When it comes to crafting the perfect kitchen knife, the choice of steel can make all the difference. Among the most revered options are Japanese steel and Damascus steel, each boasting a rich history and distinct characteristics. But what sets these two apart? Is one sharper or more durable than the other? And how do their manufacturing processes influence their performance and maintenance needs? In this comprehensive comparison, we delve into the nuances of Japanese and Damascus steel, exploring everything from their unique properties and production techniques to their aesthetic and historical value. Whether you’re a seasoned chef or an avid knife collector, join us as we uncover the secrets behind these legendary materials and help you decide which steel is the ideal choice for your culinary arsenal.

Steel, an alloy mainly composed of iron and carbon, exhibits diverse properties depending on its type and manufacturing process. Two notable types of steel are Japanese steel and Damascus steel, each renowned for distinct characteristics and applications.

Japanese steel is celebrated for its exceptional sharpness and durability, making it a preferred choice for high-quality kitchen knives and industrial tools. The high-carbon varieties, such as White Steel (Shirogami) and Blue Steel (Aogami), are particularly noted for their ability to maintain a razor-sharp edge. These steels are typically produced using traditional methods, such as the Tatara furnace, or modern techniques involving Basic Oxygen Furnaces (BOF) and Electric Arc Furnaces (EAF).

Damascus steel is famous for its unique patterns and historical significance. Characterized by distinctive patterns, Damascus steel is often chosen for its artistic value. Traditionally, it was produced using pattern welding techniques, which involved forging multiple layers of steel together. Modern Damascus steel may replicate this process but often lacks the exact properties of original Wootz steel.

The unique appearance of Damascus steel is achieved through a process of pattern welding, where different types of steel are layered and forged together. This method enhances the steel’s visual appeal while also imparting flexibility and shock resistance.

Damascus steel is frequently used in high-end knives and specialized tools, where both performance and appearance are important. It is also popular among collectors due to its historical and artistic value.

When comparing Japanese and Damascus steel, several key characteristics stand out:

| Steel Type | Edge Retention | Maintenance | Corrosion Resistance | Aesthetic Value |

|---|---|---|---|---|

| Japanese Steel (High-Carbon) | Excellent | High | Low | Moderate |

| Japanese Steel (Stainless) | Good | Low | High | Low |

| Damascus Steel | Very Good | Moderate | Varies | High |

Pattern welding is a traditional technique used to create the distinctive patterns found in Damascus steel. This process involves layering different types of steel and iron, which are then forge-welded together and folded multiple times. The repeated folding and welding not only enhance the visual appeal but also contribute to the steel’s strength and flexibility, creating characteristic wave-like designs.

The Tatara furnace is a traditional Japanese smelting furnace used to produce Tamahagane steel, renowned for its use in making Japanese swords. This process involves the following steps:

The San-mai technique is a traditional Japanese method used to enhance the performance and durability of blades. It involves sandwiching a hard steel core between two layers of softer steel. This construction provides a balance between the sharpness of the hard core and the toughness of the outer layers.

Both manufacturing processes reflect the cultural heritage and technological advancements of their respective origins. They contribute significantly to the unique properties and aesthetic appeal of Japanese and Damascus steels.

Japanese steel, particularly high-carbon variants like VG-10 and powdered steels, is renowned for its exceptional sharpness. Their fine grain structure enables extremely precise edges, ideal for high-accuracy tasks like slicing and dicing in the kitchen. Typically, Japanese steels can achieve a Rockwell hardness (HRC) rating of 60-62, which directly contributes to their sharpness and edge retention.

Damascus steel also achieves high sharpness, relying on its layered structure, which combines hard and soft steel layers to create microscopic serrations along the edge. The hardness of Damascus steel generally ranges from 58 to 62 HRC, depending on the specific steels used in its composition.

Japanese steels are known for their durability, particularly those enhanced with alloying elements such as chromium and molybdenum, which improve resistance to wear and corrosion. However, high-carbon Japanese steels are sharper but more prone to rust and need diligent care to avoid corrosion. This brittleness is a trade-off for their superior sharpness and hardness.

