Imagine transforming an ordinary object into a gleaming, corrosion-resistant masterpiece with just a few simple steps. Nickel electroplating is a fascinating and accessible technique that can achieve this dazzling effect, even for beginners. This guide will walk you through everything you need to know to get started, from gathering the essential materials and tools to mastering the step-by-step process of nickel plating. Whether you’re curious about how to prepare surfaces, set up your electrolyte solution, or fine-tune the plating parameters, this comprehensive guide has got you covered. Ready to dive into the shiny world of nickel electroplating? Let’s begin by exploring the basics and beyond!

Introduction to Nickel Electroplating

Understanding Nickel Electroplating

Nickel electroplating is a process where a thin layer of nickel is deposited onto a part’s surface through an electrochemical method. This process enhances the part’s appearance, corrosion resistance, hardness, and wear properties.

Key Benefits of Nickel Electroplating

- Corrosion Resistance: Nickel layers offer excellent protection against rust and chemical attacks, making parts more durable in harsh environments.

- Wear Resistance: The hard nickel coating significantly extends the lifespan of mechanical parts by reducing wear and tear.

- Aesthetic Enhancement: Nickel plating provides a bright, smooth, and decorative finish, which is often desirable for consumer products.

- Versatility: Nickel electroplating can be applied to various substrates, including steel, copper, and plastic, making it useful across multiple industries.

Basic Principles

Preparation of the Part

Before plating, the metal part must be thoroughly cleaned to remove any dirt, grease, corrosion, or surface defects. Cleaning methods include degreasing, pickling, and etching to ensure good adhesion of the nickel layer.

Electrolyte Solution

The electrolyte solution, or nickel plating bath, contains dissolved nickel salts and additives to maintain the pH and quality of the plating. This solution serves as the source of nickel ions needed for the electroplating process.

Electroplating Setup

In the electroplating setup, the part to be plated is the cathode (negative electrode), and a piece of pure nickel acts as the anode (positive electrode). When direct current is applied, nickel ions from the electrolyte are reduced and deposited onto the cathode surface, while nickel from the anode dissolves into the solution to replenish the ions.

Electric Current and Voltage

A controlled electric current and low voltage (typically between 1 to 6 volts) are crucial to achieving a smooth, even nickel coating. Higher voltages can lead to poor surface quality and other plating defects.

Applications of Nickel Electroplating

- Automotive Industry: Enhances the durability and appearance of car parts.

- Electronics: Improves the conductivity and wear resistance of electrical connectors and components.

- Consumer Goods: Provides a decorative finish on items such as jewelry, kitchen utensils, and hardware.

- Industrial Equipment: Protects machinery and tools from corrosion and wear.

Required Materials and Tools

Core Materials

To begin with nickel electroplating, you will need several key materials that are essential for a successful and efficient plating process.

Nickel Anodes

Nickel anodes are pure nickel strips or rods that serve as the source of nickel in the electroplating process. These anodes dissolve into the electrolyte solution and deposit onto the substrate, forming the nickel coating.

Electrolyte Solution

The electrolyte solution, also known as the nickel plating bath, is crucial for the electroplating process. You can make your own by dissolving nickel in vinegar and salt to create nickel acetate. Alternatively, commercial nickel plating baths are available and often provide more consistent results.

Cleaning Agents

Thoroughly cleaning the substrate is essential for a high-quality nickel coating. The following cleaning agents are commonly used:

- Degreaser: Dish soap or acetone can be used to remove grease and contaminants from the substrate.

- Hydrochloric Acid: A diluted solution (50:50 with water) is used for etching and final cleaning to ensure the substrate is free of oxides and ready for plating.

Substrate

The substrate is the metal object that you want to plate with nickel. Common substrates include steel and copper, which must be thoroughly cleaned and prepared before the electroplating process.

Essential Tools

In addition to the core materials, several tools are necessary to set up and conduct the electroplating process effectively.

Power Source

A DC power supply, such as a 1-6V battery or an adjustable power unit, is required to provide the necessary electrical current for electroplating. Lower voltages (1-3V) are typically used to achieve smoother finishes.

Alligator Clips

Alligator clips are used to connect the anode and cathode (the substrate) to the power supply. These clips ensure a secure and reliable electrical connection during the plating process.

