When it comes to the world of metallurgy, few debates are as compelling as the comparison between Japanese and American steel. Both have earned stellar reputations for their quality, but what sets them apart? Is it the meticulous craftsmanship and ancient traditions embedded in Japanese steel, or the robust industrial advancements and innovative techniques of American steel? This article delves into the intricate details of these two titans of the steel industry. We’ll explore their unique characteristics, production processes, cost factors, and the quality and durability of their products. By the end, you’ll have a comprehensive understanding of how Japanese steel measures up against its American counterpart and the subtle nuances that distinguish them. So, which one stands out in the realm of steel—Japan’s revered legacy or America’s powerhouse production? Let’s find out.

When evaluating steel for various applications, two prominent types often come up: Japanese steel and American steel. These categories have distinct characteristics shaped by their historical and cultural contexts, influencing their performance in different scenarios. Understanding these differences is essential for making informed decisions, whether for industrial applications, knife making, or general manufacturing.

Japanese steel has a long history rooted in traditional craftsmanship. Known for its meticulous production methods, Japanese steel often emphasizes high carbon content, resulting in very hard and sharp blades. This heritage is reflected in the famous samurai swords, which require precision and skill to produce. Modern Japanese steel continues this tradition, focusing on achieving high hardness and edge retention. As a result, it is highly sought after for precision tools and knives.

American steel developed in the context of mass production and industrial efficiency. The steel industry in the United States grew rapidly during the industrial revolution, focusing on producing large quantities of durable and versatile steel. American steel generally prioritizes toughness and resistance to wear, making it ideal for a wide range of heavy-duty applications, including construction, automotive manufacturing, and heavy machinery.

Japanese steel is often used in applications where precision and sharpness are paramount. This includes high-end kitchen knives, surgical instruments, and fine cutting tools. The emphasis on sharpness and edge retention makes it ideal for tasks requiring meticulous accuracy.

American steel is favored in industries where durability and resistance to wear are critical. This includes construction, automotive manufacturing, and heavy machinery. The focus on toughness and flexibility makes it suitable for heavy-duty tools and components that need to withstand significant stress and impact.

Japanese steel is famous for its high carbon content, which results in exceptional hardness and sharpness. Historically, the production of Japanese steel is deeply rooted in traditional craftsmanship, leading to materials highly prized for their precision and quality. Japanese steel typically exhibits a fine grain structure, allowing for sharper edges and more precise cuts, particularly evident in high-end kitchen knives and cutting tools.

Japanese steel is predominantly used in industries that require precision and sharpness. Key sectors include culinary tools, surgical instruments, and fine cutting tools. The emphasis on achieving and maintaining a sharp edge makes it suitable for applications where meticulous accuracy is paramount.

American steel is characterized by its emphasis on toughness and durability. Developed during the industrial revolution, the production of American steel has been geared towards mass production and industrial efficiency. It typically features a coarser grain structure, enhancing its toughness and resistance to impact.

American steel is used extensively in industries that require durability and resistance to wear. Key sectors include construction, automotive manufacturing, and heavy machinery. The focus on toughness and flexibility makes it suitable for heavy-duty tools and components that need to withstand significant stress and impact.

| Property | Japanese Steel | American Steel |

|---|---|---|

| Hardness (HRC) | 58-68 | Typically under 59 |

| Grain Structure | Finer | Coarser |

| Corrosion Resistance | Varies with alloy (e.g., VG-10) | Moderate (varies) |

| Applications | Precision cutting; knives, culinary tools | Versatile; construction, automotive, machinery |

| Maintenance | Needs careful sharpening, more prone to chipping | Easier to sharpen, less prone to chipping |

This table highlights the key differences between high-end Japanese steel types and their American counterparts, emphasizing the strengths and applications of each. Japanese steel excels in precision cutting tasks due to its higher hardness and fine grain structure, while American steel is valued for its durability and ease of maintenance, making it suitable for a broader range of industrial applications.

Understanding the steel production processes of Japan and the United States reveals important differences that contribute to the unique characteristics and qualities of their steel products. Both countries utilize advanced technologies, but their approaches and historical developments have led to distinct methodologies and outcomes.

