Welding Corten steel can be a rewarding yet challenging task for those looking to combine durability with unique aesthetic appeal. As an intermediate welder, you might wonder about the best techniques and tools required to master this skill. How do you ensure your welds not only hold strong but also retain the material’s renowned corrosion resistance? In this comprehensive guide, we will explore step-by-step methods for welding Corten steel, covering everything from essential equipment and preparation to specific welding techniques and post-weld treatments. Dive in to learn how to achieve professional-grade results while preserving the integrity and sustainability of your projects. Ready to transform your welding skills? Let’s get started!

Corten steel, also known as weathering steel, is a high-strength, low-alloy steel that shows excellent resistance to atmospheric corrosion. The name “Corten” comes from its corrosion resistance and tensile strength properties. It’s designed to form a stable, rust – like appearance when exposed to the weather, and this layer acts as a protective shield against further corrosion. Corten steel typically has a tensile strength ranging from 68,000 to 78,000 pounds per square inch, which makes it suitable for heavy – duty applications.

Weathering steel is a broad category of steels that includes Corten steel and other similar products. These steels are designed to develop a stable, rust – like appearance over time, which serves as a protective barrier against further corrosion.

Corten steel is considered eco – friendly. Its long – term durability reduces the need for frequent replacements and maintenance. This characteristic contributes significantly to sustainability in several ways:

MIG welding is ideal for Corten steel due to its efficiency and user – friendliness. The process involves feeding a continuous wire electrode through a welding gun. A shielding gas mix of 75 – 80% argon with the remainder carbon dioxide is ideal for MIG welding Corten steel, as it provides a stable arc and minimizes spatter.

TIG welding is precise and controlled, ideal for thin sections or detailed work, but it is slower and requires more skill than MIG welding.

Stick welding is versatile for less – controlled environments and can be effective for Corten steel with the right electrodes, though it is less commonly used.

For single – pass welds on Corten steel, mild steel fillers like ER70S – 6 are suitable. When dealing with thicker or multi – pass welds, low – alloy fillers such as Cor – Match™ products are recommended to match Corten’s weathering properties.

AWS E7018 is a popular choice for Corten steel. It has low – hydrogen properties and can provide strong welds.

ER805 – Ni1 and LA – 75 are suitable for applications where high strength and corrosion resistance are required.

Use an angle grinder with a metal grinding disc to grind the weld area and remove any scale or debris. This step is crucial for ensuring a clean welding surface.

After using the angle grinder, a wire brush can be used for final cleaning to ensure a debris – free surface.

If you are welding mild steel to Corten steel, degreasers and sanding tools are needed for mild steel preparation.

A thermometer is essential to monitor preheat and interpass temperatures. Maintaining appropriate temperatures is crucial for preventing thermal shock and cracking.

The intermittent welding technique helps manage heat input by welding in short intervals.

After welding, clean the weld area with a wire brush and power washer to remove slag and spatter, promoting uniform patina formation.

Proper cleaning and preparation are essential for high-quality welds on Corten steel. Follow these steps for the best results:

Start by using an angle grinder with a flap or metal grinding disc to remove rust, mill scale, or dirt. Then, use a wire brush to clear away any remaining debris. Next, use a degreaser to remove oils and contaminants, ensuring a strong weld.

If you are welding Corten steel to mild steel, the preparation steps for the mild steel are equally important. Use an angle grinder to remove any surface contaminants such as rust or scale. Then, sand the surface to create a smooth, clean area for welding.

Bevel the edges of the Corten steel using an angle grinder with a flap disc. This step enhances weld penetration and reduces the risk of warping or cracking during the cooling process.

Ensure your workspace is clean, well-lit, and free of flammable materials to provide a safe welding environment. Adequate ventilation is crucial to handle welding fumes effectively. Make sure your workspace is properly ventilated. Wear appropriate protective gear such as welding helmets, gloves, and safety glasses to protect against sparks and debris.

For thicker Corten steel (over 3/4 inches), preheat to 150 – 225°F (65 – 110°C). This helps prevent warping and cracking during welding. Maintain appropriate interpass temperatures to avoid thermal shock and ensure consistent weld quality. Use a thermometer to monitor these temperatures throughout the welding process.

