Welding brass and mild steel together might seem like a daunting task, but with the right techniques and materials, it can be achieved successfully. This article is designed to guide intermediate metalworkers through the intricacies of joining these two metals, offering step-by-step instructions and expert insights. Whether you’re wondering about the best filler materials to use or the most effective welding methods, we’ve got you covered. You’ll learn about the compatibility and corrosion considerations essential for a strong, lasting bond, and discover detailed guides on both brazing and TIG welding processes. Ready to master the art of welding brass and mild steel together? Let’s dive in and explore the methods and materials that will ensure your welding projects are both efficient and durable.

Welding brass and mild steel together is a challenging but crucial skill in metalworking. These metals, each with unique properties, are often combined in industrial and artistic projects, requiring precise techniques to ensure strong, durable joints.

Brass, an alloy primarily composed of copper and zinc, is valued for its durability, corrosion resistance, and aesthetic qualities, with a melting point typically between 900°C and 940°C. Mild steel, a low carbon steel, is known for its strength, affordability, and ease of use, with a melting point around 1425°C to 1540°C. These differing properties necessitate careful consideration when welding the two metals together.

The main challenge in welding brass to mild steel is their different melting points. Brass melts at a lower temperature, which requires careful heat control to avoid damaging it while ensuring a strong bond with steel. Additionally, the zinc in brass can evaporate at high temperatures, weakening the weld and making precise heat control crucial.

Brazing involves heating a filler metal to a temperature below the base metals’ melting points, allowing it to flow into the joint and create a strong bond. Silver soldering is similar but uses a lower temperature filler metal, making it ideal for delicate parts where maintaining metal properties is crucial.

Always use safety gear like gloves, goggles, and a mask to protect against heat, fumes, and sparks. Ensure both metals are clean and free of contaminants before joining. Use flux to prevent oxidation during heating, which improves joint quality. Maintain consistent temperatures to avoid overheating and degrading the materials.

When welding brass to mild steel, it is crucial to understand the compatibility of these materials. Brass, composed mainly of copper and zinc, has different physical properties compared to mild steel, primarily due to its lower melting point and the presence of zinc, which can evaporate at high temperatures.

Brass melts at a lower temperature, between 900°C and 940°C. This can cause issues like porosity and zinc evaporation during welding. Additionally, brass is softer and more malleable compared to mild steel, which requires careful handling to prevent deformation during welding.

Mild steel is known for its strength and higher melting point, which ranges from 1425°C to 1540°C, making it more durable and widely used in structural applications due to its ability to withstand significant stress without deformation. The higher melting point of mild steel necessitates precise control of heat input when welding with brass to avoid damaging the brass component.

Joining dissimilar metals like brass and mild steel can introduce potential corrosion issues. Proper consideration of the environmental factors and material properties can help mitigate these risks.

In environments where corrosion is prevalent, such as marine or industrial settings, brass can corrode rapidly, especially when in contact with steel. The galvanic corrosion process can be accelerated if the joint is exposed to electrolytes like saltwater. Therefore, careful selection of filler materials and protective measures is essential.

Choosing the right filler metal, such as silicon bronze or nickel-based alloys, is critical for preventing corrosion and ensuring a durable joint. These fillers offer excellent corrosion resistance, making them suitable for joints exposed to harsh environments.

By understanding the compatibility and corrosion considerations when welding brass to mild steel, and by implementing these best practices, you can achieve strong, durable, and corrosion-resistant joints suitable for various applications.

Joining brass to mild steel requires selecting the right filler material to ensure a strong, durable bond. The different melting points and properties of these metals necessitate careful consideration. Here are the most suitable filler materials for this process:

Silicon bronze is one of the most effective filler materials for joining brass to mild steel. It offers excellent fluidity, making it easier to work with and ensuring a smooth, consistent bond. Silicon bronze is also highly corrosion-resistant, making it ideal for environments with moisture or chemicals.

Copper-based fillers are also a good choice for joining brass to mild steel. Copper has a lower melting point than steel. It is compatible with both metals, ensuring a strong bond. Additionally, copper’s thermal conductivity helps distribute heat evenly during the brazing process, reducing the risk of thermal shock and distortion.

Silver-based fillers, like BAg-7 or BAg-24, are highly recommended for their excellent fluidity and strong bonding characteristics. They are ideal for applications requiring high strength and durability, particularly where the joint must endure significant stress or thermal cycling.

Choosing the right filler material involves considering several key factors to ensure optimal performance and longevity of the joint.

The filler material must be compatible with both brass and mild steel. This compatibility ensures that the filler can adequately bond with both metals, creating a strong, cohesive joint. Incompatible fillers may lead to weak bonds, which can fail under stress or environmental exposure.

