Ever wondered how machinists and engineers achieve such precise measurements? The answer lies in mastering the use of a micrometer. If you’re new to this essential tool, fear not—this guide is designed just for you. We’ll break down the micrometer’s structure, explain the functions of its various parts, and walk you through the process of taking accurate measurements, step-by-step. Whether you’re curious about how to read the scales or how to ensure your readings are spot-on, we’ve got you covered. Ready to dive into the world of micrometry and unlock the secrets of precision? Let’s get started!

A micrometer is a precision measuring instrument used to measure small dimensions with high accuracy. Understanding the different parts of a micrometer and their functions is essential for using the tool effectively.

The frame is the C-shaped body of the micrometer. It holds the anvil and spindle in place and provides a stable base for the measurements. The frame is typically made from steel or cast iron to ensure durability and resistance to thermal expansion and mechanical stress.

The anvil, located at one end of the frame, is the fixed surface where the object being measured rests. It provides a stationary surface for the measurement process. The anvil can come in various shapes, such as flat or spherical, depending on the type of measurements being performed.

The sleeve, or barrel, is the stationary part that holds the spindle and features a measurement scale. It supports the moving parts of the micrometer and provides a reference point for the main scale.

The spindle is the movable measuring face of the micrometer, located opposite the anvil. It moves towards or away from the anvil to accommodate the object being measured. The spindle is finely threaded to ensure precise movement and accurate measurements.

The thimble is the rotating part of the micrometer that controls the movement of the spindle. It is turned to adjust the distance between the anvil and the spindle. The thimble is graduated with a scale that, when combined with the sleeve scale, provides the measurement reading.

The ratchet stop ensures consistent pressure by clicking when the correct pressure is applied. This prevents the user from applying too much force, which could distort the measurement.

The lock nut secures the spindle after a measurement, ensuring the reading stays stable and accurate. This prevents any accidental movement that could alter the measurement.

The micrometer screw inside the spindle converts the thimble’s rotation into precise spindle movement. The precision of the screw is critical for the micrometer’s accuracy, as it directly affects the measurement resolution.

Each part of the micrometer plays a specific role in ensuring precise and accurate measurements:

Understanding these parts and their functions is fundamental for anyone using a micrometer, ensuring accurate and reliable measurements in various applications.

The main scale, also called the sleeve scale, is found on the fixed sleeve of the micrometer. It provides the primary measurement in either millimeters or inches. This scale consists of:

As the thimble rotates, the spindle moves, causing the sleeve scale to reveal the distance moved by the spindle, which can be read directly from these marks.

The thimble scale, engraved on the rotating part of the micrometer, typically has 50 or 100 divisions. Each division on the thimble represents a fractional increment of the main scale unit:

When the thimble is rotated, the line on the thimble that aligns with the reference line on the sleeve indicates the fractional part of the measurement.

To accurately read a measurement with a micrometer:

If the last visible line on the main scale is 10 mm and the next half-millimeter mark is visible, the main scale reads 10.5 mm. If the 15th division on the thimble aligns with the sleeve’s reference line, the thimble reads 0.15 mm. Therefore, the total measurement is 10.65 mm (10.5 mm + 0.15 mm).

Some micrometers are equipped with an additional vernier scale for higher precision. This scale allows the user to measure even finer increments, typically 0.001 mm or 0.0001 inches. The vernier scale is read by noting which vernier mark aligns best with a mark on the thimble.

By understanding and correctly using these scales, you can achieve precise and reliable measurements with a micrometer.

In the metric system, micrometer measurements are usually expressed in millimeters (mm). Micrometers designed for metric measurements typically have ranges like 0-25 mm, 25-50 mm, etc. The smallest increment that can be read on a metric micrometer is often 0.01 mm or 0.001 mm, depending on the precision of the instrument.

Micrometers using imperial units often have ranges like 0-1 inch, 1-2 inches, etc., with the smallest increment being 0.001 inches or 0.0001 inches, depending on the instrument’s precision.

