Unlocking the secrets of machining Nitronic 60 can transform your manufacturing processes. Known for its superior wear and corrosion resistance, Nitronic 60 is a material of choice in demanding industries like aerospace, food processing, and oil fields. However, its unique chemical composition poses specific machining challenges that require a strategic approach.

In this comprehensive guide, we will walk you through the entire process of machining Nitronic 60, from understanding its chemical properties and their impact on machinability to mastering the techniques for optimal tool selection and cutting parameters. You’ll discover best practices, detailed step-by-step instructions, and solutions to common problems, ensuring you achieve the best possible results with this exceptional alloy.

Ready to enhance your machining skills and tackle Nitronic 60 with confidence? Let’s dive in and explore the intricacies of working with this remarkable material.

Nitronic 60, also known as Alloy 218 or UNS S21800, is a high-performance austenitic stainless steel known for its exceptional resistance to wear and galling. This alloy is commonly used in industrial and mechanical components, particularly in environments where high temperatures and corrosive conditions are prevalent.

One of the most significant advantages of Nitronic 60 is its remarkable resistance to wear and galling. High levels of manganese and silicon in the alloy help it resist wear and galling under harsh conditions. This property is crucial in applications where metal-to-metal contact occurs, such as valve components, fasteners, and bushings.

Nitronic 60 offers excellent corrosion resistance, comparable to that of Type 304 and 316 stainless steels, making it suitable for use in environments where exposure to corrosive elements is a concern, such as in the food processing and oil field industries. The presence of chromium and nickel in the alloy enhances its ability to resist various types of corrosion, including pitting and crevice corrosion.

In the aerospace industry, Nitronic 60 is used for components that require high strength and durability, such as engine parts and fasteners, due to its ability to maintain mechanical properties at high temperatures.

The food processing industry benefits from Nitronic 60’s corrosion resistance and ability to withstand high temperatures. It is used in equipment that comes into direct contact with food products, ensuring that the machinery remains free from contamination and degradation over time.

In oil field applications, Nitronic 60 is valued for its resistance to wear and galling, which is essential for components exposed to abrasive and corrosive environments. It is commonly used in pumps, valves, and other equipment that must endure harsh operating conditions.

Nitronic 60’s composition includes chromium, nickel, manganese, silicon, and nitrogen, which together enhance its wear resistance, corrosion resistance, and mechanical strength. This carefully balanced composition results in a material that offers a unique combination of strength, toughness, and resistance to wear and corrosion.

Nitronic 60 exhibits high tensile and yield strength, with a yield strength nearly twice that of Type 304 and 316 stainless steels. This makes it an excellent choice for applications requiring robust and durable materials.

The alloy can maintain its mechanical properties at temperatures up to 1800°F (980°C), making it suitable for high-temperature applications. Its resistance to thermal expansion and scaling further enhances its performance in such environments.

Nitronic 60, also known as UNS S21800, is a high-strength austenitic stainless steel alloy. The main elements in Nitronic 60 and their typical percentages are as follows:

The unique combination of elements in Nitronic 60 significantly influences its machinability.

Manganese and silicon in Nitronic 60 boost its hardness and wear resistance, enhancing its performance. However, these elements also create hard, abrasive chips during machining, leading to rapid tool wear and necessitating the use of high-quality, durable tools.

Nitrogen increases Nitronic 60’s yield strength and toughness, improving performance but making machining more challenging. The higher nitrogen levels contribute to the material’s increased hardness and strength, complicating standard machining techniques.

The presence of chromium and nickel enhances Nitronic 60’s corrosion resistance, making it ideal for harsh environments. While these properties are beneficial for the alloy’s performance, they do not significantly affect machinability. However, machining processes must ensure these properties remain intact.

Nitronic 60 tends to work harden quickly, which can complicate machining. As the material is cut, the surface layer hardens, increasing the difficulty of subsequent passes. Careful control of machining parameters is essential to minimize work hardening and maintain tool effectiveness.

Due to the alloy’s hardness and abrasiveness, tools for machining Nitronic 60 need to be robust and wear-resistant. Carbide-tipped tools are typically recommended to manage the increased tool wear effectively. Proper tool selection and maintenance are crucial for efficient machining operations.

To tackle Nitronic 60’s machining challenges, use high-performance cutting tools like carbide-tipped tools to handle its hardness and abrasiveness.

Nitronic 60 is a type of austenitic stainless steel known for its outstanding wear and galling resistance. However, its high strength and hardness present significant challenges during machining. Knowing its properties and choosing the right techniques are key to successful machining.

Its high hardness and strength can cause rapid tool wear and cutting difficulties, necessitating high-quality tools and precise machining parameters.

