Steel is everywhere, from the skyscrapers that define our cities to the tools that shape our world. But not all steel is created equal. When it comes to mild steel versus tool steel, the differences can be as stark as night and day. What sets these two types of steel apart? Why would a builder choose one over the other? This article dives deep into the chemical compositions, mechanical properties, and applications of mild steel and tool steel to help you make informed decisions for your projects. We’ll explore which is harder, how carbon content plays a pivotal role, and the unique advantages each type offers. Ready to uncover the secrets behind these essential materials? Let’s delve into the fascinating world of steel and discover which one reigns supreme for your needs.

Mild steel, also known as low carbon steel, is primarily distinguished by its low carbon content. The carbon content usually falls between 0.16% and 0.29%, but some types may contain up to 0.45%, depending on their use. This low carbon content is a key factor that gives mild steel its unique properties, such as high ductility and ease of welding.

Besides carbon, mild steel generally contains small amounts of other elements to enhance specific properties:

The balance of mild steel is primarily iron (Fe), usually comprising over 98% of the total composition.

Tool steel has a higher carbon content, usually between 0.5% and 1.5% or more, depending on the grade. This higher carbon content is critical for achieving the hardness and wear resistance necessary for cutting and shaping tools.

Tool steels are alloyed with various elements to enhance their mechanical properties:

| Element | Mild Steel | Tool Steel | Effect on Properties |

|---|---|---|---|

| Carbon (C) | 0.16% – 0.29% (up to 0.45%) | 0.5% – 1.5%+ | Higher carbon in tool steel increases hardness and wear resistance but reduces ductility. Mild steel is more ductile and weldable. |

| Chromium (Cr) | Trace to 0.25% | 0.25% and higher | Cr improves hardness and corrosion resistance, more significant in tool steel. |

| Manganese (Mn) | ~1.0% – 1.7% | 0.3% – 1.7% | Mn enhances strength and hardness. Present in both but often higher in tool steel. |

| Molybdenum (Mo) | Usually absent or trace | Present (up to 0.1% or more) | Mo enhances toughness and heat resistance, typical in tool steels. |

| Nickel (Ni) | Trace or absent | Present (up to 0.4% or more) | Ni improves toughness and corrosion resistance, common in tool steels. |

| Sulfur (S) and Phosphorus (P) | Low amounts (≤0.04%) | Low amounts (≤0.04%) | Controlled to improve machinability and toughness in both steels. |

| Other alloys (V, W, Co) | Usually absent | Present in some tool steels | Add wear resistance and heat resistance in tool steels. |

The differences in chemical composition between mild steel and tool steel result in varied mechanical and physical properties:

Hardness is a key property that determines a material’s resistance to deformation, scratching, or indentation.

Mild steel typically has a Brinell hardness number (BHN) ranging from 120 to 160. The relatively low hardness of mild steel is due to its low carbon content (usually between 0.05% and 0.25%), which does not significantly increase its strength or hardness. This makes mild steel suitable for applications where ease of machining and forming are essential.

Tool steel, on the other hand, is characterized by significantly higher hardness, often reaching Brinell hardness numbers above 200 and Rockwell hardness numbers between 55 and 65 HRC, depending on the specific grade and heat treatment. The high carbon content (0.5% to 1.5% or more) and the presence of alloying elements such as tungsten, vanadium, and molybdenum contribute to the enhanced hardness. This makes tool steel ideal for cutting, shaping, and wear-resistant applications.

Ductility refers to the ability of a material to deform plastically before fracturing, which is crucial for forming and shaping processes.

Mild steel exhibits high ductility due to its low carbon content and minimal alloying elements. This property allows it to be easily bent, drawn, and shaped without cracking, making it suitable for applications requiring complex shapes and high flexibility.

Tool steel has lower ductility compared to mild steel, primarily due to its higher carbon content and hardening alloying elements. This reduced ductility limits its ability to bend or stretch significantly without breaking, making tool steel less suitable for applications requiring extensive forming but ideal for high-strength and wear-resistant tools.

Weldability is the ease with which a material can be welded without resulting in defects.