In contrast, Damascus steel’s layered structure enhances its overall durability. The combination of hard and soft steel layers provides a balance of strength and flexibility, reducing the likelihood of chipping or breaking under stress. This makes Damascus steel particularly suitable for tasks that involve more impact or require the blade to flex without compromising its integrity.

Japanese steels, especially high-carbon varieties like VG-10 and powdered steels, are designed for excellent edge retention. The high hardness and fine grain structure allow these steels to maintain a sharp edge for prolonged periods, reducing the frequency of sharpening needed.

Damascus steel also offers very good edge retention due to its layered construction. The hard layers in Damascus steel retain the cutting edge, while the softer layers provide support and flexibility, which helps in maintaining the edge even with regular use. However, the edge retention of Damascus steel can vary depending on the specific materials used in its layers and the quality of the forging process.

Japanese stainless steels, such as VG-10 and AUS-10, feature high corrosion resistance due to their chromium and molybdenum content. This makes them easier to maintain and ideal for environments where exposure to moisture is frequent, such as kitchens. High-carbon Japanese steels, while offering superior sharpness, are more prone to rust and require diligent care to prevent corrosion.

The corrosion resistance of Damascus steel depends on the materials used in its layers. When constructed with stainless steel cores, Damascus blades can offer good corrosion resistance. However, if high-carbon steels are used, the blade will require more careful maintenance to prevent rust. The outer layers in Damascus steel can also provide some protection against corrosion, but regular oiling and drying are still recommended.

High-carbon Japanese steels demand rigorous maintenance to prevent rust and maintain their edge. Regular oiling, drying, and careful storage are necessary to keep these blades in optimal condition. Stainless Japanese steels, on the other hand, are easier to maintain and require less frequent attention.

Damascus steel blades, depending on their composition, generally require moderate maintenance. Blades with stainless steel cores need less frequent care, while those with high-carbon cores will require regular oiling and drying to prevent rust. The aesthetic patterns of Damascus steel also mean that careful cleaning is necessary to preserve their appearance.

Japanese steels are primarily valued for their functional performance, particularly in precision tasks. Their sharpness, edge retention, and ease of maintenance (in stainless variants) make them ideal for professional culinary use. Chefs and serious home cooks prefer Japanese steel knives for their precision and delicate cuts.

Damascus steel is appreciated for its balance of functionality and aesthetic appeal. The layered construction provides durability and flexibility, making these knives suitable for both practical use and display. Collectors and enthusiasts often choose Damascus steel knives for their unique patterns and historical significance, as well as their reliable performance in various cutting tasks.

While Japanese steel knives are known for their clean, minimalistic design, the primary focus is on functionality. Damascus steel, however, stands out for its striking, intricate patterns resulting from the pattern-welding process. These visually appealing designs make Damascus steel a favorite among collectors and those who appreciate the artistry of knife making.

Japanese steel knives, known for their sharpness and precision, require specific maintenance practices to ensure longevity and optimal performance. The care routine varies depending on whether the knife is made from high-carbon steel or stainless steel.

High-carbon Japanese steels, such as Tamahagane, are susceptible to rust if not properly maintained. To prevent rust:

Proper cleaning is essential to maintain the sharpness and integrity of Japanese steel knives:

Maintaining the sharp edge of Japanese steel knives involves:

Damascus steel knives, renowned for their distinctive patterns and layered construction, require moderate maintenance to preserve their aesthetic appeal and performance.

To maintain the intricate patterns and prevent corrosion:

While Damascus steel’s resistance to corrosion can vary, it’s important to follow general maintenance practices:

Damascus steel blades benefit from a consistent maintenance routine:

For optimal maintenance of both Japanese and Damascus steel knives, consider the following tools and products:

Understanding the specific maintenance needs of Japanese and Damascus steel knives ensures their longevity and preserves their performance and aesthetic value. Regular and proper care will keep these knives in excellent condition, ready for precise and effective use.