Containers

Use acid-resistant containers, like plastic or glass, for the electrolyte solution and acid etching. These containers should be resistant to the chemicals used in the process to prevent contamination or damage.

Cleaning Tools

To prepare the substrate surface, you will need cleaning tools such as sandpaper or a wire brush. These tools help to remove surface imperfections and ensure good adhesion of the nickel layer. Additionally, safety equipment like gloves and goggles are essential to protect yourself from harmful chemicals.

Preparation Process

Before starting the electroplating process, you need to prepare both the materials and the tools.

Surface Cleaning

Clean the substrate with dish soap or acetone to remove grease, then etch it in a diluted hydrochloric acid solution (50:50 with water) for about one minute to remove oxides and prepare the surface.

Electrolyte Setup

Prepare the nickel acetate solution by dissolving nickel in a mixture of vinegar and salt until the solution turns green. Attach the nickel anode to the positive terminal of the power supply and the substrate to the negative terminal. Submerge both in the electrolyte solution, ensuring they do not touch each other.

Key Considerations

When conducting nickel electroplating, there are several important factors to keep in mind:

- Voltage Control: Use a voltage of 1-3V for shiny finishes. Higher voltages may cause roughness and other surface defects.

- Plating Time: Typically, the plating process takes around 20 minutes. Periodically rotate the substrate to ensure an even nickel coating.

- Safety: Always work in a well-ventilated area and avoid direct skin contact with acids. Use appropriate safety gear, including gloves and goggles, to protect yourself from potential hazards.

Step-by-Step Nickel Electroplating Process

Surface Preparation

Before beginning the nickel electroplating process, it’s crucial to prepare the surface of the object you wish to plate. This step ensures the nickel adheres well and results in a smooth finish.

Cleaning the Object

- Wash with Soap and Water: Start by thoroughly washing the object with soap and water to remove any dirt, grease, or grime.

- Degreasing: Use acetone or a similar degreaser to remove any remaining oils or contaminants.

- Etching: Optionally, dip the object in a diluted hydrochloric acid solution (50% acid and 50% water) for about one minute. This helps to remove oxides and activate the surface for better plating adhesion.

- Rinsing: Rinse the object with distilled or tap water to remove any acid residue and prevent contamination of the plating bath.

Setting Up the Electrolyte Solution

Preparing the Solution

- Nickel Salts: Dissolve nickel salts, such as nickel acetate, in distilled water. The solution should be well mixed and may appear greenish.

- Mixing: Stir the solution thoroughly to ensure it is uniform and ready for plating.

Configuring the Power Source

Connecting the Electroplating Circuit

- Attach the Cathode: Connect the object to be plated to the negative lead (cathode) of your DC power supply or battery.

- Attach the Anode: Connect a nickel strip or rod to the positive lead (anode).

- Submerge in Solution: Suspend both the cathode and anode in the electrolyte solution. Ensure they are equidistant to promote even plating.

Immersing the Object in the Nickel Plating Bath

Starting the Plating Process

- Power Supply: Turn on the DC power supply or battery, setting it to a low voltage, ideally between 1V to 6V.

- Electrochemical Reaction: Nickel ions from the anode dissolve into the electrolyte solution and deposit onto the cathode (the object). Tiny bubbles should form, indicating that the plating process has started.

Adjusting Plating Parameters (pH, Temperature, Current)

Monitoring and Adjusting

- pH Levels: Maintain the pH level of the electrolyte solution around 4-5 for optimal plating conditions.

- Temperature Control: Keep the solution temperature between 50-60°C (122-140°F) to facilitate smooth plating.

- Current Settings: Adjust the current to ensure an even and consistent nickel deposit. Lower currents typically yield a finer finish.

Monitoring and Completing the Plating Process

Ensuring Quality

- Plating Time: The plating duration can vary, but around 20 minutes is common for hobbyist projects. Adjust the time based on the desired thickness.

- Object Positioning: Rotate or reposition the object occasionally to ensure even coverage and prevent missed areas.

- Bath Maintenance: Keep the electrolyte solution and anode clean during the process to achieve consistent results.

Finishing and Cleaning the Plated Object

Final Steps

- Removing the Object: After the plating is complete, carefully remove the object from the bath.