The melting point of the filler material should be lower than the base metals to prevent them from melting or deforming during the brazing process. This is particularly important for brass, which has a lower melting point than mild steel. Using a filler with an appropriate melting point helps maintain the integrity of both metals.

Corrosion resistance is vital, especially in environments prone to moisture or chemical exposure. Fillers like silicon bronze and silver offer excellent corrosion resistance, protecting the joint from degradation over time. Selecting a corrosion-resistant filler extends the lifespan of the welded assembly.

Consider the mechanical properties required for the joint, such as tensile strength, ductility, and wear resistance. Phosphor bronze fillers are ideal for high-wear applications because of their excellent mechanical properties. Matching the filler material’s properties with the application’s requirements ensures the joint can withstand the expected load and stress.

Certain applications may have unique requirements that influence filler material selection. For instance, in high-stress environments, nickel-based alloys may be preferred due to their ability to accommodate thermal expansion differences and provide robust mechanical strength. Always consider the specific demands of the application when choosing a filler material.

By carefully selecting the right filler materials and considering these factors, you can achieve strong, reliable joints when welding brass to mild steel. This ensures the integrity and durability of your metalworking projects.

To join brass and mild steel, two main methods are often used: brazing and TIG welding. Each technique has its own set of advantages and disadvantages, making them suitable for different applications.

Brazing involves melting a filler metal and flowing it into the joint between base metals at a temperature below their melting points, making it particularly effective for joining dissimilar metals like brass and mild steel.

Advantages:

Disadvantages:

TIG (Tungsten Inert Gas) welding uses a tungsten electrode to produce the weld. This method is known for its precision and ability to create high-quality welds.

Advantages:

Disadvantages:

Selecting the appropriate welding method depends on the specific requirements of the project and the characteristics of the metals involved.

Several factors should be taken into account when deciding between brazing and TIG welding for joining brass to mild steel:

Understanding the pros and cons of brazing and TIG welding, along with considering your project’s specific needs, will help you choose the best method for joining brass and mild steel.

To successfully braze brass and mild steel, gather the following tools and materials:

Proper surface preparation is crucial for a strong braze joint. Use wire brushes or metal files to thoroughly clean both the brass and mild steel surfaces, removing all contaminants, oxides, and dirt. Design the joint with the correct clearance for capillary action, ideally ranging from 0.001 to 0.005 inches. Align the brass and steel components accurately and secure them with clamps or fixtures to maintain correct alignment during brazing.

Remove any remaining flux residue by rinsing with hot water, and use an emery cloth or wire brush to ensure the joint is clean. Inspect the brazed joint for any defects or incomplete brazing, and re-braze if necessary.

By following these steps and considerations, you can achieve strong, reliable joints between brass and mild steel using the brazing process.

Brass is made from a combination of copper and zinc. It is known for its corrosion resistance and aesthetic appeal, making it suitable for various decorative and industrial applications. However, brass has a lower melting point compared to mild steel, and when heated, it releases zinc fumes, which can pose challenges during welding.

Mild steel is a ferrous alloy with a higher melting point than brass. It is commonly used in construction and manufacturing due to its strength, affordability, and versatility. The higher melting point of mild steel requires careful heat management when welding it to brass to avoid damaging the brass component.

Ensure both brass and mild steel surfaces are free from oxidation, grease, and contaminants. Use a wire brush, sandpaper, or scouring pad to clean the surfaces thoroughly. Proper cleaning is crucial to prevent porosity in the weld.

Beveling the edges of the brass and mild steel pieces increases the surface area for the weld and helps achieve better penetration. This step is essential for creating a stronger weld joint.

Preheating the brass to about 200-300°F (94-149°C) can help reduce thermal shock and minimize the evaporation of zinc. This preheating process improves the weld quality and helps maintain the integrity of the brass.

Use argon or a mixture of argon and helium as shielding gases. Argon is typically sufficient, but helium can enhance heat input for thicker materials.

Adjust your TIG welder to use DC (Direct Current) with a straight polarity setup. This configuration provides a more stable arc necessary for welding brass.

Position the tungsten electrode close to the joint. Use the foot pedal to start the arc, ensuring a steady and controlled heat application.

Move the torch along the joint, allowing the filler rod to melt into the puddle created by the heated brass. Maintain a consistent distance with the torch to ensure even heat distribution. Avoid overheating, as this can lead to the brass becoming brittle or producing excessive fumes.

Modulate the heat input carefully. Keep the arc length short to maintain control over the weld pool and prevent overheating the brass.

Once the desired weld bead is achieved, remove the torch and allow the weld to cool slowly to prevent cracking. Controlled cooling is essential for maintaining the integrity of both materials.

Examine the joint for any signs of porosity or cracks. A good weld should have a smooth, shiny appearance without any voids.