After welding, use a wire brush or chipping hammer to remove slag and spatter. To blend the new weld with the existing patina, apply a weathering steel primer or use treatments to accelerate patina formation.

Conduct a thorough inspection to identify any inconsistencies or weaknesses in the weld. This step ensures the integrity and strength of the weld. Regularly maintain the Corten steel by allowing it to weather naturally. This enhances its distinctive rusted appearance and provides ongoing protection against corrosion.

Before welding, ensure the metal is clean by using an angle grinder and wire brush to remove rust, scale, and contaminants. Proper fit – up of the parts is also essential, maintaining a consistent gap for the weld bead.

MIG welding is a popular method for welding Corten steel due to its efficiency and ease of use. After preparing the metal surface, set up your welding equipment. Use a MIG welder with a shielding gas mixture of 75 – 80% argon and 20 – 25% carbon dioxide. Select the filler wire; ER70S – 6 wire is commonly used for single – pass welds, and for multi – pass welds, consider Cor – Match™ products. Set the voltage and wire feed speed according to the material’s thickness. Refer to the welder’s manual for specific settings. When welding, maintain a consistent speed and angle. Keep the torch about 10 – 15 degrees from vertical and have a steady hand to produce a clean weld.

The advantages of MIG welding include high efficiency, good penetration, and strong welds. However, it requires a shielding gas supply, which may not be ideal for outdoor conditions.

TIG welding is ideal for precision work and thin sections of Corten steel. After the metal is prepared, prepare the tungsten electrode by sharpening it to a fine point for precise arc control. Set up the TIG welder with a pure argon shielding gas. Select the filler rod; ER805 – Ni1 or LA – 75 are recommended for high strength and corrosion resistance. Set the amperage based on material thickness. For thin materials, start with a low amperage. Use a foot pedal to control the heat. Maintain a short arc length and add filler metal carefully to avoid overheating.

The advantages of TIG welding are excellent control, high – quality welds, and minimal spatter. But it is a slower process, requires more skill, and has a higher initial equipment cost.

Stick welding, or SMAW, is a versatile method for Corten steel and can be performed in less controlled environments. After cleaning the metal, choose the electrode; AWS E7018 is suitable for Corten steel. Set up the stick welder with the appropriate settings for the electrode and material thickness. Strike the arc and maintain a consistent travel speed. Keep the electrode at an angle of about 20 – 30 degrees from vertical.

The advantages of stick welding are that it is good for outdoor and less controlled environments, and the equipment is portable. However, it has more spatter, is a slower process, and offers less control compared to MIG and TIG welding.

For MIG welding, set the voltage at 18 – 22 volts and the wire feed speed at 200 – 300 inches per minute. For TIG welding, set the amperage at 50 – 150 amps (depending on material thickness) and the shielding gas flow rate at 15 – 20 cubic feet per hour. For stick welding, set the amperage at 70 – 150 amps (depending on electrode size). A 1/8 – inch electrode is common for Corten steel.

Refer to AWS D1.1 and D1.5 for detailed specifications and guidelines on welding processes, filler materials, and equipment settings to ensure compliance and achieve high – quality welds.

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

When determining the best welding method for Corten steel, consider the specific requirements of the project, such as material thickness, desired precision, and working conditions.

Selecting the right filler metal is essential when welding Corten steel to ensure the weld retains the same corrosion-resistant properties and structural integrity as the base material.

These fillers are ideal for single-pass welds, particularly on thinner sheets of Corten steel, as they pick up alloying elements from the base material, helping to mimic its anti-corrosion properties. While they are suitable for non-structural applications, their corrosion resistance is limited.

These fillers contain important elements like nickel, copper, and chromium, which help maintain the weathering properties of Corten steel. They are preferred for multi-pass welds, where base metal dilution is minimal, thus ensuring the longevity and strength of the weld.

These fillers are specifically designed to match both the mechanical and corrosion-resistant properties of Corten steel, making them perfect for applications that require close color matching and high corrosion resistance. They are particularly beneficial in architectural and infrastructural projects where aesthetics and durability are paramount.

Ensure the chosen filler metal matches or exceeds the tensile strength of the base material, especially for structural applications where weld integrity is critical. For optimal corrosion resistance, low-alloy fillers with essential elements are preferred, while specialized fillers should be used when color matching is important.

