Imagine a metal that is as strong as steel yet incredibly lightweight, resistant to corrosion, and capable of withstanding extreme temperatures. This marvel is titanium, a material prized in industries ranging from aerospace to medical devices. But when it comes to its flammability, titanium holds a few surprising secrets. Is titanium flammable? And if so, what conditions make it catch fire? In this article, we will dive deep into the physical and chemical properties of titanium to uncover the truths about its flammability, explore how it reacts with water, and understand the safety precautions necessary for handling it. Whether you’re curious about titanium’s behavior or looking to enhance your knowledge about this versatile metal, join us as we unravel the complexities of titanium’s properties and its fascinating role in modern technology.

Titanium, symbolized as Ti with an atomic number of 22, is a chemical element. It is a lustrous transition metal known for its silver-grey color, high strength, and low density. Titanium is highly valued in various industries due to its unique combination of physical and chemical properties.

Titanium has an atomic structure characterized by a hexagonal close-packed (hcp) crystal lattice at room temperature, which transforms into a body-centered cubic (bcc) structure at higher temperatures. This atomic arrangement contributes to its notable strength and low density of approximately 4.5 grams per cubic centimeter (g/cm³), making titanium significantly lighter than steel.

Titanium has a low density of approximately 4.5 grams per cubic centimeter (g/cm³), making it significantly lighter than steel. Its strength-to-weight ratio makes it ideal for applications where both factors are critical.

Titanium has a high melting point of around 1,660°C (3,020°F) and a boiling point of approximately 3,287°C (5,949°F). These high thermal thresholds make titanium suitable for high-temperature environments.

When heated, titanium becomes ductile and malleable, allowing it to be formed into various shapes without breaking. This property is essential for manufacturing complex components in industries such as aerospace and medical devices.

Titanium has poor thermal and electrical conductivity compared to metals like copper, so it is not used in applications requiring high conductivity.

Titanium primarily exhibits an oxidation state of +4, although it can also exist in other states such as -2 and -1 under specific conditions. The +4 oxidation state is the most stable and commonly observed in titanium compounds.

Titanium is notably resistant to corrosion. When exposed to air, titanium forms a thin, protective oxide layer of titanium dioxide (TiO₂), which prevents further oxidation. This makes titanium highly resistant to corrosion from seawater, chlorine, and many acids, except hydrofluoric acid.

Titanium can react with various elements, particularly at high temperatures. For example, it reacts with oxygen to form titanium dioxide and with nitrogen to form titanium nitride. These reactions contribute to titanium’s unique properties but also require careful handling, especially in powdered form.