Mild steel is highly weldable, thanks to its simple composition and low carbon content. It can be welded using common techniques like MIG, TIG, and arc welding, with minimal risk of cracking or other welding defects. This makes mild steel a preferred choice for construction and manufacturing projects where welding is a common process.

Tool steel is less weldable than mild steel due to its complex composition and higher carbon content. The presence of alloying elements can lead to challenges such as cracking and brittleness in the weld zone. Specialized welding techniques and pre-heating may be required to successfully weld tool steel, which is often avoided unless necessary.

Corrosion resistance is the ability of a material to withstand damage caused by oxidization or other chemical reactions.

Mild steel has limited corrosion resistance due to its low chromium content and other alloying elements that enhance resistance. It is prone to rusting and requires protective coatings to prevent rust in corrosive environments.

Tool steel can offer better corrosion resistance, especially grades containing significant amounts of chromium. These elements help form a passive oxide layer that protects against corrosion, making tool steel more suitable for environments where corrosion resistance is critical.

Strength refers to the ability of a material to withstand an applied load without failure.

Mild steel generally exhibits tensile strength ranging from 400 to 550 MPa, sufficient for many construction and manufacturing applications. Its strength is adequate for structures and components that do not require extreme hardness or wear resistance.

Tool steel provides higher tensile strength compared to mild steel, often exceeding 700 MPa. The combination of higher carbon content and alloying elements significantly enhances its strength, making it suitable for high-stress applications such as tooling and high-performance machine parts.

Heat treatment involves heating and cooling materials to alter their physical and mechanical properties.

Mild steel can undergo heat treatment processes like annealing and normalizing to improve its ductility and machinability. However, due to its low carbon content, the extent of property enhancement through heat treatment is limited compared to tool steel.

Tool steel benefits greatly from heat treatment processes such as quenching and tempering, which can significantly increase its hardness and strength. The high carbon content and alloying elements respond well, making tool steel ideal for high-performance uses.

Mild steel is widely utilized across various industries due to its favorable properties such as high ductility, toughness, and ease of fabrication. Below are some common applications:

Mild steel is extensively used in construction for structural components like beams, columns, and frames. Its toughness and strength make it ideal for supporting loads in buildings and infrastructure projects.

Mild steel is favored in the fabrication industry for shaping, welding, and bending, and is commonly used in automotive bodies, pipelines, and sheet metal products. Its excellent weldability and formability ensure efficient and cost-effective manufacturing.

Mild steel is also employed in general engineering applications where flexibility and ease of machining are required. This includes the production of parts like brackets, supports, and other components that do not need high wear resistance or extreme hardness.

Because it can rust, mild steel is often coated or galvanized for protection outdoors or in corrosive environments. Protective coatings enhance its durability, making it suitable for use in fencing, outdoor structures, and various exposed applications.

Tool steel is designed for high-stress applications requiring hardness, wear resistance, and sharp edge retention. Here are key areas where tool steel is employed:

Tool steel is the material of choice for manufacturing cutting tools such as drills, taps, reamers, and dies. Its exceptional hardness and wear resistance allow it to maintain sharp edges and perform effectively in cutting and drilling operations.

In high-stress applications like punches, dies, and molds, tool steel excels due to its high strength and durability. These tools are essential in industries that require precise forming and shaping of materials, including metalworking and plastic molding.

Tool steel is ideal for components exposed to friction and abrasion, such as gears, bearings, and machine tool parts. Its ability to withstand wear and maintain performance under harsh conditions makes it suitable for demanding industrial applications.

Certain grades of tool steel are used for saw frames, hand tools, and agricultural implements, benefiting from its hardness and wear resistance for long-term reliability.

Some tool steels are formulated to retain their hardness and strength at elevated temperatures, making them suitable for hot work tools like forging dies and extrusion tools. These applications demand materials that can perform under extreme heat without losing their mechanical properties.

Affordability: Mild steel is typically more affordable than tool steel, making it ideal for budget-conscious projects. Its affordability promotes widespread use in construction and manufacturing.

