Choosing the right knife steel can be a daunting task, especially with the multitude of options available today. Whether you’re a culinary enthusiast, an outdoor adventurer, or simply someone who appreciates the art of a finely crafted blade, understanding the nuances of knife steel is essential. This guide will navigate you through the complexities of various knife steels, from high-end options known for exceptional edge retention to budget-friendly alternatives that still offer reliable performance. We’ll delve into the comparative aspects of edge durability, corrosion resistance, and ease of sharpening, ensuring you have the knowledge to select the perfect steel for your needs. Ready to find out which steel reigns supreme? Let’s dive in and explore the best materials for blades.

Knife steel is the core material in blade crafting, significantly impacting a knife’s performance, durability, and maintenance needs. Understanding the different types of knife steels and their characteristics is essential for selecting the right knife for your needs.

Carbon steel primarily consists of iron and carbon, with minimal alloying elements. Its high carbon content allows for exceptional sharpness and edge retention. However, it tends to be less tough than stainless steels, making it more prone to chipping or breaking under stress. Additionally, carbon steel is highly susceptible to rust and corrosion, requiring regular maintenance. Popular types include 1095, known for its sharpness and edge retention, commonly used in survival knives, and 52100, which offers great toughness and can be effectively hardened for high-performance blades.

Tool steels are high-carbon steels with additional alloying elements to enhance hardness and wear resistance. They are designed for high-stress applications, making them ideal for heavy-duty knives. Tool steels balance edge retention and durability, although specific grades may excel in one area. Notable examples include D2, a high-carbon, high-chromium steel known for excellent edge retention but lower corrosion resistance, and CPM-3V, a high-performance steel offering superior toughness and wear resistance, perfect for heavy use.

Stainless steel contains at least 11% chromium, providing significant corrosion resistance. This makes stainless steel knives easier to maintain and less prone to rust and staining, making them popular for everyday carry (EDC) knives. While stainless steels typically offer a trade-off in sharpness and toughness compared to high-carbon steels, they still provide a good balance of properties. Common types include 154CM, which balances edge retention, toughness, and corrosion resistance, and S30V, a premium steel with excellent edge retention and corrosion resistance. CPM-S90V is another high-end option known for exceptional wear resistance and edge retention, suitable for premium knives.

These steels are engineered for extreme performance, combining multiple alloying elements to enhance durability, wear resistance, and edge retention. They are often used in specialized knives and industrial cutting tools. Examples include CPM-S110V, which offers outstanding edge retention and wear resistance but can be challenging to sharpen, and M4, a high-speed steel known for its hardness and wear resistance, making it suitable for tools and high-performance knives.

Specialty and emerging steels feature innovative formulations designed to combine the best properties of existing steels, focusing on corrosion resistance, edge retention, and toughness. MagnaCut, for instance, was developed to eliminate chromium carbides, resulting in excellent edge retention and corrosion resistance. LC200N offers exceptional corrosion resistance, even in saltwater environments, while maintaining decent toughness.

Selecting the right knife steel involves balancing these factors based on your specific needs. Each steel type offers unique advantages and trade-offs, making it essential to consider what you prioritize in a knife.

When comparing high-end and budget knife steels, several factors must be considered, including edge retention, durability, corrosion resistance, and ease of sharpening. Each type of steel offers unique advantages and trade-offs that affect performance and maintenance.

Edge retention determines how long a knife stays sharp, making it a key factor in knife performance. High-end knife steels generally excel in this area due to their advanced alloy compositions and heat treatments.

Budget steels like 440C, though more affordable, often trade some edge retention for other properties like durability.

Corrosion resistance is crucial for a knife’s durability, especially in moist environments.

Budget steels typically provide adequate corrosion resistance but are easier to maintain.

| Steel Type | Edge Retention | Toughness | Corrosion Resistance | Ease of Sharpening |

|---|---|---|---|---|

| CPM-S110V | Very High | Moderate | High | Difficult |

| M390 | High | Moderate | Very High | Moderate |

| ZDP-189 | Extremely High | Low | Moderate | Very Difficult |

| CPM-S90V | High | High | High | Moderate |

| Steel Type | Edge Retention | Toughness | Corrosion Resistance | Ease of Sharpening |

|---|---|---|---|---|

| 440C | Moderate | Moderate | Good | Easy |

| AUS-8 | Moderate | High | Moderate | Easy |

| 14C28N | High | Moderate | Good | Moderate |

Selecting the right knife steel involves balancing these factors according to how you plan to use the knife. High-end steels like CPM-S110V and M390 are best for tasks needing top-notch edge retention and corrosion resistance, while budget steels like 440C and AUS-8 provide good performance at a lower cost.