Modern Designs and Functionality: Japanese steel knives are known for their sleek, modern designs that prioritize both functionality and performance. These knives are celebrated for their sharpness and durability, attributes that are essential for professional culinary applications. The aesthetic appeal of Japanese steel lies in its minimalist approach, focusing on clean lines and subtle elegance rather than elaborate patterns.

Minimalist Approach: The minimalist design philosophy of Japanese knives emphasizes simplicity and efficiency. This approach not only enhances the knife’s functionality but also reflects the cultural values of precision and restraint. The blades often have a polished, smooth finish with understated beauty, making them suitable for both professional kitchens and everyday use.

Artistic Patterns: Damascus steel is famous for its visually striking patterns, created through a unique process of folding and hammering. These intricate, wave-like designs are not only aesthetically pleasing but also serve as a testament to the skill and craftsmanship involved. The patterns can vary widely, from subtle swirls to bold, dramatic lines, making each piece of Damascus steel unique.

Aesthetic Significance: The aesthetic value of Damascus steel extends beyond its appearance. The layered construction provides a historical and artistic depth that many enthusiasts find captivating. Collectors and knife enthusiasts often seek out Damascus steel for its distinctive look, which combines both form and function in a visually compelling way.

Historical Significance: Japanese steel, particularly Tamahagane, has a long and storied history in traditional Japanese sword making. The production of Japanese swords, such as the katana, involves meticulous craftsmanship and centuries-old techniques, including the Tatara furnace method, a traditional smelting process that yields high-quality steel with rich cultural heritage.

Evolution of Techniques: Over time, Japanese steel production has evolved, incorporating both traditional methods and modern technologies. This evolution has allowed for the creation of high-performance steels that maintain the historical significance of their predecessors while benefiting from contemporary innovations. The blend of old and new techniques results in steel that is both historically significant and technologically advanced.

Ancient Origins: Damascus steel has its roots in ancient techniques and materials, such as Wootz steel, which were highly prized for their strength and durability. Damascus steel’s historical significance is closely tied to its Middle Eastern origins and the legendary reputation of its blades. These blades were known for their purported unbreakable nature and superior cutting ability.

Symbolism and Collectibility: Today, Damascus steel is often sought after by collectors for its historical significance and the craftsmanship involved in its production. The intricate patterns and limited production make each piece a valuable collectible. The historical narrative of Damascus steel adds to its allure, making it a symbol of ancient metallurgical prowess and artistry.

| Characteristics | Japanese Steel | Damascus Steel |

|---|---|---|

| Aesthetic Value | Emphasizes functionality and simplicity | Known for artistic patterns and historical design |

| Historical Value | Rich tradition in Japanese sword making | Ancient origins and craftsmanship |

| Usage | Ideal for practical applications like cooking | Often chosen for both functionality and visual appeal |

| Manufacturing | Modern techniques ensure durability and performance | Pattern welding and folding for aesthetic and strength |

Japanese steel is valued for its minimalist design and functional excellence, rooted in a rich sword-making tradition. Conversely, Damascus steel captivates with its intricate patterns and historical depth, making it a favorite among collectors and art enthusiasts. Both types of steel provide distinct benefits, catering to different preferences and uses.

Japan’s steel industry is recognized for its innovative approach, combining traditional methods with advanced technologies to enhance quality, efficiency, and sustainability.

Traditionally, Japanese steel production relies on the blast furnace method, which is highly efficient for mass production with minimal impurities. However, conventional blast furnaces use carbon to reduce iron ore, resulting in significant CO₂ emissions. By using hydrogen instead of some of the carbon, this method reduces CO₂ emissions to water vapor, significantly lowering the carbon footprint. The COURSE50 project aims to cut CO₂ emissions by approximately 30%, with plans to commercialize this “green steel” technology by 2040.