Ease of Fabrication: Mild steel’s ductility and malleability make it easy to shape, cut, and weld. These properties enable efficient manufacturing processes and simplify the creation of complex structures and components, making it ideal for applications requiring intricate designs and frequent modifications.

Versatility: Mild steel can be used in a wide range of applications, from building frames and pipelines to automotive components and machinery parts. Its balanced properties make it suitable for various engineering and construction tasks.

High Hardness and Strength: Tool steel is renowned for its exceptional hardness and strength, which are essential for applications requiring durable and wear-resistant materials. The high carbon content and alloying elements like tungsten and vanadium make tool steel perfect for cutting tools and high-stress components.

Corrosion Resistance: Certain grades of tool steel offer enhanced corrosion resistance due to the presence of alloying elements like chromium. This property is particularly beneficial for applications exposed to harsh environments, where corrosion resistance is crucial for maintaining the integrity and longevity of the tools.

Dimensional Stability: Tool steel exhibits excellent dimensional stability during heat treatment processes. This stability ensures that the tools and components retain their precise dimensions and shapes, which is vital for applications requiring high accuracy and reliability, such as molds and dies.

Low Strength and Hardness: Compared to tool steel, mild steel has lower strength and hardness. This limitation restricts its use in applications requiring high wear resistance and durability. Mild steel is less suitable for tools and machinery parts that experience significant stress and abrasion.

Corrosion Susceptibility: Mild steel is prone to rusting and corrosion, especially in environments with high moisture or chemical exposure. Protective coatings or galvanization are often necessary to prevent rust, adding to the overall cost and maintenance efforts.

High Cost: Tool steel is generally more expensive than mild steel. The higher cost is due to its complex composition and multiple alloying elements.

Difficulty in Machining: The high hardness of tool steel can make it challenging to machine and shape. Specialized equipment and techniques are often required to process tool steel, increasing the complexity and cost of manufacturing.

Limited Ductility: Tool steel has lower ductility compared to mild steel, making it less suitable for applications requiring extensive forming and bending. The reduced ductility can lead to difficulties in shaping tool steel without causing fractures or other issues.

Choosing the right steel for your tools and projects depends on factors like material properties, cost, and specific needs. Here’s a comparative guide to help you make informed decisions.

Mild Steel: Mild steel is generally more affordable than tool steel, making it a suitable choice for budget-conscious projects. Its lower price is due to the simpler composition and widespread availability.

Tool Steel: Tool steel tends to be more expensive due to its higher carbon content and additional alloying elements. The increased cost is justified by the superior performance characteristics required for demanding applications. Beyond cost, it’s also important to consider how easy the material is to work with.

Mild Steel: Known for its excellent weldability and ease of machining, mild steel is ideal for projects that require extensive forming, bending, and welding. Its high ductility allows for complex shapes and modifications during fabrication.

Tool Steel: Tool steel is tougher to machine and weld because it’s harder and has a more complex composition. Specialized equipment and techniques are often necessary, and heat treatment may be required to achieve desired properties.

Mild Steel: While mild steel offers sufficient strength for many structural and general engineering applications, it doesn’t offer the same level of hardness and wear resistance as tool steel.

Tool Steel: Tool steel provides exceptional strength and wear resistance, making it ideal for cutting tools, dies, and molds. Its ability to withstand repeated abrasion and impact is crucial for tools subjected to heavy use.

Mild Steel: Choose mild steel for applications where high strength is not critical, but ease of fabrication and cost-effectiveness are important. Examples include structural components, automotive bodies, and general-purpose engineering projects.

Tool Steel: Opt for tool steel when precision, durability, and wear resistance are paramount. It is the preferred material for manufacturing cutting tools, punches, dies, and any application requiring high-performance materials.

Mild Steel: Mild steel can undergo basic heat treatments like annealing and normalizing to improve ductility and machinability. However, the extent of property enhancement is limited due to its low carbon content.

Tool Steel: Tool steel benefits greatly from advanced heat treatments like quenching and tempering. These processes enhance its hardness and strength, making it ideal for high-stress applications and tools that need to stay sharp.