- Rinsing: Thoroughly rinse the plated object with water to remove any residual electrolyte.

- Drying and Polishing: Dry the object and, if desired, polish the nickel surface to enhance its brightness and aesthetic appeal.

Parameter Control: Current, Voltage, pH, Temperature

Current density, measured in amperes per square decimeter (A/dm²), plays a vital role in controlling how nickel deposits onto the surface during electroplating. Low current density results in a finer, smoother nickel layer, while high current density speeds up deposition but may cause rough, brittle coatings and dark deposits, known as “burning.” To avoid these issues, it’s best to start with a lower current density and adjust as needed based on the results.

Voltage influences the quality of the nickel plating significantly. A low voltage range of 1–6 volts is ideal for achieving smooth, shiny coatings: 1–3 volts provides a more even finish, while 4–6 volts speeds up plating but can produce rough surfaces and more bubble formation. While a 6V battery is practical for small or hobbyist setups, keep an eye on the plating time to get the thickness you want.

Temperature affects both the plating rate and deposit quality. The optimal temperature range for nickel plating is 20–60°C. Plating below 30°C offers slower deposition for finer control, whereas temperatures closer to 50–60°C improve electrolyte conductivity and promote uniform deposition. Keep the solution below 60°C to prevent it from breaking down, and use a thermometer to maintain consistent temperature during plating.

Maintaining the electrolyte pH between 3 and 5 is crucial for optimal nickel plating. An acidic environment (pH 3–4) enhances adhesion and reduces hydrogen embrittlement. Regularly check pH with test strips or a meter, adjusting as necessary by adding dilute sulfuric acid to lower pH or nickel carbonate to raise it. Consistent pH control ensures durable, uniform nickel coatings.

For the best results, prepare the substrate by cleaning it with a 50/50 hydrochloric acid solution to remove contaminants. Agitate the plating bath or manually rotate the piece during electroplating to avoid uneven deposition, especially on complex shapes. After plating, quickly rinse the plated item with distilled water to stop any further chemical reactions.

Always use appropriate safety equipment, such as nitrile gloves and eye protection, when handling acids and electrolytes to ensure safe operation throughout the electroplating process.

Differences Between Electrolytic and Electroless Nickel Plating

Basic Principle

- Electrolytic Nickel Plating: The substrate serves as the cathode in an electrolytic cell, which needs an external power source to enable the plating process. An electric current reduces nickel ions from the solution, depositing them onto the substrate.

- Electroless Nickel Plating: In this chemical (autocatalytic) process, a reducing agent in the plating solution chemically reduces nickel ions, resulting in a uniform nickel-phosphorus alloy coating on the substrate without the need for external electricity.

Process Setup

- Electrolytic: This method requires a rectifier or DC power supply, electrodes, and precise electrical control. Adjusting the current and plating time controls the thickness of the plating.

- Electroless: The substrate is simply immersed in a heated chemical bath (around 195°F or 90°C). The nickel plating occurs uniformly due to the autocatalytic reaction, without the need for electrical equipment.

Coating Composition

- Electrolytic: Typically deposits pure nickel or nickel alloys, depending on the bath chemistry.

- Electroless: Deposits a nickel-phosphorus alloy; the phosphorus content can vary (usually 2% to 14%), affecting hardness, corrosion resistance, and magnetic properties.

Uniformity and Thickness Control

- Electrolytic: Thickness can vary, especially on complex shapes due to uneven current distribution. Thicker deposits may require longer plating times and complex fixturing.

- Electroless: The process is chemical and not dependent on electrical current distribution, ensuring uniform thickness even on complex shapes, recesses, and holes.

Surface Preparation

Both methods require thorough cleaning and surface preparation to ensure good adhesion. Electroless plating often needs surface activation with a palladium-tin catalyst to start the chemical deposition.

Applications and Advantages of Electroless Nickel Plating

- Excellent corrosion resistance and wear resistance due to the nickel-phosphorus alloy layer.

- Uniform coating thickness on complex shapes.

- No need for electrical contacts or current, simplifying setup.

- Can plate non-conductive materials when properly activated.

- Often used in engineering applications where consistent coating properties are critical.

