Imagine a world where your laser cutting projects are perfectly optimized, saving you both time and material costs. Efficient part nesting is the key to unlocking this potential. In the manufacturing process, mastering the art of part nesting can significantly enhance productivity, reduce waste, and improve overall efficiency. But how do you achieve this level of precision? In this article, we will provide a comprehensive, step-by-step guide to efficient part nesting for laser cutting, tailored for intermediate users like you. From understanding the basics of part nesting and laser cutting technology to exploring advanced strategies and software tools, we’ve got you covered. Ready to dive in and transform your laser cutting process? Let’s get started!

Part nesting in laser cutting involves arranging parts on a single sheet to maximize material use and minimize waste. This technique is crucial for manufacturers, engineers, and technicians who aim to optimize the efficiency and cost-effectiveness of their cutting operations.

Common-line nesting is a method where parts are nested inside each other to share cut paths. This method can improve material use and precision. However, this approach can sometimes result in imprecise cuts due to factors like the width of the laser cutter beam and kerf. Therefore, it is often avoided by many services to ensure the quality and accuracy of the parts.

The main goal of part nesting is to achieve high material efficiency. This involves optimizing the arrangement of parts to minimize scrap and maximize the number of parts that can be cut from a single sheet of material. Adjusting the angle or orientation of parts can significantly impact material utilization and lead to substantial cost savings.

A gap of 0.006″ to 0.012″ or more is usually needed to easily separate parts after cutting. For inner parts, designing them slightly smaller (about 0.005″) can facilitate a slip-fit, making the separation process more efficient.

Experimenting with different orientations and angles of parts can help minimize waste and increase the number of parts that can be cut from a sheet. By carefully adjusting the placement of each part, manufacturers can achieve better material utilization and reduce production costs.

For parts with large cutouts or smaller dimensions (less than 6 inches), implementing strategies like slug-destruct sequences can prevent parts from tipping over during the cutting process. This involves cutting slugs into smaller pieces that can fall safely through the machine slats, ensuring a stable and safe cutting operation.

Efficient part nesting in laser cutting requires a combination of strategic planning, advanced software tools, and a deep understanding of material properties and machine capabilities. By mastering these techniques, manufacturers can significantly reduce waste, enhance production efficiency, and achieve high-quality laser-cut products.

Laser cutting is a precise and versatile process that uses a high-powered laser to cut, engrave, or mark various materials. The laser beam is typically generated by a laser source and directed through optics and CNC (computer numerical control) to focus on the material. The intensity of the laser melts, burns, or vaporizes the material, creating clean and precise cuts.

Laser cutting is widely used in the automotive industry for making components like body panels and gears. The precision and speed of laser cutting enable manufacturers to meet the high demand for quality and consistency in automotive parts.

In construction, laser cutting is used to fabricate structural steel components, such as beams and columns. The ability to cut complex shapes and precise dimensions is essential for ensuring the integrity and safety of construction projects.

Laser cutting is crucial in the production of machinery and heavy equipment parts. The process allows for the cutting of various material thicknesses, from thin sheets to thick plates, ensuring that components meet the stringent requirements of the industry.

The packaging industry benefits from laser cutting by creating custom and intricate designs for packaging materials. The precision of laser cutting ensures that prototypes and small batches are produced with high accuracy, which is essential for unique and innovative packaging solutions.

In the military sector, laser cutting is used to process advanced materials like hardened steel and super alloys for armored plates and weapon components. The precision and ability to handle tough materials make laser cutting an invaluable tool in the production of military hardware.

Laser cutting offers unparalleled precision and accuracy, making it possible to produce parts with tight tolerances. This is particularly important in industries where even minor deviations can lead to significant issues in assembly and functionality.

The high speed of laser cutting allows for rapid production cycles, which is essential in industries with high demand. The efficiency of the process reduces the overall production time and increases throughput.

Laser cutting works on a wide range of materials, including metals, plastics, wood, and textiles, making it a versatile choice for many applications.

Laser cutting minimizes waste by allowing for efficient material use and optimal part nesting. This not only reduces costs but also contributes to more sustainable manufacturing practices.

Laser cutting typically produces high-quality edges that require little to no additional finishing. This reduces the need for secondary operations, saving time and resources.

