Imagine needing a material that can withstand extreme temperatures, resist chemical attacks, and maintain its mechanical strength under pressure. Would you choose PEEK or stainless steel? This article delves into the intricate comparison between these two powerhouse materials, helping you make an informed decision. From aerospace to medical applications, we will uncover how PEEK and stainless steel stack up in various industries. You will learn about their mechanical properties, thermal stability, and chemical resistance, and discover the cost implications of using each. By the end, you’ll have a clear understanding of which material is the best fit for your specific needs. Ready to dive into the fascinating world of PEEK vs stainless steel? Let’s get started!

Polyetheretherketone (PEEK) is a high-performance thermoplastic known for its exceptional mechanical and chemical properties. Its high strength, thermal stability, and chemical resistance make PEEK ideal for applications in industries such as aerospace, automotive, medical, and chemical processing.

PEEK exhibits several critical attributes that contribute to its extensive use in demanding environments:

Stainless steel is a versatile metal alloy primarily composed of iron, chromium, and other elements such as nickel and molybdenum. The addition of chromium provides stainless steel with its characteristic corrosion resistance. This material is commonly used in a variety of industries, including construction, food processing, and medical devices, due to its strength, durability, and resistance to corrosion.

Stainless steel offers several important properties that make it a preferred choice for many industrial applications:

While both PEEK and stainless steel are high-performance materials, they are suited to different types of applications due to their distinct properties. Understanding these differences is crucial for selecting the right material for specific industrial needs.

PEEK has a tensile strength of about 115 MPa and maintains its integrity across a wide temperature range, while stainless steel generally has a higher tensile strength, from 515 MPa to over 1,030 MPa, but is heavier.

PEEK can continuously operate at temperatures up to 170°C (338°F) and briefly withstand up to 260°C (500°F), with a low thermal expansion. Stainless steel retains its properties at temperatures up to about 800°C (1,472°F), making it suitable for very high-temperature applications.

PEEK resists many chemicals, including acids, bases, and solvents, as well as steam and hot water. Stainless steel is known for its corrosion resistance, especially in water and acidic environments, though it can be vulnerable to certain chemicals like hydrochloric acid.

PEEK is preferred in applications where weight reduction, chemical resistance, and thermal stability are critical, such as in aerospace and medical implants. Stainless steel is ideal for applications requiring high strength, durability, and corrosion resistance, such as in construction, food processing, and medical instruments.

By understanding the unique advantages and limitations of PEEK and stainless steel, engineers and material scientists can make informed decisions about the most appropriate material for their specific applications.

Mechanical properties are essential parameters that describe how a material behaves under different forces and conditions. These properties determine a material’s performance in various applications, especially in terms of strength, durability, and flexibility. Understanding the mechanical properties of Polyetheretherketone (PEEK) and stainless steel is crucial for selecting the right material for specific industrial applications.

PEEK exhibits a tensile strength ranging from 97 to 200 MPa, making it suitable for applications requiring a high strength-to-weight ratio.

With a Young’s modulus between 4.0 and 24 GPa, PEEK is less stiff than metals but still offers enough rigidity for various uses.

PEEK is highly impact-resistant due to its toughness and flexibility, making it ideal for applications that need to withstand sudden forces without breaking.

Stainless steel generally has a much higher tensile strength, often up to 620 MPa or more, allowing it to resist significant mechanical stress and deformation.

Stainless steel typically has a Young’s modulus around 200 GPa, showcasing much higher stiffness compared to PEEK. This high modulus makes stainless steel capable of handling heavy loads without significant deformation.

Stainless steel is known for its excellent impact resistance, which remains effective across a wide range of temperatures. This property ensures that stainless steel maintains structural integrity even in demanding conditions.

When comparing PEEK and stainless steel, several key differences in their mechanical properties become apparent:

The choice between PEEK and stainless steel depends on the specific requirements of the application, including factors such as weight constraints, environmental exposure, and mechanical demands.