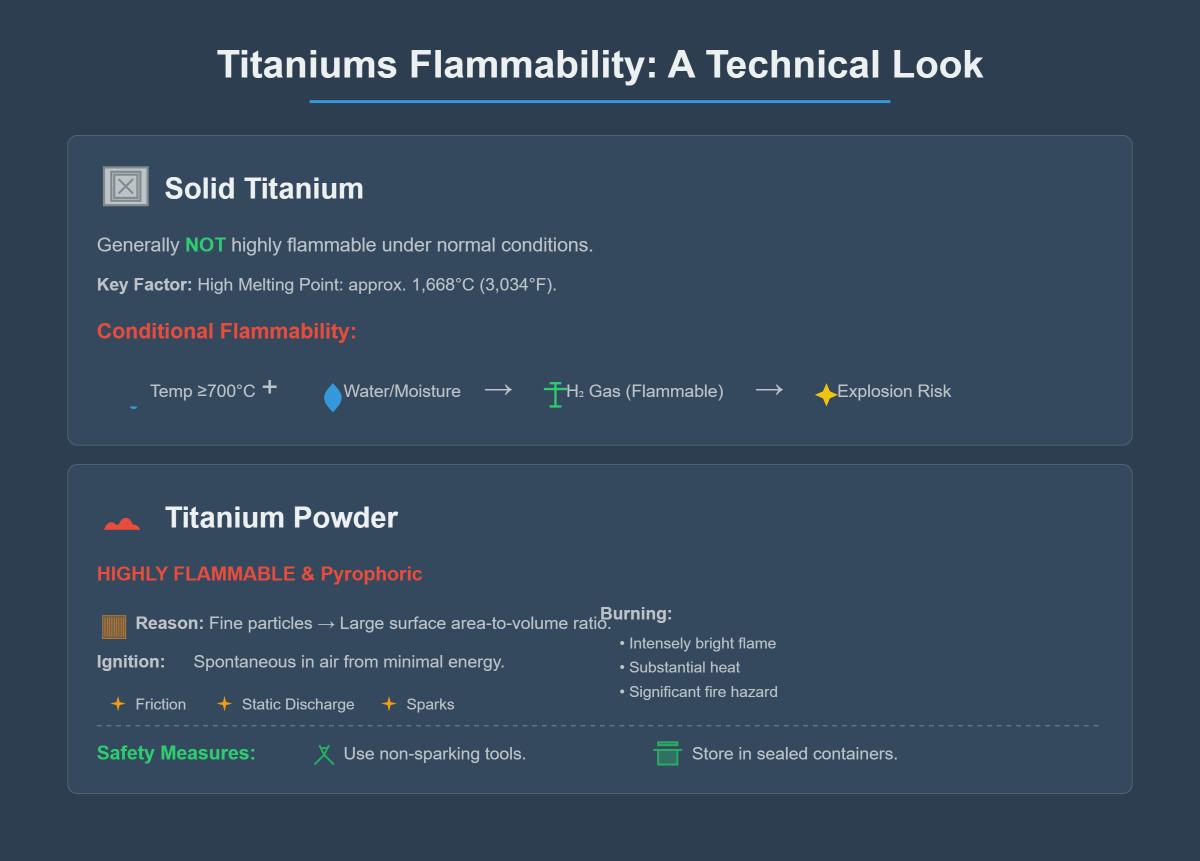

Under normal conditions, solid titanium is not highly flammable. Its high melting point and stable structure contribute to its resistance to ignition. However, at elevated temperatures, titanium can react with moisture in the air, potentially producing flammable hydrogen gas.

In contrast, titanium powder is highly flammable and classified as pyrophoric. Due to its high surface area-to-volume ratio, titanium powder can ignite spontaneously in air, releasing intense heat and light. This property necessitates strict safety measures when handling titanium in powdered form.

Handling titanium, particularly in powdered form, requires adherence to stringent safety protocols to prevent fires and explosions. This includes using explosion-proof equipment, controlling environmental conditions, and employing specialized fire extinguishing agents. Traditional fire-fighting methods, such as using water, can exacerbate titanium fires by producing flammable gases and should be avoided.

Flammability refers to the ability of a material to catch fire and sustain combustion. It is a critical property to consider in materials, especially in industrial applications where safety is paramount. Flammable materials can pose significant risks, including fires and explosions, which can lead to property damage, injury, or even loss of life.

Under normal conditions, solid titanium is not highly flammable. Its high melting point of about 1,668°C (3,034°F) makes it resistant to ignition. However, at elevated temperatures, titanium can react with moisture in the air to produce hydrogen gas, which is highly flammable and can pose an explosion risk. This reaction highlights the importance of controlling the environmental conditions when working with titanium in high-temperature settings.

In contrast to its solid form, titanium powder is highly flammable and pyrophoric due to its high surface area-to-volume ratio, which allows it to ignite spontaneously in air with minimal energy input, such as a spark or friction. Once ignited, titanium powder burns intensely and generates significant heat, posing severe fire hazards. Therefore, strict safety measures are necessary when handling titanium in powdered form to prevent accidental ignition.

Several factors influence how easily titanium can catch fire, especially in its powdered form:

Titanium is more likely to ignite and sustain combustion in oxygen-enriched environments. For instance, commercially pure titanium can burn in atmospheres containing 70% oxygen and balance nitrogen at relatively low pressures. This increased reactivity in oxygen-rich conditions necessitates careful control of the ambient atmosphere when working with titanium, especially in industrial settings.

Higher temperatures and pressures can increase the likelihood of titanium ignition and accelerate its burning rate. Thin titanium samples, which have a larger surface area relative to their volume, are more prone to ignition than thicker samples. This property underscores the importance of monitoring and regulating temperature and pressure conditions during the processing and handling of titanium.

Titanium dust, a byproduct of various manufacturing processes, is particularly hazardous due to its high flammability. The fine particles can easily become airborne and disperse, creating an explosive atmosphere if ignited. Proper dust control measures, such as ventilation systems and dust collection equipment, are essential to minimize the risk of titanium dust explosions.