After welding, clean the area to remove any residual slag or oxidation that may have formed during the process.

Make sure the welding area is well-ventilated since welding brass releases harmful zinc fumes.

If you are new to TIG welding, practice on scrap pieces of brass and mild steel to refine your technique before attempting your final project.

By following these steps and focusing on proper preparation and technique, you can successfully weld brass to mild steel using TIG welding, resulting in strong and aesthetically pleasing joints.

Below are answers to some frequently asked questions:

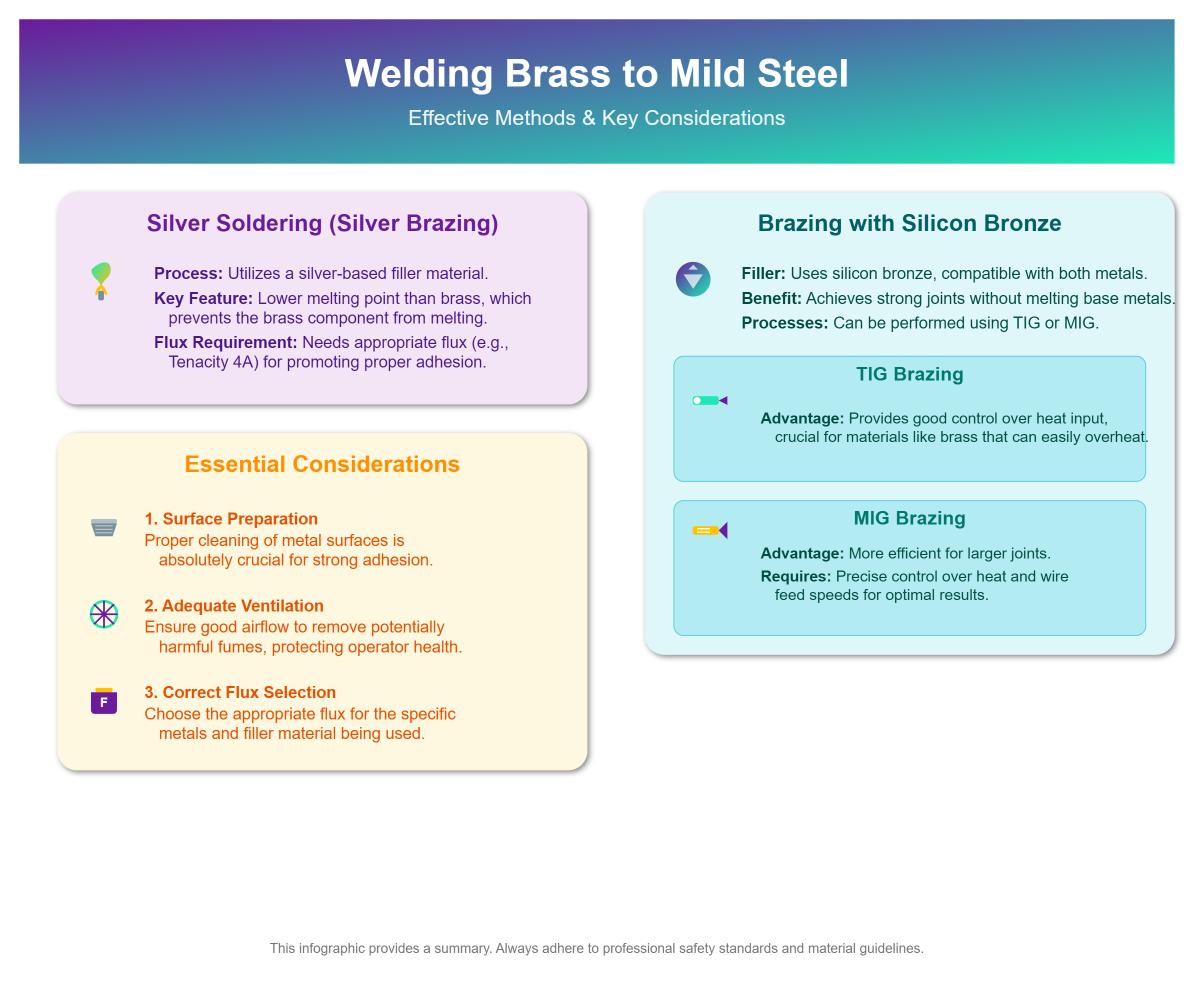

Several methods can be used to weld brass to mild steel effectively, despite the challenges posed by the differing properties of these metals. One common technique is silver soldering, also known as silver brazing, which uses a silver-based filler material with a lower melting point than brass, ensuring that the brass does not melt during the process. This method requires appropriate flux, such as Tenacity 4A, to promote proper adhesion.