Nitronic 60 quickly work hardens, complicating further machining. Using the right techniques and tools can help manage this.

The alloy produces hard, abrasive chips that can accelerate tool wear. Effective chip control and management are necessary to maintain machining efficiency.

Good lubrication and cooling are crucial to prevent overheating and reduce tool wear. Minimum Quantity Lubrication (MQL) is recommended over dry cutting due to its ability to lower tool wear and improve surface finish.

Nitronic 60 cannot be hardened by heat treatment. Instead, annealing at 1900-2000°F followed by rapid quenching is used to restore the alloy’s microstructure after cold working.

Grinding and polishing may be necessary to achieve the desired surface finishes, especially for components requiring high precision. Proper finishing techniques ensure that the material’s excellent wear and corrosion resistance properties are maintained.

Nitronic 60 is widely used in industrial applications such as valves, fasteners, and aerospace components, due to its high strength, corrosion resistance, and cost-effectiveness. It offers superior performance at a lower cost compared to other wear-resistant alloys, making it a preferred choice in demanding environments.

Carbide tools are crucial for machining Nitronic 60 because of their superior hardness and resistance to wear. These tools can withstand the high cutting forces and abrasive nature of Nitronic 60, ensuring efficient and effective machining.

Carbide-tipped tools are highly recommended for machining Nitronic 60. They stay sharp longer and resist wear, making them ideal for Nitronic 60’s hardness and abrasiveness. Additionally, using coated carbide inserts such as TiAlN (Titanium Aluminum Nitride) or TiCN (Titanium Carbo-Nitride) can further enhance tool life. These coatings reduce friction and improve heat resistance, allowing for smoother cutting and longer tool usage.

Minimize dwell times and spring passes to prevent localized work hardening, which can complicate subsequent machining processes.

Effective cooling and lubrication techniques reduce heat buildup and friction, leading to better surface finishes.

Use precise finishing operations with optimized cutting speeds and feed rates to achieve the desired surface texture and quality.

By following these guidelines, machinists can effectively select and optimize tools for machining Nitronic 60, overcoming its inherent challenges and achieving high-quality results.

Cutting speed is the rate at which a cutting tool engages with the material being worked on. It is typically measured in surface feet per minute (SFM) or meters per minute (m/min). Selecting the correct cutting speed is crucial to ensure efficient material removal, minimize tool wear, and achieve a high-quality surface finish.

Feed rate is the distance the cutting tool advances along the workpiece during one revolution of the spindle. It is typically measured in inches per revolution (IPR) or millimeters per revolution (mm/rev). Proper feed rates are essential to balance material removal rates and tool life.

Carbide tools are ideal for machining Nitronic 60 because they are durable and resistant to wear. Effective grades for turning include Sumitomo AC6020M, AC6030M, AC1030U, and AC6040M. For milling and grooving, use AC520U and AC830P.

Optimizing tool life involves using the correct cutting edge geometry. This includes:

Nitronic 60 has a machinability range of 35% to 45%, making it more challenging than some stainless steels. High manganese and silicon content enhance strength and wear resistance but complicate machining.

Effective cooling and lubrication techniques, such as minimum quantity lubricant (MQL) and flooded cooling, are crucial for reducing tool wear and improving surface finish during machining.

Machining Nitronic 60 presents a unique set of challenges primarily due to its composition and material properties. Understanding these challenges is the first step in developing effective machining strategies.

Nitronic 60 has a tendency to work harden during machining operations. As the material is cut, the surface layer hardens, making further passes more difficult and causing rapid tool wear. The high manganese and silicon content result in hard, abrasive chips that contribute to this issue.

The inherent hardness and toughness of Nitronic 60 can cause tool deflection and heat buildup during machining. This requires strong tools and precise machining to handle these effects and keep accuracy.

Chips from machining Nitronic 60 can stick to cutting tools. This chip adhesion leads to tool rubbing and chatter, which can degrade the surface finish and necessitate frequent tool sharpening.

To address the challenges posed by Nitronic 60, a combination of tool selection, machining parameters, cooling and lubrication techniques, and quality control measures should be employed.

Efficient cooling and lubrication are crucial to managing heat buildup and preventing chip adhesion. Several strategies can be employed:

Minimize dwell times and spring passes to prevent localized work hardening. This helps maintain a consistent machining process and prolongs tool life.

Consistently engaging the tool with fresh material helps prevent the formation of work-hardened zones, which can complicate machining operations.

Stabilize the workpiece to reduce tool deflection and increase precision. This is critical for maintaining dimensional accuracy and surface finish.