In aerospace, PEEK is highly valued for its combination of lightweight properties and high strength-to-weight ratio. These characteristics significantly contribute to enhancing fuel efficiency and reducing overall operational costs.

Stainless steel is preferred in aerospace applications requiring maximum strength and durability. Its superior tensile strength and stiffness are essential for high-stress components like landing gear, engine parts, and structural supports. Stainless steel’s exceptional corrosion resistance ensures longevity and reliability in various atmospheric conditions. Although heavier than PEEK, stainless steel’s robustness and ability to retain mechanical properties at elevated temperatures make it indispensable in many aerospace applications.

In the medical field, PEEK is favored for its biocompatibility, radiolucency, and chemical resistance. These properties make PEEK an excellent choice for medical implants, such as spinal cages and joint replacements, where compatibility with human tissue and imaging equipment is crucial. PEEK’s resistance to sterilization processes and its ability to withstand repeated exposure to bodily fluids and cleaning agents enhance its usability in surgical instruments and other medical devices.

Stainless steel remains a staple in medical applications due to its high strength, durability, and ease of sterilization. It is commonly used in surgical instruments, orthopedic implants, and dental tools. However, its metal content can sometimes interfere with imaging techniques and cause sensitivity issues in certain patients. Despite these limitations, stainless steel’s robustness and corrosion resistance ensure its continued use in environments where mechanical integrity and hygiene are paramount.

In the automotive industry, PEEK is utilized in applications such as fuel system components, electrical connectors, and engine parts where weight reduction and resistance to high temperatures and chemicals are critical. Its ability to withstand mechanical stress and provide long-term reliability makes PEEK an ideal choice for parts that require durability and efficiency.

Stainless steel is extensively used in the automotive industry for components that demand high strength and durability, such as exhaust systems, body panels, and structural elements. Its excellent corrosion resistance ensures longevity and performance in varying environmental conditions, including exposure to road salts and moisture. While heavier than PEEK, stainless steel’s robustness and ability to maintain mechanical properties under high loads make it a preferred material for many automotive applications.

A notable example in the aerospace industry is the use of PEEK in lightweight brackets and fasteners for aircraft interiors. These components contribute to significant weight savings, resulting in improved fuel efficiency and reduced operational costs. Stainless steel, on the other hand, is employed in critical structural parts like the landing gear, where high strength and resistance to mechanical stress are essential.

In the medical sector, PEEK has been successfully used in spinal implants, offering patients a biocompatible and radiolucent solution that integrates well with human tissue. Stainless steel continues to be used in surgical instruments, offering the necessary strength and ease of sterilization required for repeated use in operating rooms.

In the automotive industry, PEEK has been utilized in high-performance fuel system components, offering resistance to aggressive fuels and high temperatures. Stainless steel is prominently used in exhaust systems, where its ability to withstand high temperatures and corrosive exhaust gases ensures long-term durability and performance.

Each material’s unique properties make it suitable for specific industry applications, highlighting the importance of selecting the right material based on the specific requirements and conditions of the intended use.

Thermal Stability

PEEK has excellent thermal stability and can continuously operate at temperatures up to 170°C (338°F). It can also withstand short-term exposure to temperatures as high as 260°C (500°F), making it suitable for applications that experience frequent temperature variations.

Heat Resistance

PEEK can maintain its mechanical integrity up to 330°C. Its melting onset occurs at approximately 340°C, indicating the temperature at which it starts to transition from a solid to a liquid state.

Specific Heat Capacity

PEEK’s specific heat capacity ranges from 1390 to 1700 J/kg-K. This high capacity allows PEEK to absorb and store a lot of heat, making it effective for thermal insulation applications.

Thermal Conductivity

PEEK exhibits low thermal conductivity, typically between 0.25 and 0.93 W/m-K. This low conductivity makes it an excellent insulator, preventing heat transfer and maintaining stable temperatures within components.

Thermal Expansion

The coefficient of thermal expansion for PEEK ranges from 15 to 52 µm/m-K. This moderate expansion rate allows PEEK to maintain dimensional stability over a range of temperatures, which is crucial for precise engineering applications.

