Imagine a material so versatile and resilient that it stands strong in the face of extreme heat, relentless corrosion, and immense stress. Welcome to the world of Inconel 625, an alloy that has become indispensable in industries ranging from aerospace to marine engineering. In this comprehensive guide, we will delve into the key properties that make Inconel 625 a material of choice for critical applications. You will discover its remarkable mechanical and physical properties, explore its complex chemical composition, and understand why it thrives in some of the most challenging environments. Whether you are an engineer, a materials scientist, or simply curious about advanced alloys, this article will provide you with a detailed technical reference that answers your questions and deepens your understanding. Ready to uncover the secrets behind Inconel 625’s exceptional performance? Let’s dive in.

Inconel 625 is a high-performance nickel-based superalloy known for its exceptional mechanical properties, corrosion resistance, and high-temperature durability. This solid-solution strengthened alloy is primarily composed of nickel, chromium, and molybdenum, with significant additions of niobium and tantalum. These elements collectively contribute to the alloy’s robustness and versatility in demanding environments.

In the aerospace sector, Inconel 625 is used extensively due to its excellent fatigue and thermal-fatigue properties, oxidation resistance, and weldability, making it ideal for components such as engine exhaust systems, thrust reversers, fuel and hydraulic line tubing, and aircraft ducting systems. These applications benefit from the alloy’s ability to maintain strength and integrity at high temperatures, ensuring safety and performance.

The marine industry values Inconel 625 for its exceptional resistance to seawater corrosion, making it ideal for submarine components, propeller blades, and undersea communication cable sheathing. The alloy’s durability in harsh marine environments extends the lifespan of components and reduces maintenance costs.

Inconel 625 is widely used in chemical processing due to its resistance to a broad spectrum of corrosive media, including acids and alkalis. Typical applications include heat exchangers, reactor vessels, distillation columns, and bubble caps. The alloy’s ability to withstand aggressive chemicals without degrading ensures the reliability and longevity of processing equipment.

In the nuclear industry, Inconel 625’s high strength, excellent corrosion resistance, and stability under high radiation exposure are crucial. It is used in reactor core components, control rod mechanisms, and heat exchangers, contributing to the safe and efficient operation of nuclear power plants.

Inconel 625’s diverse applications across industries underscore its importance as a material that delivers exceptional performance in the most challenging environments.

Inconel 625 is known for its remarkable tensile strength, which measures the maximum stress the material can endure while being stretched or pulled before breaking. The tensile strength of Inconel 625 ranges from 827 MPa to 1103 MPa, depending on the specific heat treatment and processing methods applied. This high tensile strength makes it suitable for applications requiring significant load-bearing capacity and resilience under mechanical stress.

Yield strength, the stress at which a material begins to deform plastically, ranges from 414 MPa to 690 MPa for Inconel 625. This property is crucial for engineering applications where the material must maintain its shape and not undergo permanent deformation under operational loads.

Hardness is a measure of a material’s resistance to localized plastic deformation (e.g., indentation). Inconel 625 typically exhibits a hardness of approximately 240 HB (Brinell Hardness). This level of hardness indicates good wear resistance, making the alloy suitable for abrasive environments and high-contact applications.

The density of Inconel 625 is approximately 8.44 g/cm³. This relatively high density is characteristic of nickel-based superalloys and contributes to the material’s robustness and stability in high-stress and high-temperature environments.

Inconel 625 has a melting point range of 1288°C to 1349°C. This high melting point is a key factor that contributes to the alloy’s excellent performance at elevated temperatures, as it maintains structural integrity and strength.

Inconel 625 is renowned for its excellent corrosion resistance, which is due to its high chromium and molybdenum content. These elements form a protective oxide layer on the surface of the alloy, preventing further oxidation and corrosion. This makes Inconel 625 particularly effective in harsh environments, including those with high levels of chloride ions, such as seawater.