Micrometers are renowned for their high accuracy, making them preferable for precise measurements over other tools like calipers.

Metric micrometers typically offer precision up to 0.001 mm, or one-thousandth of a millimeter. Imperial micrometers provide precision up to 0.0001 inches, which is one ten-thousandth of an inch.

Micrometers are generally more accurate than vernier calipers. For instance, while a standard vernier caliper has an accuracy of around 0.02 mm or 0.001 inches, a micrometer can achieve significantly finer measurements. This higher precision is crucial for tasks that require exact measurements.

Several key factors contribute to the remarkable accuracy of micrometers:

Regular calibration is essential to ensure that the micrometer provides accurate readings. Calibration involves adjusting the micrometer to a known standard, ensuring that its measurements are correct.

Using the ratchet stop ensures consistent measuring pressure. This prevents the user from applying excessive force, which could distort the measurement, ensuring that the readings are repeatable and reliable.

Proper handling and maintenance of the micrometer are crucial. Avoid dropping the micrometer or exposing it to extreme temperatures, as these can affect its precision. Keeping the micrometer clean and well-maintained also helps preserve its accuracy.

Understanding these aspects of measurement units and accuracy is fundamental for anyone using a micrometer. By paying attention to these details, users can achieve highly accurate and reliable measurements essential for various technical applications.