Laser cutting has revolutionized manufacturing by providing a versatile, precise, and efficient method for producing high-quality components across various industries. Its ability to handle complex designs and a wide range of materials makes it an indispensable tool in modern manufacturing.

Before starting the nesting process, it’s essential to prepare and clean up design files to ensure precision and efficiency in laser cutting.

Eliminate redundant elements such as double lines, overlapping parts, and extraneous complexities. This reduces cutting errors and enhances the performance of nesting software.

Simplifying intricate details that don’t impact the final quality reduces cutting time and minimizes errors.

Using advanced nesting software can greatly improve the efficiency and effectiveness of the nesting process.

Use software with geometry-driven or genetic algorithms to automatically optimize part placement. These algorithms maximize material usage by minimizing gaps between parts.

When selecting nesting software, consider features like automatic elimination of overlapping parts, control over spacing and kerf allowance, grain direction alignment, and simulation capabilities to preview the layout and identify potential issues before cutting.

Implementing strategic approaches to nesting leads to better material utilization and enhanced cutting efficiency.

Arrange parts to share cut lines where possible. This reduces the overall cut length, saves material, and shortens cutting time. However, use this method cautiously with complex parts to avoid tip-up issues.

Align parts according to the material grain, especially for metals and woods, to preserve structural integrity and visual consistency. Nesting software often includes settings to maintain grain alignment within specified tolerances.

Optimize the arrangement of parts to reduce the laser beam’s travel distance between cuts. This increases cutting efficiency and reduces machine wear.

Ensuring the stability of parts during the cutting process is essential to maintain quality and prevent issues.

Design slugs or internal cutouts with small dimensions to be cut into smaller pieces (slug-destruct sequences) to prevent tipping or falling during cutting.

Add small bridges or tabs to isolated internal shapes that might fall out during cutting. This keeps them attached until post-processing, preventing loss of integral design features.

Leave sufficient gaps between parts to prevent heat buildup and warping while maximizing material usage. A minimum spacing of about 1 mm is generally recommended.

Rotating and positioning parts can help fill irregular spaces and maximize material use.

Rotate and position parts dynamically to fill irregular spaces efficiently. Tessellation techniques can be used to nest parts within the cutouts of other parts.

Include kerf compensation in nesting to ensure parts maintain accurate dimensions after cutting. The kerf is the width of material removed by the laser beam.

Conduct thorough checks after nesting to ensure the layout is optimized and free of errors.

Check for any empty shapes or isolated cutouts that serve no purpose and remove them to avoid unnecessary cuts.

Use nesting software simulations to verify the cutting sequence, detect potential collisions, and ensure the laser head moves efficiently away from cut profiles.

Advanced nesting strategies are essential for efficiently and precisely handling complex designs. These strategies manage intricate shapes and patterns, optimizing material usage and reducing waste.

Advanced nesting software uses sophisticated algorithms to automatically find the most efficient layout for cutting parts, considering factors like part geometry, material type, and thickness.

High-volume production demands strategies that maximize efficiency and minimize downtime. Advanced nesting techniques ensure that large quantities of parts are produced with minimal waste and optimal material use.

Dynamic alignment and rectangular nesting maximize material use by generating several layout options and choosing the most efficient one.

Maintaining stability during the cutting process is essential to avoid part tipping and machine crashes. Strategies like slug management and tip-up prevention help ensure smoother and safer operations.

Advanced algorithms automate the nesting process, ensuring optimal part placement and material usage.

These algorithms analyze the geometry of parts and material constraints to create efficient nesting patterns.

Implementing advanced nesting strategies can lead to significant improvements in manufacturing efficiency. Real-world examples and expert insights provide valuable lessons and best practices.

By leveraging advanced nesting strategies, manufacturers can achieve higher efficiency, reduced waste, and improved production outcomes. These techniques are essential for handling complex designs and high-volume production, ensuring optimal use of resources and maintaining high-quality standards.

Nesting software plays a crucial role in optimizing material usage during laser cutting. These tools use algorithms to arrange parts efficiently on a sheet, minimizing waste and maximizing productivity. Some popular nesting software tools include Deepnest, Sigmanest, and NestFab.

Automated nesting features allow the software to arrange parts on a sheet automatically, optimizing layout without manual intervention, which saves time and ensures efficient material usage.