Compared to other nickel-based superalloys, Inconel 625 offers superior resistance to a wide range of corrosive environments, including both oxidizing and reducing conditions. For instance, while Inconel 718 also provides excellent mechanical properties, it does not match the corrosion resistance of Inconel 625 in marine and chemical processing environments. This makes Inconel 625 a preferred choice for applications where both high strength and outstanding corrosion resistance are required.

Inconel 625 is a nickel-based superalloy characterized by a complex chemical composition that contributes to its outstanding mechanical properties and corrosion resistance. Understanding the chemical makeup of Inconel 625 is crucial for appreciating its performance in various applications.

Nickel, which makes up at least 58% of Inconel 625, forms the alloy’s foundation, providing excellent toughness, corrosion resistance, and stability at high temperatures.

Chromium is present in Inconel 625 in amounts ranging from 20% to 23%. Chromium improves the alloy’s resistance to oxidation by creating a stable surface layer that protects against further corrosion.

In addition to nickel and chromium, several other elements play significant roles in the properties of Inconel 625:

Each element in Inconel 625’s composition has a specific role that contributes to the alloy’s superior performance:

For engineers and material scientists, knowing Inconel 625’s chemical composition is crucial for choosing the right material for demanding applications, ensuring it meets specific environmental and mechanical needs.

UNS N06625, also known as Inconel 625, is a highly regarded nickel-based superalloy celebrated for its outstanding properties. The Unified Numbering System (UNS) standardizes the naming of alloys, ensuring consistency and clarity across various industries and applications.

Inconel 625 is governed by several international specifications that outline the requirements for its chemical composition, mechanical properties, and processing methods. These standards ensure that the alloy’s chemical composition is meticulously controlled to meet the rigorous demands of various applications.

The chemical composition of UNS N06625 is specified to guarantee its performance in demanding environments. Key elements and their ranges include:

UNS N06625 specifications also define the mechanical properties required for various forms of the alloy, ensuring that it can withstand extreme conditions:

Various industry standards regulate the use and certification of UNS N06625, ensuring its quality and suitability for diverse applications:

The American Society for Testing and Materials (ASTM) provides multiple standards for Inconel 625:

The American Society of Mechanical Engineers (ASME) includes Inconel 625 in its Boiler and Pressure Vessel Code:

The Aerospace Material Specifications (AMS) are crucial for aerospace applications:

Inconel 625 is also recognized under various international standards:

Different industries have unique requirements for UNS N06625 to ensure safety and performance, such as high strength and thermal fatigue resistance in aerospace, corrosion resistance in marine environments, and stability under radiation in nuclear applications.

Inconel 625 is prized in the marine industry for its outstanding resistance to seawater corrosion, essential for components in harsh marine environments.

In the aerospace industry, Inconel 625 is prized for its high strength, oxidation resistance, and ability to withstand extreme temperatures.

Inconel 625 is utilized in the nuclear industry for its high strength, corrosion resistance, and stability under radiation exposure.

Inconel 625’s resistance to various corrosive environments makes it a preferred choice in the chemical processing industry.

In addition to marine, aerospace, and nuclear uses, Inconel 625 is also employed in other sectors due to its versatile properties.

Vacuum Induction Melting (VIM) and Vacuum Arc Remelting (VAR) are essential processes for producing Inconel 625, ensuring a refined microstructure by removing impurities. VIM involves melting the alloy under a vacuum to avoid contamination, while VAR further refines the alloy by remelting it in an electric arc furnace under a vacuum.

Hot forming at elevated temperatures is ideal for complex shapes due to the alloy’s high ductility, while cold forming at room temperature suits simpler geometries. Both methods require robust tools and lubricants to handle the alloy’s high strength and work-hardening characteristics.

Carbide and ceramic-tipped tools are recommended because they resist wear and withstand high temperatures. These tools provide the durability needed to machine the alloy efficiently.

Inconel 625 must be machined at lower cutting speeds to avoid work hardening and tool wear. Moderate speeds balance tool wear and surface finish. Optimizing feed rates ensures consistent tool engagement and prevents tool failure. Controlling the depth of cut manages thermal and mechanical loads on the tools.