Thorough cleaning of Corten steel is necessary to remove rust, mill scale, and contaminants, ensuring a strong bond and optimal filler metal performance.

Preheat the steel, especially for thicker sections, to prevent cracking, and maintain interpass temperatures between 250°F and 400°F for consistent weld quality.

Ensure the welding area is well-ventilated and use appropriate safety gear to protect against fumes and other hazards.

By carefully selecting the appropriate filler metal and adhering to proper welding techniques, welds on Corten steel can achieve the desired strength, durability, and aesthetic appeal.

Ensuring a pristine weld area is crucial for developing a uniform patina on Corten steel. Start by meticulously cleaning the area using a wire brush or chipping hammer to remove any slag, spatter, or contaminants. This step is vital for the steel to form its distinctive protective oxide layer.

Welding can disrupt the protective patina of Corten steel. There are two primary methods to restore this layer:

To ensure a smooth finish, use an angle grinder with a flap disc. Carefully grind the weld to blend it with the surrounding steel. Avoid excessive grinding, as this can weaken the weld joint.

Choosing the right shielding gas is essential for a clean weld surface. A mix of 75-80% argon and the rest carbon dioxide is recommended. This combination minimizes spatter and ensures a stable arc during welding.

Selecting the correct filler materials is crucial for maintaining the corrosion resistance and aesthetic consistency of Corten steel. Proprietary fillers like Cor-Match™ products are ideal for their excellent corrosion resistance and color matching capabilities.

After completing the welding and post-weld treatment processes, perform a thorough inspection to identify any defects or inconsistencies in the weld. Regular maintenance involves either allowing the steel to weather naturally or applying treatments to enhance its distinctive rusted appearance over time. Proper inspection and maintenance ensure the longevity and integrity of the weld, preserving the structural and aesthetic qualities of Corten steel.

A welding helmet is crucial for protecting your eyes from the intense light and sparks produced while welding. Ensure it has an auto-darkening feature to adjust the shade level automatically.

Welding gloves are vital for shielding your hands from heat, sparks, and sharp edges. Choose gloves that provide both protection and dexterity.

Welding fumes can be hazardous, so use a suitable respirator mask and ensure your workspace is well-ventilated to reduce fume concentration.

Keep your workspace clean and free from flammable materials. A well-organized area reduces the risk of accidents and ensures a smooth workflow.

Proper ventilation is necessary to manage welding fumes. Use exhaust systems or welding fume extractors to maintain a safe environment.

Welding can ignite nearby materials. Keep a fire extinguisher or blanket nearby and remove any flammable objects from the area.

Clean the Corten steel surface thoroughly to remove rust, mill scale, and other contaminants. Use tools like angle grinders and wire brushes to achieve a clean surface.

Choose filler metals that are compatible with Corten steel to ensure the weld maintains the mechanical properties and corrosion resistance of the base material.

Select suitable welding techniques such as MIG (GMAW), Stick (SMAW), or Flux-Cored Arc Welding (FCAW) based on the specific application and desired weld properties.

Use appropriate electrodes like E7018 for flat and horizontal positions, and select filler rods based on the welding position and material thickness.

To enhance patina formation and ensure a uniform appearance, apply weathering steel primers or treatments designed for Corten steel.

Post-weld treatments are crucial for maintaining the corrosion resistance of Corten steel, particularly in harsh environments. Apply suitable treatments to protect the weld area.

Prevent hydrogen cracking by ensuring a dry workspace and using low-hydrogen electrodes. Maintain proper preheating and interpass temperatures.

Monitor the heat-affected zone for potential distortion and warping, especially in thicker sections of Corten steel.

In salty or coastal environments, Corten steel may corrode faster. Additional protective coatings or more corrosion-resistant alloys may be required to enhance durability.

Corten steel is widely used in landscape and garden design due to its unique aesthetic and durability. Its rusty look blends well with nature, creating nice-looking installations.

Corten steel planter boxes are popular for their sleek, industrial look. They develop a natural patina over time, which enhances their visual appeal. These planters are also highly durable, resistant to weather conditions, and require minimal maintenance.

Using Corten steel for garden edging helps define spaces clearly while adding a modern touch to garden layouts. The steel’s weathering properties ensure that it maintains its structural integrity and appearance over time, even with constant exposure to moisture and soil.