High-end knife steels are renowned for their superior performance, offering a combination of properties that cater to various demanding applications. These steels are engineered to excel in edge retention, toughness, and corrosion resistance, making them ideal for enthusiasts and professionals alike.

Edge retention refers to a knife’s ability to stay sharp over extended use, achieved through advanced alloy compositions and precise heat treatments. Steels like CPM-S90V and ZDP-189 are known for their superior edge retention due to high carbon content and hard carbides.

Toughness is the ability of a steel to withstand chipping and breaking under stress, which is crucial for knives used in heavy or impact-prone tasks. While some high-end steels like CPM-S110V prioritize hardness and wear resistance, others like CPM-3V offer a balance, providing significant toughness without sacrificing edge retention.

Corrosion resistance is important for knives exposed to moisture or corrosive environments. High-end steels often contain higher levels of chromium or other elements that enhance their resistance to rust and staining. Steels like M390 and CPM-S90V are particularly noted for their excellent corrosion resistance, making them suitable for outdoor and culinary applications.

CPM-S110V is celebrated for its outstanding edge retention and wear resistance. It achieves a high hardness of around 63-65 HRC, thanks to its high vanadium carbide content. Its extreme hardness can make sharpening difficult, and it has moderate toughness, making it better suited for precise cutting tasks rather than heavy-duty use.

M390 is a premium steel known for its well-rounded performance. It combines high edge retention, excellent corrosion resistance, and moderate toughness. With a hardness of 60-62 HRC, M390 is easier to sharpen compared to some other high-end steels. Its balanced properties make it a popular choice for both EDC knives and high-end culinary tools.

ZDP-189 is a high-carbon Japanese steel that offers exceptional edge retention due to its extreme hardness, often reaching 64-66 HRC. While it excels in maintaining a sharp edge, ZDP-189 is more prone to corrosion and requires careful maintenance. It is favored for premium folding knives and applications where cutting performance is paramount.

CPM-S90V is known for its high wear resistance and edge retention, achieved through a significant amount of vanadium carbides. It offers a balance of hardness (60-62 HRC) and toughness, making it versatile for various cutting tasks. Although it can be difficult to sharpen, its corrosion resistance and durability make it a reliable choice for high-performance knives.

When selecting a high-end knife steel, several factors should be taken into account:

By understanding these characteristics and considerations, users can make informed decisions when selecting high-end knife steels, ensuring they choose the best material for their specific needs.

Mid-range knife steels are popular for their balanced performance, affordability, and versatility. They offer a good mix of hardness, toughness, wear resistance, and corrosion resistance, making them suitable for many uses.

Mid-range knife steels typically have a hardness of 57 to 62 HRC, allowing them to maintain a sharp edge while resisting deformation during normal use.

Toughness is a steel’s ability to withstand impacts without chipping or cracking. Mid-range steels offer enough toughness for everyday tasks, even if they aren’t as tough as high-end steels.

Mid-range steels balance hardness and wear resistance, making them durable for regular use and relatively easy to sharpen.

Corrosion resistance is crucial for preventing rust and staining, especially in humid or wet environments. Mid-range knife steels typically offer good to excellent corrosion resistance, making them easier to maintain than high-carbon steels.

Mid-range steels are generally easier to sharpen than high-end steels, making maintenance simple without needing specialized tools.

Composition: 0.95% Carbon, 16% Chromium

Properties: 440C is a high-carbon stainless steel known for its high hardness and excellent edge retention. It offers reasonable corrosion resistance but can be more challenging to sharpen compared to other mid-range steels.

Ideal Uses: Commonly used in hunting and tactical knives, where durability and edge retention are crucial.

Composition: Approximately 0.75% Carbon, 14% Chromium

Properties: AUS-8 is known for its balanced performance, offering good hardness, toughness, and ease of sharpening. While it may not match the edge retention of higher-end steels, its reliability and ease of maintenance make it a popular choice.