Effective cooling is vital when machining Inconel 625 to reduce heat buildup and prolong tool life. High-performance cutting fluids designed for high-temperature alloys are recommended. These fluids help dissipate heat and lubricate the cutting zone, improving machining efficiency.

A rigid setup and secure clamping are essential to counteract the high forces generated during machining. Properly securing the workpiece ensures dimensional accuracy and prevents vibrations that can damage both the tool and the material.

Post-machining processes such as grinding, honing, polishing, and electropolishing help achieve the desired surface finish and improve the performance of Inconel 625 components. These processes help remove any residual stresses and improve the surface integrity, reducing the likelihood of surface defects that could lead to premature failure.

Inconel 625 can be welded using various techniques, including Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW). These methods require careful control to avoid issues such as cracking and thermal stresses.

GTAW, also known as TIG welding, is preferred for its precision and control. It is suitable for joining thin sections and provides high-quality welds with minimal contamination.

GMAW, or MIG welding, is used for thicker sections and offers higher deposition rates. It is essential to use appropriate filler materials and maintain proper heat input to achieve sound welds.

Inconel 625 and Inconel 718, both nickel-based superalloys, cater to different needs because of their unique properties.

Inconel 625 and Incoloy 825 are designed for corrosion resistance but serve different specific applications.

Hastelloy C276 is another high-performance alloy used in similar applications as Inconel 625.

Monel 400 is a nickel-copper alloy with distinct properties compared to Inconel 625.

Inconel 625 is increasingly favored in industries where sustainability and high performance are paramount. Several trends are driving the adoption of this superalloy, reflecting a broader shift towards materials that offer both durability and environmental benefits.

A major trend driving the use of Inconel 625 is its efficiency in material usage. The alloy’s exceptional durability and resistance to corrosion mean that components made from Inconel 625 require less frequent replacements. This longevity reduces material waste and supports sustainable manufacturing practices. Industries are recognizing the importance of using materials that minimize the need for repairs and replacements, thereby conserving resources and reducing environmental impact.

Inconel 625’s performance in high-temperature applications contributes to improved energy efficiency. Its ability to maintain structural integrity and resist oxidation at elevated temperatures means that machinery and equipment can operate more efficiently with less energy loss.

The environmental impact of Inconel 625 is mitigated by its resistance to degradation in harsh conditions. This property is particularly beneficial in marine and chemical processing environments, where materials face aggressive elements. By reducing the frequency of replacements and maintenance, Inconel 625 helps minimize environmental disruption and the consumption of raw materials.

Another sustainability advantage of Inconel 625 is its recyclability. Nickel-based superalloys can be recycled without significant loss of properties, making them a sustainable choice for long-term applications. The ability to recycle Inconel 625 contributes to a circular economy, where materials are reused and repurposed, reducing the demand for virgin raw materials and lowering the overall environmental impact.

Inconel 625’s mechanical properties, including high tensile and yield strength, enable it to withstand extreme conditions while maintaining superior corrosion resistance, particularly in chloride and acidic environments. The alloy’s ability to maintain performance under these harsh conditions ensures long-term reliability and functionality, which is crucial for applications in marine, chemical, and nuclear industries.

Inconel 625’s thermal stability makes it suitable for applications that involve significant temperature variations. This stability ensures that the alloy can perform reliably in high-temperature environments, reducing the risk of thermal degradation and extending the lifespan of components. The ability to maintain performance under thermal stress supports the efficient and sustainable operation of systems in demanding industries.

In the aerospace sector, Inconel 625 is used in components such as jet engine exhausts and thrust-reverser systems due to its high-temperature and stress resistance. The alloy’s ability to maintain strength and integrity at high temperatures contributes to the efficiency and reliability of aerospace systems, supporting sustainable aviation practices.

Inconel 625’s resistance to seawater corrosion makes it ideal for marine applications, including submarine components and undersea communication cable sheathing. The alloy’s durability in harsh marine environments reduces the need for frequent maintenance and replacements, promoting sustainable marine engineering.