Thermal Diffusivity

PEEK’s thermal diffusivity is relatively low, ranging from 0.1 to 0.51 mm²/s. This indicates that PEEK has a slow heat transfer rate, which can be advantageous in applications where gradual temperature changes are preferred.

Thermal Stability

Stainless steel offers exceptional thermal stability, retaining its mechanical properties at temperatures up to 1100°C (2012°F) or higher, depending on the specific alloy. This makes it ideal for high-temperature environments such as furnaces and engines.

Heat Resistance

Stainless steel can operate effectively in environments with temperatures up to 1100°C or more. Its melting point is significantly higher than PEEK, around 1410°C, making it robust against thermal deformation.

Specific Heat Capacity

The specific heat capacity of stainless steel is about 470 J/kg-K. While lower than PEEK, this capacity is sufficient for many industrial applications, allowing stainless steel to absorb moderate amounts of heat.

Thermal Conductivity

Stainless steel has a higher thermal conductivity, approximately 16 W/m-K. This allows it to transfer heat efficiently, making it suitable for applications needing rapid heat dissipation.

Thermal Expansion

Stainless steel’s thermal expansion coefficient is around 13 µm/m-K, indicating lower expansion with temperature changes compared to PEEK. This low expansion rate ensures that stainless steel components remain dimensionally stable even under significant thermal stress.

Thermal Diffusivity

Stainless steel’s thermal diffusivity is around 4.2 mm²/s, indicating a faster heat distribution rate. This property is beneficial in applications where quick heat dissipation is necessary to prevent overheating.

Comparing the thermal properties of PEEK and stainless steel reveals several key differences:

Selecting between PEEK and stainless steel depends on the specific thermal requirements of the application, such as the need for heat resistance, insulation, or efficient heat transfer.

PEEK is highly regarded for its extensive chemical resistance, making it suitable for challenging environments.

PEEK exhibits excellent resistance to many diluted acids. It can withstand exposure to acetic acid, phosphoric acid, and hydrochloric acid up to concentrations of approximately 37%. However, it is less resistant to highly concentrated acids like sulfuric acid and nitric acid, which can cause significant degradation.

PEEK also shows good resistance to diluted bases, though its tolerance decreases with concentrated bases, leading to potential chemical breakdown over time. This makes PEEK suitable for applications involving mild alkaline environments but less so for highly caustic conditions.

PEEK effectively resists solvents like acetone, methanol, and hexane, but may degrade with solvents such as methylene chloride, DMSO, and THF.

PEEK resists many organic compounds, including alcohols, hydrocarbons, ethers, esters, and ketones. This broad resistance makes it an excellent choice for applications that involve exposure to various organic chemicals.

Stainless steel, especially grades like AISI 316, is known for its corrosion resistance due to a protective chromium oxide layer.

Stainless steel offers good resistance to many chemicals, but its performance can vary significantly depending on the specific alloy and environmental conditions. It is generally effective in resisting corrosion in acidic and neutral environments.

Stainless steel can withstand exposure to many acids and bases, though it may corrode in the presence of strong acids or high-chloride environments. The protective oxide layer can be compromised, leading to pitting and crevice corrosion, especially in harsh chemical settings.

| Property | PEEK | Stainless Steel |

|---|---|---|

| Cost | More expensive due to high-performance properties | Very expensive due to alloying elements like chromium and nickel |

| Chemical Resistance | PEEK offers broad resistance to diluted acids, bases, and most organic solvents but is limited by concentrated sulfuric and nitric acids. Stainless steel provides good resistance to many acids and bases but can be affected by strong acids and high-chloride environments. | |

| Mechanical Properties | High strength-to-weight ratio, excellent wear resistance, and dimensional stability | Superior tensile strength, stiffness, and impact resistance |

| Thermal Properties | Continuous service temperature up to 260°C; low thermal conductivity | Can handle higher temperatures depending on the alloy; high thermal conductivity |

Both PEEK and stainless steel offer excellent chemical resistance, but their suitability depends on the specific application requirements. PEEK is generally preferred for applications needing broad chemical inertness, lightweight properties, and dimensional stability. Stainless steel is favored in environments requiring high mechanical strength, thermal conductivity, and durability against specific chemical exposures.