Japanese steel production has deep roots, with traditional methods like the Tatara furnace dating back to the 6th century. The Tatara furnace was a charcoal – fired bloomery that produced high – quality iron. Its long – standing use in Japan instilled a culture of precision and quality in steelmaking. The careful control of the combustion process and the slow, labor – intensive nature of the Tatara furnace taught Japanese steelmakers the importance of heat management, material purity, and the right balance of elements. These lessons were gradually adapted and incorporated into modern steelmaking techniques, influencing everything from the selection of raw materials to the precision control of modern furnaces.

Japan employs state – of – the – art technologies such as the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF). These methods allow for efficient steel production with high quality. The BOF process is notable for its ability to produce large quantities of high – quality steel rapidly. In this process, pure oxygen is blown into molten iron. The oxygen reacts with the carbon in the iron, forming carbon monoxide and carbon dioxide. These gases escape from the molten metal, reducing the carbon content and transforming the iron into steel.

Japanese steelmakers excel in producing specialty steels such as Tamahagane, which is used in traditional sword making, and modern high – carbon steels like Aogami Super Blue and VG10. These steels are known for their purity, strength, and superior edge retention.

Japan is a leader in green steel production. It uses hydrogen – based reduction processes. Instead of using carbon – based fuels like coal or coke, hydrogen is used to remove oxygen from iron ore. Since hydrogen only produces water when it reacts, this process significantly reduces carbon emissions. The goal is to achieve carbon neutrality by 2050, demonstrating a commitment to sustainable practices.

The American steel industry grew significantly during the Industrial Revolution, focusing on mass production to meet the demands of a rapidly expanding economy. This period established a foundation of efficiency and scalability in steel production.

American steel production primarily utilizes blast furnaces and Electric Arc Furnaces (EAF). The blast furnace method, a traditional approach, involves smelting iron ore with coke and limestone. Coke acts as a fuel and a reducing agent, while limestone helps remove impurities. This process produces molten iron, which is then converted to steel. The EAF method, on the other hand, melts scrap steel using electrical energy, offering flexibility and reduced production costs.

A notable advancement in American steel production is the widespread use of continuous casting. This process allows for the direct casting of steel into semi – finished shapes, significantly improving efficiency and reducing waste compared to traditional ingot casting.

American steelmakers emphasize cost – effectiveness and durability. The use of recycled steel in EAFs not only reduces costs but also supports sustainability efforts. Although not as focused on specialty steels as Japan, the U.S. produces a wide range of steels suitable for various industrial applications.

Both Japan and the United States have stringent quality control measures, but their focus areas differ. In Japan, the emphasis on high precision and uniformity is evident in the production of specialty steels for high – end applications like aerospace components. For example, the production of turbine blades requires extremely precise dimensions and a uniform microstructure to ensure optimal performance. American quality control, on the other hand, prioritizes durability and cost efficiency. In the automotive industry, American – made steel components are designed to withstand the rigors of daily use while keeping production costs down.

Japan’s investment in advanced technologies and its focus on reducing carbon emissions highlight its commitment to innovation and environmental sustainability. The United States, while also incorporating modern technologies, has a stronger focus on scalability and cost – effective production.

Japan’s proactive approach to decarbonization through hydrogen – based processes sets it apart in terms of environmental initiatives. The United States is also making strides in reducing the environmental impact of steel production, though not as aggressively as Japan.

The cost of raw materials plays a crucial role in determining the price of steel. While Japan relies on efficient supply chain management and long-term contracts to stabilize costs, the United States benefits from abundant domestic reserves of iron ore and coal in regions like the Great Lakes and Appalachia. This domestic availability can potentially reduce raw material costs, but factors such as mining regulations and extraction expenses also play a role.

Japan has been quick to adopt new technologies like the basic oxygen furnace, which reduces production costs and enhances efficiency. This technology allows for large-scale production with high-quality output in a relatively short time. Conversely, the U.S. has focused on electric arc furnaces, which, although cleaner and more efficient, come with higher operational costs. The use of recycled steel in electric arc furnaces can lower raw material costs, but the energy consumption and maintenance of these furnaces add to the overall expenses.

