Ever found yourself grappling with a bent piece of metal, wondering how to straighten it without causing further damage? Whether you’re a seasoned metalworker or an enthusiastic DIYer, mastering the art of unbending metal is a crucial skill. In this article, we delve into the most effective methods and tools to restore metal to its original form. From the trusty hammer and dolly method to the precise technique of flame straightening, you’ll discover step-by-step instructions tailored for various types of metal. We’ll also highlight essential safety precautions and recommend the best tools for the job. Ready to transform that twisted metal? Let’s get started on your journey to becoming a metal-straightening expert!

Introduction to Metal Straightening

Importance of Choosing the Right Method

Metal straightening is essential in industries like automotive repair, construction, and manufacturing. Choosing the right method for straightening metal is crucial to ensure the integrity and precision of the components being worked on. The choice of method depends on factors such as the type of metal, the extent of deformation, and the specific requirements of the project. Using an inappropriate technique can lead to further damage or even compromise the structural properties of the metal.

Overview of Required Tools and Safety Precautions

Effective metal straightening requires a range of specialized tools and adherence to stringent safety protocols. Tools can range from simple hand tools to advanced machinery, each suited to different metals and deformation scenarios.

Essential Tools for Metal Straightening

- Hydraulic Presses and Cylinders: Used for hydraulic straightening, these tools apply controlled force gradually to shape heavy or large metal components.

- Oxy-Acetylene Torches and Multi-Nozzle Torches: Crucial for heat straightening, these tools use controlled heating and cooling to manipulate the metal’s shape.

- Hammer and Dolly Sets: Traditional tools used in manual straightening, particularly effective for small dents and localized distortions.

- I-Beams and Bottle Jacks: Utilized for mechanical pressing, especially for long or heavy metal sections that require even pressure distribution.

Safety Precautions

Safety is paramount during the metal straightening process to prevent injuries and ensure a safe working environment. Key safety measures include:

- Always wear appropriate PPE, such as gloves, safety goggles, and protective clothing, to protect against metal shards, heat, and other hazards.

- Ensure tools are used correctly and maintained regularly to avoid accidents caused by tool failure.

- Adequate ventilation is necessary, especially when using heat or working with fumes, to prevent respiratory issues.

- Carefully control the temperature when using heat straightening methods to prevent overheating and damaging the metal.

- Use proper lifting techniques and ergonomic practices to reduce the risk of musculoskeletal injuries.

By understanding the importance of selecting the right method and adhering to safety precautions, professionals can effectively restore deformed metal components to their original or desired shapes while maintaining material integrity and safety.

Common Methods to Unbend Metal

Hydraulic Straightening

Hydraulic straightening uses hydraulic presses or cylinders to apply controlled force on deformed metal parts. This method is ideal for straightening large and heavy components, such as those found in industrial machinery and automotive parts. The hydraulic system allows for precise control over the force applied, ensuring the metal is reshaped without causing further damage.

Use Case

- Heavy machinery parts

- Automotive components

- Large metal structures

Heat Straightening

Heat straightening involves applying heat to the deformed area of the metal, making it more malleable. Tools like oxy-acetylene flames or heat guns are used to carefully heat the metal. Once the metal reaches the desired temperature, it can be reshaped with minimal force.

Use Case

- Delicate or intricate parts

- Situations where mechanical force might cause damage

Hammer and Dolly Method

The hammer and dolly method is a traditional technique for smaller, precision tasks. A hammer applies force to the deformed area while a dolly (a shaped metal tool) supports the metal from behind. This method is widely used in automotive repair for bodywork and restoring small metal pieces.

Use Case

- Automotive bodywork

- Small metal pieces

- Precision tasks

Flame Straightening

Flame straightening focuses on a more localized application of heat. It is commonly used for shrinking metal panels in automotive repair. The process involves heating the metal to a “cherry red” color, causing it to expand. Rapid cooling with a wet rag then shrinks the metal, effectively pulling it inward.

Use Case

- Mild steel, such as car body panels

- Situations requiring localized heating

Press with Blocks or I-Beam and Bottle Jack

This method is suitable for larger metal components that require significant force to straighten. It involves using a press with blocks or an I-beam combined with a bottle jack to apply controlled pressure. The setup ensures even distribution of force, making it effective for heavy and long metal sections.