Corten steel is extensively used in architectural projects where both aesthetics and durability are crucial. Its ability to form a stable, protective patina makes it ideal for various structural elements.

Corten steel is used in roofing and siding applications for its weather resistance and distinctive look. The patina layer acts as a protective barrier. This reduces the need for maintenance and ensures longevity. This makes it an excellent choice for buildings in harsh climates.

Architects often choose Corten steel for building facades to create striking visual effects. The material’s evolving appearance over time adds character to the structure, making it a dynamic and engaging feature of the design.

In structural engineering, Corten steel is valued for its strength and durability. It is used in various infrastructure projects where long-term performance is essential.

Corten steel is often used for bridges because it’s strong and corrosion-resistant. The material’s ability to form a protective layer reduces the need for frequent maintenance, making it cost-effective for long-term use.

Corten steel is also used in support structures for buildings and other infrastructure. Its strength and durability ensure that these structures can withstand significant loads and environmental stressors.

Artists and designers frequently use Corten steel in public art installations for its distinctive appearance and ability to withstand outdoor environments. Corten steel sculptures and large-scale art installations or monuments are popular in public spaces like parks and plazas. Their unique, evolving appearance due to the material’s patina adds depth and character, making them attractive communal features and ensuring they remain visually appealing and structurally sound over time.

Corten steel is also used in specialized applications such as mobile laboratories and industrial equipment, where durability and resistance to harsh conditions are paramount.

In mobile laboratories, Corten steel makes a strong and weather-proof structure. These labs are often deployed in challenging environments, and the steel’s properties ensure that the lab remains operational and secure.

Corten steel is used in the construction of industrial equipment that operates outdoors or in corrosive environments. Its ability to withstand harsh conditions while maintaining structural integrity makes it a preferred material for these applications.

Below are answers to some frequently asked questions:

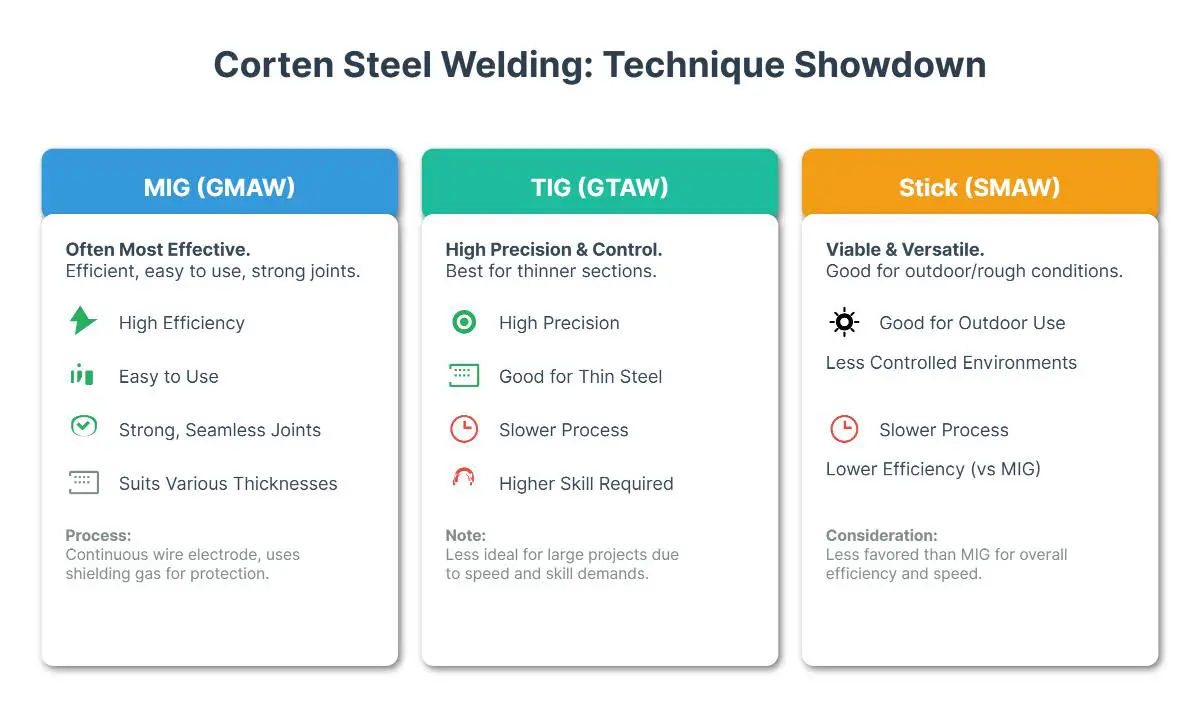

The best method for welding Corten steel typically depends on the specific requirements of your project, but MIG (GMAW) welding is often considered the most effective. This process is favored for its efficiency, ease of use, and ability to produce strong, seamless joints. MIG welding involves feeding a continuous wire electrode through a welding gun, accompanied by a shielding gas to protect the weld pool from contamination. This method is suitable for various thicknesses and provides good control over the weld.

For projects requiring high precision and control, TIG (GTAW) welding can be an excellent choice, especially for thinner sections of Corten steel. However, TIG welding is slower and requires a higher skill level, making it less ideal for larger projects.

Stick (SMAW) welding is another viable option, particularly for outdoor or less controlled environments, though it is less favored than MIG welding due to its slower process and lower efficiency.

To ensure the weld retains corrosion resistance when working with Corten steel, several steps must be followed. First, select appropriate filler materials that align with the corrosion-resistant properties of Corten steel, such as low-alloy fillers containing nickel, copper, and chromium. Examples include ER80S-Ni1 and Cor-Match™ products.

Next, use controlled welding techniques like intermittent welding to manage heat input, preventing excessive distortion and preserving the protective rust layer. Shielding gas mixtures of 75-80% argon and 20-25% carbon dioxide are recommended to protect the weld pool from oxidation.

Thorough preparation and cleaning of the weld area are crucial. Ensure the removal of all contaminants before welding and clean the weld area afterward using techniques like wire brushing or power washing.

To weld Corten steel, also known as weathering steel, you need specific tools and equipment to ensure optimal results and maintain its corrosion resistance. Here’s a comprehensive list:

Following these guidelines will help you achieve high-quality welds on Corten steel while preserving its durability and aesthetic appeal.

AWS D1.1 and D1.5 standards are essential for welding Corten steel, ensuring the structural integrity, safety, and longevity of welded structures. AWS D1.1 covers the general welding requirements for structural steel, including material specifications, welding techniques, and inspection methods. It ensures that welds meet necessary strength and durability standards for various structural applications. AWS D1.5 specifically addresses welding requirements for bridge construction, with detailed guidelines for welding different types of steel, including weathering steels like Corten.

When welding Corten steel, adhering to these standards ensures that the welds maintain the unique weathering properties of the material. This includes selecting appropriate filler metals that match the chemical composition and mechanical properties of Corten steel, using suitable welding techniques like MIG or TIG welding, and maintaining appropriate preheat and interpass temperatures to prevent thermal shock. Post-weld treatment, such as cleaning the weld area, is also critical to restore the protective patina and maintain both appearance and durability.

By following AWS D1.1 and D1.5 standards, welders can ensure that Corten steel welds are structurally sound, corrosion-resistant, and aesthetically consistent, thus meeting industry requirements for quality and safety.

Corten steel offers several sustainable benefits in welding projects. It is 100% recyclable, aligning with eco – friendly building practices. The natural patina eliminates the need for environmentally harmful paints and coatings. Its self – protective rust layer gives it a long lifespan, often over 100 years, reducing the need for frequent replacements and conserving resources. With minimal maintenance requirements, it cuts down on long – term costs and environmental impacts related to repairs. Corten steel’s unique appearance blends well with natural landscapes, and its versatility allows for various designs. Although it has a higher initial cost, long – term savings are significant due to durability and low upkeep.

While it is possible to use the same filler metal for various welding processes on Corten steel, the selection should be carefully considered to maintain the material’s unique properties, such as corrosion resistance and weathering characteristics. For single-pass welds, mild steel fillers like ER70S-6 can be used across MIG, TIG, and Stick welding. However, for multi-pass welds or thicker sections, low-alloy fillers containing elements like nickel, copper, and chromium (e.g., ER80S-Ni1) are recommended to ensure the weld’s mechanical properties and corrosion resistance align with those of Corten steel. Therefore, while some versatility exists, the optimal choice depends on specific welding requirements and desired outcomes.