The ability to rotate and align parts dynamically is crucial for fitting pieces together tightly and reducing gaps. Look for software that supports multiple rotation angles and alignment options.

Ensure the software can handle various file types such as SVG, DXF, and DWG. This flexibility allows for easy import of design files from different CAD programs.

A comprehensive material database helps in setting accurate cutting parameters based on material type and thickness, enhancing the precision and quality of cuts.

Invest in training programs for operators to ensure they can effectively use the nesting software and manage laser cutting equipment. Proper training helps maximize the benefits of the software and improves overall productivity.

Maintain the laser cutting machines regularly to ensure they operate at optimal performance. This includes cleaning, calibration, and replacing worn parts as necessary.

By following these steps and leveraging advanced nesting software, you can significantly enhance the efficiency and effectiveness of your laser cutting operations.

Nesting involves arranging designs on a flat sheet of material to minimize waste and optimize the machining process. Effective nesting is critical in laser cutting operations as it maximizes material utilization, reduces production time, and enhances overall efficiency.

Nesting software arranges parts efficiently to reduce waste, making the cutting process more cost-effective. By maximizing material use, manufacturers can significantly reduce material costs.

Nesting minimizes the travel distance between cuts and reduces the number of cuts required. This speeds up production, making it more efficient and lowering costs.

Proper nesting ensures that parts are cut with optimal orientation relative to the material grain. This maintains uniformity, prevents defects, and upholds high-quality standards.

Common-Line Cutting involves sharing cutting lines between adjacent parts. This technique reduces gaps and the number of cuts required, enhancing efficiency by allowing single-pass cutting of shared lines. Consequently, machine travel time and overall cutting time are significantly reduced.

Ensuring parts are oriented parallel to the material grain is crucial. This practice maintains part quality and appearance by preventing incorrect cuts and ensuring uniformity across all parts. Automated nesting systems quickly arrange parts efficiently, reducing manual errors. These systems dynamically adjust layouts to enhance production efficiency and extend machine lifespan by optimizing tool paths.

Effective management of slugs (unwanted material between cuts) and ensuring sufficient spacing for kerf width are essential for maintaining cut quality. Maintaining proper spacing prevents distortion and ensures precise cuts.

Select software capable of optimizing layouts based on material type, thickness, and cutting path efficiency. This selection is foundational for achieving optimal nesting results.

Set parameters for material size, grain orientation, and thickness. These constraints ensure that the nesting process accommodates the material properties and results in optimal layouts.

Use nesting tools to arrange parts in a way that minimizes waste and optimizes cutting paths. Effective part layout design is crucial for achieving high material efficiency.

Test designs on scrap material before cutting to ensure they meet quality standards. Validation helps identify and rectify potential issues before the actual production, saving time and resources.

Continuously monitor nesting outcomes and adjust settings as needed. Regular monitoring ensures that nesting remains efficient and material use is optimized throughout the production process.

Efficient nesting techniques are essential for optimizing material usage and reducing costs in laser cutting operations. By minimizing gaps between parts and maximizing sheet utilization, nesting software can significantly decrease scrap rates. For instance, automated nesting can reduce waste by up to 30% compared to manual methods. Implementing common-line cutting (CLC) further enhances material efficiency by sharing cutting lines between adjacent parts, thus reducing the number of cuts required and shortening cutting times.

Automated nesting software offers substantial operational efficiency gains by eliminating the need for manual part arrangement and reducing processing time. This automation minimizes human errors, leading to faster production cycles and improved accuracy. Moreover, optimized tool paths lower machine movement, which extends equipment lifespan and reduces energy consumption. By grouping parts to reduce travel paths, nesting software also enhances machine utilization and scalability, allowing manufacturers to handle complex designs with ease.

Efficient nesting techniques contribute to environmental sustainability by reducing material waste and the need for scrap disposal. Lower waste rates directly decrease recycling or disposal costs, aligning with eco-friendly manufacturing goals. Additionally, the optimized use of raw materials reduces overall demand, promoting more sustainable production practices. These environmental benefits, along with improved efficiency and cost savings, make advanced nesting techniques crucial in modern laser cutting.