Use Case

- Large metal components

- Situations needing high force

Paintless Dent Repair (PDR)

PDR uses specialized tools to access the backside of a damaged panel and push out dents without damaging the paint. This method is particularly useful for small, symmetrical dents, such as those caused by hail, and is essential for maintaining the original finish of vehicles.

Use Case

- Small, symmetrical dents

- Maintaining original vehicle finish

Hot Glue Dent Pulling

Hot glue dent pulling involves using hot-melt glue to attach a tool to the dent. The tool is then pulled to remove the dent, and the adhesive is subsequently removed using heat or solvent. This method is effective for small dents and is a recent development in PDR techniques.

Use Case

- Small dents

- Situations requiring minimal paint damage

Tools and Safety Considerations

Key Tools

- Adjustable wrench

- Vise

- Hammer and dolly

- English wheel

- Glue pulling systems

Safety Precautions

- Always wear appropriate PPE, including safety goggles, gloves, earplugs, and a hard hat.

- Ensure proper machine maintenance and adhere to safety guidelines to avoid hazards such as pinch points and unexpected metal movements.

When selecting a method to unbend metal, consider the metal’s properties, such as ductility, malleability, and tensile strength. Ductile metals like copper and aluminum can handle significant deformation, while harder metals may require more forceful techniques like hot mechanical straightening.

Step-by-Step Guide for Hammer and Dolly Method

What is a Hammer and Dolly?

A hammer and dolly are essential tools used in metalworking, particularly in the process of unbending and shaping metal. The hammer, typically a ball-peen or cross-peen hammer, is used to apply force to the metal, while the dolly acts as a supportive anvil behind the metal. Dollies come in various shapes—flat, round, and curved—allowing for precise manipulation of the metal to achieve the desired shape.

Step-by-Step Instructions for Using a Hammer and Dolly

1. Prepare the Work Area

- Ensure your workspace is clean and stable to avoid accidents.

- Securely position a vise on a sturdy surface to hold the metal piece during the process.

2. Secure the Metal Piece

- Place the metal piece in the vise, making sure it is held firmly but not overly tightened, as this could damage the metal.

3. Assess the Bend

- Carefully inspect the bend to determine the pressure points and understand the direction in which the metal needs to be unbent.

4. Apply Force with Hammer and Dolly

- Position the dolly on the inside of the bend to provide support.

- Gently tap the metal with the hammer on the outside of the bend. Start with light taps to begin unbending the metal.

- Gradually increase the force as needed, ensuring not to apply excessive force to avoid causing deformation or cracking.

5. Refine the Shape

- Continue tapping and adjusting the metal piece until it reaches the desired shape.

- Utilize different dolly shapes as needed to achieve specific curves or flatness.

6. Check and Adjust

- Regularly check the metal shape by taking it out of the vise.

- Make any necessary adjustments to ensure the metal piece conforms to the required dimensions and shape.

7. Final Check

- When you’re happy with the shape, take the metal out of the vise and inspect it closely for any imperfections.

- Perform minor adjustments as needed to finalize the shape.

Tips for Effective Hammering

Understand Metal Properties

- Know the metal’s flexibility, softness, and strength. This knowledge helps in choosing the appropriate force and technique for unbending.

Perform Trial Runs

- Practice on scrap metal pieces to refine your technique and avoid damaging the actual workpiece.

Use Precision Tools

- Ensure you use high-quality tools to maintain precision and control during the unbending process.

Troubleshooting Common Issues

Metal Cracking

- If the metal starts to crack, reduce the force applied and ensure you are using a suitable dolly shape to support the area being worked on.

Uneven Surface

- If the surface becomes uneven, switch to a different dolly shape to better match the contour of the metal and distribute the force more evenly.

Difficulty in Unbending

- If hammering isn’t working, check the pressure points and adjust your technique. Sometimes applying heat can make the metal more malleable, aiding in the unbending process.

By following these steps and tips, you can effectively use the hammer and dolly method to unbend and shape metal with precision and control.

Using Heat Safely for Metal Straightening

Introduction to Flame Straightening

Flame straightening is a precise method for correcting metal deformations through controlled heating and cooling. This technique is particularly useful for in-place repairs and is favored for its ability to preserve the structural integrity of the metal.