Electroless Nickel Plating Process

Introduction to Electroless Nickel Plating

Electroless nickel plating is a chemical process that deposits a nickel-phosphorus alloy onto a substrate without using electricity. This method is autocatalytic, meaning once it starts, it continues on its own, providing a uniform coating regardless of the shape or geometry of the part.

Basic Principles of Electroless Nickel Plating

Chemical Reduction

Electroless nickel plating relies on a chemical reduction reaction. Nickel ions in the plating solution are reduced to nickel metal by a phosphorus-containing reducing agent, typically sodium hypophosphite. This reaction deposits a layer of nickel-phosphorus alloy onto the surface of the substrate.

Uniform Coating

Unlike electroplating, which can result in uneven coatings due to the distribution of electric current, electroless plating provides a uniform thickness over all surfaces. This makes it ideal for plating complex shapes and internal cavities.

Substrate Compatibility

Electroless nickel plating can be applied to a variety of metals including steel, iron, copper, brass, and zincated aluminum. With proper surface activation, it can even be applied to some non-conductive materials.

Pre-Plating Process

Surface Preparation and Activation

- Cleaning: The substrate must be thoroughly cleaned to remove oils, greases, oxides, and other contaminants. This step is crucial for ensuring strong adhesion and preventing defects. Cleaning typically involves chemical washes and sometimes mechanical treatments.

- Rinsing: After cleaning, the substrate is rinsed with water to remove any residual cleaning agents.

- Acid Treatment: The cleaned substrate is often treated with acid to remove any remaining oxides and make the surface catalytically active for nickel deposition.

- Catalyst Application: For certain substrates, a catalyst such as palladium-tin is applied to activate the surface further.

Plating Bath Immersion

- Bath Composition: The prepared parts are immersed in a heated aqueous plating bath. The bath contains nickel salts, a reducing agent like hypophosphite, substances that help keep the nickel ions in solution (complexing agents), and chemicals that ensure the reaction proceeds smoothly (stabilizers).

- Temperature Control: The bath is maintained at a specific temperature, typically around 85°C (195°F), to ensure optimal plating conditions.

Nickel Deposition

- Chemical Reaction: The autocatalytic chemical reaction begins, depositing a nickel-phosphorus alloy uniformly on the substrate surface without the need for external current.

- Bath Monitoring: Conditions such as pH and temperature are carefully controlled to maintain consistent deposition rates and quality.

Agitation and Filtration

- Agitation: Continuous agitation is employed to ensure bath homogeneity and to prevent particulate contamination.

- Filtration: Filtration systems are used to remove any particles that could cause defects in the plating.

Inspection and Testing

- Thickness Measurement: After plating, the coated parts are inspected to verify the coating thickness.

- Uniformity Check: The uniformity of the coating is checked to ensure it meets the required standards.

- Adhesion Testing: Adhesion tests are performed to confirm that the nickel layer is firmly bonded to the substrate.

Key Characteristics and Benefits

- Consistent Thickness: The autocatalytic nature of electroless nickel plating ensures an even coating thickness on complex geometries.

- Corrosion and Wear Resistance: The nickel-phosphorus alloy provides excellent protection against corrosion and wear in industrial applications.

- No External Power Needed: Unlike electroplating, this process does not require electrical power, simplifying the setup and enabling plating on non-conductive materials with proper pretreatment.

- Adjustable Phosphorus Content: The phosphorus content in the deposit can be controlled to tailor hardness, corrosion resistance, and other surface properties.

Electroless nickel plating is widely used in industries such as automotive and aerospace, where durable and reliable coatings are essential. For example, automotive parts such as fuel injectors and hydraulic systems benefit from enhanced wear resistance and reduced friction, while aerospace components like landing gear and engine parts gain improved corrosion protection and longevity.

Safety Precautions and Best Practices

Understanding Nickel Electroplating Risks

Nickel electroplating involves handling hazardous materials such as nickel salts and alloys, which can pose several health and environmental risks. Key hazards include:

- Skin Contact: Exposure to nickel compounds can cause allergic dermatitis and long-term skin sensitization.

- Inhalation: Airborne nickel particles or mist from plating baths may lead to lung irritation and chronic respiratory conditions.

- Environmental Impact: Improper disposal of nickel-laden wastewater contributes to toxic metal accumulation in ecosystems.

