengths, which is then analyzed to determine the sample’s elemental composition. The key components of a spectrometer include a light source, a sample holder, a diffraction grating or prism, and a detector.

Step-by-Step Instructions on Testing Copper Purity with a Spectrometer

Step 1: Preparing the Sample

- Clean the Sample: Clean the copper sample with a soft cloth to remove any contaminants.

- Cut the Sample: Trim the sample to a suitable size for the spectrometer, ensuring the cut is precise to avoid contamination.

Step 2: Setting Up the Spectrometer

- Calibrate the Spectrometer: Use known standards to calibrate the spectrometer. This step is crucial for obtaining accurate readings.

- Set the Wavelength: Determine and set the appropriate wavelength for copper analysis. This ensures the spectrometer is tuned to detect the specific light emitted by copper atoms.

Step 3: Conducting the Analysis

- Place the Sample: Insert the prepared copper sample into the spectrometer’s sample chamber or position it on the stage.

- Start the Analysis: Start the analysis. The spectrometer will emit light at the set wavelength and measure the sample’s absorbance or emission spectrum.

- Collect Data: The spectrometer will record the light spectrum emitted by the sample, displaying the data as a series of peaks corresponding to different elements.

Step 4: Interpreting Results

- Identify Peaks: Look at the spectrum to find peaks that indicate copper and any impurities. Each element has a unique spectral signature.

- Quantify Elements: Use the calibration standards to quantify the concentration of copper and any detected impurities.

Tips for Accurate Measurements

- Ensure Cleanliness: Both the sample and the spectrometer components must be clean to avoid contamination.

- Regular Calibration: Calibrate the spectrometer regularly to maintain accuracy.

- Control Environmental Factors: Temperature and humidity can affect spectrometer performance. Ensure the testing environment is stable.

- Skill and Knowledge: Operating a spectrometer requires a basic understanding of spectroscopy principles. Adequate training is essential for accurate analysis.

Common Types of Spectrometers

Atomic Emission Spectrometry (AES)

- Process: Involves heating the sample to excite the atoms, which then emit light at specific wavelengths.

- Application: Useful for detecting and quantifying the presence of various elements in the sample.

X-Ray Fluorescence (XRF)

- Process: Uses X-rays to excite atoms in the sample, causing them to emit secondary X-rays.

- Application: Effective for analyzing the elemental composition of a wide range of materials, including metals.

By following these steps and tips, you can accurately determine the purity of copper using a spectrometer. This method provides a detailed analysis of the elemental composition, ensuring the copper meets the required standards for its intended applications.

Step-by-Step Guide to Using a Conductivity Meter

A conductivity meter measures the electrical conductivity of a material, which indicates its purity. For copper, higher conductivity means higher purity, making the meter an essential tool for assessing copper quality.

How a Conductivity Meter Works

Conductivity meters operate by applying a small voltage to the material and measuring the resulting current flow. The meter then calculates the conductivity based on these measurements. Pure copper has a conductivity value of approximately 58 MS/m (mega siemens per meter).

Step-by-Step Instructions on Testing Copper Purity with a Conductivity Meter

Step 1: Preparing Your Equipment

- Conductivity Meter: Ensure you have a conductivity meter suitable for metals.

- Probes or Electrodes: Use probes specifically designed for measuring metal conductivity.

- Reference Materials: Gather samples of pure copper and other known standards for calibration.

Step 2: Calibrating the Meter

- Select Calibration Standards: Choose standards with conductivity values close to pure copper.

- Ensure both the meter and standards are at room temperature.

- Perform Calibration: Immerse the probe in the calibration standard, adjust the meter to the known value, and save the settings.

Step 3: Preparing Copper Samples

- Clean the Samples: Remove any contaminants from the copper samples.

- Shape the Samples: Shape them into forms suitable for the probe or measurement technique.

Step 4: Measuring Conductivity

- Place the probe against the copper sample and record the conductivity reading displayed by the meter.

- Repeat Measurements: Take multiple readings to ensure accuracy.

Step 5: Interpreting Results

- Compare your measured conductivity to the known value for pure copper. Lower readings suggest the presence of impurities.

- Consider Influencing Factors: Temperature, sample shape, and measurement technique can affect readings.

Additional Tips for Accurate Measurements

- Regularly clean and maintain the meter and probes to ensure accurate readings.

- Use Eddy Current Techniques: Consider eddy current-based methods like SIGMATEST for high precision.

- Consistent Temperature: Conduct measurements in a temperature-controlled environment.

Step-by-Step Guide to Electrodeposition

Electrodeposition and Testing Copper Purity

Electrodeposition is especially effective for analyzing high-purity copper, providing accurate results by isolating copper from impurities through an electrochemical process. This technique is reliable for assessing copper purity levels ranging from 99.75% to 99.95%.

Step-by-Step Guide to Performing Electrodeposition

Step 1: Sample Preparation

- Dissolve the Copper Sample:

- Dissolve the copper sample in a mixture of sulfuric acid (H₂SO₄) and nitric acid (HNO₃). Stir the solution thoroughly using a magnetic stirrer to ensure complete dissolution of the copper, and prepare the solution to be homogeneous and free from undissolved particles.