For Japan, steel is a major export product. The country’s strategic pricing strategies and lower production costs enable it to offer competitive prices in international markets. In the U.S., tariffs on imported steel can increase the cost of foreign steel, making domestic steel more competitive. However, these tariffs can also lead to retaliatory measures from other countries, affecting the global trade dynamics and potentially increasing the cost of steel in the long run.

Japanese steel is typically 20 to 40% cheaper than American steel in markets like the U.S. West Coast and Gulf Coast. This price competitiveness is due to a combination of lower production costs, efficient manufacturing processes, and strategic pricing. Japanese steelmakers can offer high-quality products at relatively low prices, making them attractive to customers who value cost-effectiveness without sacrificing too much on quality.

American steel generally has a higher price tag. Higher labor costs, stricter environmental and labor regulations, and relatively higher operational costs of production technologies all contribute to the elevated price. U.S. government policies, such as the Buy American Act, can increase demand for domestic steel, helping producers sustain their pricing.

The durability of steel is greatly influenced by how it’s made. Japanese steel production is renowned for its precision and attention to detail. Combining traditional techniques with modern technology, Japanese manufacturers produce steel that is pure and consistent. This careful approach results in a fine grain structure, contributing to the steel’s strength and sharpness.

On the other hand, American steel production emphasizes efficiency and large-scale production. The widespread use of Electric Arc Furnaces (EAF) allows for recycling scrap steel, making the process more sustainable and cost-effective. However, this focus on mass production can sometimes lead to a coarser grain structure, which affects the steel’s edge retention and sharpness but enhances its toughness and wear resistance.

Japanese steel, especially high carbon types, is famous for its exceptional hardness and sharpness. For example, a high-end Japanese kitchen knife can maintain a razor-sharp edge for a long time due to its fine grain structure and high carbon content. However, this same property can make the steel more brittle and prone to chipping if not handled properly.

In contrast, American steel tends to be more flexible and less brittle. Think of a construction tool that needs to withstand heavy use without breaking. American steel, with its lower hardness, offers greater toughness and resistance to impact. This makes it ideal for applications where durability and flexibility are crucial.

Japanese steel shines in tasks that require precision and sharpness. For instance, a Japanese chef’s knife can slice through delicate foods with ease, thanks to its fine edge and high hardness. In surgical instruments, the sharpness and precision of Japanese steel ensure clean and accurate cuts, which are vital in medical procedures.

American steel, however, excels in heavy-duty applications where durability is key. Think of construction tools that need to endure significant impact without breaking. American steel is perfect for these environments due to its toughness. In the automotive industry, the robust nature of American steel components ensures they perform reliably under strenuous conditions.

The longevity of steel products is closely tied to their maintenance. Japanese steel, while offering superior sharpness and edge retention, requires careful handling and regular upkeep to prevent rust and chipping. The high carbon content makes it more susceptible to corrosion if not properly cared for, necessitating frequent sharpening and protective measures.

American steel, being more flexible and less prone to chipping, is generally easier to maintain. Its lower hardness makes it less likely to crack, and its higher chromium content in stainless steel variants provides better corrosion resistance. This makes American steel more forgiving in environments where maintenance might not be as rigorous, extending the lifespan of the products.

Japanese steel production has significantly reduced its carbon footprint through technological advancements and regulatory measures. Leading companies like Nippon Steel aim for carbon neutrality by 2050, but their current efforts have been criticized for not being aggressive enough, with projections showing alignment with over 3.2°C of global warming. Despite this, Japan remains a leader in environmental technologies within the steel industry, having adopted advanced manufacturing processes that contribute to lower emissions.

Japan has heavily invested in hydrogen-based reduction processes as a means to decarbonize steel production. This new method uses hydrogen instead of coal to process iron ore, greatly reducing CO2 emissions. Additionally, Japanese steelmakers are exploring the use of carbon capture and storage (CCS) technologies to further mitigate their environmental impact.

The American steel industry has focused on cleaner production methods, particularly the use of electric arc furnaces (EAFs). These furnaces, which accounted for 70.6% of U.S. steel production in 2020, are more environmentally friendly than traditional blast furnaces. EAFs predominantly use recycled steel, which not only reduces the need for raw materials but also lowers energy consumption and greenhouse gas emissions. By relying on scrap metal, EAFs minimize the environmental impact associated with mining and processing iron ore.