Continuously monitor the machining process to ensure parameters are maintained within specified limits. This helps in early detection of any deviations that could affect the quality of the final product.

Implement strict quality control measures throughout the machining process. Regular inspections and adherence to specified tolerances ensure that the finished product meets the required standards.

By addressing these challenges with tailored solutions, machinists can effectively manage the machining of Nitronic 60, achieving optimal results in various demanding applications.

Below are answers to some frequently asked questions:

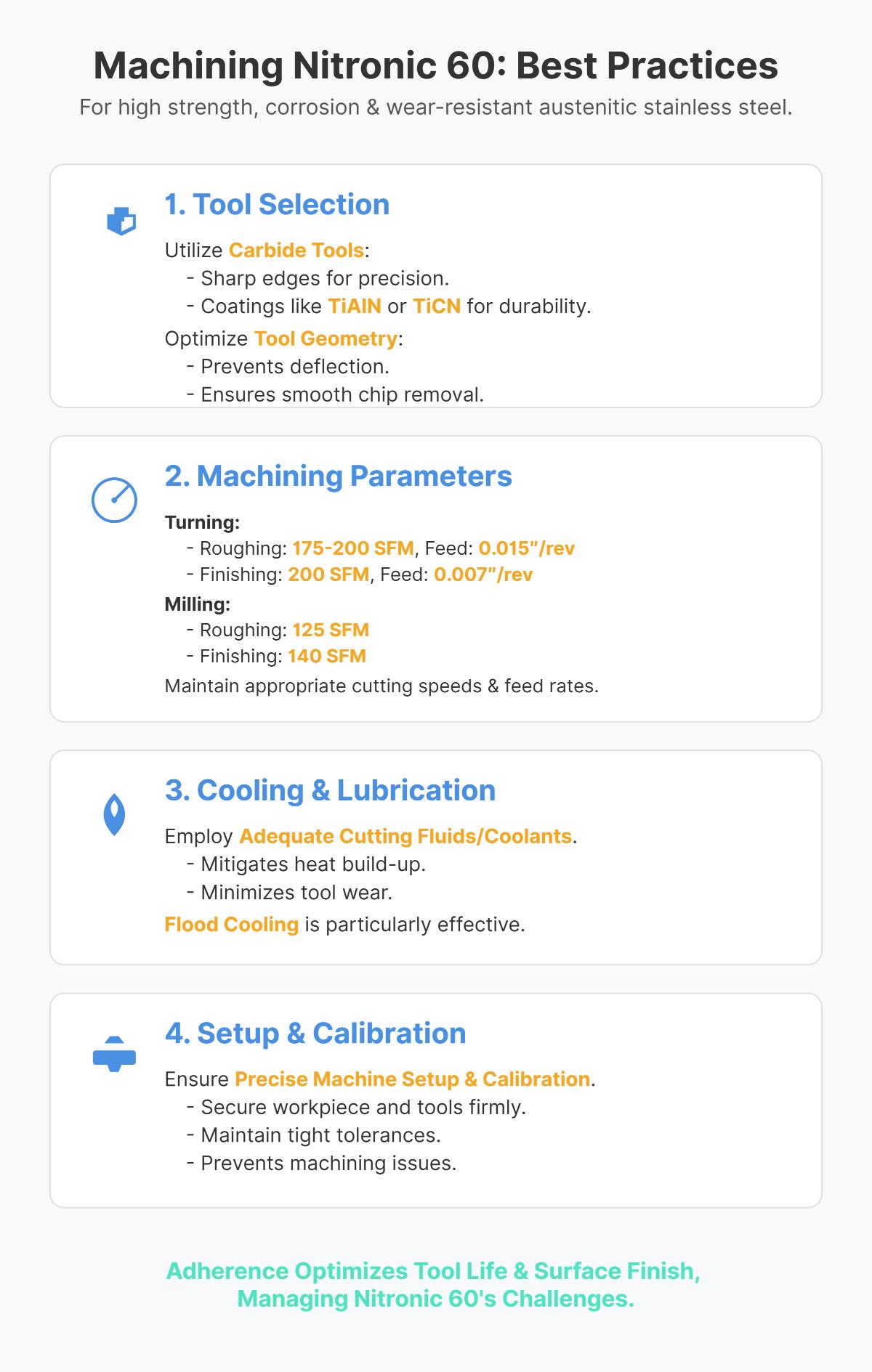

To effectively machine Nitronic 60, an austenitic stainless steel known for its high strength, corrosion resistance, and wear resistance, follow these best practices:

By adhering to these practices, machinists can optimize tool life and surface finish while effectively managing the challenges posed by Nitronic 60’s properties.