Mild Steel: Mild steel has limited corrosion resistance and often requires protective coatings or galvanization for use in corrosive environments. This additional step can increase the overall project cost.

Tool Steel: Certain grades of tool steel offer improved corrosion resistance due to the presence of alloying elements like chromium. This makes tool steel a better choice for applications where resistance to rust and corrosion is essential.

By understanding the key differences and application-specific advantages of mild steel and tool steel, you can make informed decisions that optimize performance and cost-effectiveness for your tools and projects.

Below are answers to some frequently asked questions:

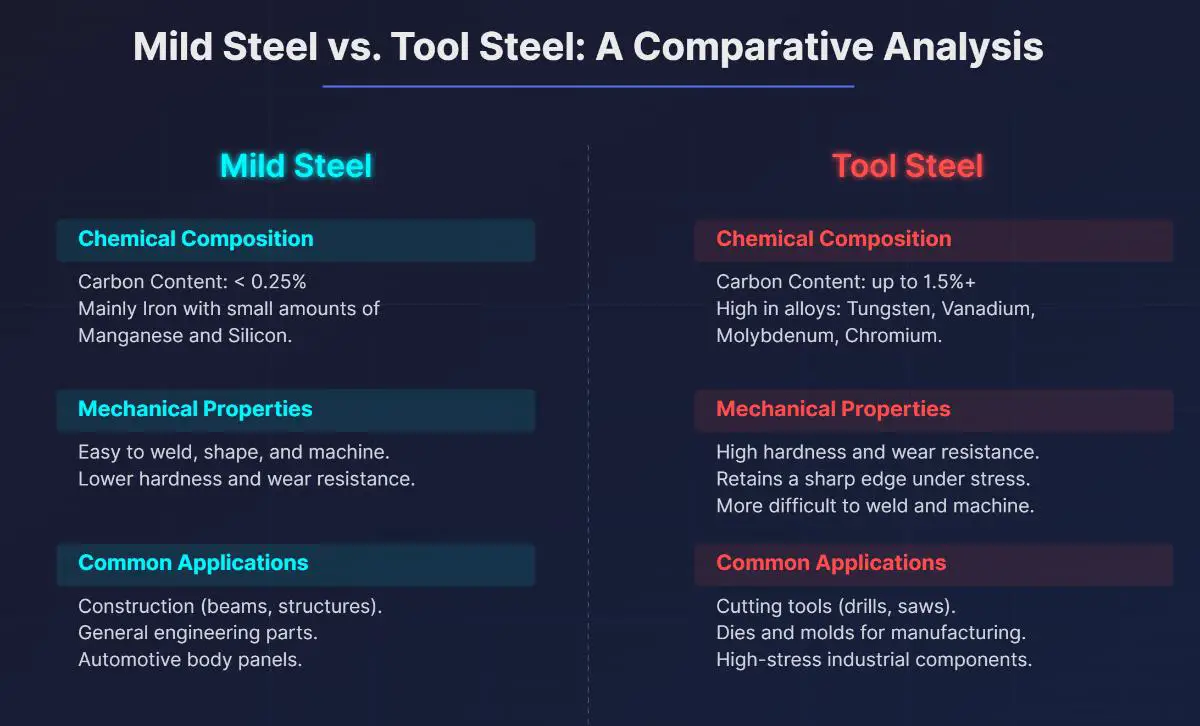

The main difference between mild steel and tool steel lies in their chemical composition and mechanical properties. Mild steel, with a carbon content typically less than 0.25%, is primarily composed of iron with small amounts of alloying elements like manganese and silicon. This composition results in a material that is easy to weld, shape, and machine, making it ideal for construction and general engineering applications.

Tool steel, on the other hand, contains a higher carbon content (up to 1.5% or more) and additional alloying elements such as tungsten, vanadium, molybdenum, and chromium. These elements significantly enhance its hardness, wear resistance, and ability to retain a sharp edge. As a result, tool steel is suited for high-stress applications like cutting tools, dies, and molds. However, its higher alloy content makes it more difficult to weld and machine compared to mild steel.