The energy consumption and carbon footprint of PEEK and stainless steel production vary significantly.

PEEK is produced using energy-efficient methods like injection molding and extrusion, which require less energy and contribute to a lower carbon footprint. This reduced energy demand is crucial for minimizing environmental impacts during the manufacturing phase.

Producing stainless steel uses a lot of energy due to processes like smelting and refining. However, its recyclability helps reduce long-term environmental impacts. Recycling stainless steel consumes less energy than primary production, thereby mitigating some of the initial environmental costs.

The lifecycle costs and maintenance requirements of PEEK and stainless steel significantly affect their environmental sustainability.

PEEK’s resistance to wear, corrosion, and chemicals leads to lower maintenance and replacement costs, reducing environmental impacts over time. This durability minimizes the need for frequent replacements, which further lessens the environmental burden associated with repeated production and disposal.

Stainless steel, while durable and requiring less frequent maintenance, has higher initial production costs and energy consumption. Nevertheless, its recyclability helps balance these costs over time, making it a sustainable option through reduced energy demands for recycling.

The density and weight of PEEK and stainless steel influence their environmental efficiency, especially in weight-sensitive applications like aerospace and automotive.

PEEK is significantly lighter than stainless steel, with a density of about 1.3-1.45 g/cm³. This lightweight property is advantageous in applications where reducing weight can lead to fuel savings and lower emissions.

Stainless steel, with a higher density of 7.9-8.1 g/cm³, is less favorable for weight-sensitive applications. However, its strength and durability make it suitable for high-stress environments, where its weight is less of a concern compared to its mechanical properties.

The chemical and thermal resistance of materials are critical for their performance in various environments.

PEEK offers excellent chemical resistance and thermal stability up to 260°C. This makes it suitable for harsh environments where exposure to chemicals and high temperatures is common. However, it has limitations with certain chemicals like sulfuric acid.

Stainless steel provides superior chemical resistance due to its chromium content and can withstand higher temperatures than PEEK, often up to 550°C or more, depending on the grade. This makes stainless steel ideal for applications requiring high thermal resistance.

PEEK is not generally recycled in the same way as metals. However, its durable nature reduces the need for frequent disposal. The development of end-of-life management practices for PEEK is less advanced compared to metals, which is an area for potential improvement.

Stainless steel is highly recyclable, which significantly reduces its carbon footprint over time. The energy required for recycling stainless steel is much lower than for primary production, making it a sustainable choice in the long run.

PEEK’s higher cost stems from its complex synthesis process and the high-quality monomers it requires. Despite the initial expense, PEEK can be more cost-effective over its lifecycle. Its high resistance to wear, corrosion, and chemical attack reduces the need for frequent maintenance and replacements, leading to significant savings in specialized applications. This long-term durability makes PEEK a viable option in industries where maintenance costs are a critical factor.

Stainless steel generally has a lower initial purchase price compared to PEEK, making it more accessible for projects with budget constraints. The widespread availability of stainless steel and established manufacturing processes contribute to its affordability. However, stainless steel may require more frequent maintenance and replacements in certain environments, potentially raising long-term costs. Despite these additional expenses, stainless steel’s robustness often justifies its use in applications requiring high strength and durability.

The manufacturing of PEEK involves sophisticated techniques, which can increase production costs. Processes like CNC machining, injection molding, and 3D printing are commonly used to produce PEEK components. This flexibility makes PEEK suitable for a wide range of applications, from small precision parts like gears and bushings to large structural components such as aircraft wings. Additionally, the production and processing of PEEK generally require less energy compared to metals like stainless steel, contributing to reduced operational costs and a lower environmental impact.