The chemical composition of Nitronic 60 significantly impacts its machinability. This austenitic stainless steel alloy contains high levels of manganese (7-9%) and silicon (3.5-4.5%), which enhance its wear and galling resistance but also increase its hardness, making the machining process more challenging. The formation of hard, abrasive chips during machining leads to rapid tool wear, necessitating the use of carbide tools and precise cutting techniques.

Additionally, the nitrogen content (0.08-0.18%) boosts the alloy’s yield strength, further complicating machining by requiring careful selection of machining parameters to avoid tool failure. Chromium (16-18%) and nickel (8-9%) contribute to corrosion resistance without significantly affecting machinability. To overcome these challenges, optimized cutting speeds, feed rates, and the use of carbide tools are essential.

For machining Nitronic 60, optimal cutting speeds and feed rates are crucial to ensure efficient operations and minimize tool wear.

In turning operations, roughing should be performed with cutting speeds between 155-195 m/min (510-640 SFM) and finishing at 175-200 m/min (575-660 SFM). For milling, roughing side and slot milling operations should use speeds of 95-125 m/min (310-410 SFM), and finishing operations at 125-140 m/min (410-460 SFM). Drilling operations typically require speeds around 45-55 m/min (150-180 SFM).

Regarding feed rates, in turning, roughing should use a feed rate of approximately 0.015 inches per revolution (0.38 mm/rev) with a depth of cut of 0.15 inches (3.81 mm), while finishing should use a feed rate of about 0.007 inches per revolution (0.18 mm/rev) with a depth of cut of 0.025 inches (0.64 mm). For milling, roughing feed rates should be 0.007 inches per tooth with a depth of cut of 0.25 inches (6.35 mm), and finishing feed rates should be 0.005 inches per tooth with a depth of cut of 0.050 inches (1.27 mm). In drilling, for 1/4 inch diameter holes, use a feed rate of 0.004 inches per revolution, and for 3/4 inch diameter holes, use a feed rate of 0.010 inches per revolution.

These parameters help optimize the machining process for Nitronic 60, improving tool life and achieving superior surface finishes.

To optimize tool life when machining Nitronic 60, several strategies should be considered. Firstly, the use of carbide tools is highly recommended due to their superior wear resistance and ability to handle the hardness of Nitronic 60. Carbide tools with sharp edges are particularly effective when used at high cutting speeds and slow feed rates. Additionally, ceramic tools like SiAlON can be beneficial for specific high-performance machining scenarios.

Adjusting cutting parameters is crucial. Employ relatively high cutting speeds, around 175-200 SFM, combined with slow feed rates, such as 0.015″ per revolution. This reduces tool deflection and work hardening, which are common issues with Nitronic 60.

Effective cooling and lubrication are also essential. Minimum Quantity Lubrication (MQL) significantly reduces cutting forces and temperatures, enhancing tool life. Using appropriate cooling lubricants helps manage heat buildup and chip formation.

Tool geometry plays a role as well. Negative rake tools and coated carbide inserts (e.g., TiAlN or TiCN) improve wear resistance and reduce friction. Ensuring a rigid setup and stabilizing the workpiece minimizes vibrations and tool deflection, further extending tool life.

Common issues faced during the machining of Nitronic 60 include work hardening, tool wear, chip sticking, heat build-up, and maintaining tolerances and surface finish.

To address work hardening, it is essential to use sharp, rigid tools and avoid prolonged tool engagement. High cutting speeds and slow feed rates can help minimize this effect. Tool wear can be mitigated by employing carbide-tipped tools with appropriate cutting edge geometry and using coated carbide inserts, such as TiAlN or TiCN, to enhance tool life. Proper workpiece stabilization is crucial to reduce tool deflection.

For chip sticking and tool chatter, regular tool sharpening and the use of appropriate cutting fluids are necessary. Heat build-up and burr formation can be managed with efficient cooling strategies, such as using cutting fluids or coolant systems. Proper chip clearance is also important to prevent chip accumulation and heat build-up.

To achieve precise tolerances and smooth surface finishes, use advanced machining techniques with precise tool paths and ensure secure clamping of both the workpiece and tools. Consistent lubrication practices also improve surface finish.

By understanding and addressing these challenges with the recommended strategies, machinists can effectively machine Nitronic 60 and produce high-quality components.

When machining Nitronic 60, various methods can be employed, each with distinct characteristics and suitability based on the material’s properties. Here are the primary differences:

Each method requires optimized cutting speeds, feed rates, and cooling techniques to mitigate the challenges posed by Nitronic 60’s high strength and wear resistance. Using carbide tools and maintaining sharp, rigid tool edges are essential across all methods to ensure efficient machining and prolonged tool life.