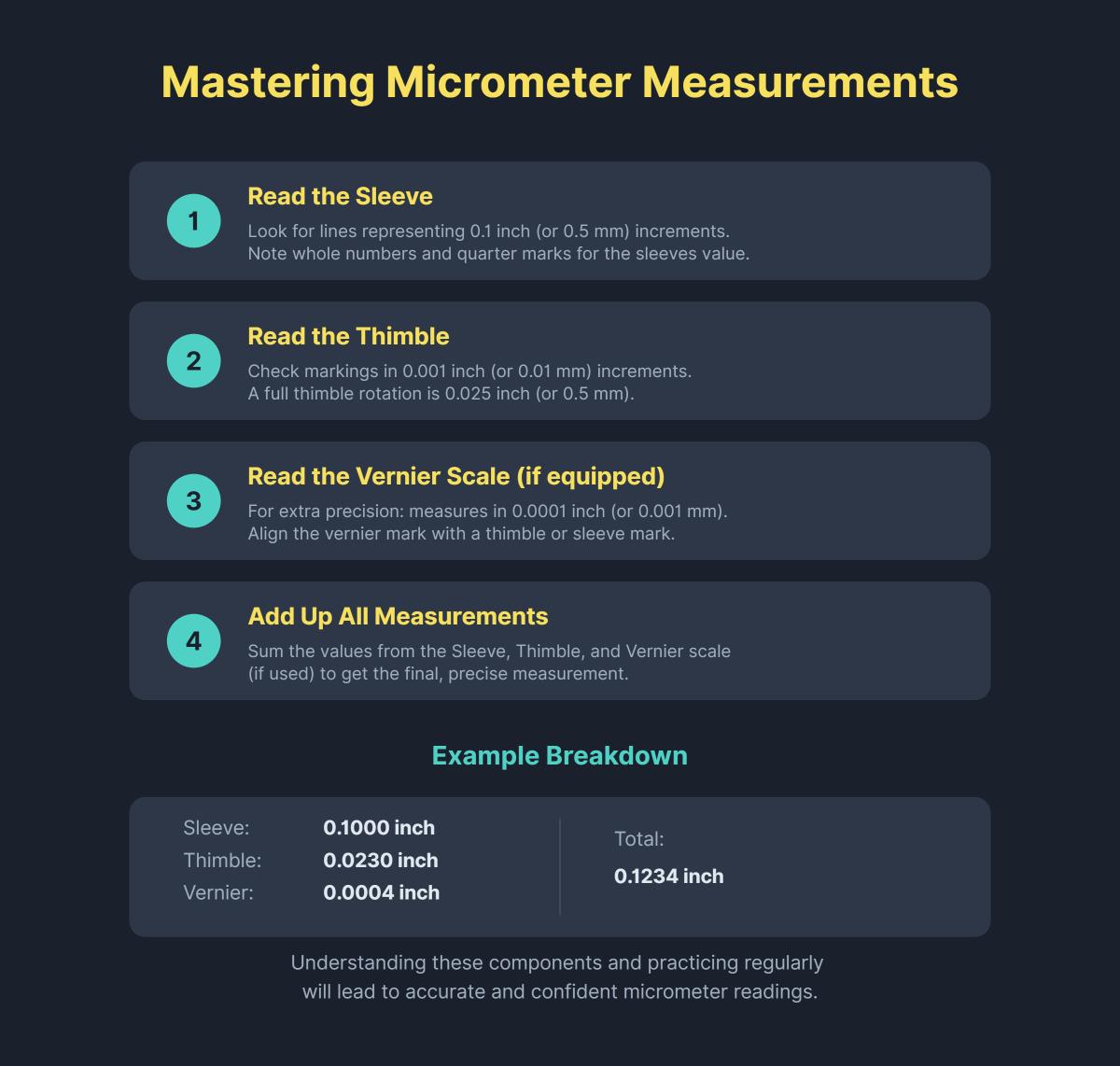

Accurate micrometer readings are easy with a few simple steps. Follow these steps for precise measurements every time.

Before taking measurements, familiarize yourself with the main components of the micrometer:

Ensure the micrometer is clean and free of any debris. Close the spindle and anvil gently using the ratchet stop to check for zero error. If the zero marks on the sleeve and thimble align perfectly, your micrometer is correctly zeroed.

Place the object between the anvil and spindle, then use the ratchet stop to apply consistent pressure. This ensures an accurate measurement without deforming the object.

First, check the sleeve scale. Note the last visible number and any half-unit marks. For example, if you see 5 and a 0.5 mark, the reading is 5.5 mm.

Next, read the thimble scale by rotating it until its edge aligns with the sleeve scale’s reference line. Note the value, typically in 0.01 mm increments.

If your micrometer has a vernier scale, use it for additional precision. Check which vernier mark aligns with a mark on the thimble scale. This step adds an extra decimal place to your measurement.

Add the readings from the sleeve, thimble, and vernier scales to get the final measurement. For example:

Ensure both the micrometer and the object are at room temperature before measuring. Temperature variations can cause materials to expand or contract, leading to inaccurate readings. Allowing both items to stabilize at the same temperature helps in achieving precise measurements.

Use a soft, lint-free cloth or white paper to clean the measuring surfaces, ensuring accurate contact and preventing errors caused by debris. Clean measuring surfaces ensure accurate contact between the micrometer and the object, preventing errors caused by debris.

Know the parts of a micrometer, like the anvil, spindle, thimble, ratchet, and sleeve. Understanding how these parts work together and how to read the scales correctly can prevent misinterpretation of measurements and enhance accuracy.

When taking a measurement, rotate the ratchet or thimble until you hear about three clicks. This indicates the correct measuring force. Applying too much force can distort the object or damage the micrometer’s precision surfaces, while too little pressure can result in inaccurate readings. Consistent pressure is key to reliable measurements.

Secure the object using a stationary vise or a stable surface to prevent movement during measurement. Movement can cause inconsistent results, leading to inaccurate measurements.

If your micrometer has a thimble lock, use it to secure the spindle at the measured position. This prevents accidental changes in measurement and allows you to read the scale without any shift in the spindle.

For increased accuracy, especially with cylindrical or irregularly shaped objects, take measurements at different points and average the results. This practice helps in identifying any inconsistencies and provides a more accurate overall measurement.

Taking measurements immediately after moving the micrometer or the object from a different environment can lead to expansion or contraction errors. Always allow time for temperature equalization to avoid such inaccuracies.

Neglecting to clean the micrometer or the object can lead to false readings. Dust, dirt, or oil on the measuring surfaces can prevent proper contact, resulting in erroneous measurements.