The combustion temperature of titanium is exceedingly high, often exceeding 3,000°C (5,432°F). This intense heat can cause significant damage to nearby materials and structures. Firefighting efforts must take this into account, as traditional extinguishing methods may be ineffective or even exacerbate the situation.

Titanium’s reaction with water can produce hydrogen gas, especially at elevated temperatures. This reaction can be dangerous because hydrogen is highly flammable and can lead to explosions. Therefore, water should not be used to extinguish titanium fires. Instead, dry chemical powders, sand, or lime are recommended for extinguishing titanium fires to prevent the production of flammable gases.

Understanding the flammability characteristics of titanium is crucial for ensuring safe handling and processing practices. Proper safety measures and environmental controls can mitigate the risks associated with titanium’s flammability, particularly in its powdered form.

Titanium is prized for its strength, lightweight nature, and resistance to corrosion, especially when in powdered form. This makes it a valuable material, but also one that requires careful handling due to its pyrophoric properties, meaning it can ignite spontaneously in air under certain conditions.

When working with titanium powder, it is crucial to control environmental factors that could lead to ignition. Avoid any open flames, sparks, or heat sources by using non-sparking tools and explosion-proof equipment. Additionally, operations that might generate titanium dust should be conducted in a controlled environment, such as a chemical fume hood, to prevent the formation of explosive powder clouds.

Static electricity can ignite titanium powder. Prevent this by grounding equipment and using floors that dissipate static. This ensures any static charge is safely managed, reducing the risk of accidental ignition.

Titanium powder should be stored wet in tightly closed containers to reduce reactivity and prevent spontaneous ignition. It is also important to keep it away from strong oxidizing agents and incompatible materials. Storage cabinets should be clearly labeled with hazard warnings and be well-ventilated and secure.

If a titanium fire occurs, use Class D fire extinguishers or dry sand. Avoid water and conventional extinguishers, as they can make the fire worse. Having the right firefighting materials on hand is essential for managing titanium fires safely.

Always wear safety glasses, gloves, and a lab coat when handling titanium to protect against irritation. Use a respirator and ensure proper ventilation to avoid inhaling titanium dust. This protective gear helps safeguard against the health risks associated with titanium exposure.

Personnel handling titanium should be trained in safe handling procedures. Maintaining good laboratory hygiene practices, such as frequent hand washing and avoiding eating or drinking in the laboratory, is also important to prevent contamination.

Manipulations involving titanium powder should be conducted in a contained environment like a fume hood. Using wet titanium powder can help minimize its reactivity and reduce the risk of ignition.

Titanium powder should be stored in well-ventilated, secure cabinets that are clearly labeled with hazard warnings. Proper storage helps ensure the powder is kept safely and reduces the risk of accidental ignition.

Titanium powder and any materials contaminated with it should be disposed of as hazardous waste, following local regulations. This ensures that the materials are handled safely and do not pose a risk to people or the environment.

By following these safety precautions, the risks associated with handling and storing titanium, particularly in its powdered form, can be significantly reduced. Proper safety measures and environmental controls are essential to ensure the safe use of this valuable material.

Titanium is crucial in aerospace because of its unique properties. Its high strength-to-weight ratio allows for the construction of lightweight yet durable aircraft components. Titanium is used in critical parts such as fuselages, wings, and landing gear, where both strength and weight savings are crucial. Additionally, its ability to withstand high temperatures makes it ideal for use in jet engines and other high-temperature environments.

Titanium’s excellent corrosion resistance makes it ideal for construction and industrial engineering, particularly in environments where other materials degrade quickly. For example, titanium is often used in chemical processing plants, where it resists corrosion from acids and chlorides. It is also used in heat exchangers and other equipment that must endure harsh conditions.

Titanium is favored for marine use due to its seawater corrosion resistance. It is used in shipbuilding for components such as propeller shafts and hulls, where long-term exposure to seawater can cause significant corrosion issues. Titanium is also employed in offshore equipment and seawater desalination plants, where its durability and resistance to corrosion are invaluable.

Titanium is highly biocompatible, making it ideal for medical devices like surgical implants, which do not react with bodily fluids and are less likely to be rejected. Common medical applications include joint replacements, dental implants, and surgical instruments. Its strength and light weight also contribute to the comfort and effectiveness of these medical devices.