Detailed Process of Flame Straightening

1. Preparation and Safety Measures

- Personal Protective Equipment (PPE): Always wear appropriate PPE, such as heat-resistant gloves, safety goggles, and protective clothing, to shield yourself from heat and metal splashes, and ensure your workspace is well-ventilated with a stable surface.

- Tool Inspection: Inspect your oxy-acetylene torch and other equipment for defects or malfunctions before starting. Ensure all connections are secure and the torch is functioning correctly.

2. Heating the Metal

- Flame Setting: Adjust the oxy-acetylene flame to achieve the appropriate temperature for the metal you are working with. For mild steel, the ideal temperature is between 600–650 °C, which corresponds to a dark red glow.

- Pattern Application: Apply heat in a specific pattern to the deformed area. This pattern should create a thermal gradient that will allow the metal to expand and contract in a controlled manner. Common patterns include triangular or line heating.

3. Reshaping the Metal

- Passive Restraints: Use passive restraints such as clamps or blocks to hold the cooler parts of the metal in place. These restraints help guide the reshaping process by preventing unwanted movement.

- Controlled Heating: Heat the targeted area evenly. The cooler, restrained sections will guide the heated metal to deform and reshape as intended.

4. Cooling the Metal

- Gradual Cooling: Allow the metal to cool gradually to avoid thermal shock, which can cause cracking or other damage. In some cases, controlled cooling can be achieved using air or water.

- Inspection and Adjustment: After cooling, inspect the metal for any remaining deformations. If necessary, repeat the heating and cooling process in smaller increments to achieve the desired shape.

Understanding Hot Mechanical Straightening

Hot mechanical straightening uses heat and mechanical force to reshape metal. However, it is generally less predictable and can lead to material degradation.

Comparison to Flame Straightening

- Predictability: Flame straightening is more predictable due to the controlled application of heat and absence of external mechanical forces.

- Material Integrity: Hot mechanical straightening can compromise the structural integrity of the metal, making it unsuitable for load-bearing elements. In contrast, flame straightening preserves material properties.

Safety Measures When Using Heat

Temperature Control

- Monitoring Tools: Use infrared thermometers or temperature crayons to monitor the metal’s temperature accurately during the heating process. Avoid overheating to prevent altering the metal’s properties.

- Consistent Application: Ensure consistent and even heating to prevent localized overheating, which can lead to warping or weakening of the metal.

Protective Equipment

- Heat Shields: Employ heat shields or barriers to protect surrounding areas and materials from heat exposure.

- Ventilation: Maintain proper ventilation to dissipate fumes and gases generated during heating.

Troubleshooting Common Issues

Overheating

- Symptoms: Discoloration, warping, or excessive softening of the metal.

- Solutions: Reduce flame intensity and allow the metal to cool before reapplying heat. Use temperature monitoring tools to maintain control.

Uneven Reshaping

- Symptoms: Irregular bends or unintended deformation.

- Solutions: Reassess the heating pattern and ensure passive restraints are correctly positioned. Apply heat more evenly and adjust the cooling process.

Leveraging Simple Tools for Small Jobs

Introduction to Using a Vise for Metal Straightening

Straightening small metal pieces is easy and effective when using a vise. This tool provides a stable and secure grip on the metal, allowing you to apply controlled force to unbend it.

Steps for Using a Vise and Hammer

- Secure the Metal: Clamp the bent metal piece in the vise tightly, but not too tightly to avoid damage.

- Assess the Bend: Examine the extent and direction of the bend to determine the best approach for straightening.

- Apply Force with a Hammer: Use a hammer to gently tap the bent area, gradually increasing the force as needed. Aim to apply even pressure to avoid creating new bends or deformities.

- Check Progress: Periodically release the metal from the vise to check the progress and make adjustments as necessary.

How to Use a Pipe as a Form for Bending

A pipe can serve as an excellent form for bending or unbending long, thin pieces of metal. This method leverages the pipe’s rigidity to apply consistent force along the length of the metal.

Steps for Using a Pipe

- Select the Right Pipe: Choose a pipe with a diameter that matches the curvature you need for the metal.

- Align and Apply Leverage: Align the bent metal piece along the pipe and use your hands or a wrench to apply leverage, gradually straightening it by bending around the pipe.

- Check Alignment: Frequently check the alignment to ensure the metal is straightening as intended.