Another method is brazing with silicon bronze, which can be performed using either TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding processes. Silicon bronze has a lower melting point and is compatible with both brass and mild steel, allowing for strong joints without reaching the melting points of the base metals.

TIG brazing is particularly effective, providing good control over heat input, which is crucial for materials like brass that can easily overheat. MIG brazing, using a continuous wire feed, is more efficient for larger joints but also requires precise control over heat and wire feed speeds.

Regardless of the method, proper surface preparation, adequate ventilation, and the correct selection of flux are essential for successful welding of brass to mild steel.

The best filler materials for joining brass and mild steel are primarily Silicon Bronze and Silver-based fillers. Silicon Bronze is highly recommended for its excellent corrosion resistance and mechanical properties, making it suitable for both TIG and GMAW processes. It provides a durable bond and can accommodate the different thermal expansions of brass and mild steel. Silver-based fillers, such as BAg-7 or BAg-24, are effective for brazing applications where high strength is not a critical requirement. These fillers ensure a reliable joint and are particularly useful when a braze is preferred over welding. When selecting filler materials, consider the specific application requirements, including mechanical strength and corrosion resistance.

To prepare brass and mild steel surfaces for welding, start by cleaning both metals thoroughly. For brass, use a degreaser or acetone and a wire brush to eliminate grease, dirt, and oxidation. For heavily oxidized brass, sandpaper or steel wool can be used to create a clean, slightly rough surface. Preheat brass to 200-300 degrees Fahrenheit to prevent cracking and ensure a stable weld. Apply a thin layer of flux, such as zinc chloride or rosin-based flux, to the brass to prevent oxidation and improve filler metal flow.

For mild steel, clean the surface with a wire brush or sandpaper to remove contaminants. While preheating is less critical for mild steel, it can be beneficial, especially for thicker sections or dissimilar metal welding, to reduce thermal stress. Use appropriate shielding gases like Argon or CO2 to protect the weld from atmospheric contamination.

When welding brass to mild steel, brazing is often preferred due to the metals’ different properties. Use a suitable brazing alloy and flux compatible with both metals. Ensure you wear proper safety equipment, including welding goggles, gloves, and a respirator, to protect against toxic fumes from brass. Following these steps will help you achieve a strong, clean weld.

When welding brass and mild steel together, several safety precautions are essential due to the unique properties of these metals and the potential for toxic fumes. First, always wear appropriate personal protective equipment (PPE), including a welding helmet with a shaded lens, flame-resistant clothing, welding gloves, and steel-toed boots to protect against heat, sparks, and UV radiation. Eye protection, such as goggles with side shields, is also crucial.

Ensure adequate ventilation to remove harmful fumes, especially those containing zinc oxide from brass and iron oxides from mild steel. If ventilation is insufficient, use approved respirators to prevent inhalation of toxic fumes. Regularly inspect welding equipment for damage or wear and ensure all electrical connections are secure and properly insulated to prevent electrical shock.

Clear the area of flammable materials, use fire-resistant curtains or shields to contain sparks, and have a fire extinguisher nearby. Welding in confined spaces requires special precautions, including proper ventilation and safety checks for pressure vessels.

Understand the compatibility challenges between brass and mild steel, particularly their differing thermal expansion and contraction properties. Be aware that brass can release toxic fumes when heated, and follow specific safety guidelines for these metals. By adhering to these safety precautions, you can minimize risks and ensure a safe welding process.

TIG welding can be used for some brass and mild steel joints, but it is not suitable for all types. The primary challenge lies in the differing properties of brass and mild steel, such as their thermal expansion rates and melting points. Brass, which contains zinc, can volatilize at high temperatures, leading to potential porosity and fume hazards.

For successful TIG welding, it is crucial to select appropriate filler materials, like silicon bronze, which is compatible with both brass and mild steel. However, due to the inherent difficulties and potential issues, brazing is often preferred over TIG welding for joining these dissimilar metals. Brazing involves lower temperatures and can accommodate the material differences more effectively, resulting in stronger and more reliable joints. Therefore, while TIG welding is possible, it is generally not the best method for all brass and mild steel joints.

To prevent corrosion when welding brass to mild steel, you need to manage the electrochemical differences between the metals and protect the weld area. First, ensure both surfaces are thoroughly cleaned to remove contaminants. Use appropriate filler materials such as nickel-based alloys or silicon bronze, which offer good corrosion resistance and compatibility.

Preheat the brass to 200-300°F to minimize thermal shock and use argon or helium-rich shielding gases to protect the weld pool. After welding, apply protective coatings like paint or varnish to shield the area from moisture and oxygen. Regularly inspect and maintain these coatings to ensure long-term protection. Using corrosion inhibitors like benzotriazole and sacrificial anodes in moist environments can further reduce corrosion risks. By following these steps, you can achieve a durable and corrosion-resistant weld.