The U.S. is a global leader in steel recycling, with all steel produced containing recycled content. This practice contributes to lower emissions compared to primary steel production. However, the transition to greener technologies like direct reduced iron (DRI) with green hydrogen is still in the planning stages and lacks concrete timelines.

Both Japan and the U.S. aim for carbon neutrality by 2050, but their strategies and progress are quite different. Japan’s reliance on coal-based production methods has been a point of criticism, while the U.S. faces challenges in transitioning its existing coal-based facilities to cleaner technologies.

Japan leads in adopting advanced environmental technologies and has been proactive in exploring hydrogen-based steel production. In contrast, the U.S. has made significant strides in utilizing electric arc furnaces and prioritizing recycling, which contributes to lower emissions but still faces hurdles in adopting greener technologies like DRI with green hydrogen.

Japanese steel production still relies heavily on coal, which poses challenges for its decarbonization efforts. Conversely, the high use of EAFs in the U.S. results in cleaner production methods, although the industry struggles with transitioning from coal-based blast furnaces.

Both industries face significant pressure from regulatory bodies and local communities. In Japan, Nippon Steel has been criticized for its environmental accountability and slow progress in reducing emissions. In the U.S., companies like U.S. Steel encounter scrutiny over pollution from coal-based production and face demands for cleaner technologies.

The Japanese and American steel industries have launched several initiatives to reduce their environmental impact. Japan’s focus on hydrogen-based reduction processes and carbon capture technologies highlights its commitment to innovation and sustainability. The U.S. emphasizes the use of recycled steel and cleaner production methods through EAFs, showcasing its efforts to reduce emissions and enhance efficiency.

Both countries are working towards their decarbonization goals, but the path to achieving these targets involves overcoming significant technological and regulatory challenges. The ongoing efforts in both nations reflect a growing awareness of the need for sustainable practices in the steel industry.

In Japan, the steel industry is a fundamental part of its manufacturing – based economy. It supplies critical materials to sectors like automotive, electronics, and machinery, which are major contributors to Japan’s export revenue. For example, high – quality Japanese steel is essential for producing world – renowned Japanese cars that are exported globally.

In the United States, the steel industry is equally vital but impacts the economy differently. It plays a significant role in heavy industries such as construction and defense. Large – scale infrastructure projects in the U.S. rely heavily on American steel, and the defense sector needs steel for military equipment. Additionally, the steel industry is a major employer, especially in regions with a long history of steel – making.

Japan has long been an exporter of steel and has developed strategic trade policies to access international markets. These policies focus on quality and cost – effectiveness. However, Japan faces challenges from anti – dumping regulations in some countries, which can limit its market access.

The United States has implemented various trade policies to protect its domestic steel industry. One major approach has been the imposition of tariffs on imported steel, making foreign steel more expensive and domestic steel more competitive. However, these tariffs can lead to retaliatory measures from other countries, disrupting the global supply chain and increasing costs for downstream industries in the U.S.

In November 2023, Nippon Steel proposed a $14.9 billion acquisition of U.S. Steel. This deal, if approved, could strengthen economic ties between the U.S. and Japan. For Nippon Steel, it would enhance its presence in the Western market. For the U.S. steel industry, it could bring significant investment, fostering innovation and helping it compete against Chinese competitors.

There are, however, concerns. Critics worry that foreign ownership might lead to production being concentrated in Japan, potentially harming U.S. manufacturing and national security interests. Supporters, on the other hand, highlight potential benefits like improved supply chain resilience and technological collaboration.

Japan’s investment in U.S. Steel is part of a broader trend of foreign companies investing in the U.S. to offset declining domestic markets. U.S. policymakers encourage investments from trusted allies like Japan to secure supply chains and compete with China. These investments can create jobs and opportunities for local businesses, especially in manufacturing sectors, aligning with the U.S. “friendshoring” strategy.

The Japanese and American steel industries, while both important, face different economic landscapes shaped by their national economic structures, trade policies, and recent market developments.