Applying too much force can distort the object or damage the micrometer’s precision surfaces. This compromises the accuracy of the measurement. Always use the ratchet to apply the correct amount of pressure.

Common mistakes include confusing metric and inch scales or misunderstanding the graduations on the scale, such as the half-millimeter and hundredth-of-a-millimeter marks. Ensure you are familiar with the scales and read them carefully.

Holding the object loosely or allowing it to move during measurement can result in unreliable readings. Secure the object properly to maintain consistent and accurate measurements.

Regular calibration of your micrometer is essential to maintain its accuracy. Neglecting calibration can lead to gradual measurement drift over time, affecting the precision of your readings.

Below are answers to some frequently asked questions:

To properly read the measurement on a micrometer, follow these steps:

For example, if the sleeve shows 0.1 inch, the thimble reads 0.023 inch, and the vernier scale shows 0.0004 inch, the total measurement is 0.1234 inch.

By understanding these steps and practicing regularly, you can accurately read measurements on a micrometer.

A micrometer is a precision instrument used to measure small dimensions with high accuracy. It consists of several key parts, each with a specific function. The frame (C-Frame) provides stability and support, holding the anvil and barrel in place. The anvil is the stationary part that contacts one side of the object being measured, ensuring a stable reference point. The sleeve (or barrel) is a stationary cylindrical component with an engraved scale that shows the measurement. The spindle is a movable part that approaches the anvil to secure the object for measurement. The thimble rotates around the sleeve and has a fine scale for detailed measurements. The lock nut secures the thimble to maintain the measurement once it is set. Lastly, the ratchet stop ensures consistent pressure is applied, preventing over-tightening and potential damage to both the micrometer and the object. Understanding these parts is essential for using a micrometer effectively.

Using the scales on a micrometer involves understanding the sleeve scale, thimble scale, and possibly the vernier scale, each contributing to the final measurement. First, identify if your micrometer is metric or imperial, as this will affect the base units.

Start with the sleeve scale, which provides the main measurement in larger increments (e.g., 1 mm or 0.1 inch). Next, read the thimble scale for additional precision; each line on the thimble typically represents smaller increments (e.g., 0.01 mm or 0.025 inch). If your micrometer has a vernier scale, use it for even finer measurements, often in ten-thousandths of an inch or hundredths of a millimeter.

To get the total measurement, add the values from the sleeve, thimble, and vernier scales. For instance, if the sleeve shows 10 mm, the thimble shows 0.05 mm, and the vernier shows 0.003 mm, the total measurement is 10.053 mm. Ensuring proper alignment and gentle pressure while measuring will help achieve accurate results.

To take a measurement with a micrometer, follow these steps:

These steps ensure accurate and precise measurements using a micrometer.

The least count of a micrometer is the smallest value that it can measure accurately. For mechanical micrometers, this is typically 0.01 mm, meaning they can detect differences as small as 0.01 mm. Digital micrometers can be even more precise, with least counts such as 0.001 mm. Understanding the least count is crucial for achieving precise measurements. It is calculated using the formula:

For example, if the pitch is 1 mm and there are 100 divisions on the circular scale, the least count would be 0.01 mm. Knowing the least count helps users select the appropriate micrometer for their measurement needs.

To ensure your micrometer is calibrated correctly, start by cleaning the measuring faces with a lint-free cloth and suitable solvent to remove any debris. Inspect the micrometer for any visible damage and ensure the spindle moves smoothly. Close the micrometer gently using the ratchet mechanism until it clicks, ensuring the zero line on the sleeve aligns with the zero on the thimble scale. If they do not align, use the adjusting spanner to make fine adjustments. For further accuracy, use a setting bar or gauge blocks as calibration standards. Insert the standard between the measuring faces and gently close the spindle using the ratchet. Check the reading against the known dimension of the standard. If necessary, adjust the sleeve until the reading matches the standard. Repeat the check at multiple points across the micrometer’s range to ensure consistent accuracy. Regularly maintain and inspect the micrometer to keep it calibrated.