To evaluate the effectiveness of nesting techniques, manufacturers should track specific metrics:

| Factor | Manual Nesting | Automated Nesting |

|---|---|---|

| Material Waste | 15-30% | 5-10% |

| Setup Time | 1-2 hours/sheet |

Below are answers to some frequently asked questions:

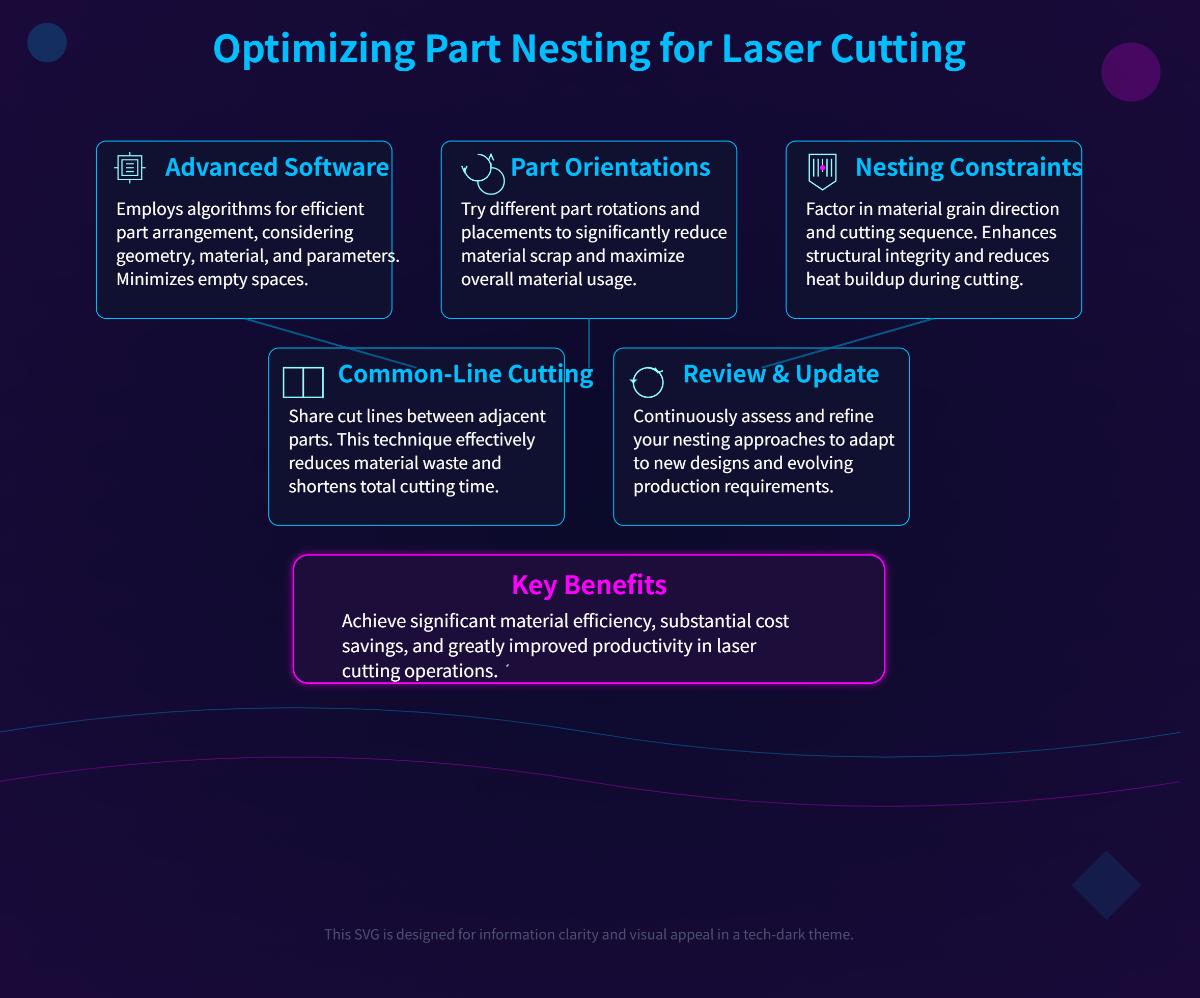

To optimize part nesting for laser cutting, start by utilizing advanced nesting software that employs algorithms to arrange parts efficiently. These programs consider part geometry, material constraints, and cutting parameters, minimizing empty spaces and shared cut lines. Experiment with different part orientations to reduce scrap and maximize material usage. Additionally, account for nesting constraints such as material grain direction and cutting sequence to enhance structural integrity and reduce heat buildup. Implement common-line cutting to share cut lines between adjacent parts, reducing waste and cutting time. Regularly review and update your nesting strategies to adapt to evolving production requirements and designs. By integrating these techniques, you can achieve significant material efficiency, cost savings, and improved productivity in your laser cutting operations.