Combining I-Beam and Bottle Jack for Effective Unbending

For larger or more stubborn bends, combining an I-beam with a bottle jack can provide the necessary force to straighten the metal. This setup distributes pressure evenly, making it suitable for heavy-duty tasks.

Steps for Using an I-Beam and Bottle Jack

- Set Up the I-Beam: Place the I-beam on a stable surface that can support the necessary weight and force.

- Place the Metal: Lay the bent metal piece on the I-beam, aligning the bent area with the bottle jack.

- Position the Bottle Jack: Place the bottle jack beneath the bend, ensuring it is centered and stable.

- Apply Pressure: Slowly pump the bottle jack to apply upward pressure, gradually straightening the metal. Monitor the progress to prevent over-correction.

- Release and Check: Release the pressure and check the alignment of the metal. Repeat the process if necessary until the desired straightness is achieved.

Safety Considerations

- Personal Protective Equipment (PPE): Always wear gloves, safety goggles, and protective clothing to protect against metal shards and accidental impacts.

- Workspace Organization: Keep your workspace clean and free of clutter to prevent accidents.

- Tool Familiarity: Ensure you are familiar with the operation of all tools and equipment to avoid misuse.

- Proper Lifting Techniques: Use proper lifting techniques to avoid back injuries, especially with heavy or awkward metal pieces.

Advanced Tools for Metal Straightening

Introduction to Advanced Tools

Advanced tools are crucial for precisely and efficiently straightening metals, especially those with complex shapes and high-strength materials. These tools offer enhanced control and capabilities compared to basic methods, making them suitable for industrial and specialized applications.

Hydraulic Straightening

Hydraulic straightening involves using hydraulic presses or cylinders to apply controlled force to deformed metal parts. This method is highly precise and suitable for various types of steel and other metals.

Method

- Setup: Place the metal component inside the hydraulic press.

- Force Application: Gradually apply pressure using the hydraulic cylinder, ensuring controlled and even force distribution.

- Monitoring: Continuously monitor the process to prevent over-stressing the metal.

Advantages

- High precision and control.

- Suitable for complex shapes and heavy components.

- Minimizes risk of further deformation.

Use Cases

- Industrial machinery parts.

- Automotive components.

- Large metal structures.

Flame Straightening

Flame straightening uses an oxy-acetylene torch to heat specific areas of the metal, causing expansion and subsequent contraction upon cooling. This method allows for targeted corrections and is effective for both small-scale and large-scale applications.

Method

- Heating: Use an oxy-acetylene torch to heat the deformed area.

- Cooling: Allow the metal to cool naturally or use a wet rag to speed up the process.

- Reassessment: Check the straightened area and repeat if necessary.

Advantages

- Precise, targeted heating.

- Suitable for various sizes of metal components.

- Flexible for different applications.

Caution

- Avoid overheating to prevent damage to the metal.

- Ensure even heating to avoid creating new distortions.

Use Cases

- Automotive bodywork.

- Industrial repairs.

- Large-scale metal straightening.

Hammer and Dolly Method

The hammer and dolly method is a traditional technique used for smaller, precision tasks such as automotive bodywork. This method uses a hammer to tap the metal while a dolly supports it from the opposite side.

Method

- Preparation: Secure the metal piece and identify the deformed area.

- Hammering: Use a hammer to gently tap the metal while holding a dolly on the opposite side for support.

- Adjustment: Continue tapping and adjusting until the desired shape is achieved.

Advantages

- Ideal for small, precise tasks.

- Versatile with various shapes and sizes of hammers and dollies available.

- Cost-effective for small-scale repairs.

Use Cases

- Automotive repair shops.

- Small metalworking projects.

- Dents and minor bends.

Roller Straightening

Roller straightening involves passing the metal through a series of rollers that alternately stretch and compress its surfaces, effectively straightening the material. This technique is especially effective for high-strength steels and other advanced materials.

Method

- Setup: Adjust the rollers to the required settings based on the metal’s properties.

- Processing: Pass the metal through the rollers, ensuring even pressure is applied.

- Inspection: Check the straightened metal for uniformity and repeat if necessary.

Use Cases

- Straightening advanced high-strength steels.

- Industrial applications requiring high precision.

- Continuous processing lines.