Titanium’s light weight and strength enhance high-performance sporting goods like golf clubs, tennis rackets, and bicycle frames by reducing weight without sacrificing durability. Titanium’s resistance to corrosion and fatigue ensures that these products have a long lifespan, even under strenuous use.

Titanium is increasingly seen as a sustainable material due to its long life and recyclability. Innovations in titanium processing and fabrication are making it more cost-effective, expanding its applications across various industries. Researchers are continually developing new titanium alloys and manufacturing techniques to further enhance its properties and reduce production costs. This ongoing innovation is driving the broader adoption of titanium, ensuring its place as a critical material in modern engineering and manufacturing.

Below are answers to some frequently asked questions:

Titanium’s flammability primarily depends on its form and environmental conditions. Solid titanium is generally not highly flammable under normal conditions due to its high melting point of approximately 1,668°C (3,034°F). However, at elevated temperatures around 700°C or higher, titanium can react with water or moisture in the air to release hydrogen gas, which is flammable and can create explosion risks.

Titanium powder, on the other hand, is highly flammable and classified as a pyrophoric material. The fine particles have a large surface area-to-volume ratio, making them capable of igniting spontaneously in air from minimal energy sources such as friction, static discharge, or a spark. This powder burns with an intensely bright flame and generates substantial heat, posing significant fire hazards. Proper safety measures, such as using non-sparking tools and storing the powder in sealed containers, are crucial to mitigate these risks.

Titanium generally does not react with water under normal conditions due to its protective oxide layer. This oxide layer prevents the metal from interacting with water at room temperature, making titanium stable and resistant to corrosion. However, under specific conditions, such as high temperatures, titanium can react with steam to form titanium dioxide (TiO₂) and hydrogen gas. This reaction typically occurs at elevated temperatures, around 700°C or higher. It’s important to note that while solid titanium is stable, titanium powder is highly reactive and can ignite spontaneously in air. This reactivity makes handling titanium powder particularly hazardous and requires specific safety precautions.

Handling titanium dust requires careful safety measures due to its highly flammable and pyrophoric nature, especially when in powdered form. The following precautions are essential to ensure safe handling:

Firstly, wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, flame-retardant clothing, and a respirator to prevent inhalation of dust. Ensure that the work environment has good ventilation to avoid dust accumulation and keep it free from ignition sources like open flames, sparks, or hot tools.

Additionally, control electrostatic discharge by grounding equipment and personnel to prevent static electricity buildup, which can ignite titanium powder. Store titanium powder in tightly sealed containers in cool, dry areas away from heat sources and reactive materials, and clearly label containers with appropriate signage to alert workers of potential hazards.

For fire safety, use specialized Class D fire extinguishers or dry sand for fires involving titanium dust, as water can worsen the situation. Have emergency response plans in place, including evacuation procedures and first aid measures.

By following these guidelines, you can significantly reduce the risks associated with handling titanium dust and ensure a safe working environment.

Titanium is highly valued in various industries due to its remarkable properties, including high strength, low density, and excellent corrosion resistance. In the aerospace industry, titanium is used for aircraft components like fuselages, wings, and landing gear, as well as jet engines, due to its high strength-to-weight ratio and ability to withstand high temperatures. In chemical and industrial engineering, titanium’s corrosion resistance makes it ideal for chemical reactors, water desalination systems, and pharmaceutical processing equipment. In power generation, titanium is used in turbine blades and condenser tubing for its durability and corrosion resistance. Marine applications benefit from titanium’s resistance to seawater corrosion, making it suitable for submersibles and shipboard systems. Additionally, in the medical field, titanium is used in implants such as hip and knee replacements due to its biocompatibility and ability to bond with bone tissue. These diverse applications demonstrate titanium’s significant role in enhancing performance and efficiency across multiple sectors.

Titanium’s flammability varies significantly based on its form. In its solid state, titanium is not highly flammable due to its high melting point of approximately 3,034°F (1,668°C). This makes solid titanium less likely to ignite under normal conditions. However, when titanium is in powdered form, it becomes highly flammable. The fine particles of titanium powder have a large surface area that can ignite spontaneously in air with minimal energy, classifying it as a pyrophoric material. Comparatively, metals like magnesium and aluminum are also flammable, especially in fine forms, but titanium powder is particularly reactive and difficult to extinguish once ignited. Stainless steel, on the other hand, is generally non-flammable due to its high thermal stability. Overall, titanium’s flammability is moderate in solid form but significantly higher in powdered form.