To achieve efficient part nesting for laser cutting, follow these best practices:

Implementing these practices will enhance the efficiency and effectiveness of your laser cutting processes.

Nesting software is essential for optimizing part placement in laser cutting processes, reducing material waste, and improving efficiency. Several reputable options are available:

When choosing nesting software, consider factors like material optimization, machine compatibility, advanced features, cost, and user interface to enhance laser cutting efficiency and productivity.

Advanced strategies for complex nesting in laser cutting involve leveraging sophisticated software tools and techniques to optimize efficiency and minimize material waste. One key approach is using automated nesting software equipped with AI-driven algorithms. These tools dynamically adjust part orientation, rotation, and spacing, ensuring optimal material utilization while avoiding collisions. Real-time simulation capabilities allow users to test and refine nested layouts virtually, identifying potential issues before actual cutting begins.

Hybrid nesting approaches combine automated processes with manual adjustments, especially useful for irregularly shaped parts or high-priority components, ensuring critical tolerances are maintained. Cluster nesting groups similar parts to reduce toolpath complexity and improve cutting consistency.

Thermal management and cut sequencing strategies are crucial for preventing localized overheating and material warping. Techniques such as alternating cutting paths, variable tabbing, and integrating micro-bridges help stabilize parts during cutting and minimize post-processing requirements.

Material-specific nesting rules take into account factors like thickness compensation and grain direction alignment, which are essential for achieving high-quality cuts and reducing edge roughness.

Integrating machine condition data into nesting plans can enhance precision by aligning cutting paths with machine health metrics, and dynamic re-nesting capabilities allow adjustments mid-job to address material slippage or alignment errors.

Sustainability-driven nesting strategies focus on designing nests that leave reusable remnant shapes for future jobs and optimizing cutting paths to reduce energy consumption.

By implementing these advanced strategies, manufacturers can achieve high material utilization and cutting stability, even for complex nested layouts.

Efficient nesting for laser cutting can lead to significant cost savings through several strategic approaches. Firstly, optimizing material utilization is crucial. By using advanced nesting software, parts can be arranged on sheets to minimize waste, thereby reducing the number of sheets required and saving material costs. Additionally, designing parts with nesting in mind and standardizing part sizes can further enhance material efficiency.

Reducing cutting time is another key factor. Efficiently laying out parts to shorten the laser cutter’s travel distance decreases overall cutting time, boosting productivity and extending equipment lifespan due to reduced wear and tear. Simplifying part geometries can also help, as intricate designs often require slower cutting speeds and more precise control, increasing operational time.

Automating the nesting process, possibly integrating it with ERP systems, ensures consistent and optimal part arrangement, minimizing human errors and further enhancing efficiency. Additionally, combining smaller parts into larger cuts can reduce the number of individual cuts and handling steps.

Optimized nesting in laser cutting offers several environmental benefits that contribute to more sustainable manufacturing practices. Primarily, it minimizes material waste by ensuring that parts are arranged efficiently on material sheets, utilizing every available inch. This reduces the amount of scrap material, which conserves resources and lowers material costs. Additionally, optimized nesting enhances energy efficiency by shortening the cutting paths required, thereby reducing cutting time and energy consumption. This not only increases productivity but also extends the lifespan of laser cutting equipment, further reducing environmental impact.

Moreover, optimized nesting supports environmental sustainability by reducing the volume of material sent to landfills or recycling facilities, thereby lowering the carbon footprint and conserving natural resources. It also improves inventory management by allowing more parts to be cut from a single sheet, optimizing storage space and reducing the need for larger storage facilities, which can also save on energy consumption. Overall, these practices contribute to a greener manufacturing process by minimizing waste and maximizing resource efficiency.