Advanced Materials Straightening

Straightening advanced materials such as advanced high-strength steels (AHSS) requires specialized techniques and equipment due to their higher tensile strength and unique properties.

Challenges

- Higher tensile strength requires more force.

- Risk of compromising material integrity if not handled correctly.

Solutions

- Use specialized straightening equipment designed for AHSS.

- Ensure the equipment has adequate motor power and torque capability.

- Conduct thorough material analysis to choose the appropriate method.

Considerations

- Machine design must accommodate the material’s properties.

- Experienced operators are essential for effective straightening.

Key Considerations for Effective Metal Straightening

Material Analysis

Understanding the material’s properties, such as ductility, malleability, and tensile strength, is crucial for selecting the appropriate straightening method.

Machine Design

The design of the straightening equipment must match the material’s requirements, particularly for advanced materials.

Safety and Precision

Ensuring safety during the straightening process and achieving precise results are paramount. Avoiding overheating and maintaining control over the force applied are essential for successful metal straightening.

Selecting the Right Tools Based on Metal Type

To choose the right tools for unbending metal, it’s important to understand the specific properties of the metal. These properties include ductility, malleability, tensile strength, and thermal conductivity, which influence the choice of tools and techniques.

Ductility and Malleability

Ductile metals, such as copper and aluminum, can be stretched or deformed significantly without breaking. These metals, along with malleable metals like gold and silver, can be hammered or pressed into various shapes without cracking. This makes them suitable for precision tools like hammers and dollies.

Tensile Strength

Tensile strength measures how much stress a metal can endure while being stretched before breaking. Metals with high tensile strength, like stainless steel, require robust tools and techniques to unbend effectively.

Thermal Conductivity

Thermal conductivity determines how quickly a metal can absorb and transfer heat. Metals with high thermal conductivity, such as copper, respond well to heat-based straightening methods.

Tool Selection Guide for Different Types of Metals

Selecting the right tools based on the type of metal is crucial for effective unbending without causing damage. Here is a guide to choosing the appropriate tools for various metals:

Ductile Metals (Copper, Aluminum)

- Recommended Tools and Techniques: For ductile metals, tools such as hammers, dollies, and English wheels are highly effective. Cold forming techniques can be employed, and the application of heat can enhance malleability for easier reshaping.

- Safety Considerations: Always wear protective gear, including safety goggles and gloves, to prevent injuries from flying debris or sparks.

Harder Metals (Stainless Steel, Hardened Steels)

- Recommended Tools and Techniques: Harder metals require more robust techniques. Hot mechanical straightening or coining with tools like oxy-acetylene or MAPP gas torches can make the metal more malleable. Specialized bending machines or a vise with a hammer and dolly setup can also be effective for cold forming.

- Temperature Control: Use a non-contact infrared thermometer to monitor the temperature to avoid overheating, which can cause structural damage to the metal.

Sheet Metals

- Recommended Tools and Techniques: For sheet metal parts, precision tools like the English wheel and glue pulling systems are effective. Smaller adjustments can be made using a vise and hammer. CAD software can be utilized to virtually reverse bends and create flat sheet metal parts.

- Accuracy and Safety: Achieve accurate dimensions with a ruler or caliper. Ensure safety by maintaining a clean workspace and following proper lifting techniques to avoid injuries.

Key Considerations for Tool Selection

Metal Properties

Understanding the specific properties of the metal is essential as they dictate the most effective unbending method. For example, ductile metals may require different tools compared to harder metals.

Safety Precautions

Always prioritize safety by using appropriate personal protective equipment (PPE) and ensuring the work area is safe and well-maintained. This includes wearing gloves, safety goggles, and protective clothing.

Precision and Accuracy

Use tools that allow for precise adjustments to avoid overworking the metal, which can lead to damage or fractures. High-quality tools ensure better control and accuracy during the unbending process.

By understanding the properties of the metal and selecting the appropriate tools and techniques, professionals can effectively unbend and reshape metals while maintaining their structural integrity and safety.

Safety Best Practices During Unbending

Personal Protective Equipment (PPE)

It is crucial to wear appropriate personal protective equipment (PPE) to ensure safety during metal unbending operations.

Essential Gear

- Safety Goggles: Protect your eyes from metal shards and sparks.

- Gloves: Safeguard your hands from cuts and heat.

- Earplugs: Shield your hearing from loud noises generated during metalwork.