Ideal Uses: Often found in folding knives and fixed blades for general-purpose tasks.

Composition: 0.62% Carbon, 14% Chromium, 0.11% Nitrogen

Properties: 14C28N is appreciated for its high corrosion resistance and good edge retention. It is also easy to sharpen, making it a favorite among knife enthusiasts who prefer a low-maintenance blade.

Ideal Uses: Suitable for kitchen knives, EDC knives, and outdoor applications due to its balanced properties.

| Steel Type | Hardness (HRC) | Toughness | Corrosion Resistance | Ease of Sharpening | Common Uses |

|---|---|---|---|---|---|

| 440C | 58-60 | Moderate | Good | Moderate | Hunting, tactical knives |

| AUS-8 | 57-59 | High | Moderate | Easy | Folding, general-purpose |

| 14C28N | 58-60 | Moderate | Very Good | Easy | Kitchen, EDC, outdoor |

Each of these mid-range knife steels offers a unique blend of properties that cater to different needs and applications. Users can choose the steel that best fits their specific requirements, whether it’s for everyday carry, kitchen use, or outdoor activities.

Corrosion-resistant knife steels are designed to withstand harsh environments that would cause other steels to rust or corrode. These steels are essential for knives used in wet or humid conditions, such as marine environments or kitchens. Corrosion resistance in these steels is primarily influenced by the alloying elements and the heat treatment process.

Chromium is the most critical element for enhancing corrosion resistance in stainless steels, requiring a minimum of 10.5% to be classified as stainless, with higher content generally offering better protection. Chromium forms a passive oxide layer on the steel surface, protecting it from further oxidation.

Molybdenum significantly boosts corrosion resistance, especially in saltwater environments. It enhances the steel’s ability to resist pitting and crevice corrosion, which are common issues in marine applications.

N680 is a stainless steel known for its excellent corrosion resistance, particularly in saltwater environments. It contains over 17% chromium and about 0.20% nitrogen, which helps in maintaining a fine edge while providing high corrosion resistance. This steel is ideal for diving knives and other applications where exposure to corrosive elements is frequent.

LC200N, a nitrogen-based steel, is known for its exceptional corrosion resistance, ideal for saltwater use. It is also recognized for its good toughness and moderate hardness, although it can be challenging to heat treat.

H1 steel is renowned for its outstanding corrosion resistance, achieved through a high nitrogen content and low carbon content. This steel is often used in knives that are constantly exposed to water, such as diving knives. While H1 is not as hard as some other steels, it offers good toughness and is virtually immune to rust.

Knives used in marine environments, such as diving knives or fishing knives, benefit significantly from corrosion-resistant steels. Users often report that steels like LC200N and H1 perform exceptionally well, withstanding the harsh conditions of saltwater exposure without rusting or corroding.

In kitchens, knives made from corrosion-resistant steels like N680 and LC200N are highly valued for their low maintenance, durability, and long-lasting sharpness, making them ideal for both chefs and home cooks.

When selecting a corrosion-resistant steel, it’s essential to consider how other properties, such as edge retention and toughness, balance with corrosion resistance. For example, while H1 offers the highest level of corrosion resistance, it may not retain its edge as well as other steels like LC200N or N680. Therefore, the choice of steel should align with the specific needs and conditions in which the knife will be used.

Choosing the right material for a knife blade is essential for achieving the best performance in different tasks. Blade materials influence key properties such as edge retention, toughness, corrosion resistance, and ease of sharpening. Understanding the advantages and disadvantages of different blade materials can help in making an informed choice.

Carbon steel is known for its high carbon content, which provides excellent sharpness and edge retention. This material is easier to sharpen compared to stainless steel but requires regular maintenance to prevent rust and corrosion.

Tool steel is characterized by its hardness and wear resistance, making it suitable for heavy-duty applications. It often contains various alloys to enhance specific properties, but it may not offer the best corrosion resistance.

Stainless steel contains at least 13% chromium, which significantly improves corrosion resistance. It is a popular choice for everyday carry (EDC) knives and kitchen knives due to its ease of maintenance. However, it can be less durable and harder to sharpen than carbon steel.

These steels are designed for extreme performance, combining various elements to enhance durability, wear resistance, and edge retention. They are often used in specialized knives and industrial tools.