Below are answers to some frequently asked questions:

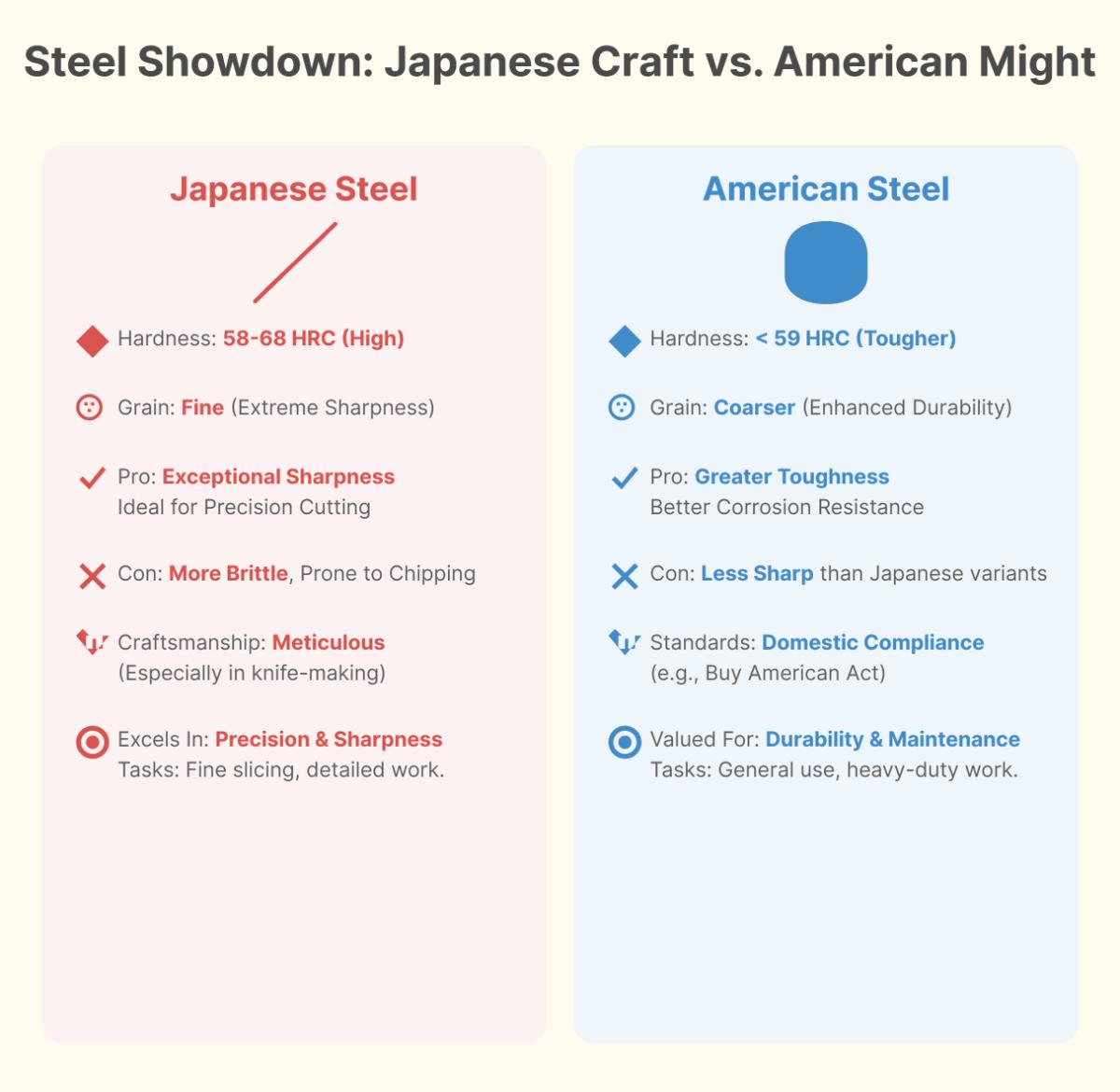

Japanese and American steels differ significantly in terms of hardness, grain structure, corrosion resistance, and applications. Japanese steel is renowned for its high hardness (58-68 HRC), fine grain structure, and exceptional sharpness, making it ideal for precision cutting tasks. This high carbon content, however, can make it more brittle and prone to chipping. In contrast, American steel, generally softer with hardness below 59 HRC, boasts greater toughness and durability, making it less likely to chip and more suitable for general use.