Tool steel is significantly harder than mild steel. Mild steel, with a low carbon content (typically 0.05% to 0.25%), has a Brinell hardness number ranging from 50 to 100. In contrast, tool steel contains a higher percentage of carbon and alloying elements, allowing it to achieve hardness levels exceeding 45 HRC (Rockwell C scale). This makes tool steel ideal for applications requiring high wear resistance and durability, such as in cutting tools and dies. Mild steel’s lower hardness is suitable for general construction and manufacturing where high strength and wear resistance are not critical.

Mild steel, with its low carbon content (0.05% to 0.25%), is known for its high ductility, malleability, and excellent weldability. These characteristics make it suitable for manufacturing components that require bending, shaping, or forming without cracking, such as jigs, fixtures, and certain types of gears. Due to its high machinability, mild steel can be easily worked with standard tools and is cost-effective due to its abundance and simple manufacturing process.

However, mild steel’s low hardness and wear resistance limit its use in high-stress tooling applications. Unlike tool steel, which is specifically engineered for high hardness, wear resistance, and the ability to retain a sharp cutting edge, mild steel cannot be significantly hardened through heat treatment and is more prone to wear and rust. This makes mild steel unsuitable for cutting tools, drills, punches, and dies, which require sustained hardness and durability.

Carbon content significantly impacts the mechanical properties of steel, making it a critical factor in differentiating mild steel from tool steel.

Mild steel, with a low carbon content (≤ 0.3%), is characterized by its softness, high ductility, and excellent weldability. This makes it suitable for construction materials, automotive body panels, and general fabrication where formability and ease of welding are essential. The microstructure of mild steel is primarily ferrite, contributing to its malleability and good magnetic properties.

In contrast, tool steel contains a high carbon content (≥ 0.6%, often up to 2.1%), resulting in exceptional hardness and strength but reduced ductility and weldability. The microstructure of tool steel includes a higher proportion of cementite and, when quenched, forms martensite, which is very hard but brittle. These properties make tool steel ideal for applications requiring high wear resistance and hardness, such as cutting tools, knife blades, and springs.

The increased carbon content in tool steel enhances hardness and strength, but also makes it more brittle and challenging to weld compared to mild steel. Thus, understanding the influence of carbon content is crucial for selecting the appropriate steel type for specific engineering and manufacturing applications.

Mild steel and tool steel each offer distinct advantages and disadvantages, making them suitable for different applications. Mild steel, primarily composed of iron with less than 1% carbon, is cost-effective, highly malleable, and easy to weld, making it ideal for general engineering and construction projects. However, its lower strength and hardness, coupled with limited corrosion resistance, restrict its use in heavy-duty or high-stress environments.

Tool steel, on the other hand, contains higher carbon content and additional alloying elements like tungsten and chromium, which enhance its hardness, strength, and wear resistance. This makes tool steel perfect for cutting tools and high-wear applications. Nonetheless, tool steel is more expensive and less ductile, making it harder to work with and weld. Additionally, it often requires specialized heat treatment to achieve desired properties, adding complexity and cost.

Heat treatment impacts the properties of mild steel and tool steel significantly but in different ways due to their distinct compositions. Mild steel, with its low carbon content (typically less than 0.25%), responds to heat treatment by becoming more ductile and stress-relieved through processes like annealing and normalizing. These treatments refine the grain structure and improve machinability, but the increase in hardness and strength is limited. Quenching and tempering can harden mild steel slightly, but it may become brittle without substantial strength gains.

In contrast, tool steel, which contains higher carbon content (0.5-1.5%) and substantial alloying elements like chromium, vanadium, and molybdenum, undergoes significant transformation when heat treated. Quenching tool steel results in a very hard martensitic structure, while tempering balances this hardness with improved toughness. This combination of high hardness, wear resistance, and thermal stability makes tool steel ideal for high-stress applications such as cutting and shaping tools. The precise control over heat treatment processes allows tool steel to achieve specific performance characteristics essential for demanding mechanical environments.