Edge retention refers to how long a blade stays sharp during use. High-carbon steels and advanced alloys like CPM-S90V are excellent in this area, making them ideal for tasks that need prolonged sharpness.

Toughness is the ability of a blade to resist chipping or breaking. Steels with higher toughness are better suited for knives that might experience impacts, such as chopping knives.

Corrosion resistance is crucial for a blade’s durability, especially in moist environments. Stainless steels are superior in this aspect, making them ideal for applications like kitchen use.

The ease with which a blade can be sharpened is an important factor for maintenance. Carbon steels are generally easier to sharpen than stainless steels.

Selecting the right knife steel involves understanding the properties and trade-offs of various steel types. Key factors to consider include intended use, edge geometry, maintenance requirements, and specific steel characteristics.

The primary factor in choosing knife steel is the intended use of the knife. Each application demands specific properties:

For outdoor knives, such as survival or camping knives, toughness and ease of sharpening are critical. Carbon steels like 1095 are excellent choices due to their durability and ability to maintain a sharp edge. However, regular maintenance is essential to keep rust at bay.

Kitchen knives benefit from high edge retention and corrosion resistance. High-carbon stainless steels like VG-10 or powdered steels such as CPM-S35VN are ideal for kitchen environments, offering sharpness and resistance to moisture.

EDC knives need a balance of edge retention, corrosion resistance, and ease of maintenance. Stainless steels like S30V and AUS-8 are popular for their excellent combination of these properties.

Understanding the specific properties of different knife steels helps in making an informed decision:

Hardness measures how well a steel can retain its edge. Higher hardness usually means better edge retention but can lead to brittleness. Steels like CPM-S110V and ZDP-189 are very hard, providing excellent edge retention but requiring careful use to avoid chipping.

Toughness is the steel’s ability to resist chipping or breaking, crucial for knives exposed to impacts. Steels like CPM-3V and O1 tool steel offer high toughness, making them suitable for heavy-duty applications.

Wear resistance determines how well a steel can withstand abrasion and cutting. Steels with high carbide content, such as CPM-S90V, offer superior wear resistance, maintaining their edge longer under heavy use.

Corrosion resistance is vital for knives used in wet or humid conditions. High-chromium steels like M390 and LC200N excel at resisting rust and stains.

Some steels are easier to sharpen than others, which can be important for regular maintenance. Steels like AUS-8 and 14C28N are relatively easy to sharpen, making them suitable for users who prefer low-maintenance knives.

Users of survival and camping knives often prefer 1095 carbon steel for its toughness and ease of sharpening, despite the need for regular maintenance to prevent rust.

Chefs frequently choose VG-10 stainless steel for kitchen knives due to its sharpness and corrosion resistance, ensuring long-lasting performance and minimal upkeep.

Everyday carry knife users favor steels like S30V for their balanced edge retention and corrosion resistance, providing reliable performance with minimal maintenance.

By considering these factors and comparing the characteristics of various knife steels, users can select the best steel that aligns with their specific needs and preferences.

Below are answers to some frequently asked questions:

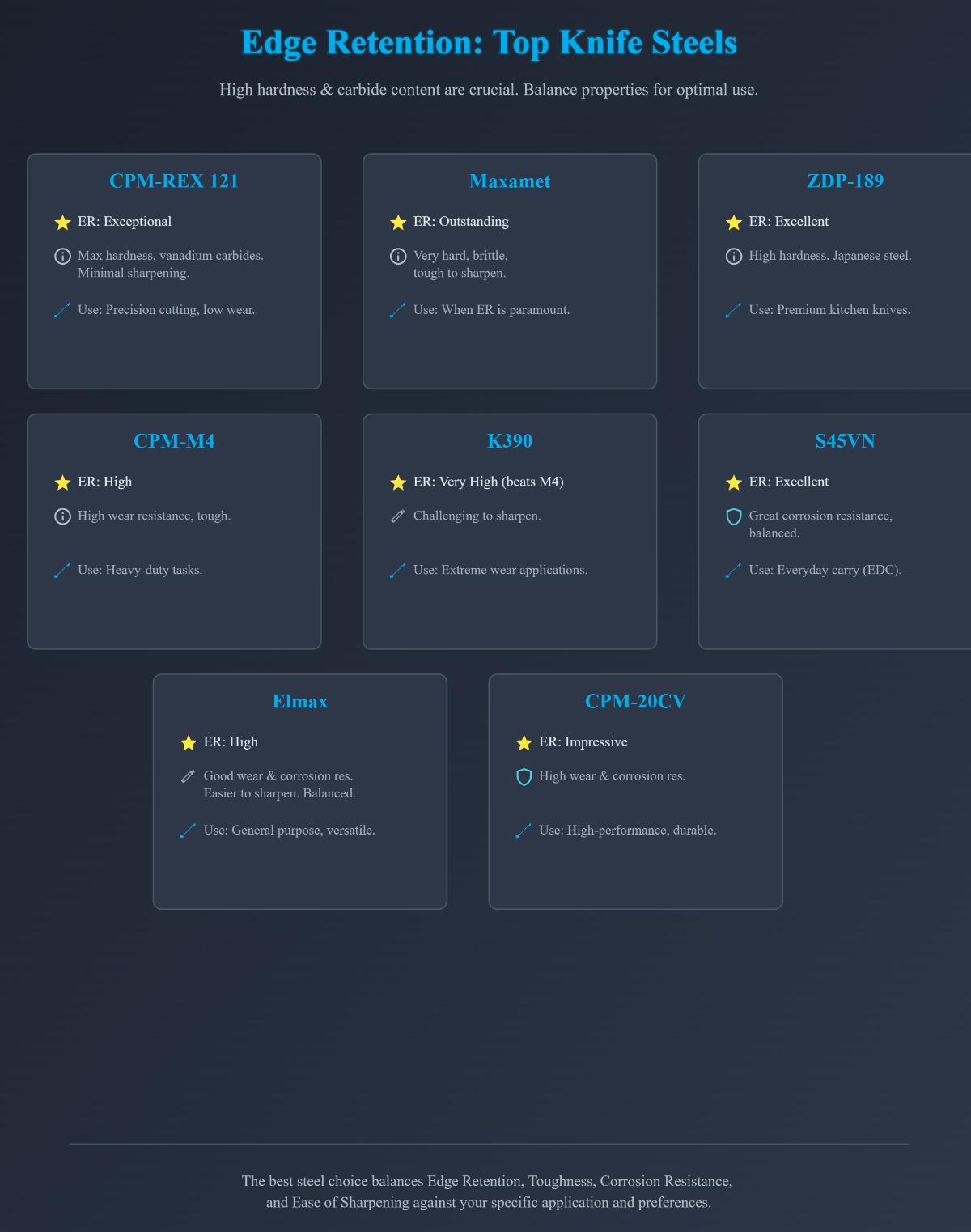

When considering the best knife steels for edge retention, several options stand out due to their high hardness and carbide content. Notable choices include CPM-REX 121, renowned for its exceptional edge retention with high hardness and abundant vanadium carbides, making it ideal for knives requiring minimal sharpening. Maxamet also offers outstanding edge retention but is brittle and difficult to sharpen, suitable for applications prioritizing edge retention over frequent sharpening. ZDP-189, a Japanese steel, is favored for its high hardness and excellent edge retention, commonly used in high-end kitchen knives. CPM-M4 provides high wear resistance and edge retention, suitable for knives under heavy use, while K390 offers slightly better edge retention than M4 but is more challenging to sharpen. S45VN excels in edge retention and corrosion resistance, ideal for daily carry knives. Elmax combines high wear resistance, ease of sharpening, and good corrosion resistance, making it suitable for general-purpose knives. CPM-20CV, with impressive wear resistance and high chromium content for corrosion resistance, is used in high-performance knives needing durability and environmental resistance. Each steel’s choice depends on the intended use and desired balance of properties in the knife.

Choosing the right knife steel for your needs involves understanding several key factors about knife steel properties and matching them to your intended use. Knife steel, the material used to manufacture the blade, significantly influences a knife’s performance and durability.

First, consider hardness, which impacts edge retention and is measured on the Rockwell C scale. Harder steels hold an edge longer but can be less tough. Toughness is crucial for knives subject to heavy use or impacts, preventing chipping or breaking. Wear resistance determines how well a knife withstands abrasive wear, while corrosion resistance is essential for preventing rust, especially in humid or wet environments. For outdoor or survival knives, prioritize toughness and edge retention, typically found in high-carbon or tool steels like 1095 or D2. Kitchen knives benefit from corrosion-resistant stainless steels like 440C or high-end powdered steels like CPM-S30V, which offer a balance of edge retention and ease of maintenance.