Step 2: Electrode Setup

- Select and Connect the Electrodes:

- Select a platinum cathode and an inert anode such as platinum or graphite. Connect the cathode to the negative terminal and the anode to the positive terminal of a power source.

- Position the Electrodes:

- Place the electrodes in the electrolyte solution, ensuring they do not touch each other. The distance between the electrodes should be optimized for uniform deposition.

Step 3: Electrodeposition Process

- Apply Electric Current:

- Apply the electric current at the appropriate voltage and current settings. Monitor the process until the solution becomes clear, indicating most copper ions have been plated. This may take several hours.

Step 4: Post-Deposition Analysis

- Weigh and Calculate Copper Content:

- Carefully remove, rinse, dry, and weigh the cathode to determine the mass of the deposited copper. Calculate the copper content by comparing the initial and final weights of the cathode. For further accuracy, measure any remaining copper ions in the solution using atomic absorption spectroscopy (AAS).

Tips for Effective Electrodeposition

- Maintain Cleanliness: Ensure all equipment, including the electrodes and containers, are thoroughly cleaned to prevent contamination.

- Control Temperature: Conduct the process at a consistent temperature to avoid fluctuations that could affect deposition rates.

- Use Quality Standards: Follow ASTM E53 guidelines and ensure your laboratory meets quality standards such as ISO 9001:2015 and ISO/IEC 17025:2017 for reliable results.

Comparison of Different Testing Methods

Spectrometer Analysis

Spectrometers offer a highly accurate and detailed analysis by identifying and quantifying specific impurities within copper samples.

Advantages:

- High Precision: Provides highly accurate and detailed analysis.

- Comprehensive Data: Offers a thorough examination of the sample’s elemental composition.

- Detection of Trace Impurities: Capable of detecting even minute amounts of impurities.

Disadvantages:

- Expensive Equipment: High initial investment and maintenance costs.

- Skilled Operation Required: Requires specialized training and expertise.

Best Suited For:

- Industrial and research applications requiring precision and detailed analysis.

- Situations needing detection of trace impurities to ensure high purity levels.

Conductivity Meter Analysis

Advantages:

- Quick and Easy: Conductivity measurements are straightforward, providing rapid, non-destructive results that allow for further testing or use.

- Non-Destructive: Does not damage the sample.

- Cost-Effective: Generally less expensive than spectrometers and requires less specialized training.

Disadvantages:

- Less Precise: Less precise than spectrometer analysis, particularly for detecting low levels of impurities.

- Affected by External Factors: Accuracy can be influenced by temperature and sample shape.

Best Suited For:

- Field testing and quick assessments.

- Applications where moderate precision is acceptable, such as routine quality checks.

Electrodeposition Technique

Advantages:

- High Purity Analysis: Effective for analyzing high-purity copper.

- Versatile: Suitable for both small and large samples.

- Detailed Examination: By isolating copper from impurities through deposition, this method allows for a thorough examination of the copper layer.

Disadvantages:

- Time-Consuming: Requires several hours to complete the deposition.

- Complex Setup: Needs precise control of conditions, including temperature and electrical current.

Best Suited For:

- Laboratory settings requiring detailed and accurate purity analysis.

- Applications involving the production and certification of high-purity copper.

Factors to Consider When Choosing a Method

When selecting a method for testing copper purity, consider the following factors:

- Accuracy Requirements: For high precision and detailed impurity analysis, spectrometers are the best choice. For quick assessments, conductivity meters are more suitable.

- Cost: Consider the budget for both purchasing the equipment and ongoing maintenance costs. Conductivity meters are typically more affordable than spectrometers.

- Ease of Use: Evaluate the level of expertise required. Conductivity meters are easier to use, while spectrometers and electrodeposition setups require specialized training.

- Application Context: Match the testing method to the specific needs of the application. For industrial quality control, spectrometers and electrodeposition might be preferred, while conductivity meters are ideal for routine checks and field testing.

Economic Benefits and Efficiency

Accurate testing of copper purity can lead to significant economic benefits by ensuring the quality and performance of copper products. Choosing the right testing method can enhance efficiency, reduce waste, and improve the overall reliability of the supply chain.

Visual Inspection

Visual inspection is a straightforward and cost-effective method to initially assess copper purity. Check for the following:

- Color: Pure copper typically exhibits a reddish-orange color.

- Surface Uniformity: The surface should be smooth and consistent.

- Patina: A greenish-blue patina may form over time, indicating oxidation.

Physical Properties Tests

These tests provide a practical approach to assessing copper purity by examining its physical characteristics:

- Density and Magnetism: Measure the density using water displacement (pure copper has a density of about 8.96 g/cm³) and check for magnetism (copper is non-magnetic and should not be attracted to a magnet).

- Acoustic Testing: Strike the copper to listen for a deep, ringing sound.

Conductivity Tests

Conductivity tests are efficient for determining copper purity through its electrical properties:

- Electrical Conductivity: Use a multimeter to measure the electrical conductivity; pure copper has high conductivity with low resistance.