The nuclear industry benefits from Inconel 625’s high strength and corrosion resistance, particularly under radiation exposure. Its use in reactor core components and control rod mechanisms ensures the safe and efficient operation of nuclear power plants, contributing to sustainable energy production.

Below are answers to some frequently asked questions:

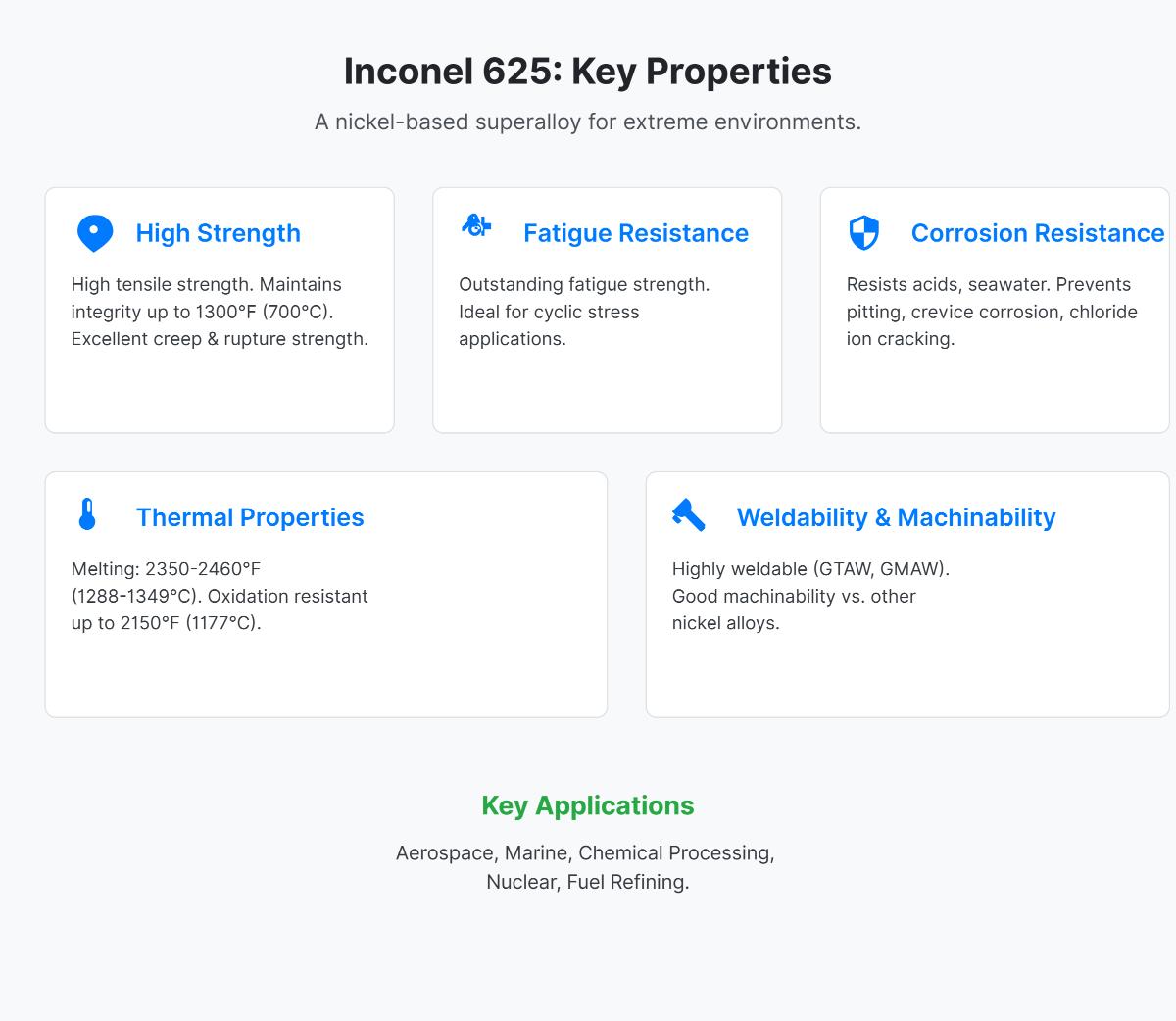

Inconel 625 is a nickel-based superalloy known for its excellent performance in extreme environments. The key properties of Inconel 625 include:

These properties make Inconel 625 highly valuable in industries such as aerospace, marine, chemical processing, nuclear, and fuel refining.