Consider the knife’s intended use and your maintenance willingness. Stainless steels are ideal for low-maintenance needs, while high-carbon steels require more care but offer superior edge retention. Heat treatment and edge geometry also affect performance, with proper heat treatment enhancing any steel’s properties.

Balancing these factors based on your specific needs and preferences will help you choose the right knife steel for your application.

High-end and budget knife steels differ primarily in composition, performance attributes, and cost. High-end steels, such as M390, S45VN, and CPM-3V, are produced using advanced techniques like powder metallurgy and contain high levels of vanadium, molybdenum, and tungsten. These elements contribute to superior edge retention and corrosion resistance but often result in lower toughness and greater difficulty in sharpening. These steels are ideal for applications requiring extended sharpness and durability, like hunting or tactical knives.

Budget steels, including 420, 440A, and AUS-8, are manufactured using conventional methods with lower alloy content, making them more affordable and tougher but with reduced edge retention and variable corrosion resistance. They are easier to sharpen, making them suitable for everyday carry knives or tasks requiring frequent maintenance.

For kitchen use, specific knife steels are recommended based on their properties and intended use. Stainless steels like VG-10 and 440C are popular due to their excellent corrosion resistance and durability, making them suitable for the humid and varied environment of the kitchen. VG-10 is favored for its sharpness and edge retention, often found in high-quality chef knives. For those seeking a balance between performance and maintenance, mid-range steels like 14C28N and AUS-8 are excellent choices; they offer good edge retention and are easier to sharpen.

High-end options such as M390 and SG2 provide exceptional wear resistance and edge retention, making them ideal for professional chefs who require precision and long-lasting sharpness. However, these steels may come at a higher cost. Carbon steels, like Japanese Shirogami and Aogami, offer superior sharpness and edge retention but require diligent maintenance to prevent rust. For those prioritizing aesthetics and functionality, Damascus steel combines high-carbon steel with nickel-alloyed metals, offering both strength and a unique appearance, though it also needs proper care to avoid corrosion.

Corrosion-resistant steels, particularly stainless steels, are highly valued in knife making due to their ability to resist rust and staining, which is essential in harsh or humid environments. These steels contain at least 10.5% chromium, forming a protective layer that prevents oxidation. While they excel in environments where moisture is prevalent, they often balance corrosion resistance with other properties like edge retention and toughness.

For example, steels like N680, LC200N, and H1 are specifically designed to offer excellent corrosion resistance, making them ideal for marine applications. However, they may not offer the same level of edge retention as some high-carbon or high-end tool steels such as CPM-S90V or M390, which have higher carbon content and other alloying elements that enhance their hardness and wear resistance but reduce their corrosion resistance.

In comparison to other metals like aluminum or titanium, which also resist corrosion, stainless steels provide superior strength and edge retention, making them more suitable for knife blades. Therefore, choosing a corrosion-resistant steel involves considering the specific use case, balancing the need for durability and sharpness with the environmental conditions the knife will encounter.

Different blade materials offer various advantages, tailored to specific uses and user preferences. Carbon steel is renowned for its exceptional strength, hardness, and ability to retain a razor-sharp edge, making it ideal for heavy-duty cutting tasks. However, it requires regular maintenance to prevent rust. Stainless steel, in contrast, excels in corrosion resistance, making it suitable for environments with frequent exposure to moisture. It is also cost-effective and easier to sharpen, although it may not hold an edge as long as carbon steel.

Tool steel is valued for its wear resistance and high hardness, ideal for professional-grade tools, though it can be more challenging to sharpen and is generally more expensive. Damascus steel is celebrated for its unique aesthetic patterns and balance of strength and flexibility, offering both sharpness and durability, but it is costly and requires more maintenance.

High-carbon stainless steel combines the best of both worlds, offering excellent edge retention and corrosion resistance. It achieves high hardness levels but can be more expensive and harder to sharpen. When choosing a blade material, consider factors like intended use, edge retention, corrosion resistance, and maintenance requirements to find the best match for your needs.