- Temperature Effects: Since conductivity varies with temperature, conduct tests in controlled conditions.

Chemical Tests

Chemical tests involve using reagents to identify impurities:

- Nitric Acid Test: A blue-green color signifies pure copper; however, handle all chemicals with caution.

- Advanced Spectroscopy: Techniques like XRF and OES provide precise elemental composition.

Laboratory Testing

For high-accuracy results, especially in critical applications, advanced laboratory testing is recommended:

- Spectroscopy: Provides detailed analysis of copper’s elemental composition.

- Accredited Laboratories: Consider using ISO 17025 accredited labs for reliable and precise results.

Practical Tips

- Combine Multiple Methods: Using several testing methods together provides a more comprehensive assessment.

- Safety First: Always follow safety protocols, especially when handling chemicals.

- Balance Practicality and Precision: Select testing methods that balance the needed accuracy with cost-effectiveness.

By applying these guidelines, you can effectively test and ensure the purity of copper, enhancing its performance and reliability in various applications.

Frequently Asked Questions

Below are answers to some frequently asked questions:

How do I test copper for purity?

To test copper for purity, you can use several methods ranging from simple to advanced. For a beginner, visual inspection is the easiest starting point. Pure copper has a reddish-brown color and a smooth, reflective surface. Physical tests include using a magnet (pure copper is non-magnetic) and measuring its density (pure copper has a density of about 8.96 g/cm³).

For more accurate results, you can use conductivity measurements. A conductivity meter will measure the electrical conductivity of copper, where higher conductivity indicates higher purity. Additionally, you can use a spectrometer, which analyzes the atomic composition and detects impurities by measuring light absorption or emission.

Lastly, for high-purity copper, the electrodeposition method can be used. This involves dissolving the copper in acid and then electroplating it onto a platinum cathode to analyze its purity. Each method varies in accuracy, cost, and ease of use, so choose based on your needs and available resources.

What methods can I use to check copper purity?

To check copper purity, there are several methods available, each suited to different levels of accuracy and application needs. For beginners, the most accessible methods include visual inspection and basic physical tests. Visual inspection involves checking the color and texture of copper, while physical tests like measuring density and checking for magnetism can help identify pure copper, as it is non-magnetic and has a density of approximately 8.96 g/cm³.

For more precise measurements, conductivity meters and spectrometers are used. Conductivity meters measure the electrical conductivity of copper, which correlates directly with its purity since pure copper has high conductivity. Spectrometers analyze the atomic emission spectrum to detect impurities, providing detailed compositional information.

Another advanced method is electrodeposition, which involves dissolving copper in an acid solution and then using electricity to deposit it onto a platinum cathode, allowing for precise purity measurement, especially for high-purity copper samples.

Choosing the appropriate method depends on the required accuracy and available resources. For quick checks, visual inspections and conductivity measurements are sufficient, while laboratory tests like spectroscopy or electrodeposition offer more precise results.

What is the most accurate method for testing copper purity?

The most accurate method for testing copper purity is advanced spectroscopic methods. Techniques such as X-Ray Fluorescence (XRF) Spectrometry, Optical Emission Spectrometry (OES), and Inductively Coupled Plasma Mass Spectrometry (ICP-MS) are highly precise. These methods provide detailed chemical compositions and can detect even trace amounts of impurities. They are non-destructive and offer high sensitivity, making them ideal for critical applications requiring exact measurements. While these techniques are more complex and costly, their accuracy and reliability are unmatched compared to simpler methods like visual inspection or conductivity measurement.

How much does it cost to test copper purity?

The cost to test copper purity varies depending on the method used. Common laboratory techniques include Electrolysis, Optical Emission Spectroscopy (OES), and Inductively Coupled Plasma (ICP) or Atomic Absorption Spectroscopy (AAS).

- Electrolysis Method: Approximately $800 for a standard analysis.

- OES: Ranges from $300 for a single element analysis to $1,200 for grade confirmation.

- ICP/AAS: Around $500 for a single element, with additional elements costing $250 each.

- Colorimetric Assay Kits: Generally less expensive but suited for dissolved copper in solutions rather than solid copper purity.

DIY kits, while cheaper, are not suitable for testing solid copper purity and are best for simple applications like dissolved copper in water. For accurate results, laboratory testing is recommended.

Can I test copper purity at home?

Yes, you can test copper purity at home using several simple techniques. While these methods may not be as precise as professional tests, they can give you a good indication of copper purity.

- Visual Inspection: Pure copper has a reddish-orange color and a smooth, uniform texture. Compare your sample to known pure copper.

- Density Test: Measure the sample’s weight and volume to calculate its density. Pure copper has a density of approximately 8.92 g/cm³.

- Magnet Test: Pure copper is non-magnetic. If a magnet does not attract your sample, it is likely pure.

- Acoustic Test: Pure copper produces a deep, resonant sound when struck.

- Conductivity Test: Use a multimeter to measure electrical resistance. Pure copper has low resistance.

While these methods can help assess copper purity, for more accurate results, consider professional testing with specialized equipment like spectrometers or conductivity meters.