American steel often features a coarser grain structure, which enhances its toughness but may not achieve the same sharpness as Japanese steel. Additionally, American stainless steels typically contain more chromium, offering better corrosion resistance and making them easier to maintain in diverse environments.

In terms of production, Japanese steel is highly regarded for its meticulous craftsmanship, especially in knife-making, whereas American steel is noted for its compliance with domestic manufacturing standards, such as the Buy American Act. Each type of steel caters to different needs: Japanese steel excels in precision and sharpness, while American steel is valued for its durability and ease of maintenance.

Japanese steel generally surpasses American steel in hardness (HRC 58-68 vs. 52-59) and sharpness, featuring finer grain structures that enable razor-sharp edges ideal for precision cutting, while American steel offers superior durability and chip resistance with its coarser grain structure. Production methods also differ significantly: Japanese steelmaking often incorporates traditional techniques like the tatara system alongside modern innovations, emphasizing meticulous craftsmanship and quality, while American production prioritizes efficiency, scale, and environmental sustainability, with the U.S. recognized as the most energy-efficient steel producer globally. These distinctions make Japanese steel preferred for applications requiring exceptional sharpness and edge retention, such as high-end cutlery, while American steel excels in applications demanding toughness and durability. Both countries continue to innovate, with Japan developing hydrogen reduction technology for “green steel” production and the U.S. focusing on reducing emissions while maintaining industrial scale.

While there are no direct American equivalents to high-end Japanese steels like Aogami Super Blue, some American steels are often used as substitutes in the market. Aogami Super Blue, known for its exceptional hardness (HRC 61-65), edge retention, and wear resistance, contains a unique combination of carbon, chromium, tungsten, molybdenum, and vanadium. This composition results in superior performance, making it highly sought after for professional chef knives.

In contrast, American steels such as 52100 and 1095 are popular alternatives. Both are high-carbon steels with good hardness and edge retention but lack the specific alloying elements of Aogami Super Blue. Another option, W2 steel, is known for its high carbon content and fine grain structure, though it does not match the complexity of Aogami Super Blue’s composition.

Japanese and American steel production differ notably in their sustainability approaches. Japan is at the forefront of green steel initiatives, aggressively pursuing technologies like hydrogen-based reduction to achieve its 2050 carbon neutrality goal. This includes maximizing the use of scrap steel in electric furnaces and developing hydrogen direct-reduced iron (H2-DRI) methods. Key projects, such as COURSE50, exemplify Japan’s commitment to reducing carbon emissions from traditional blast furnaces.

In contrast, American steel production remains more traditional, with significant reliance on blast and electric arc furnaces. While there has been progress in energy efficiency and increased use of scrap metal, the U.S. has been slower to adopt green steel technologies. The transition to sustainable methods is challenged by high energy costs and infrastructure requirements.

Economic factors significantly affect the Japanese and American steel industries. Market demand varies: Japan’s domestic demand has dropped about 40% since the 1990s, prompting overseas expansion, while the US market remains appealing. Both face global competition, especially from Chinese steel. Technologically, Japanese steelmakers led in labor – productivity, but the US has advanced with EAF technology. Trade policies and tariffs create challenges for both; the US uses tariffs for protection, and Japan seeks international cooperation. National security concerns arise from foreign acquisitions, like Nippon Steel’s bid for US Steel. Investments, such as Japan’s in the US, strengthen economic ties and supply – chain resilience. Future growth depends on adapting to market changes and tech advancements.

In the global market, both Japanese and American steel are high – quality products, but their costs are affected by different factors. Japanese steel generally has higher costs due to expensive raw materials, high energy expenses, and advanced manufacturing processes. On the other hand, American steel faces challenges from high labor costs and trade policies. While the U.S. benefits from relatively lower energy costs, tariffs and domestic policies like the Buy American Act can impact its cost and demand. The choice between the two depends on application needs and market dynamics.