Japanese steel manufacturers like JFE Steel are leveraging digital twin technology to optimize furnace operations. This involves creating virtual models of physical systems to simulate and improve processes, significantly reducing downtime. For example, blast furnace restart times have been reduced from over six months to about two months. Additionally, automation is enhancing logistics, with autonomous vehicles using GNSS and LiDAR sensors to transport steel products. This addresses labor shortages and improves operational safety.

Japan is also utilizing electric arc furnace technology, which melts recycled scrap metal to reduce dependence on raw iron ore. This aligns with sustainability goals by promoting recycling and reducing environmental impact. EAFs are particularly advantageous for their flexibility in melting various scrap types and their ability to produce high-quality steel with lower emissions.

Japanese steel production includes unique processes such as the Basic Oxygen Furnace (BOF) and continuous casting techniques. These methods produce high-grade steel with specific properties, benefiting industries such as automotive and infrastructure. The BOF process, in particular, allows for precise control over chemical composition, resulting in steel with superior strength, durability, and precision.

| Aspect | Japanese Steel | Damascus Steel |

|---|---|---|

| Production Method | Modern blast furnace with hydrogen integration, advanced casting, and heat treatment | Pattern welding of layered steels, traditional forging |

| Material Composition | High-purity alloy steels with precise chemical control | Layered steels of varying carbon content |

| Technological Innovation | Digital twin technology, automation, hydrogen-based decarbonization | Traditional hand-forging; modern versions use machine-assisted layering |

| Environmental Impact | Emphasis on reducing carbon emissions, recycling, and sustainability | Traditional methods less environmentally controlled; modern Damascus may vary |

| Mechanical Properties | Superior uniformity, toughness, edge retention, and purity | Unique layered microstructure offering a balance of hardness and flexibility |

| Aesthetic Appeal | Generally uniform finish, sometimes with fine grain patterns | Distinctive wavy or watery Damascus patterns |

Japan’s steel industry is moving towards a future defined by environmental responsibility without compromising steel quality. The integration of hydrogen in blast furnaces and the use of digital twin simulations represent significant advancements in both sustainability and efficiency, surpassing traditional methods used for Damascus steel.

Japanese steel benefits from rigorous industrial processes that ensure consistent chemical composition and controlled microstructures. This results in steel that meets exacting specifications for modern applications, including blades requiring a balance of hardness and toughness. Damascus steel’s layered approach provides unique aesthetics and a historically valued balance of mechanical properties.

Japan’s adoption of automation, robotics, and sensor-based logistics enhances production speed, safety, and worker conditions. This level of industrial sophistication is largely absent in traditional Damascus steel production, which remains artisanal or semi-industrial in modern interpretations.

Selecting the best steel type for different uses involves evaluating various factors, including the specific application, the user’s skill level, and budget constraints. Each steel type offers distinct advantages that cater to different needs.

Below are answers to some frequently asked questions:

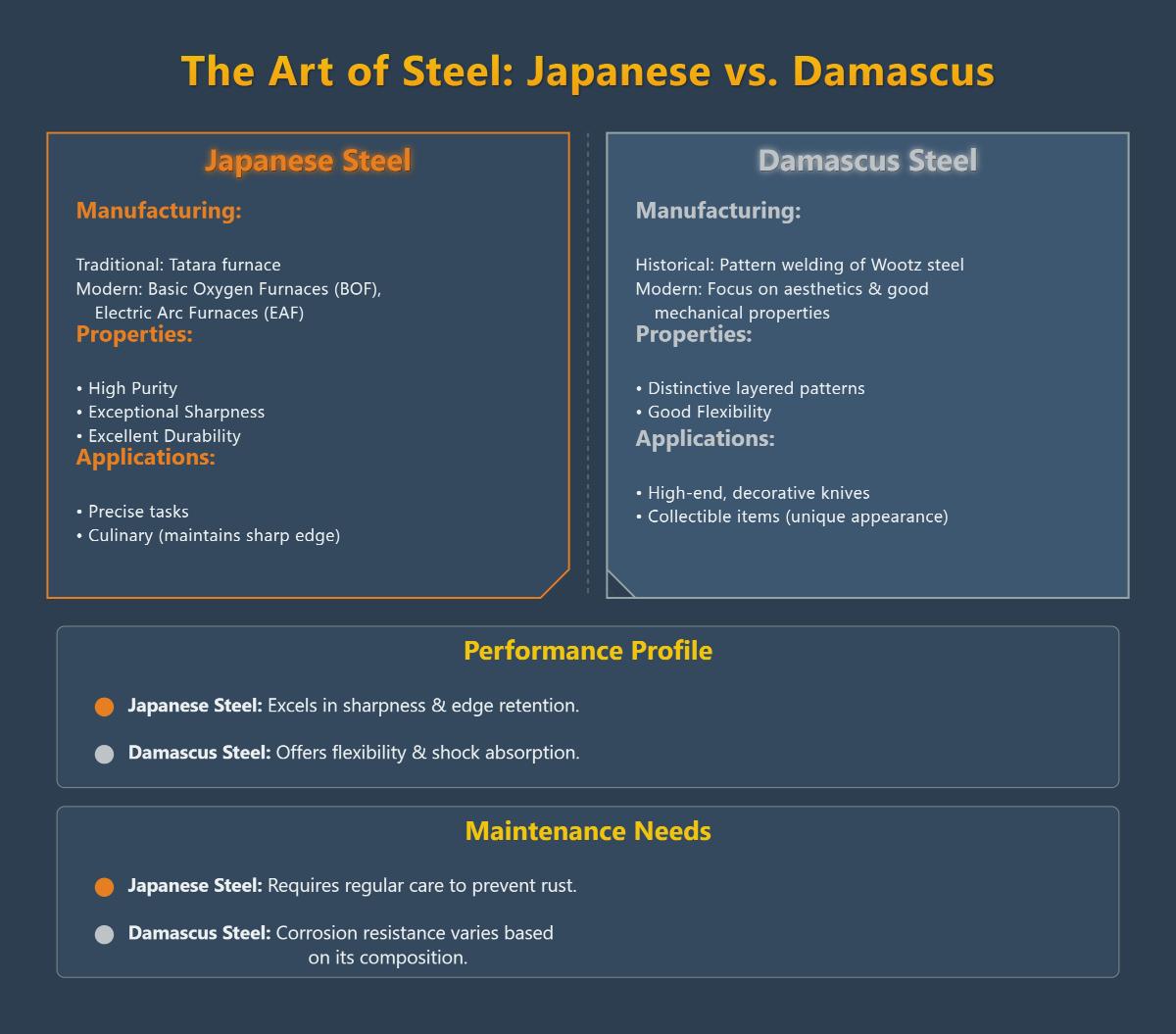

Japanese steel and Damascus steel differ primarily in their manufacturing processes, properties, and applications. Japanese steel, often produced using methods like the Tatara furnace and modern techniques such as Basic Oxygen Furnaces (BOF) and Electric Arc Furnaces (EAF), is known for its high purity, sharpness, and durability. It is favored for precise tasks, particularly in culinary applications, due to its ability to maintain a sharp edge.

Damascus steel, historically created through pattern welding of Wootz steel, is recognized for its distinctive layered patterns and flexibility. Modern Damascus steel focuses more on aesthetics while maintaining good mechanical properties. It is highly valued for its unique appearance and is often used in high-end, decorative, and collectible knives.

In terms of performance, Japanese steel excels in sharpness and edge retention, while Damascus steel offers flexibility and shock absorption. Maintenance needs differ, with Japanese steel requiring regular care to prevent rust, whereas Damascus steel’s corrosion resistance can vary based on its composition.

When comparing Japanese steel and Damascus steel for kitchen knives, Japanese steel typically stands out for its sharpness and edge retention. High-carbon Japanese steels, such as Aogami (Blue Steel) and Shirogami (White Steel), are known for their ability to achieve and maintain a very fine edge due to their high hardness (usually between 58-68 HRC). This makes them ideal for precise slicing and chopping tasks.