- Hard Hat: Protect your head from falling objects and debris.

Proper Use

- Correct Fit: Ensure that PPE fits properly to maximize protection.

- Regular Checks: Inspect PPE regularly for wear and tear, and replace damaged gear promptly.

Machine Safety and Maintenance

Proper machine safety and maintenance are vital to prevent accidents and ensure efficient operation.

Regular Inspections and Maintenance

- Safety Features: Check all safety features of bending and unbending machinery to ensure they are functioning correctly.

- Wear and Tear: Regularly inspect machines for signs of wear and tear that could lead to malfunctions.

- Manufacturer Guidelines: Follow the manufacturer’s maintenance guidelines to keep machinery in optimal condition.

- Scheduled Servicing: Perform scheduled servicing to prevent unexpected breakdowns and ensure safe operation.

Work Environment Safety

Maintaining a safe work environment minimizes the risk of accidents and enhances productivity.

Clean Workspace

- Organization: Keep the workspace clean and organized to prevent trips and falls.

- Clutter-Free: Ensure tools and materials are stored properly to avoid accidents.

Proper Lifting Techniques

- Ergonomics: Use proper lifting techniques, such as bending at the knees and keeping the load close to your body, to prevent back injuries.

- Mechanical Aids: Utilize mechanical aids like hoists and lifts for heavy objects.

Environmental Factors

- Temperature: Consider environmental factors such as temperature, which can affect the properties and handling of metal.

- Ventilation: Ensure adequate ventilation to disperse fumes and maintain air quality.

Awareness of Hazards

Being aware of potential hazards is essential for preventing injuries during metal unbending.

Pinch Points

- Identification and Guarding: Identify and guard against potential pinch points around moving parts to prevent injuries.

Flying Parts

- Caution: Exercise caution with parts that can swing or snap up quickly during operations.

- Secure Clamping: Ensure parts are securely clamped to prevent unexpected movements.

Heat Hazards

- Temperature Monitoring: Monitor temperatures when working with heated metals to avoid burns.

- Heat Protection: Use heat-resistant gloves and shields to protect against burns.

Training and Supervision

Proper training and supervision ensure that operators are knowledgeable and adhere to safety protocols.

- Professional Training: Provide comprehensive training to operators on equipment and processes.

- Safety Protocols: Ensure operators are familiar with safety protocols and procedures.

- Experienced Oversight: Assign experienced supervisors to oversee operations and ensure compliance with safety standards.

- Guidance: Offer guidance and support, especially to new operators, to ensure safe practices are followed.

Tool Selection and Calibration

Selecting and calibrating the right tools is crucial for effective and safe metal unbending.

Tool Choice

- Appropriate Tools: Choose tools suitable for the type of metal and the extent of the bend.

- Tool Quality: Ensure tools are of high quality and appropriate for the task at hand.

Calibration

- Accuracy: Regularly calibrate tools to ensure precision and effectiveness.

- Maintenance: Maintain tools properly to avoid errors and accidents.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the most effective methods to unbend metal without damaging it?