The production of stainless steel is energy-intensive. This is primarily due to the need for alloying elements such as chromium and nickel. The smelting and refining processes consume significant amounts of energy, contributing to higher production costs and environmental impacts. Stainless steel benefits from well-established manufacturing techniques, including casting, forging, welding, and machining. These processes are highly refined and widely available, allowing for consistent and reliable production.

PEEK offers an excellent strength-to-weight ratio, which is crucial in industries like aerospace and automotive, where reducing component weight improves performance and fuel efficiency. It is highly resistant to a wide range of chemicals and corrosive environments, making it suitable for demanding applications in chemical processing and medical devices. PEEK can operate continuously at temperatures up to 260°C, with brief exposures to even higher temperatures. Its low thermal conductivity makes it an effective insulator, advantageous in applications requiring thermal stability and resistance to heat.

Stainless steel exhibits higher tensile strength compared to PEEK; some grades can withstand up to 620 MPa of force. This high strength makes stainless steel suitable for high-stress applications where maximum resistance to mechanical stress is required. Stainless steel can withstand extremely high temperatures, often up to 550°C or more, depending on the alloy. This superior heat resistance makes stainless steel ideal for applications involving high-temperature environments, such as engines and industrial furnaces. Its excellent corrosion resistance is due to its chromium content, which forms a protective oxide layer on the surface, preventing rust and corrosion even in harsh environments.

PEEK’s properties make it highly suitable for aerospace, automotive, and medical industries. Its lightweight nature and high mechanical strength contribute to performance improvements and cost savings in these fields. PEEK is biocompatible and resistant to radiation, making it an excellent choice for medical implants and surgical instruments. Its ability to withstand sterilization processes and compatibility with human tissues are critical factors in medical applications.

Industries such as construction, chemical processing, and high-temperature machinery benefit from stainless steel’s durability and temperature resistance. Its ability to maintain structural integrity under extreme conditions makes it indispensable in these sectors. When high performance is not critical, stainless steel’s lower initial cost makes it a more cost-effective option. Its widespread use and established manufacturing processes ensure that stainless steel remains a versatile and economical choice for many applications.

Below are answers to some frequently asked questions:

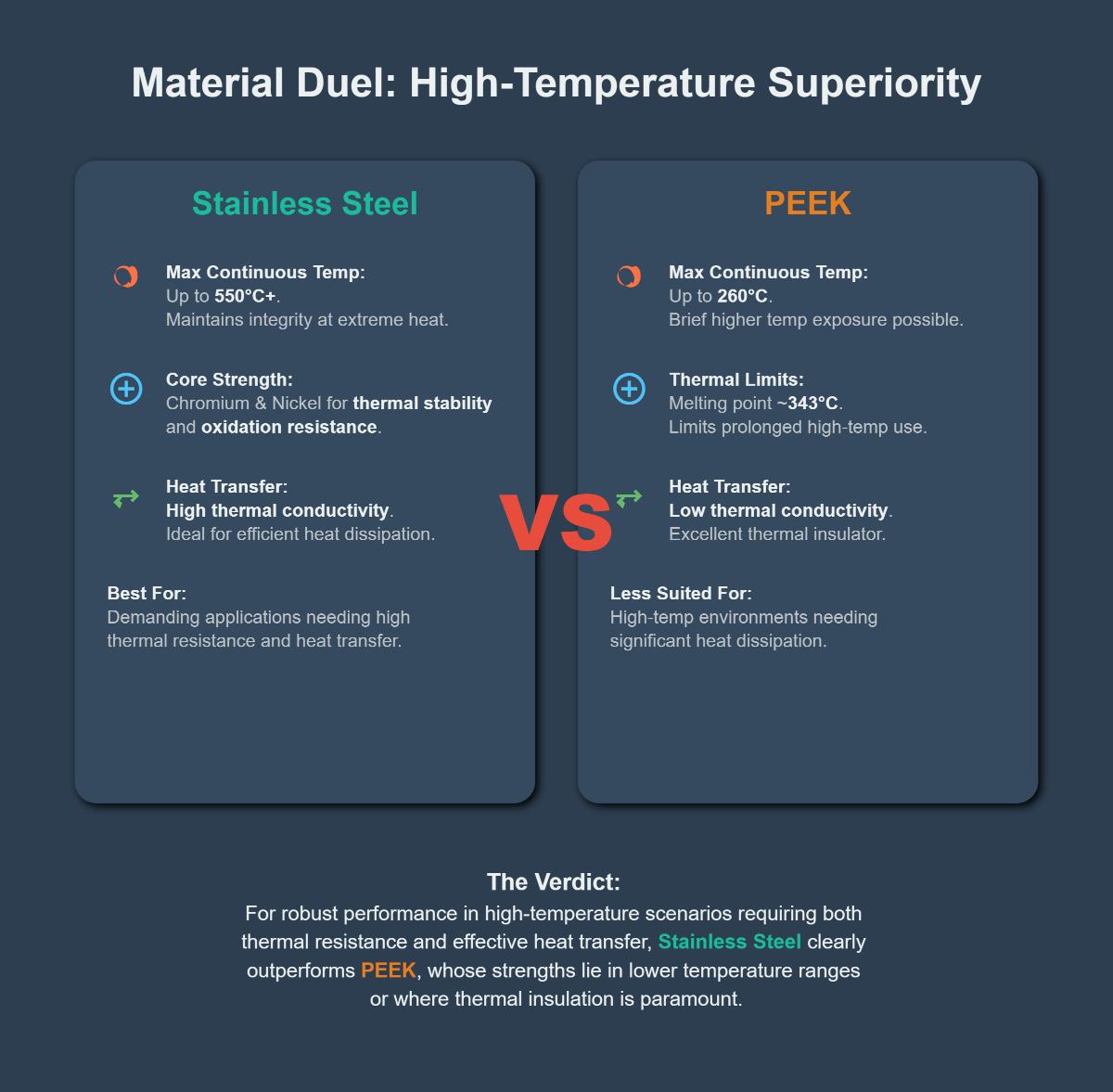

For high-temperature applications, stainless steel is generally better suited than PEEK. Stainless steel can withstand continuous temperatures up to 550°C or more, owing to its composition which includes chromium and nickel, enhancing its thermal stability and oxidation resistance. On the other hand, PEEK can operate continuously at temperatures up to 260°C and handle brief exposures to higher temperatures, but its melting point is around 343°C, limiting its effectiveness for prolonged high-temperature use.

Additionally, stainless steel has higher thermal conductivity, making it suitable for applications requiring efficient heat transfer. PEEK, while an excellent thermal insulator due to its low thermal conductivity, is less suitable for high-temperature environments where significant heat dissipation is necessary. Therefore, for applications demanding high thermal resistance and efficient heat transfer, stainless steel is the preferred material.

When comparing PEEK and stainless steel in terms of mechanical strength, several key differences become evident. PEEK, or Polyether Ether Ketone, typically has a tensile strength ranging from 97 MPa to 200 MPa, making it suitable for applications requiring moderate strength and high durability. In contrast, stainless steel exhibits significantly higher tensile strength, often between 520 MPa and 1180 MPa, depending on the grade, making it ideal for high-stress environments.

PEEK’s Young’s modulus ranges from 4.0 GPa to 24 GPa, indicating flexibility and a high strength-to-weight ratio, beneficial for applications where weight reduction and resistance to deformation are crucial. Stainless steel, with a Young’s modulus around 200 GPa, is much stiffer, providing greater resistance to deformation under load.

Shear strength and flexural strength also differ between the two materials. PEEK generally has shear strength between 50 MPa and 100 MPa, while stainless steel ranges from 350 MPa to 690 MPa. PEEK can withstand flexural pressures up to 25,000 psi, whereas stainless steel’s flexural strength varies by grade but remains high due to its Both materials exhibit excellent impact resistance, but PEEK is particularly noted for its fatigue properties, making it suitable for dynamic applications. Stainless steel also performs well in impact resistance, especially at higher temperatures, though this can vary with specific alloys.