Damascus steel, while also capable of achieving a sharp edge, depends heavily on the quality of its core steel. Modern Damascus knives often use high-quality Japanese steels like VG-10 as the core, but the layered structure can limit the maximum hardness achievable, potentially affecting edge retention. However, the layered construction can provide improved toughness and some resistance to chipping, offering a balance between sharpness and durability.

The manufacturing processes of Japanese steel and Damascus steel significantly impact their properties, including strength, durability, and aesthetic appeal.

Damascus steel is produced through forge welding and layering multiple types of steel, creating a distinctive pattern. This involves heating the steel to high temperatures, quenching, and repeating the folding process multiple times. The resulting structure enhances the steel’s strength and durability by distributing impurities and forming a more uniform composition. Additionally, the intricate patterns revealed through etching contribute to its aesthetic value.

Japanese steel, particularly high-carbon varieties like Tamahagane, undergoes a meticulous refining and alloying process to achieve high purity and carbon content. Techniques such as quenching and tempering are employed to achieve a balance of hardness and flexibility. Traditional hand forging methods ensure precise control over the steel’s microstructure, resulting in superior sharpness and edge retention. The emphasis on craftsmanship further underscores the artisanal quality of Japanese steel.

Maintaining Japanese steel knives involves ensuring they remain dry to prevent rust, especially given their high-carbon content. After each use, it’s essential to wash these knives by hand with mild soap, dry them immediately, and apply food-safe mineral oil monthly if not used regularly. Sharpening should be done with ceramic honing rods and whetstones to maintain their sharp edge.

Damascus steel knives, known for their decorative patterns, require gentle cleaning to preserve these aesthetics. While they often incorporate corrosion-resistant alloys, it’s still important to avoid prolonged exposure to moisture and acidic foods. Regular oiling can help maintain their layered structure if they are not stainless-clad. Sharpening should be performed cautiously with fine grit whetstones to avoid damaging the patterns.

Damascus steel, known for its distinctive patterns and historical craftsmanship, holds significant appeal for collectors. Each blade showcases unique, irreplicable patterns due to its layered and folded manufacturing process, enhancing its aesthetic and collectible value. The traditional craftsmanship, combined with modern precision forging techniques, adds to its allure for those who value artisanal quality and historical significance.

In terms of practical use, Damascus steel also offers strong performance characteristics. Its composite structure of alternating hard and soft layers provides excellent toughness, edge retention, and hardness, typically ranging from 60-62 HRC. This makes it suitable for various applications, including kitchen knives and custom tools, where durability and sharpness are essential.

However, for precision tasks requiring an ultra-fine edge, such as those performed with Japanese steel knives, Damascus may not always match the consistency and sharpness provided by homogeneous high-carbon Japanese steels. Therefore, while Damascus steel is highly valued by collectors for its visual and historical attributes, it also performs well in practical applications, offering a balance between aesthetics and functionality.

AUS-10 steel is a high-carbon stainless steel produced by Japan’s Aichi Steel, optimized for knife-making with a balanced composition including 0.95–1.10% carbon, 13–14.5% chromium, 0.10–0.30% molybdenum, and 0.10–0.25% vanadium. This formulation prioritizes edge retention, corrosion resistance, and wear resistance, with a hardness rating of HRC 58–61. AUS-10 offers a balanced combination of sharpness, durability, and ease of maintenance, making it versatile and suitable for both professional and home use.

Compared to other Japanese steels, AUS-10 provides a middle ground between performance and cost. It is tougher and less prone to chipping than VG-10, easier to sharpen than SG2, and offers better edge retention and wear resistance than AUS-8. Unlike high-carbon steels like Shirogami, AUS-10’s stainless properties reduce the risk of rust, making it more practical in humid environments. Overall, AUS-10 is a reliable choice for those seeking a durable, well-rounded steel that offers good value for money.