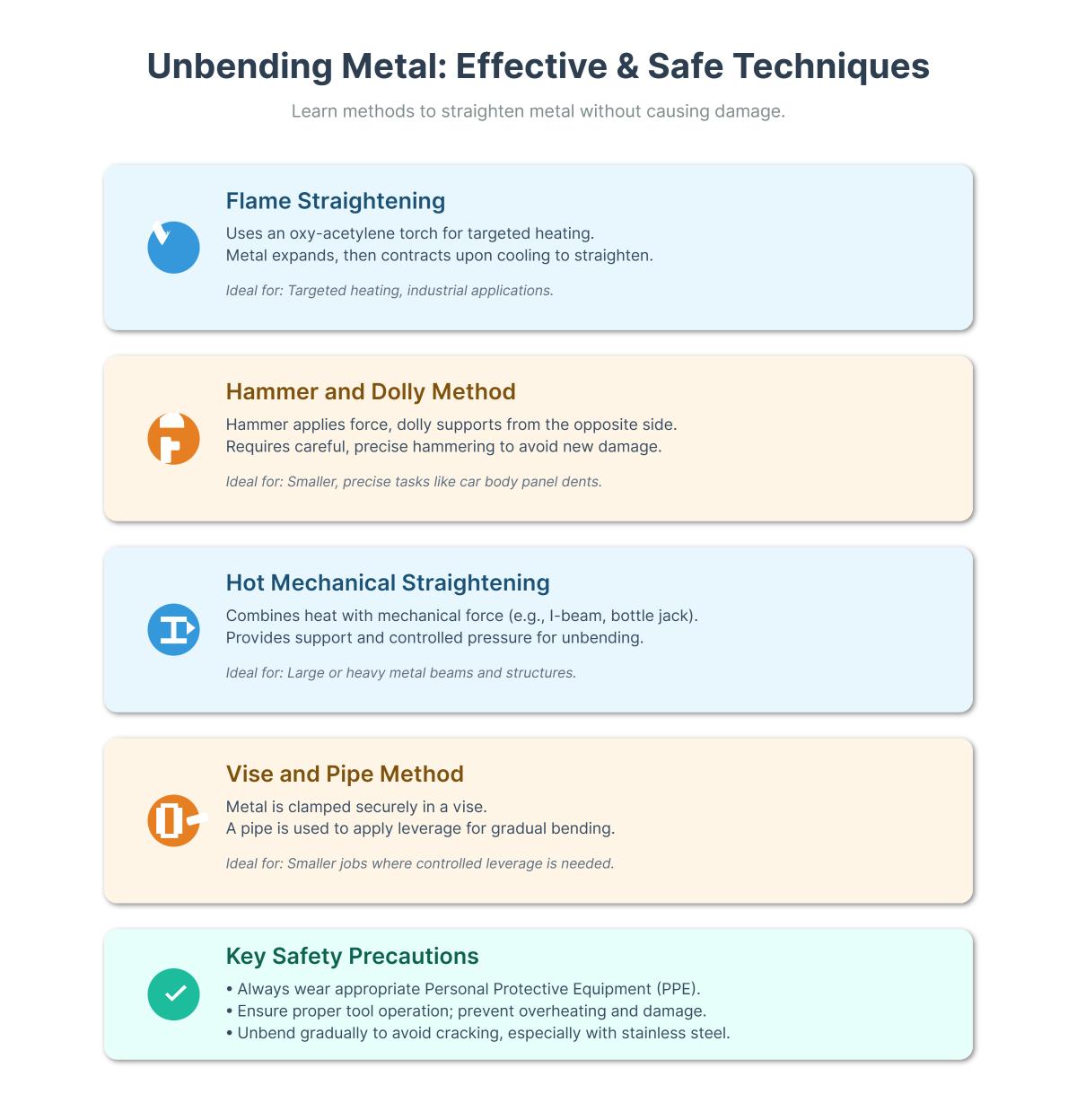

To unbend metal effectively without damaging it, several methods can be employed, each suited to different types and extents of bends.

Flame straightening is a precise technique that uses an oxy-acetylene torch to heat specific areas of the metal, causing it to expand and contract upon cooling, which helps to straighten it. This method is ideal for targeted heating and is commonly used in industrial settings.

The hammer and dolly method is a traditional approach involving the use of a hammer to apply force to the bent metal while a dolly supports the opposite side. This method is best for smaller, precise tasks, such as fixing dents in car body panels. It requires careful hammering to avoid further deformation.

Hot mechanical straightening combines heat with mechanical force to unbend metal, particularly useful for large or heavy metal beams. Tools like an I-beam and a bottle jack provide support and controlled pressure during the process.

For smaller jobs, simple tools like a vise and a pipe can be effective. The metal is clamped in the vise, and the pipe is used to apply leverage for bending.

Safety precautions are crucial when using these methods, including wearing appropriate personal protective equipment (PPE) and ensuring proper tool operation to prevent overheating and damage. Unbending should be done gradually to avoid cracking or kinking, especially with metals like stainless steel.

Which tools are best suited for unbending different types of metal?

The best tools for unbending different types of metal depend on the metal’s properties and the specific requirements of the task. Here are some effective tools:

- Manual Benders: These versatile tools are ideal for smaller, precise adjustments and can handle various metals by adjusting their curvature.

- Roll Benders: Primarily used for creating curves, roll benders can also straighten metal sheets by applying gentle pressure and rolling them back into shape.

- Hydraulic Press Brake: Suitable for heavy-duty tasks, this tool applies controlled pressure to unbend thicker metals, making it ideal for large or thick sections.