Essential Safety Precautions

Personal Protective Equipment (PPE)

- Gloves: Use chemical-resistant gloves (e.g., nitrile or neoprene) to prevent skin contact with nickel solutions.

- Eye and Respiratory Protection: Wear goggles or face shields to avoid splashes, and use NIOSH-approved respirators with particulate filters when handling aerosols or powders.

- Protective Clothing: Wear aprons or coveralls to minimize skin exposure.

Workspace Controls

- Ventilation: Install local exhaust ventilation (LEV) near plating tanks to capture fumes and mists.

- Barrier Methods: Use automated barrel plating or pumps (instead of manual pouring) to reduce direct contact.

- Spill Management: Keep absorbent materials and neutralizing agents nearby for accidental spills.

Hygiene Practices

- Handwashing: Provide dedicated sinks with pH-neutral soap to remove nickel residues.

- Eating/Drinking Restrictions: Do not eat or drink in plating areas to prevent ingestion of nickel.

- Contamination Control: Regularly clean control dials, switches, and surfaces to avoid indirect exposure.

Best Practices for Risk Mitigation

Workflow Modifications

- Automate High-Risk Tasks: Automate tasks that involve high exposure risk, such as loading/unloading parts or handling anode cages.

- Closed-Loop Systems: Implement filtration and ion-exchange systems to recycle plating solutions and reduce waste.

- Training Programs: Educate workers on safe chemical handling, PPE use, and emergency protocols.

Waste Management

- Secure Disposal: Collect nickel sludge and spent electrolytes in labeled, sealed containers for hazardous waste treatment.

- Neutralization: Treat acidic or alkaline waste streams to pH 7–9 before discharge.

Health Monitoring

- Regular Check-Ups: Conduct regular health check-ups for workers to detect early signs of nickel allergy or respiratory issues.

- Skin Creams: Provide barrier creams (pre-work) and moisturizers (post-exposure) to protect skin integrity.

Troubleshooting Common Plating Issues

Common Nickel Plating Problems and Their Causes

Dull or Hazy Deposits

Dull or hazy deposits typically result from incorrect bath temperature, insufficient solution agitation, or contamination in the plating solution. Maintain the bath temperature between 130–140°F (54–60°C) and ensure adequate agitation for uniform plating. Regularly check and filter the plating solution to remove impurities and contaminants.

Orange Peeling (Rough or Grainy Surface)

This problem usually results from excessive current density, improper solution composition, or contamination. To address it, reduce the current density to recommended levels, ensure the plating bath chemistry is correct, and maintain cleanliness to prevent rough surfaces.

Brittleness and Cracking

Regularly check and control the use of additives, keep the current density optimal, and analyze the bath chemistry. To prevent brittleness, make sure to rinse parts properly and consider baking them if needed.

Laminated or Peeling Deposits

Ensure the substrate is thoroughly cleaned and activated before plating. Use proper pre-treatment steps like degreasing, acid dips, and activation to achieve good adhesion.

Dark Streaks or Black Spots

To fix dark streaks or black spots, filter the bath to remove contaminants, ensure proper solution circulation, and check for faulty anodes or other contamination sources.

Key Troubleshooting Checkpoints

- Bath Temperature: Keep nickel plating baths between 130°F and 140°F. Deviations from this range can result in poor deposit quality.

- Current Density: Maintain recommended current density to avoid roughness, brittleness, or dull deposits. High current densities can speed up plating but increase the risk of defects.

- Anode Condition and Placement: Use correctly placed conforming anodes to ensure even current distribution and avoid dark or uneven plating.

- Solution Chemistry: Regularly test and adjust nickel concentration, pH, and additive levels to maintain plating quality.

- Surface Preparation: Ensure parts are clean and free from oils, oxides, or other contaminants before plating for optimal adhesion.

- Equipment Check: Inspect rectifiers and power supplies for consistent current output. Faulty equipment can cause dull or uneven plating.

Practical Tips for Beginners

- Always follow the plating solution manufacturer’s instructions for bath composition and operating parameters.

- Regularly filter and analyze the plating bath to avoid contamination buildup.

- Preheat parts to the bath temperature to prevent defects caused by temperature differences.

- Use agitation to promote uniform plating and prevent local depletion of plating ions.