Inconel 625 is utilized in various demanding applications due to its excellent mechanical properties, high corrosion resistance, and ability to maintain structural integrity at extreme temperatures. In the aerospace industry, it is employed in components such as turbine blades, combustion chambers, seals, and fuel and hydraulic systems, where high thermal stability and stress resistance are critical. The chemical processing sector uses Inconel 625 for reaction vessels, heat exchangers, and valves, benefiting from its resistance to corrosive media and high temperatures. In the nuclear industry, it is applied in reactor components, including control rods and core elements, due to its strength and corrosion resistance. The oil and gas industry leverages Inconel 625 in high-pressure systems and natural gas processing equipment for its durability in corrosive and high-temperature environments. Additionally, the marine industry employs it in propeller blades and submarine equipment for its superior resistance to seawater corrosion. These diverse applications underscore the alloy’s versatility and reliability in extreme conditions.

Inconel 625 is a nickel-chromium alloy known for its outstanding strength and corrosion resistance. Its chemical composition is as follows:

Each element plays a critical role in enhancing the alloy’s properties. Nickel provides a base for high strength and corrosion resistance, chromium offers oxidation resistance, molybdenum and niobium contribute to high-temperature strength and resistance to pitting and crevice corrosion, while the remaining elements fine-tune the material’s mechanical properties, ductility, and overall stability.

Inconel 625 is a nickel-based superalloy that stands out in comparison to other nickel alloys due to its unique blend of high strength, excellent corrosion resistance, and versatility in various applications. Inconel 625 contains a significant amount of nickel (58%) and chromium (20-23%), along with molybdenum and niobium, which enhance its mechanical properties and corrosion resistance. Compared to Inconel 718, another popular nickel alloy, Inconel 625 offers superior resistance to pitting and crevice corrosion, making it particularly suitable for marine and chemical processing environments. While Inconel 718 is favored for its higher strength and better performance at cryogenic temperatures, Inconel 625 is more easily fabricated and welded, allowing for greater flexibility in complex and thin-walled structures. Its ability to maintain integrity in high-temperature and high-stress conditions also makes it a preferred material in aerospace and nuclear applications.

Machining Inconel 625, a high-strength, corrosion-resistant nickel-based superalloy, presents specific challenges due to its hardness and tendency to work harden. Best practices include:

By adhering to these best practices, manufacturers can effectively machine Inconel 625, leveraging its excellent properties while managing its challenging characteristics.

Inconel 625 is preferred in high-temperature applications due to its exceptional ability to maintain mechanical properties under extreme conditions. This nickel-based superalloy exhibits excellent tensile strength, yield strength, and resistance to oxidation, which are crucial for performance in high-temperature environments. Specifically, Inconel 625 retains its strength and stability across a broad temperature range, from cryogenic conditions to up to 1800°F (982°C). Additionally, its high resistance to oxidation prevents degradation and material loss at elevated temperatures, ensuring longevity and reliability in demanding applications.

The alloy’s composition, which includes significant amounts of nickel, chromium, molybdenum, and niobium, contributes to its outstanding performance. Nickel and chromium enhance its oxidation and corrosion resistance, while molybdenum and niobium improve its strength and stability. These properties make Inconel 625 ideal for applications in aerospace (e.g., engine components and exhaust systems), chemical processing (e.g., high-temperature equipment), and the nuclear industry (e.g., reactor core parts), where materials must endure high temperatures and corrosive environments.