- Tube and Pipe Benders: Designed for shaping tubes and pipes, these tools can also adjust the curvature of metal rods and pipes.

- Malco Metal Benders: Built with durable materials, these portable tools are excellent for on-site adjustments of various metal types, including flashing and roofing details.

- Sheet Metal Benders: These tools are adept at making precise bends and unbending metal sheets, especially for radii and curves.

When selecting a tool, consider the metal’s thickness, type, and the desired outcome. For precision and versatility, modular benders like Malco are ideal. For heavier-duty work, hydraulic press brakes are more suitable. Always ensure the tool is designed for the specific task and apply controlled pressure to avoid damaging the metal.

How do metal properties influence the choice of unbending method?

Metal properties such as ductility, malleability, tensile strength, and thermal conductivity significantly influence the choice of unbending method. Ductile metals like copper and aluminum can endure substantial deformation, making them suitable for techniques that involve stretching and bending, such as using a hammer and dolly. Malleable metals, which can be reshaped under compressive stress without breaking, are ideal for forging or pressing methods.

Metals with high tensile strength, like steel, resist deformation and typically require forceful methods, such as hot mechanical straightening, where heating increases ductility temporarily. High thermal conductivity metals, such as copper, benefit from flame straightening due to their efficient heat conduction, allowing controlled heating to relieve stresses and reshape the metal.

Understanding these properties ensures the selection of appropriate techniques, optimizing the unbending process while maintaining the metal’s integrity and preventing damage. Safety precautions, including the use of personal protective equipment, are essential during the unbending process to prevent injuries.

What safety precautions should be taken when unbending metal?

When unbending metal, it’s crucial to observe several safety precautions to protect both the operator and the integrity of the metal. First, always wear appropriate personal protective equipment (PPE), including safety goggles, heavy-duty gloves, ear protection, a hard hat, and sturdy work boots to guard against debris, sharp edges, loud noises, and falling objects. Respiratory protection is also necessary if there is dust or fumes, especially when using heat.

Proper tool selection is essential; use tools suited to the specific metal type and bend severity, such as hammers, dollies, vises, and presses. When applying heat, such as with an oxy-acetylene torch, control the temperature to avoid burns and metal damage.

Ensure all machines are well-maintained and the work area is free of hazards. Use proper lifting techniques or mechanical aids for heavy items to prevent injuries. Be aware of specific hazards like hot surfaces, pinch points, and sharp edges, and ensure operators are trained and supervised. Regularly inspect tools and equipment for wear or damage to maintain a safe working environment.

Can unbending metal be done effectively using simple tools at home?

Unbending metal at home can be done effectively using simple tools, provided that the metal type and the severity of the bend are taken into account. Common tools for home use include hammers, dollies, vises, pipes, and bottle jacks. For smaller jobs, a hammer and dolly can be used to reshape metal by hammering it over a pipe or dolly. This method is straightforward but may leave marks that need finishing.

For more controlled bending, a bottle jack placed under an I-beam can exert precise force on larger or thicker pieces. Heating the metal with a torch before hammering can make it more pliable and reduce the risk of cracking. Additionally, using a vise to hold the metal steady while applying leverage with an adjustable wrench or pipe can be effective for minor bends.

Safety precautions are crucial when working with metal, especially when using heat or heavy equipment. Always wear appropriate personal protective equipment (PPE) and ensure a safe working environment.

Are advanced tools necessary for all types of metal straightening tasks?

Advanced tools are not necessary for all metal straightening tasks. The requirement for advanced tools largely depends on factors such as the type of metal, its thickness, the extent of deformation, and the precision needed for the job. For instance, simple tools like hammers, dollies, vises, and pipes can be effective for minor bends or softer metals such as aluminum, copper, and brass. These tools are often sufficient for small jobs or less critical applications.

However, for thicker metals, severe deformations, or tasks requiring high precision, such as automotive body repairs or industrial component manufacturing, advanced tools like hydraulic presses, flame straightening equipment, and powered roller straighteners may be necessary. These tools ensure that sufficient force is applied evenly and accurately, preventing further damage and restoring the metal to its original geometry. Therefore, while advanced tools enhance efficiency and precision for certain tasks, simpler methods remain viable for less demanding straightening jobs.