Regarding the strength-to-weight ratio, PEEK offers an excellent ratio, comparable to metals like aluminum, making it ideal for weight-sensitive applications. Stainless steel, though strong, is much heavier, which can be a disadvantage in applications where weight is a concern.

The costs associated with using PEEK versus stainless steel vary significantly in both initial and lifecycle expenses. PEEK, derived from petroleum-based sources, is typically 20 to 30 times more expensive than stainless steel due to its complex manufacturing process and high purity requirements. Stainless steel, although costly to produce because of alloying elements like chromium and nickel, remains more affordable upfront.

However, PEEK’s higher initial costs are often offset by its lower lifecycle costs. PEEK’s superior wear resistance, chemical durability, and reduced need for maintenance and replacement contribute to its cost-effectiveness over time. Additionally, its lightweight nature helps reduce energy consumption and environmental impact.

In contrast, stainless steel may require more frequent maintenance and replacement, especially in corrosive environments, increasing its lifecycle costs. While stainless steel has lower manufacturing costs due to conventional metalworking techniques, PEEK’s specialized equipment requirements can make its processing and fabrication costs higher.

PEEK (Polyetheretherketone) and stainless steel have distinct environmental impacts. PEEK production generally requires less energy compared to stainless steel due to more efficient processing methods like injection molding and extrusion. Consequently, PEEK has a lower carbon footprint during production. However, PEEK is not as commonly recycled as metals, although its durability and long lifespan can reduce the need for frequent replacements, indirectly contributing to sustainability.

In contrast, stainless steel production is more energy-intensive, involving processes like smelting and refining. Despite this, stainless steel’s high recyclability significantly reduces its overall environmental impact. Stainless steel can be recycled indefinitely without losing its properties, which means that a large proportion of stainless steel in use today is made from recycled material. This high recyclability helps to offset the initial energy costs associated with its production.

PEEK (Polyether Ether Ketone) is preferred over stainless steel in several industries due to its unique properties. In the aerospace and defense sectors, PEEK’s lightweight and high strength-to-weight ratio contribute to fuel efficiency and reduced emissions, making it ideal for aerospace parts and moving equipment. In the medical industry, PEEK’s biocompatibility and resistance to chemical and radiation exposure make it suitable for implants, surgical instruments, and medical devices, especially where metal sensitivity or corrosion could be problematic.

In the chemical and pharmaceutical industries, PEEK’s high chemical resistance is advantageous in environments exposed to harsh chemicals, outperforming stainless steel in specific scenarios, particularly with acids and solvents. In the automotive sector, PEEK’s lightweight nature and resistance to wear and tear are beneficial for components like gears, bearings, and seals, contributing to better fuel efficiency and handling.

Additionally, in electrical and electronic applications, PEEK is favored for its excellent electrical insulation properties, unlike the conductive nature of stainless steel. These factors make PEEK a superior choice in applications requiring weight reduction, chemical and wear resistance, biocompatibility, and high strength-to-weight ratio. However, stainless steel is still preferred for applications needing high impact strength and extreme temperature resistance.

PEEK (Polyether Ether Ketone) and stainless steel (specifically SUS316) both offer excellent chemical resistance, but they perform differently based on the type of chemicals and conditions involved. PEEK demonstrates high resistance to a wide range of chemicals, including most solvents, diluted acids, and bases. However, it has limitations when exposed to concentrated acids like sulfuric and nitric acids, as well as some solvents such as dimethyl sulfoxide (DMSO) and tetrahydrofuran (THF).

Stainless steel, on the other hand, owes its corrosion resistance to the presence of chromium, which forms a protective oxide layer. This makes it highly resistant to oxidation and corrosion in many environments. Nonetheless, stainless steel can still be affected by certain aggressive chemicals and high-temperature conditions that may compromise its integrity over time.

In summary, PEEK generally offers superior chemical resistance, especially in environments with a broad range of solvents and diluted acids and bases. Stainless steel, while robust against corrosion, might not perform as well in extremely harsh chemical environments but excels in high-temperature applications. The choice between these materials depends on the specific chemical exposure and operating conditions of the application.