- Keep detailed records of bath conditions, current settings, and plating times to identify trends and issues.

Frequently Asked Questions

Below are answers to some frequently asked questions:

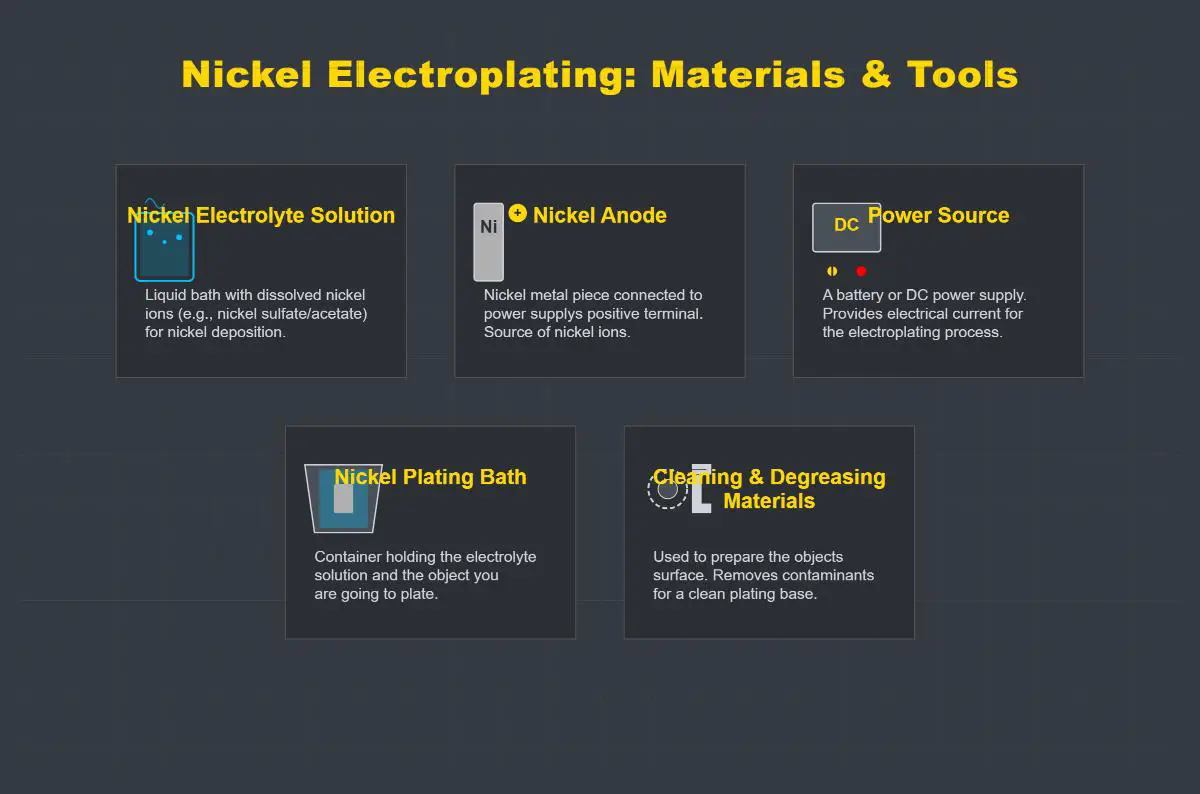

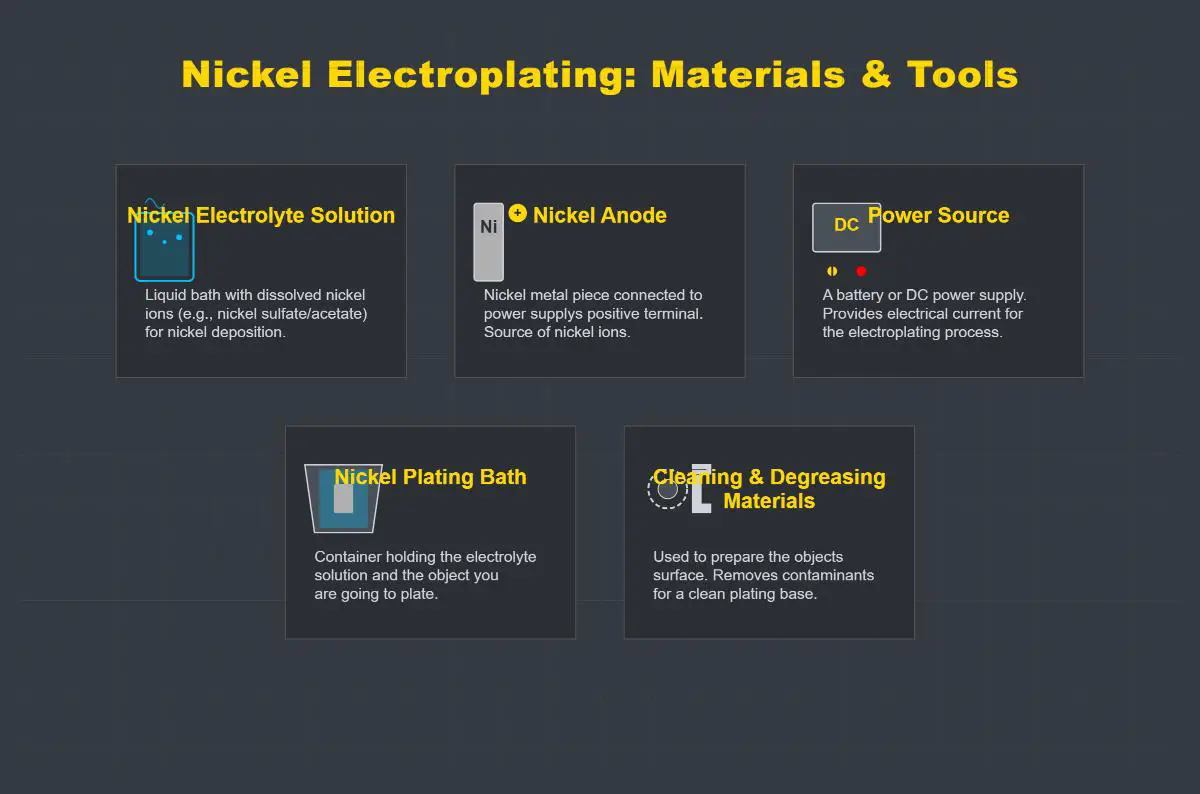

What materials and tools are needed for nickel electroplating?

To perform nickel electroplating, especially for beginners, you need a set of essential materials and tools to ensure a successful and safe plating process. The key components include:

- Nickel Electrolyte Solution: This is the liquid bath where nickel ions are dissolved. Common solutions include nickel sulfate or nickel acetate-based electrolytes, which facilitate the deposition of nickel onto the workpiece.

- Nickel Anode: A piece of nickel metal connected to the positive terminal of the power supply. It serves as the source of nickel ions during the plating process.

- Power Source: A battery or DC power supply that provides the necessary electrical current to drive the electroplating process.

- Nickel Plating Bath: A container that holds the electrolyte solution and the object to be plated.

- Cleaning and Degreasing Materials: These are used to prepare the surface of the object, ensuring it is free from contaminants and ready for plating.

These materials and tools are fundamental for anyone starting with nickel electroplating, providing the necessary setup for an effective and safe plating operation.

How to prepare the surface before nickel plating?

To prepare the surface before nickel plating, follow these essential steps to ensure proper adhesion and a high-quality finish:

- Cleaning and Degreasing: Start by thoroughly cleaning the object to remove all grease, oil, dirt, and other contaminants. Use a mild detergent or dish soap with water and scrub the surface well. This step is crucial as even microscopic oils and oxidation can hinder the plating process.

- Mechanical Cleaning: After degreasing, perform mechanical cleaning to remove rust, scale, and surface irregularities. Methods such as abrasive blasting or sanding help create a uniform, slightly rough surface that enhances the nickel layer’s adhesion.

- Chemical Cleaning and Etching: Next, chemically clean the surface by dipping it in alkaline or acidic solutions. This step removes any remaining oxides, organic residues, or metallic impurities, ensuring a pristine surface for uniform nickel deposition.

- Surface Activation: Before plating, activate the surface by dipping it in an acid bath or using a proprietary activation solution. This process creates a catalytic surface that initiates the nickel plating reaction, which is especially important for electroless nickel plating.

- Special Considerations for Certain Materials: Some metals, like stainless steel, require an intermediate copper plating layer before nickel plating can be applied successfully. This additional step ensures proper adhesion and a durable finish.

Following these steps ensures the nickel plating will adhere well and produce a smooth, durable, and shiny finish.

What are the differences between electrolytic and electroless nickel plating?

Electrolytic and electroless nickel plating differ primarily in their processes and applications. Electrolytic nickel plating uses an external electric current to deposit nickel ions onto a conductive substrate, making it suitable for items needing high conductivity and heat resistance. However, this method can lead to uneven coating thickness, particularly on complex shapes.

In contrast, electroless nickel plating relies on a chemical reduction reaction without electricity, using a reducing agent like phosphorus to deposit nickel uniformly, even on non-conductive materials such as plastics and ceramics. This results in a more consistent coating, enhancing corrosion and wear resistance.

Electrolytic plating is generally more cost-effective for high-volume production and is often used for decorative finishes and electrical connectors. Electroless plating, offering superior durability and uniformity, is preferred for precision components in industrial machinery, aerospace, and medical devices.

What safety precautions should be taken during nickel electroplating?

During nickel electroplating, several safety precautions must be taken to ensure a safe working environment. Firstly, wearing appropriate Personal Protective Equipment (PPE) is essential. This includes chemical-resistant gloves, impermeable aprons, safety goggles, and, if necessary, NIOSH-approved respirators to prevent inhalation of harmful fumes.

Proper ventilation is crucial; installing local exhaust ventilation near plating tanks can help capture airborne contaminants. Additionally, automated systems like barrel plating can minimize direct handling of chemicals. Workstations should be equipped with containment trays to manage spills effectively.

Good hygiene practices are vital. Workers should wash their hands with pH-neutral soap after handling materials and avoid skin contact with contaminated surfaces. Nickel-laden waste should be treated as hazardous and disposed of accordingly.

Training workers on chemical handling, PPE usage, and emergency procedures is also important, alongside regular health monitoring to detect any early signs of nickel sensitivity. These measures collectively help mitigate health risks and ensure a safer electroplating process.

How can common plating issues be troubleshooted?

To troubleshoot common nickel electroplating issues, follow these guidelines:

- Pitting: This is often caused by air bubbles, organic contaminants, or low agitation. To resolve this, increase the agitation of the plating bath, use wetting agents to reduce surface tension, and ensure proper filtration to remove contaminants.

- Dull or Hazy Deposits: These can result from low bath temperature, metal impurities, or insufficient brighteners. Adjust the bath temperature to the recommended range of 45-60°C, analyze and adjust metal content, and replenish brighteners as needed.

- Roughness: Particulate contamination or excessive current density can cause rough deposits. Filter the electrolyte solution, clean the anodes, and reduce the current density to an appropriate level (typically 2-6 A/dm²).

- Low Coverage: Poor surface pretreatment, low agitation, or improper pH levels are common causes. Improve the cleaning and activation steps, increase agitation, and maintain the bath pH between 3.8 and 4.6.

- Blistering or Peeling: This is often due to inadequate surface preparation or hydrogen embrittlement. Optimize the acid activation process and consider using post-bake cycles to reduce hydrogen embrittlement.

For effective troubleshooting, regularly monitor and adjust bath parameters (temperature, pH, and chemical composition), and ensure thorough surface preparation before plating.

Where can materials for nickel electroplating be sourced?

Materials for nickel electroplating can be sourced from various suppliers, depending on the specific needs of your project. Here are some common sources:

- Chemical Suppliers: These companies often carry nickel salts like nickel sulfate, nickel chloride, and boric acid, which are essential for preparing the electrolyte solution. You can find these suppliers both locally and online.

- Industrial Supply Stores: These stores typically offer equipment such as DC power sources (rectifiers) and other necessary tools for electroplating.

- Online Platforms: Websites specializing in electronics, DIY projects, or specific electroplating kits can provide all the required materials and tools.

- Scientific Stores: Laboratories and scientific supply stores often stock the chemicals and equipment needed for electroplating.

For beginners, it’s important to ensure that you follow safety guidelines when handling chemicals and setting up your equipment. Always source materials from reputable suppliers to ensure quality and safety.